Leaderboard

Popular Content

Showing content with the highest reputation on 11/22/22 in Posts

-

2 points

-

An online version can be found here : https://www.timezonewatchschool.com/WatchSchool/Glossary/glossary.shtml The following document lists the Swiss part numbers e.g. 445 for the Set Bridge dictionary_swiss_part_numbers_sa.pdf2 points

-

2 points

-

Recently there were several rants about the dreaded 3 pronged Russian shock spring. I have done quite a number of Russian movements but never had much problem with the shock springs until a couple of days ago. This Slava 2427 had the most uncooperative shock springs that I have ever come across. Just cleaning and oiling the two balance jewels took me almost an hour. I think it was a combination of a stiff shock spring and badly polished shock spring seats. I could get 2 prongs in but after that, the friction was so great that it became impossible to turn the last prong after it was pressed into the notch. It was then that I decided to make a tool to fit the shock spring in. My mentor described how to make this tool to me several years but I never made one as I never had much problems with shock springs before. It is rather simple. The tube was taken from an old spring bar and expanded slightly to fit the hole in the shock spring seat. Three shallow notches were made in the rim of the tube to catch the 3 prongs of the shock spring. The notches must be shallow, so that the tube can depress the prongs. It only took me 15 minutes to make the tool and using it to fit the shock spring is a real godsend. If any of our members have problems refitting these 3 pronged springs, I strongly advise making this tool.2 points

-

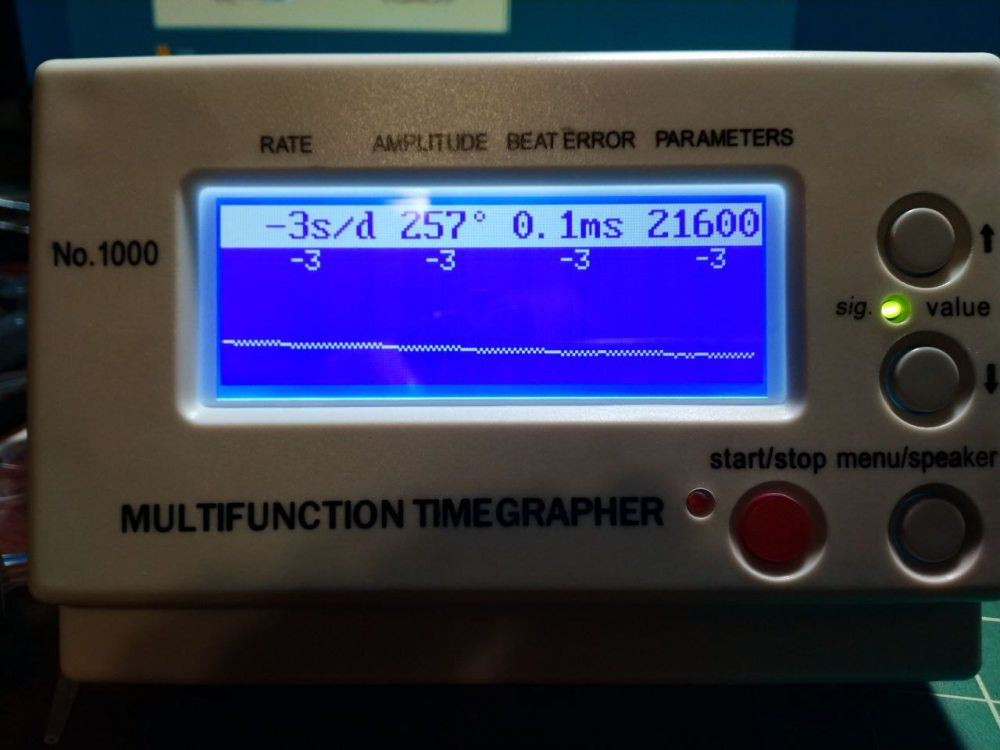

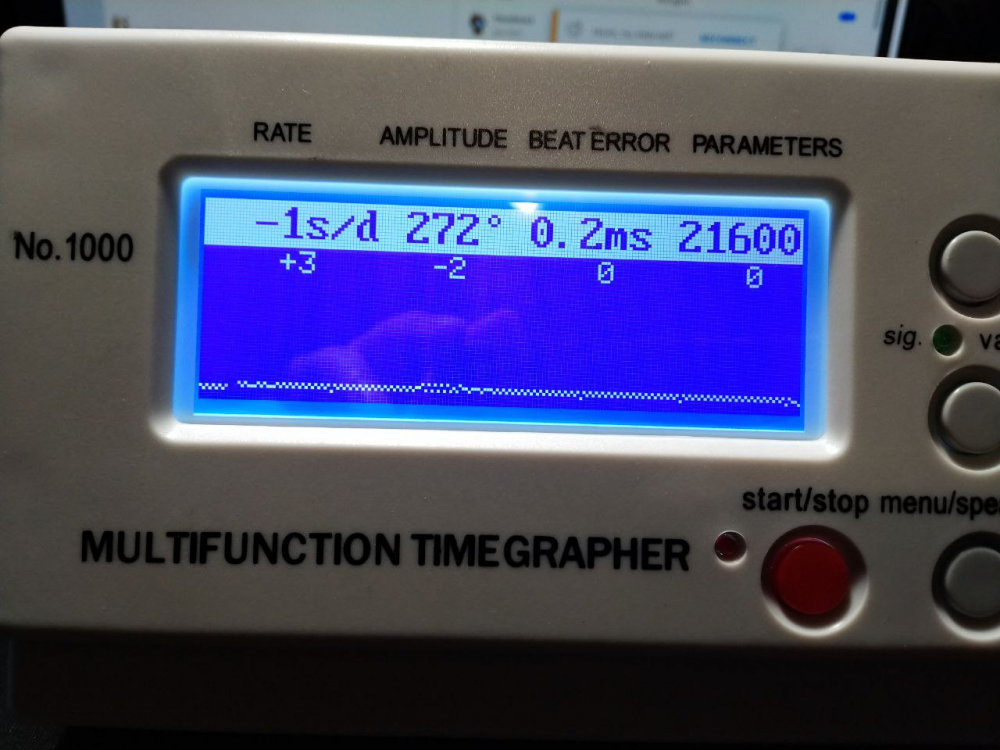

The optics are about as good as I feel like i could reasonably require. ANd so far i've only used the 20x, all iv'e really done with the thing was oil the escapement and it really helped to get right up in there and be able to see the actual oil as the pallet stones contact the escape wheel teeth. Yeah i rest my hands on the desk, steady the movement with one and push with the other, i might try two hands, that's an interesting idea. Also never doubt my minor OCD. The relubing of the escapement was the missing ingredient! Look at that amplitude baby!1 point

-

Can't grumble at that especially if its had a good few hours run time. Hows the new scope ?1 point

-

Although I have limited experience, rarely are dial dots a solution for anything. I can’t offhand remember the company in Oz that can provide jewels for some Seiko movements, this maybe something to look at to have a more permanent solution. This is for barrel arbor as a lot of seiko movements have this problem. Tom1 point

-

1 point

-

Speaking of disassembling , if you plan to disassemble the movement, you can start from the rotor, then loosen the bridge screws and try pulling the crown then. Rgds1 point

-

Have you checked the balance pivot for wear? And if shimming the bridge creates new problems then shimming isn't the right approach. We are still not sure of the exact cause of the wobble in the barrel nor that of the balance. Rgds1 point

-

1 point

-

Thank you! I learnt my way to dealing with small springs from jewels. And I also tried plastic container from food, but it didn’t work with me I just go slowly and use wooden stick to help a little. but this spring is a different animal. The way how it is attached to the small metal thingy is not clear. I am sure if it break from it I won’t be able to attach it again. I am waiting for the help of @jdm or @gbyleveldt and other masters in case they have seen this mechanism in the past1 point

-

Hi this attachment may be of some use as far as terminology is concerned. TZIllustratedGlossary.pdf1 point

-

It's odd that the holes are so round, while being so oversize. Perhaps in the past they were broached round, and the pivots retouched, but bushings not put in to compensate the new size difference? As the wear happens the hole tends to go oblong, increasing the surface area touching the pivot (as well as shifting the centers).1 point

-

Hi Ithink the key to any cleaning process with both clocks and watches is the drying process, which is of paramount importance. My machine is yonks old (National) and has a drying chamber, which is used after removing as much of the cleaning fluid by spinning off. The parts then go on to the paper and are gently dried again with a hair dryer just to be sure (belt and braces) and to date no problems. do not try and shortcut the drying process.1 point

-

1 point

-

I used water based cleaners and alcohol rinse for watches for many years with no problems. I didn't leave things in the alcohol overnight though, haha. My machine has a built in distiller for the alcohol, so the rinse is always clean, but even though the alcohol starts at 99% at a point it drops to around 80%, the max you can get from normal distillation. I don't think the main issue is the 70% alcohol, but the overnight stay. At any rate, if using water based cleaners an alcohol rinse is good at least as a final rinse, as it readily absorbs water, and evaporates easily in a warm air dryer (which I think is obligatory). The above machine has a built in dryer (the air moving conveniently past the distillation tower, clever); when I do clocks, also in water based cleaner, I rinse in clean water, then alcohol, pat dry, then onto a hot air dryer to fully evaporate the remaining alcohol/water mix. As a note, acetone will absorb water from the air, so if you regularly glue up parts for fixturing (as I do) with superglue and de-glue in acetone, an overnight stay can easily end up with rusty parts.1 point

-

After cleaning ferrous parts in a water based cleaner, the metal surface becomes very reactive. Parts can rust within minutes. I stopped using water based cleaners because parts start to rust within the time it takes to rinse twice and dry, which is about 30 mins. I know @jdm and @nickelsilver have said that it doesn't happen when using water based cleaners designed for horology. But I have not tried it personally, so I can't say. In my dental practice, I have a rust inhibitor which is sprayed on carbon steel instruments to prevent rust while sterilizing them. I don't know what the active ingredients are but it seems to work. But sadly, this product has been discontinued.1 point

-

Seiko parts manuals show the same balance complete for both 7017A and 7005A movements. All of the following movements share the same balance complete assembly (P/N - 310020) Balance cocks will obviously differ. The only one I found that shares the same balance cock as yours (P/N - 171033) is the 7018A.1 point

-

1 point

-

I know how that is, in time gentle handling becomes second nature. Watch the little buggers as they can fly far and wide. Some folk work inside a transparent bag to prevent that, i tried it once and found it very awkward. I wish i could give you more help but my experience is mostly held in vintage swiss. Jdm knows seiko but hes not been here for a while. Also Gbyleveldt is our Seiko sensei, nice guy and funny, make him laugh and he might help you out. please dont make me spell his name again though .1 point

-

It would be nice to have pictures so we know what were looking for to help you out.1 point