Leaderboard

Popular Content

Showing content with the highest reputation on 11/19/15 in all areas

-

Here is the next installment for those who are interested or even just curious. There are some interesting passages and it appears that there are some positive results in the battle. IAF Progress Report 17 Nov 2015.pdf Regards, Vic2 points

-

Hi, If you fancy some Junghans pocket watch information have a look at my website: http://dirkfassbender.de/movements-1.html On the other hand I would be grateful if you have some informations which are maybe missing. Junghans is not so well represented on the internet which I would like to change. Best regards Dirk1 point

-

I too bought from China . Didn't like the sloppy shaft and the non straight dies . So i redone mine with a stainless steel rod . And a bushing so i slides perfect . Bought some new dies from Cousinsuk . Even the hole for the shaft was out of line. Lot of work that i would not do again. If i would buy one today i probably would look for a better quality press .1 point

-

1 point

-

1 point

-

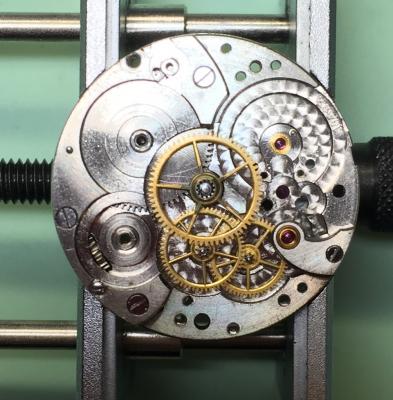

So my intentions of journalling my progress of this project seemed to have gone awry. It has been complete for some time now, and I was so focussed on the work itself, as well as a few deadline issues, that I failed to record my progress with words or photos. With apologies out of the way, it's better late than never, here's a basic recap of how things went: I decided to send out the case and crown for replacing. The 10K RGP finish on it was in decent condition, with a little bit of honest wear, and more than a few service engravings. I wanted the finished watch to reflect some of the history of itself, so I took care of the preparation and polishing myself, making sure to improve the appearance without buffing out the sentimentality. The replating was a cosmetic decision. Mrs RustyColt dislikes yellow gold, and I was concerned that may discourage her from wearing this watch, regardless of emotional connection. I found a plating service in Vancouver, BC that could do the parts in 18K rose gold, and was fairly pleased with the results. It turns out that the plater I chose does not do a lot of watches, and I think that they are used to much larger parts. In the end, all was well. The dial also went out for refinishing. It was my first foray into this, so (partly) based on the experiences of others in the WRT forums, I decided to sub out the job to International Dial Co. Having heard that the achilles of them is their often unpredictable and lengthy turnaround time, I was sure to get the dial to them a full 3 months prior to Mrs RC's birthday (when I was hoping to present it to her). Needless to say I did not make that deadline, but I was satisfied with the workmanship of International in the end. As I had changed the case from yellow to rose gold, I had International change the hands and dial indicators to match. All in all, I was pleased with those results as well. Servicing took place while the parts were out. The Longines 10L is one of the nicer movements I have had the pleasure of working on in my brief foray into watch repair, and it was a truly pleasurable experience to have hands on such a finely made piece. On final assembly, it became evident that there was damage to the balance staff pivot which would require a replacement. I was able to source a scrap movement from eBay, which yielded a suitable replacement. This was a rather nerve-wracking part of the process however, as I have had very poor results with any hairspring work I have done thus far, and the replacement balance staff needed to have the original hairspring transferred to it. Patience won the day, and the transplant succeeded. I was able to install and poise the replacement, and at this point, I was still on schedule for the birthday presentation. I still had to replace the missing crystal and seconds hand, and for this I had taken some measurements and scoured Cousins catalogue for suitable parts. Those arrived around the time I was finishing up the service, and I was, once again, pleased with what was on hand. The crystal was bang on, and the seconds hand (I had ordered a couple different ones to see what would look best in the end) also worked out quite nicely. While it would have been nice to have had the seconds hand prior to sending off the dial and hands for refinishing so that it could have been done to match, I did end up satisfied with that being a contrasting black indicator. Regrettably, the only internal photos I have from the project are the ones I took during disassembly for reference. Joyfully, and without further ado, I present those, along with the finished product for your enjoyment:1 point

-

The long thing is actually quite useful. It's used for removing the punches when there in the case and you can't get at them with your fingers. Then I've attached a link to the PDF manual for K in D staking set give you an idea of what some of the things are for. Plus a whole bunch of stuff you've probably never seen possibly. The round things shows up on page 15. http://cholla.mmto.org/watches/repair/manuals/KD_staking_tools.pdf Then stumble across a website with more K&d staking set stuff http://kanddinverto.weebly.com/1 point

-

I am just starting out in my hobby of Watch Repair. I am curious if I could solicit any suggestions when it comes to adjusting the regulator on a watch. Not meaning timing the watch. I have my own approach to that. What I am specifically referring to is knowing how much to adjust the regulator. For instance is there an industry standard for how much time the tick marks on the regulator represent? Is there a trick like adjusting it over seeing the change and then dividing? And, is there a tool that is used (other than a piece of peg-wood)? Currently I am just doing it trial and error style. Adjust, observe, repeat....etc...etc. Thanks Rob1 point

-

Before I give you an answer on regulating a watch before timing machine a note regarding standards in horology. Watchmakers are interesting they adapted whatever they had so there aren’t a lot of standards at least up until now perhaps. So for instance look at measurements they grabbed whatever they had available. So we end up with a interesting mix of definitions for measurement. Like mainsprings measured in metric, inches and Dennison. Even then they didn’t just adopt one of those systems for the mainspring typically the length was in inches the width and strength in one of the other systems. So I have a couple of books that reference adjusting a watch without a timing machine. One of them comments about the rumor you can adjust the watch in less than 24 hours but his experience was several days to weeks. He was adjusting to three positions. Then my all-time favorite the watchmaker has a 17 jewel high-grade American pocket watch is adjusting it to basically very precise timekeeping. So goes through multiple pages describing the condition of the watch exactly what he did at various times telling us what the timekeeping was and how things are improving. So he starts February 4, 1896 and finishes April 17, 1896. So timing machine speeds up things considerably but you still need to run the watch for 24 hours and see what it really does. Timing machine tells you what the watch was doing at a exact instant the time. It doesn’t tell you what it’s going to do over 24 hours. Then if you’re really doing a good job first on the timing machine then run the watch 24 hours later back of the timing machine tto make sure it still doing what it’s supposed to be doing. Even this doesn’t exactly cut it because if it’s a wristwatch it should go on a wrist. Sometimes watches will keep beautiful time sitting on a safe bench, on somebody’s arm it will do something considerably different. So some companies did have standards and they did publish them. So I’ve attached a Hamilton publication it does explain roughly what happens when you move things around to adjust things. hamilton_tech_note_on_regulation.pdf1 point

-

Here's a macro shot of my Nordic tool Untitled by Micky Aldridge, on Flickr1 point