Leaderboard

Popular Content

Showing content with the highest reputation on 01/18/15 in all areas

-

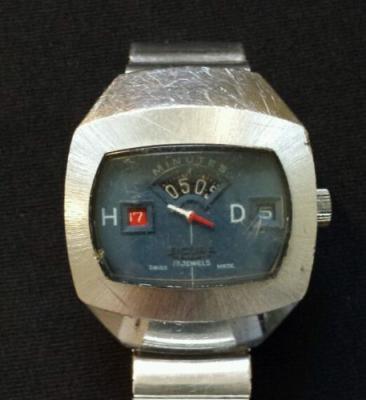

I have been looking for one of these for quite a while, and finally found the right one. Bought from the bay as a project, it was a bit hard done by when I received it, but that it what I was after. Right off the bat, it needed a new balance staff and full service. I ordered a complete balance, as the existing hairspring was not inspiring confidence, and I have yet to develop any hairspring repair skills. Turns out that the BFG866 movement has two different hairspring configurations, which in turn use two different regulator/stud mount posts. They physically work together when they are wrong, but the hairspring becomes distorted due to incorrect y-axis positioning. I have located the parts to correct this, it shall be done. In addition, I have found that the power reserve is a meagre 11 hours or so, as such, I've placed an order for a new mainspring. Today is the second day that I have worn it, and I can see that I will need to go back in and tighten up the canon pinion a little also. So still a couple more tasks on the worksheet for this watch, and I wouldn't normally wear a work in progress, but now that the replacement glass is installed, I couldn't resist putting it on this morning. Many thanks to fellow WRT member noirrac1j who has been a tremendous resource throughout this project, and who was the key to sourcing a replacement crystal - that was a huge deal, my gratitude to him for the help, and to Mark for creating this community for us to find each other in! Here is the poor thing before - I was able to polish out about 95% of the scratches and pits from the crystal, but that only revealed that there were two significant cracks, and a crater at 8:00. I was able to do some light polishing on the case, but the plating is pretty thin, and I'd rather live with a few honest scratches than brass edges, so for now, this will suffice. There is a decent chance that the bracelet is original, but I do not know for certain. The clasp has been repaired at some point, and it was done well. I think the cost of that repair would have exceeded a replacement bracelet. It is not signed, but for my purposes, I'm willing to accept it as an original part (for the time being, at least) All in all, it's good fun, and that is exactly what I bought it for. It's roughly the same vintage as I, and while that was not an era known for its timeless style and beauty, it is satisfying to embrace that bit of nostalgia and individuality. -J1 point

-

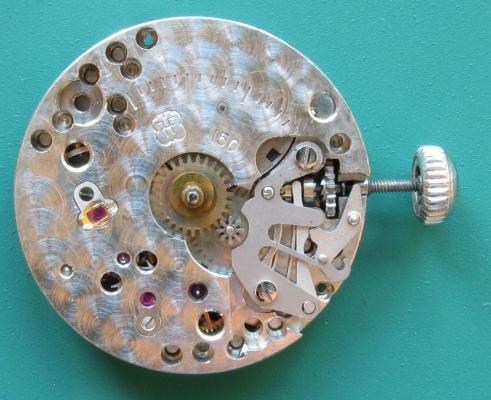

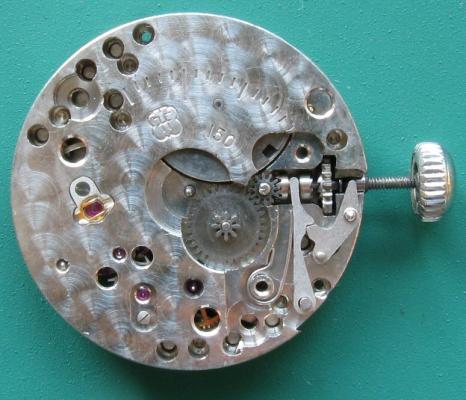

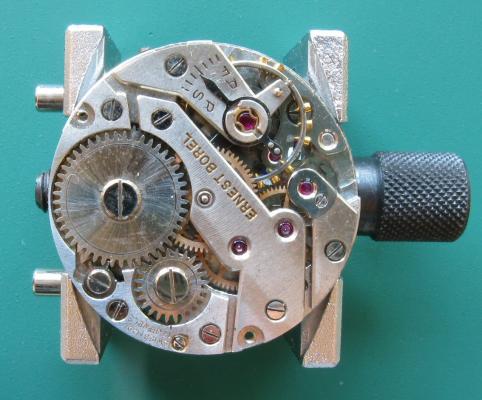

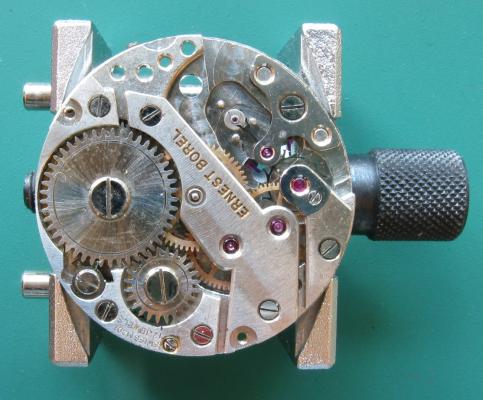

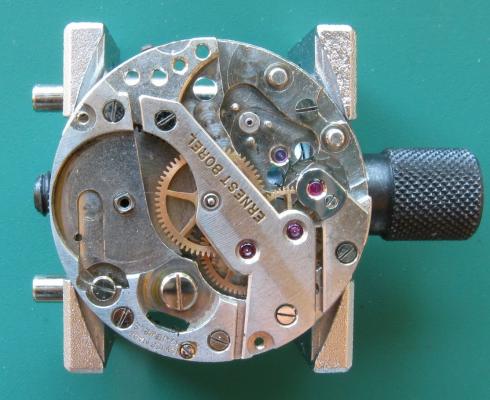

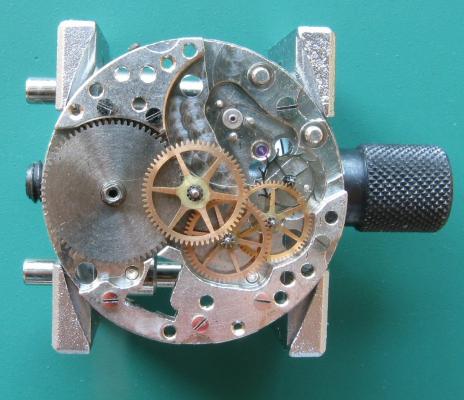

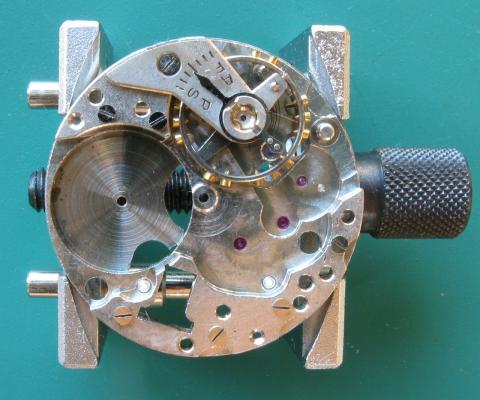

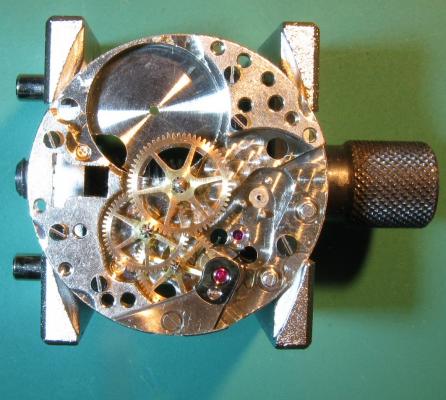

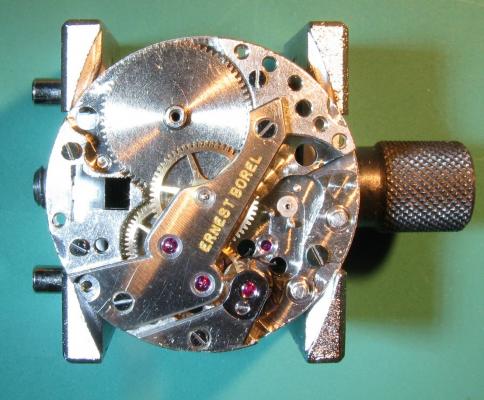

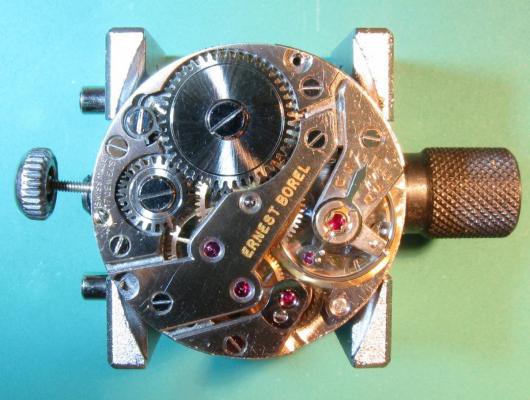

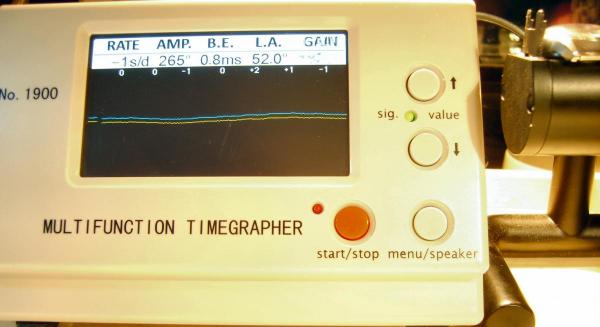

Here's another one of my recent(ish) projects. This one is an Ernest Borel all stainless steel cased watch probably dating from around the 1940's, housing a 17 jewel FHF Cal.150 with shock protection. Ernest Borel are probably best known for their cocktail watches and kaleidoscope dials, but this is a more sober example. A bit scruffy with a badly cracked crystal obscuring the dial and not running at all. The back is also a bit scuffed and the whole thing is rather dirty. The crown just keeps turning when you wind it so a broken mainspring is the likely problem. With the back off everything looks very dry and there's a fair bit of dust and fluff in evidence. Apart from the usual carnage to the barrel bridge around the set lever screw and some scratching to the escape wheel cock there doesn't appear to be much abuse, and the hairspring looks OK which is always a good sign. Out of the case and no longer obscured by the damaged crystal the dial and hands look quite good, with just a light even patina to the dial and the first signs of corrosion on the hands. The lume is all there too (and it's radioactive!!!). With the dial off everything is quite clean and with no sigh of rust. Also no sign of lubrication either though. Notice the simplified shock protection spring when compared to the top of the balance, and also the minute indices used to time the movement against a standard clock in the factory before the dial was fitted. No need to let down the mainspring on this as there's no tension in it at all. With the set lever bridge removed the layout of the keyless works can be seen. With the dial side stripped the movement is flipped. Balance removed and put to one side. Pallet fork, ratchet wheel, and crown wheel removed. There is a little bit of wear to the plating below the crown wheel but nothing excessive. The plating beneath the ratchet wheel is intact and in good order. End shake and side shake on the train wheels is fine too. Barrel and train bridges out of the way and the train wheels are there in all their glory. And the main plate is now stripped. No plating wear below the barrel and the lower pivot hole is nice and round. The underside of the bridges and escape wheel cock. Again, no damage to the plating and the barrel arbor pivot hole is not worn. Plenty of black goo around the centre wheel pivot hole. With the lid off the barrel the reason for the watch not running is very evident. The mainspring is of the old blued steel type and has snapped (as these are prone to do). This will be replaced with a white alloy spring which should be much more reliable. There is also a fair bit of dried grease around. The balance is reinstalled to the stripped main plate and the balance jewels removed. Everything is now ready for the cleaner. And there it all is fresh from the cleaning machine. A quick inspection under the microscope shows the pivots and the pinion leaves have no sign of excessive wear so everything is good for reassembly. The new mainspring ready to go into the barrel. First the escape wheel goes back in and once the cock is installed, the cap jewels are oiled and assembled. then the rest of the wheel train goes in. Train bridge installed and the train tested for free running. All is fine so the pivots are oiled and the the barrel goes back in. The barrel bridge is fully reassembled, the keyless works are back together and a couple of clicks on the crown gives very good recoil at the escape wheel. Pallet fork in, pallet stones lubricated, balance back in and beating. With the movement ticking away the case gets a very light polishing and a new crystal. The lighting in this pic is somewhat vicious in picking out the scratches from what I presume to be a previous polishing as the scratches on the bezel can only have got there with the crystal removed. It's tempting to go for a mirror finish but the risk of rounding the otherwise sharp edges and dulling the engraving on the back is too high, and in daylight the scratches are not really an issue. The movement goes back into the case and the retaining ring replaced before the back goes on with a new gasket. And there it is. The dial was treated to a light dabbing over with rodico and the hands were lightly buffed to remove the surface corrosion that was just beginning to show. And on the Timegrapher a thoroughly acceptable result for a 70+ year old watch. This one went on eBay just before Christmas and somewhat to my disappointment only managed £33. Still I had had my fun with it and was happy to sending it on its way in the knowledge that it really was in good shape and that, if looked after, it could still be ticking for a very long time yet. I do think that the buyer got an absolute bargain though.1 point

-

If you've got the equipment for installing friction jewels, and as you say provided there is enough room in the plate to accommodate it then that would certainly be a solution. If you are unsure about the process Mark has recently done one of his excellent videos (vintage Omega 30T2) in which he replaces a badly worn centre wheel bearing with a jewel. Also if you have an old main plate from a scrap watch or even a scrap piece of brass plate you could have a practice run on that before tackling the Bulova. Assuming you have a jewel the right size the most critical thing is ensuring the axis of the hole doesn't shift from where it's supposed to be in the process. As far as end shake is concerned so long as the jewel is pressed flush with the train side of the main plate you should be OK, but this can be adjusted fairly easily. Good luck, let us know how you get on.1 point

-

Thanks for all the comments Gents. Will, I do have a number of pieces of similar vintage in the pipeline so I shall definitely bear you in mind when they are ready to go. Actually Charlie I did want to keep this one but to put not too fine a point on it I needed the cash. Also, although I do have a modest collection I am much more of a tinkerer than a collector. For anyone who is interested my photographic set up is really very simple. I have an old Canon PowerShot A720IS compact camera set up on a table top tripod. It is set up in aperture priority mode with the aperture set at f8 (smallest available) and the focus set on macro, flash switched off. The shutter speed is invariably longer than 1/5 of a second so I use the 2 second self timer to take the picture without any shake. My bench is in front of a large north facing picture window so daytime lighting is just natural daylight, otherwise I have a couple of tungsten filament lamps that I work by and an LED lamp which I use for really close work as it doesn't generate any heat. The only thing I have to remember to adjust is the white balance depending on lighting (daylight or tungsten) as the auto white balance can be a bit iffy. Then I just crop the images on the PC to exclude any irrelevant details. The only problem that I have with this setup is that there is a small scratch on the camera lens which, if the lighting is just wrong, results in feint flare across the picture.1 point

-

Well, I had another go at it today, with a different movement and it worked! Thanks again for the tips. Got to use my barrel closer too. [emoji3]1 point

-

I think that may be what is happening, although the arbor barely protrudes the plate as well. The score marks are brass and are on only on one side of the barrel bridge recess on the bottom, which may point to the barrel being tiled.1 point

-

I purchased a cheap ETA 6497 pocket watch a while back with a view to making a big wristwatch, However when it arrived the balance was in bits and on assembly the hairspring decide to get itself all out of shape! This was shelved as I had no confidence in correcting the self destructing beast. Until 2 nights ago armed with my new Dumont no4 tweezers and having watched Marks excellent videos over and over, operation Do or die commenced! After a couple of hours of bending ,stroking, cursing and manipulating the little bugger the watch was running...Badly! By 4am the whiskey i had been sipping to stay relaxed had over relaxed me so I went to bed! Last night phase 2 began. A little more caressing and back together, still bad! spring looked ok but no amplitude and the loudest knocking I ever heard from a watch. Further investigation showed the balance wheel spokes were hitting the index pin, the arm had a slight bend which was finely adjusted with a set of pliers! Much better! On to the timing machine and I saw what looked like a blizzard so then decision was made to strip the movement down ready for cleaning today! I ended up cleaning reassembling and oiling and having got to bed at 4am again I left the watch running. It now shows good amplitude. 0.3 m/s beat error and around -10 to +6 secs a day. Happy Bunny. If there's a moral to this it must be never give up and all credit to Mark without whose brilliant videos this movement would most likely have never ticked again. The End....or just the beginning?1 point

-

I have found some are tight especially if it is a new spring. I attach the abour in a pin vice and then put it in at a slight angle engaging the hole first then tilting in straight.1 point