Leaderboard

Popular Content

Showing content with the highest reputation on 12/27/24 in all areas

-

Just wanted to say thanks to everyone who has provided guidance and help on this forum as I begin my journey into the world of watch repair. Today I stripped down and rebuilt the st3620 movement. It took me about an hour to reassemble it and I reckon 20 minutes of that was getting the balance in; great feeling when it started going though Maybe that’s not much to many of you but I enjoyed it and was pleased that it still worked at the end! I didn’t clean or oil it this time but thats gonna be my next attempt. Bill2 points

-

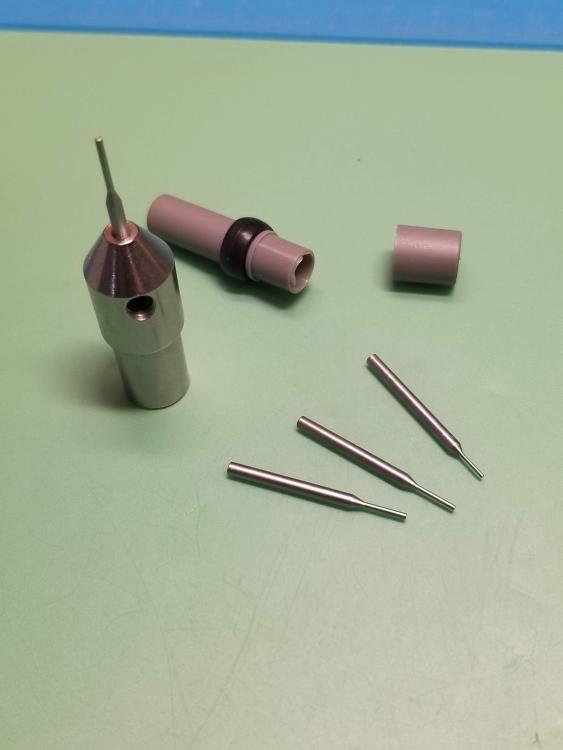

Exactly that. The stem wobbles during time setting. I've found a longer tube and will fit that when my new tube removal tool arrives.2 points

-

2 points

-

Absolutely Andy lol If there is a center point I'm sure clamping wouldn't be required, without the center point I'm sure it would be required. I still think the same as WW, and that is better to solder the feet on forca long lasting repair. WW uses elec-trickery I use pyro-pokery.2 points

-

Without the point to keep the cutter in place the workpiece will move around until some depth has been gained. There is a similar tool in woodworking that cuts the hinge holes for kitchen and bedroom cabinet doors. The center pin poking the face is a common problem when an operator has drilled the hole too deep or a door is 16mm thick or under. I overcome this by having two cutters, one with a center pin to start the hole and another with the pin ground off to finish the hole to depth.2 points

-

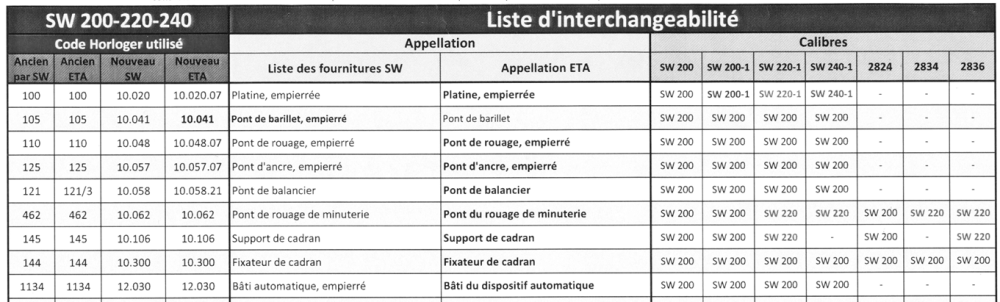

I'm sure i read somewhere that they did make for Oris at one time. Oris were always originally in-house makers then sold out some time ago and as far as I know are fairly recently back to in-house but maybe not with everything they make. Besides that Oris have for some time now RED trademark auto rotors. Yes just had a look the 752 is based on SW220-1 which is an ETA 2836 clone. I'm sure this is the Sellita caliber that got a pretty bad rap with quite a few design flaws . In an interview with one of the main men , he admitted that they had made some mistakes . It appears all the Aquis models have movements based on a Sellita engine. Interesting that they describe it as a based on movement come on Oris !! ...lets be more honest and accurate about what you tell folk shall we...It's a Sellita movement that you've modded .2 points

-

2 points

-

2 points

-

1 point

-

Thanks for the offer! I actually found a NOS one today at McCaw Supply (Toledo OH). Was their last one, so feel lucky. I was thinking this was an opportunity to explore the world of 3D printing but looks like it will have to wait for another project. Happy Holidays and thanks again for the offer.1 point

-

1 point

-

Thanks for sharing @RichardHarris123@RichardHarris123. Sad story. Boy, would I love to visit his workshop and see his tools and methods!1 point

-

1 point

-

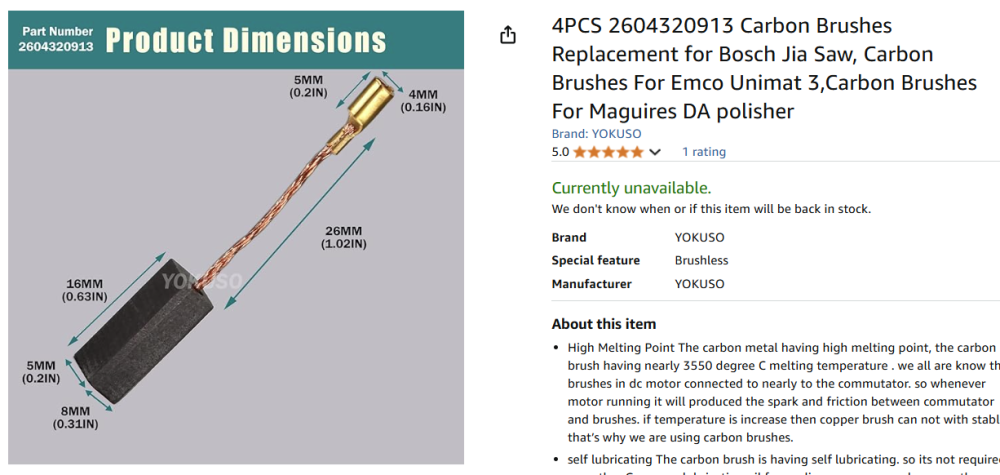

Of all the different ways of fitting dial feet the best way is soldering and if done correctly there is no problem. Ihave done quite a few Seiko dials which seem to be prone to losing feet on my home built machine. Works great built for the same cost as the Ali express cutting machine.1 point

-

Mike, thank you so much for taking the time to help me out. Sounds perfect and red numbers that move are better than black ones that always say the 12th! And thank you for putting me onto the Watch Material Interchange List. What a fantastically useful database.1 point

-

1 point

-

There's a key on page 9 of the PDF that you can use to interpret them.1 point

-

Where to lubricate, how much to add and what lubricant.1 point

-

1 point

-

Three helpful hints...1 always do as she asks of you...2 never answer back...3 have your credit card ready to hand over as she is putting on her coat to go out shopping.1 point

-

If mum is happy then thats always a result, much easier than keeping wifey happy1 point

-

How did the tube insertion go Steve ? Does the shortness let the stem wobble when a bit when setting the time ?1 point

-

Thanks for the info - I'll pop it open next time my mum is over. Meanwhile it's kept running over night and is keeping good time so I'm hoping it's something she can wear and enjoy; as well as having sentimental value it's quite a nice little watch. Result!1 point

-

Thanks everyone. To clarify, there's just an o ring in the crown. The o ring does not sit around the tube when the crown is pulled fully out as the tube is 0.6mm too short (only 2.0mm long externally when the original tube is meant to be 2.6mm long)1 point

-

1 point

-

There are always exceptions, but this simple style and colour of dial together with matching pencil hands is very common with 1960s watches. I'd have expected an older ladies watch to be smaller as well. If you can locate the town assaying and date letter hallmark stamps then we can get an accurate date. Probably on the inside of the caseback.1 point

-

It’s the phrase “ and waterproofing is lost when the crown is pulled out to set the time.” I am questioning Andy, no watch is water resistant when the crown is pulled out. Tom1 point

-

Not sure what you mean by waterproofing is lost when the crown is unscrewed? All dive watches or water resistant chronographs carry a warning not to operate crown or pushers under water. The water resistance is only valid when the crown is fully screwed down. Tom1 point

-

From what I found based on Zaria, it's a 2009: https://17jewels.info/movements/z/zaria/zaria-2009/ Thanks Neven. It came out after a little persuasion.1 point

-

Yes, you've done exactly as I suggested and drawn the right conclusions about the amplitude calculation. I personally find this easier/quicker than the 180° approach. But other may prefer it. But as you saw, the calculation results are the same. After that, the lift angle for the Pobeda is lower than the known one (42). This could also mean that someone has tampered with the escapement before you...1 point

-

Lift angle of USSR 2602 movements is 42. What seen on videos/ amplitude readings is correct. The conclusion is that for some reason the timegrapher doesn't calculate amplitude correctly. Who cares? If You know how to see amplitude, then don't mind what timegrapher shows.1 point

-

Your comments are basically the end point I was making. How deep do you want to delve into the mechanics, maths and physics of the escapement ? We're not making watches here...so not that deep, but understanding the basics are definitely needed for testing and correcting common escapement issues. Particularly when it comes to old pocketwatches that have been through the mill of escapement trial and error adjustments. There is some good books on this subject alone.1 point

-

1 point

-

1 point

-

1 point

-

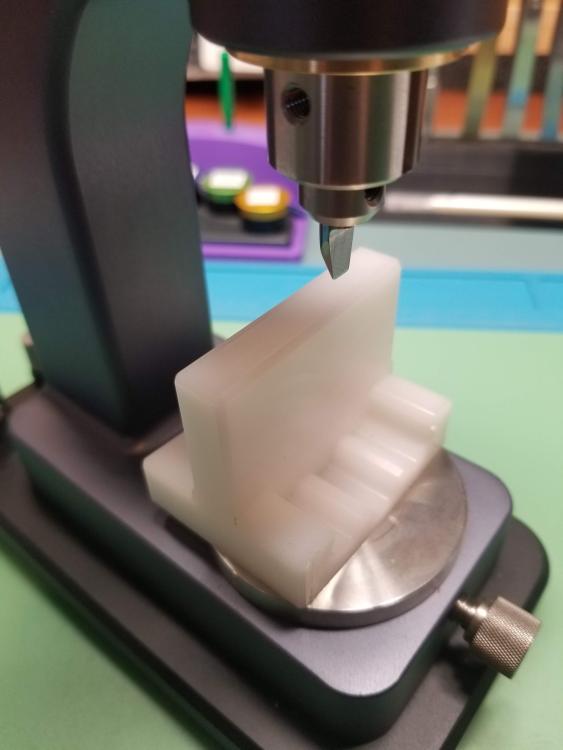

As Case suggests, the strenth of a press unless it is something so cheap is irrelevant, strength beyond breaking a crystal is pointless and all presses are capable of breaking a crystal. The important bit for the press is accuracy of the die alignment and of course the actual dies. I posted something a few weeks ago regarding the die shapes and the comparisons between various brands. I own 5 screw presses 3 of which have dies that work on the same principle as the robur dies. So Robur is about die alignment and the quantity of dies in their sets to bend crystals, and not particularly the quality of dies, I've seen so many broken ones. The screw presses I have, have no broken dies. Haha sounds like a rag on robur, its just a press, but I do like the fact that there lots of sizes of dies that you dont get with other brands, except for one that I can think of. To answer Richard's question - why not use the Robur to fit armoured crystals ? - actually no reason at all, except not to use a domed die to bend it, the ring prevents that. But in actual fact only to a degree, I bent one enough the other day to push it out and back in again, so there is a very small amount of flex but it may compress the ring and reduce it's effectiveness. Then there is the option of making your own wooden dies, to any shape you desire. I've only just bought some felt the other day to line the domes and cups that i will make.1 point

-

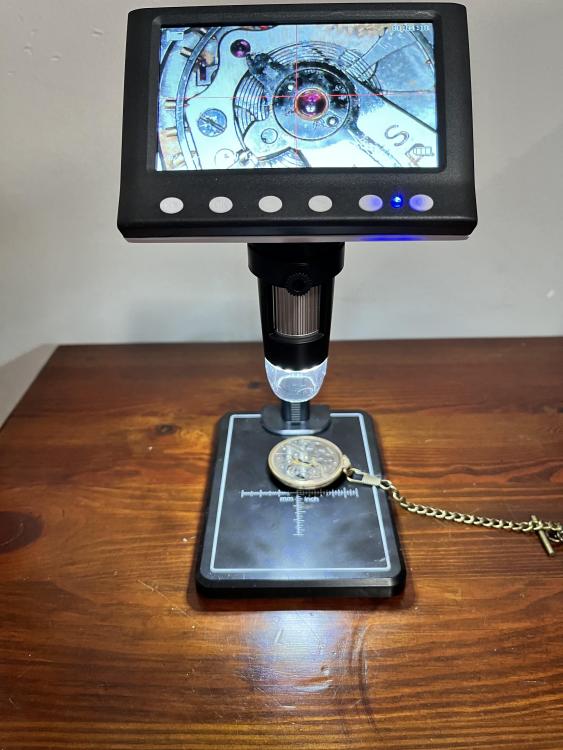

I got interested by watching some of the YouTube videos. Quickly saw the diff between content (which isn't horrible) and professionals. From there i pulled some non working pocket watches off fleabay and an st36. Disassembled , cleaned , oiled , regulated. Rinse wash repeat. Had a few misshaps but didn't dwell on them. Tools, get some good quality ones used or new. It makes a world of difference. Read up. Decarle, fried , daniels. Reread. Watch more YouTube. ( yes even the popular ones) Buy more tools. The biggest difference for me was getting a microscope. Take a million pics then take a million more. Try and form good habits every time you do something. Finger cots was the one I had to and still have to make sure I do. Don't take short cuts it will F*_! you. Buy more tools Most of all enjoy the hobby the process and the science1 point

-

Michael, I assume you mean something like this: This is an inexpensive (<AU$50) digital microscope that is still my only way of taking micrographs. It's reasonable for what it is and I have found it useful, but there's no comparison between this and a stereo microscope. You can zoom in by moving the camera closer to the work (and adjusting the focus ring) but you can't zoom out enough to be able to see the whole movement. At its highest setting there is enough room, barely, to work on the movement, but I didn't really find that helpful. Since I got my stereo microscope I find myself doing almost everything under the scope. (I keep my glasses on, otherwise I'd be forever putting them on and off since I can't focus on anything nearer than about a metre without them.) The resolution with the scope is much better than the digital and the binocular vision means I get the advantage of depth perception. I'm sure it's possible to spend more money and get a much better digital microscope than this, but it's hard to imagine how it could ever compete with the immediacy of the view through microscope optics.1 point

-

Haha. That's a good way to lose your watch. Many year's ago, I had a patient who hung her watch on the tap in the bathroom in my clinic, then forgot about it. She came back about an hour later in a panicked state. She rushed to the bathroom and found it still hanging from the tap. It was an expensive ladies Rolex.1 point

-

The oiler colors are not really standardized, though I might guess the black one is the finest. Maybe. In addition to your light 9010, get some HP 1300 as a medium oil and Moebius 9501 or 9504 as a heavy grease for sliding and high tension keyless works parts. Or Moebius D5 and Molykote dx as the cheaper alternatives to those, though the 1300 and 9501 will have a longer lifespan in your watches. But the trio of a light oil for the balance and fast wheels, a medium oil for the slower wheels and rotating parts outside the train, and a grease for high tension or sliding parts is mostly sufficient to get started. You should be able to find a service guide for the 6497/6498 movements which will show you exactly where to put those three lubricants on your ST36. Here, I'll save you the effort ETA 6497.pdf1 point

-

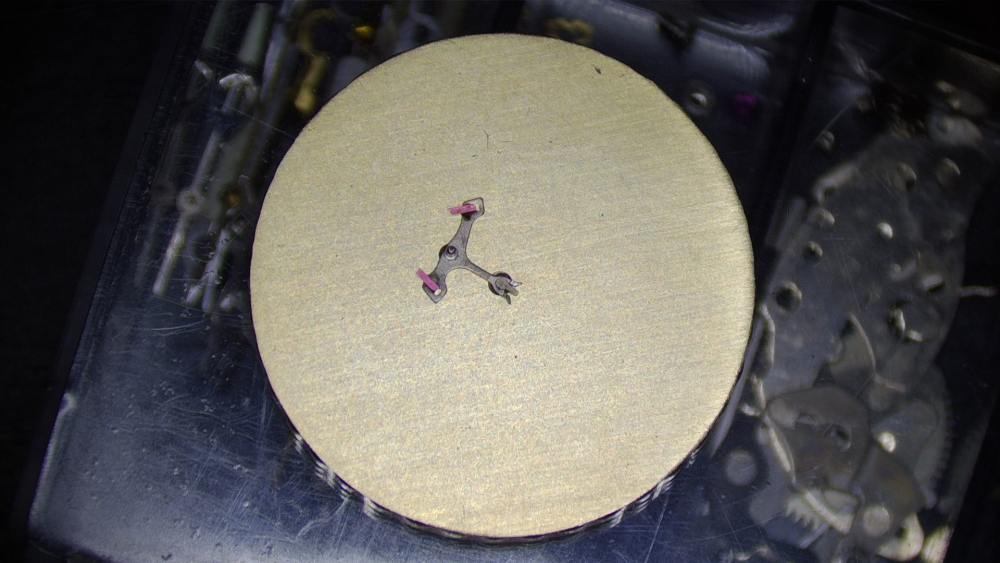

The idea of the little cutouts is that cleaning solution can get in and out. We've all seen jewels though that just won't come clean without a little help from pegwood, including cap jewels. I've had to disassemble these types of settings to get them properly clean, with a jeweling tool.1 point

-

I think my journey for a good crystal press is over. I just got the press shown below and am liking it so far. Far better than the other two cheaper Chinese ones that I have tried. It is solidly built. Can also be used to open snap on casebacks and adjusting metal band links, so it is a 3-in-1 tool. I had the problem opening up a Waltham wristwatch with a caseback knife and this opened it up no problem. What I don't like about it is that you need an Allen wrench to change out the upper bit. Maybe I can change out that grub screw for a knurled head screw. Also, the handle turns opposite of what I expected. Counter-clockwise to lower and clockwise to raise. I'll get used to it. It did not come with the crystal press dies, but those are pretty inexpensive to get a set of nylon or aluminum ones. https://www.aliexpress.us/item/3256806922669039.html Started with one like this. Ended up getting it for free, as I had to repair it. https://www.aliexpress.us/item/3256806885195604.html Then tried this one. Was certainly better than the first, but sold it when I thought that I was getting a vintage Robur press (press only) that ended up getting lost in the mail. https://www.aliexpress.us/item/3256805690261587.html As a crystal press: As a caseback opener: To adjust watch band links: Bit storage:1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)

.thumb.jpg.19a9c4ff164d78d516aa9f05a063752b.jpg)