Leaderboard

Popular Content

Showing content with the highest reputation on 03/06/15 in all areas

-

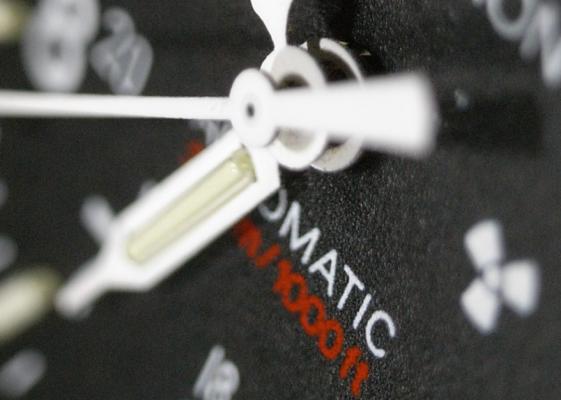

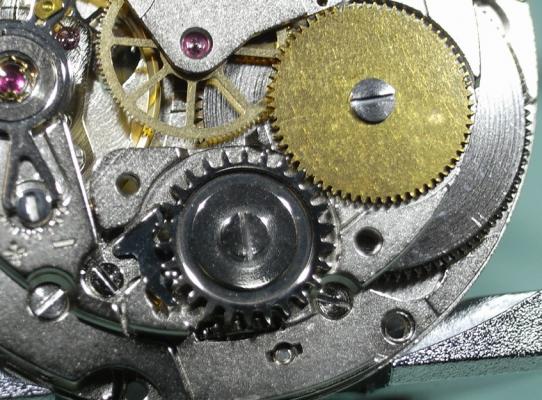

ETA2824 Service - The Radioactive Watch! Yes this watch is Radioactive ... so to speak :P It contains H3 Tritium Tubes to illuminate the dial at night. This watch belongs to my brother, and he has owned it for many years. I have to say that Marathon Watches are great "bang for buck", as this watch has served him well over those years, and he rarely takes it off his wrist. Unfortunately, on one of the rare occasions that he did (to wash his hands after work) he dropped it on the ground, and it stopped dead ... right at his quitting time 3:30pm. He was very angry with himself, and asked if I could found out what damage had been done by the drop, and repair it ... of course I was happy to help my bro :) While he was with me, I pulled the Caseback off and could instantly see the problem. The Hairspring was jammed up and the Balance was seized. I told him there also could be broken pivots, and I'd have to dig further to assess the total damage; but not to panic, as all parts for this movement are readily available (at the moment) ... so he left the watch with me. So I removed the movement from the case, pulled the Hands, and the Dial off to inspect the Calendar Works ... everything looked good. Next I removed the Oscillating Weight, and checked that the bearing hadn't been damaged by the impact ... it was fine too. Next I pulled the Automatic Work off the movement, so I could gain access to the main body of the watch. Here's a reference photo of the Automatic Work for ya Next I undid the screw of the Balance Cock and began to gently lift it ... and hey presto, and Hairspring dropped back into place, and the movement started tickin away ... these are a solid movement indeed! I carefully watched the movement ticking away, noting to see that the Pallet was working properly, and that the Train Gears ran smoothly ... all seemed fine, and the problem with this movement was resolved. I could have just stopped there, but this movement hadn't seen a service in over 8 years, and was already out of the case and 1/4 stripped, so I deiced to burn the midnight oil and do a complete service on the watch. And yes, that is a real radiation dosimeter, as I wanted to be sure nothing from those glass vials had leaked into the movement I was handling ... I'm glad to say it was clean B) Continuing with the strip down. All mainspring tension was removed from the unit. Notice with this movement too, that the click is on the Crown Wheel; instead of the Ratchet Wheel. Balance and Pallet was removed Crown Wheel, Ratchet Wheel and Barrel Bridge was removed. This is a reference photo of the Click Spring sitting on the Barrel Bridge. Under the Barrel Bridge there is a small Balance Hack to be removed as well. Next I flipped the movement and removed the Calendar Work. Then the Keyless Work Back the to other side and Train Gear was removed. Here is a reference of the Gear Train. Lastly the Automatic Work was stripped. Back from a bath, and all parts clean and ready for inspection and assembly. All pivots where intact and unburred, no damaged teeth or pallet stones, and no wrapped gears ... GOOD NEWS!! Ready to be put back together! :woohoo-jumping-smiley-emoticon: Nice clean and shiny Gear Train, Train Bridge and Barrel back in place and oiled Back on with the Barrel Bridge, Ratchet Wheel, Crown Wheel and Click Keyless Work clean, oiled and working smooooooth Automatic Work back together as well The rest of the re-assembly wasn't photographed ... sorry guys, it was VERY late, or should I say EARLY, in the wee hours of the morning, and I just got carried away with the build :huh: But it all went smoothly and as per the reference photos early. After the Dial was attached, the hands where next. Let me tell ya, these are NOT easy to fit correctly! With those glass tubes of H3, there is NO room for error fitting them. You literally have a couple of thousands of an inch to play with ... here's the photos to scare ya :o. This type of watch will really test your hand setting abilities. Here's she is all back in the case with the Automatic Work and Oscillating Weight fitted, purring like a kitten! Job Complete!! And as you can see, it now is showing my quittin time of 4:11am OUCH!! :hot: Hope you enjoyed this post as much as I enjoyed working on this movement. It was really nice to finally work on a watch that hasn't been molested, with nice clean screwheads, and no rust to deal with.1 point

-

I saw this technique on you tube a while ago and decided to give it a try today. Old lume is certainly something you do not want to be breathing in, so the safest way is to remove it under water. All you require is an ultrasonic cleaner, a piece of pith wood and a couple of matchsticks. Trim the matchsticks to fit the hole in the hand and delicately press them into the centre of the hands. I find the best way is to lay the hands on the pith wood face up and then press the matchsticks into the hands. Once you have done that, press the matchsticks into the pith wood as in the pictures below. Now take the pith wood complete with hands and float in the top of the water in the ultrasonic tank. The lume on the hands will be facing downwards as in the following pictures. Give the hands a blast for three minutes in the tank, and all the lume will be safely removed leaving spotlessly clean hands ready for the new lume. See below. :)1 point

-

I felt like recording a little music this morning after spending an hour or so on my watch pages website. Just a bit of fluff on a bright March morning... And, for those that care, I'm wearing my Omega f300 this morning, after a successful date change of the plastic calendar wheel without it breaking - from February to March! https://www.youtube.com/watch?v=PXZOjeKayWU Cheers, Will1 point

-

I'll have you know Geo that I have just returned from the local holster holserery err establishment & am slightly dessip. I think I will go fix up on my old scrappers & put it on fleabay for lots of readies, I mean that's what most people do dont they?1 point

-

Problem with isopropanol (IPA) is that it can dissolve shellac - used to 'glue' roller & pallet jewels. Or so I am told.1 point

-

Thats the stuff, a mixture of light hydrotreated petroleum distillate & hydrotreated light naphtha. Ronsol, Zippo & Essence Renata are trade names.1 point

-

So do I, but then again I'm a Gentleman of the Road (Hobo to our colonial cousins).1 point

-

I think it's a great find and piece of family history Bob, the only thing is I didn't find it! ;)1 point

-

I can concur ro, my very first watch (over 50 years ago) was a diver style with the 8800 movement and I re-stored it and it runs perfectly with incredible accuracy. It too has great sentimental value my mum purchased it for me, total cost of approx. £5 + some tokens from Weetakbix boxes.1 point

-

Amazing isn't it, after many years and working well! Nice find Geo and nice clock!1 point

-

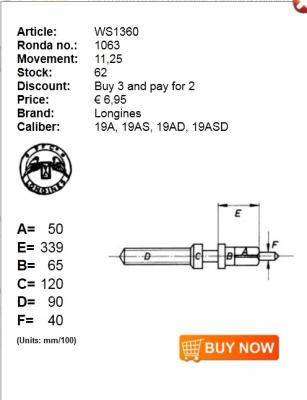

Yes, the seal came with the new tube. I do not have to search very far for parts. Luckily, I have a large folder, which gives me all the details. If you need any part number send me a PM and I'll send what I have on your submariner. Morten1 point

-

At a minimum, I would have moebius 9010 and 8200 also some D5 or Hp1300. If the watches/movements are just for practice, I'd substitute those by some silicon 100 and novostar products but I haven't tried those so it is only a guess. To seal the case and lube the gaskets silicon grease is necessary (either the Seiko or the anchor). Check out our lube posts, they are very informative. The 0.5 screwdriver is too small for general work and can break/bend easily if using as a lever (not recommended for any size). I'd rather spend good money in a bergeon or horotec set and get it done with. You'll find that the actual Chinese screwdriver body might not be the best for the bergeon tips (tip off center, wobbly, etc) and some refitting might have to be done (which is time and money in the long run). You'll never be completely satisfied in the end but done well it will last. For most watch work I believe a range between .80 and 1.4 is most useful. An ultrasonic and the right fluids is also recommended along with fine optics and lighting. Needless to say that how and where you work is very important too. There are several on line classes you can benefit from while attempting to fix a watch and of course this forum which have an incredible amount of information and helpful people. So, you see, you can tackle your watches without a worry considering the above! Cheers, Bob1 point

-

Don't hold your breath! I'm still trying to pluck up the courage to start taking it to bits. Plus I'm waiting on a new 0.5 screwdriver to remove dial screws. Just ordered a cheap Chinese set and some Bergeon blades to go in them. As to lubrication, how many different oils/greases do I need as a minimum? I see that Mark uses a number of different products in his videos but can I get away with some 10w30 and a pot of Castrolube?1 point

-

Hi Vic, All good advise here! I bet you will enjoy servicing this watch. By the way, that plastic ring is important since it is the track for the date ring. It also places the dial correctly for the date/day @ 3 depending on the crown position. This means that if your day/date combination is OK (they may misalign between them but that is another issue) the dial feet will define where the crown should be based on the holes in the plastic ring. i.e. it is the dials that are made with different dial feet positioning to accommodate the combination of crown/date (crown @ 3, day/date @3 or crown @ 4ish, day/date @ 3). Therefore, if you are going to change the dial (which I believe you said was not showing the second marks well, they are not expensive), it is important you get the right dial based on the feet. This plastic ring also serves the function of keeping the movement correctly in the case and it is place in a very specific way around the main plate, respect to the dial holes and the stem. The hands can be had for little money either on ebay and/or other suppliers, they are 150/90/20 if I'm not mistaken. Some of those watches come with the dial feet glued to the ring and no dial feet/broken dial feet so be careful during disassembly. I'm sure you can get that watch in real good shape in no time at all. It looks good right out from your pictures and you seem to be doing a great job so far! Check out Lawson walk through on the same movement. Cheers, Bob1 point

-

Welcome John, most of the guys on this forum a very keen hobbyists but we also have a good sprinkling of pro,s too. This combination is perfect for a beginner and the wealth of knowledge available at times is outstanding. No matter how small the problem or how trivial it seems post it, trust me we have all been there at some time. Enjoy.1 point

-

Hi John, no not a Triton. That was my 1958 Norton that I bought as a standard Dommie 99 back in 1967. I was continually modifying it and the picture shows it in 1970 fitted with a 750 Atlas motor and a few wee extras. :)1 point

-

A very warm welcome to the forum from way up North, and thank you for taking the time to write an excellent and informative introduction. As Morten has said, this is an excellent hobby and a wonderful profession. I too am a hobbiest, but be warned, it can become very addictive. There is such a variety of old time pieces out there waiting to be found and restored, and so much to learn on the subject of horology, that it could keep you interested for ever. When you get around to servicing your watches, please post your progress on the forum, I for one look forward to hearing about it. :)1 point

-

Welcome to the world's best hobby or job, watch repairing. It's fun to read your post. I look forward to seeing your Omega when it is finished. Morten1 point

-

Just some additional stuff that may help. I think that you need an extender that fits a stem size .9mm which is referred to as Tap 10 so the extender would have to screw on to a Tap 10 thread. If anyone finds fault in this please don't hesitate to correct me - its all part of the learning process. Cheers, Vic1 point

-

1 point