Leaderboard

Popular Content

Showing content with the highest reputation on 04/13/23 in Posts

-

How do you mean "how that went" - good or bad ? 10k oil changes went out years ago. We now have (in Europe) oil changes as long as 20k with no problem (as long as the correct synthetic oil is used). No I don't. I have always lived by the motto of the Royal Society - "Nullius in Verba" (it means take nobodies word - work it out yourself). I'm not smug. I look at the evidence, and give the opinions of the 'pros' and the 'industry' more credence than some hobbyist who blew the shellac of one watch at home. (I don't have any watch making qualifications, but some of the 'pros' on youtube seem to have some methods at odds to the general concensus). As I said above, if professional cleaning machines (and the associated recommended fluids) caused damage, the first to notice would be people like @nickelsilver and @JohnR725 who clean watches every working day. They would then stop using the machines or change the fluids/methods, and it wouldn't look good for the manufacturers in a competitive business. Yes, you should be more careful with older movements - the shellac may be cracked. I've only been cleaning watches in an ultrasonic and IPA rinse for about 10 years. I have lost shellac from an old pallet and had loose jewels - but only because it was already aged and cracked. It would have fallen off in the ultrasonic whatever fluid was used. Everyone is entitled to an opinion, if you believe ultrasonics are bad - don't use them.4 points

-

Mike's comment a little misread and ill perceived on your part i think matey. I'm not one to get in the middle of an argument , yes everyone has an opinion but suggesting being smug, a touch out of order wouldnt you say3 points

-

3 points

-

3 points

-

3 points

-

This is already done by the jewellers trade. But not very advisable for exact parts: the casting will shrink by 2...5%, not very exactly predictable. You know: for jewellers the item must look nice. For watchmakers it must be exact to 1/100 mm. That is the difference between them. Frank3 points

-

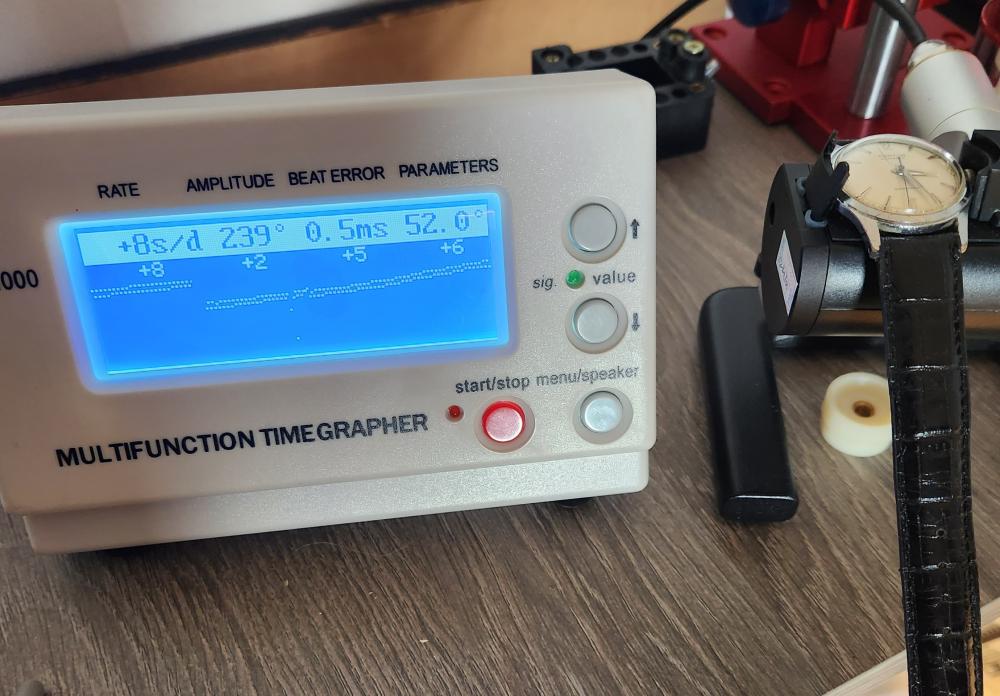

Another Croton automatic ETA 1256 in beautiful shape. Runs well added a temporary strap and pegged most of the DNA off the case. Crystal has a Crack but that is not the original one as this movement was only produced for 5 years ('50 to '54). The dial is pretty awesome. I like the tick marks between the minute makers. 5 minutes on the timegrapher got it close, but this will be a future project to see what kind of amplitude we can reach, clean the case and replace the crystal.3 points

-

for your second question there is a physical book it's available as a PDF but typically I don't give the link for it because I purchased mine and that wasn't quite sure about the copyright issues supposedly there is a copyright holder but if you ask how to get the best fit books online and by the way that's a post be one word my dictation software sometimes will do it right and other times it will. If you were to start a new discussion and say where can I download the best fit books somebody will come along and tell you where to download it for free but because I was aware that may be a copyright issue I typically will not tell you where to get it for free I will tell you where I purchased mine okay at the link below you will find on the page for nine dollars you can purchase the PDF the bestfit book. But as I said if you just go and ask is a separate question where do I get this for free to download somebody will give you a link back she seen several different links. okay just so we can see exactly what you're supposed to be getting the PDF ask the question get it for free I just won't do that. The other one is not free its $99 it's a lifetime whatever.unfortunately no pictures online but it has it all in a searchable feature C concerts by the watch caliber you concerts lookup factory part numbers and you can also look up like I did the what I call the best fit numbers which isn't entirely correct I think it's more of the Swiss the old Swiss system so the spring that had the number with 400 that refers to things related to the balance shocks stuff and in the/and then the other number is the actual parts so I went there and it told me what it cross-referenced. Which of course if I had remembered is exactly in the image up above you can see exactly what other watches use the same stuff the best fit online is very similar to the search found on the second link that I have below their similar but not exactly the same and it does give you the feature of cross referencing things a little differently then yes the bestfit book to certain degree is a must have and you also have to look through it from time to time because there is so much information in their not just on parts there's some doing some watch repair stuff it's like all the stuff they just too much to remember so you basically have to look through it from time to time just to refresh your memory of look at all the wonderful stuff in here. https://mccawcompany.com/?s=best+fit http://cgi.julesborel.com/2 points

-

The watch that is my avatar is the one I am talking about. I am wearing it now and it keeps excellent time. Note, however, it sat in a drawer for perhaps 30 of those years but I have been wearing it off an on for the last two years. Pretty sure it was serviced using Elgin M56-B. My dad would always recommend servicing once per year. Of course he was motivated to generate business...lol...and I ate a lot of groceries! I will probably service it this year. The movement is a C11KAS and I have serviced one before, so it should be straightforward.1 point

-

I have several watches where I decided to be satisfied with "it's running ". Are they anyway near to perfect, no but they would need either a silly amount of money or remanufacture various parts. Sometimes you just have to be satisfied. Which movement is it?1 point

-

Have you tried welwynwatchparts.co.uk. Or Speedtimerkollection.com. Both sellers if used watches, parts and cases.1 point

-

1 point

-

Sellita may have made this AS caliber, watchmakers could simply buy movements from makers of the movement such as AS etc. Sellita used to assemble movements for movement makers. Rgds1 point

-

The markings are usually under the balance or dial. Can you get a better photo around the balance?1 point

-

You could try a watch materiel suppler and give them the cal of the movement and the size including the movement ring and the height. I see it is a sweep second movement but no hand fitted has the center wheel pivot broken? If not you need to consider extra height.1 point

-

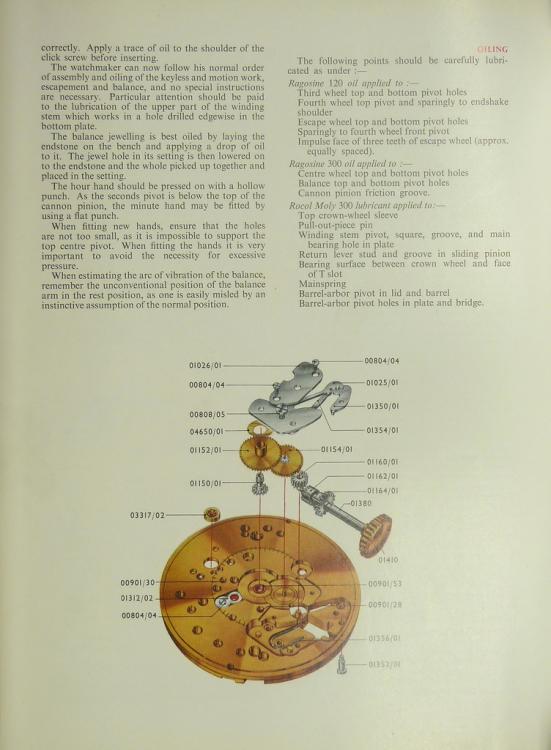

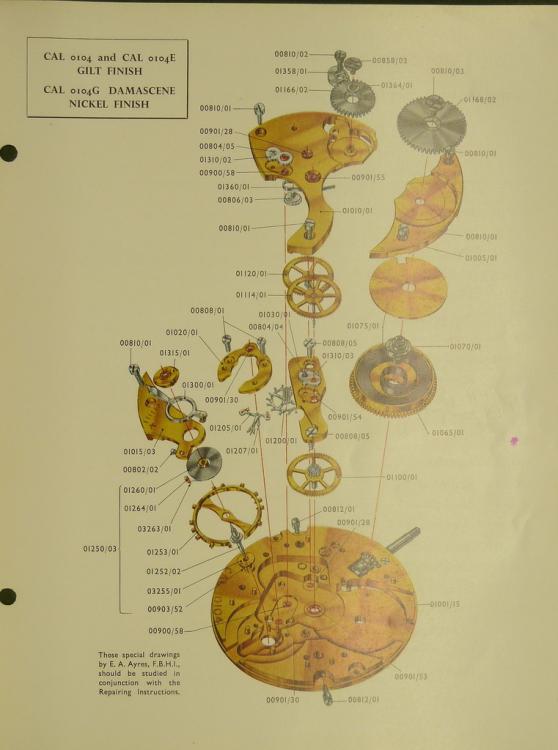

The above datasheet says it's for Cal 0104E and 0104G, so I guess it covers 0104F too? On the above website there's some useful info on the model histories.1 point

-

Movement diameter 26.56 mm Diat diameter 28.88 mm Movement thickness including dial 4.98 mm No movement holder. I'm starting a new topic, have a look.1 point

-

I got myself an Ender 3 Pro a couple of years ago. It has been a great printer, but I can't leave well enough alone and put several upgrades onto it to make it print even better. For Christmas, I got my oldest son an Ender 3 NEO. It is the same basic printer as mine, but it comes stock with many of the upgrades that I did to mine. It was right about $200. He was up and running very quickly. BTW, I intend to print these 3D winders and give them a go. I've already spent too much money on tools getting started in this hobby, so saving hundreds on main spring winders is quite attractive.1 point

-

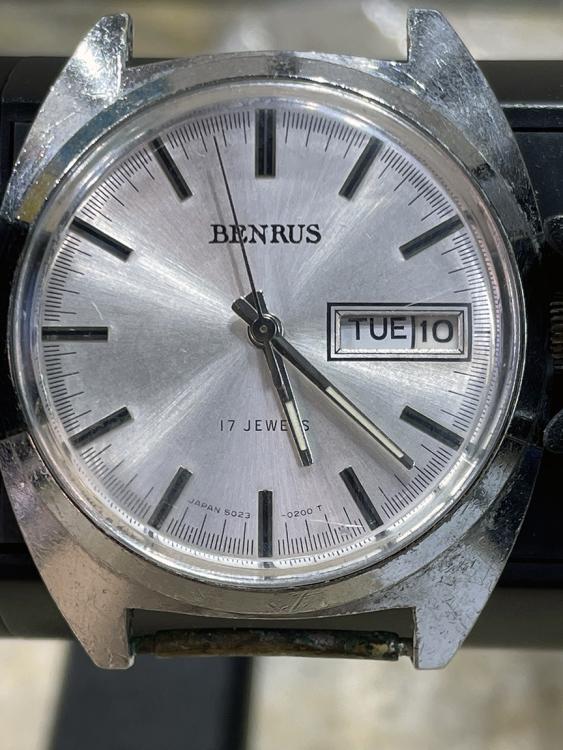

Hi all - found this site searching for info on the Hamazawa 5023A. I am a member on WUS and a moderator on Toyotanation (same user name on all). I have been picking up the watch bug and am about to start servicing a pile. Anyway, I have two of these movements, both Benrus. The first one came in a lot of 22 watches I won (unit cost a little over $7 a watch) and it is running 0 to +3 s/d with a beat error of 0.1 Nice performance! I saw another Benrus with the same movement on eBay so bought it so I would have spare parts/case/crystal (and honestly want to see if I can fit some of my other Benrus movements in the case). The second one I received (a bit over $60) is not as great, ranging +84 to +104 or so with a 1.something beat error. Serviceable I was thinking. Then read above and think I may be in for a ride here. At some point I will take on the less performing one and see if I can get it running better, then using that as my learning curve service the well performing one (it does not appear to have been serviced in any close era of time: I polished the crystal up to make it as clean as it is). Some great info above: I think I will just hand wind it back into the barrel after reading how the spring attaches. Hoping to get them clean and lubed, slap on a nice strap, then sell as they are a tad small for my preference, even given the great performance of one of them.1 point

-

1 point

-

Just spotted an issue with this watch - looks like the day (not date which is working fine) is not jumping correctly and ends up misaligned after midnight - on manual change there is no 'snap' into place of the day either, so I assume it is misaligned of the spring is not engaging correctly on the day disc??? So near and yet so far Will open the watch up and try to fix it... stay tuned1 point

-

This is an Etachron stud, best to use special tool for removing, you can make one out of a scrap screwdriver or purchase the tool, heres a link to one. https://www.cousinsuk.com/product/etachron-stud-removing-tools Good luck1 point

-

Can't really see from the photo but is that an Etachron stud?1 point

-

When I was a young lad working for my dad at his watch shop in Houston, I would often catch the bus downtown to pick up material from Prague & Kurtz material house. It was like walking into an auto parts store or a John Deere Service desk today. Long counter...several people taking orders and disappearing into a (ostensibly) warehouse and returning with the parts. The people behind the counter were very knowledgeable.1 point

-

to grasp what part of the problem is read about cousins. When cousins gets into the material business they recognize their customers are not in the same location they are so basically there a mail order business people probably sent them a letter or telephone them before the days the computer they basically had set up an online business. Which why today there very popular because it basically all online https://www.cousinsuk.com/history the problem with the US material houses are for the most part they're not online. Yes I know some of them are online but a lot of them are not or what is online is just a fraction of whatever they have. I heard a story that one of the material houses back East purchases other material houses and when they do they bring the new material house and put it in the warehouse someplace they do not integrate into the system. That is because there is actually multiple of differing numbering schemes for the parts integrating lots of little parts that cost small sums of money is not cost effective. So typically what you're going to see online is only the stuff they have insufficient quantity. Everything else you're going to have to call them email or income higher as to whether they have whatever it is you seek. Then of course there is the other material houses the ones that have no online presence at all they still exist. In Seattle we have two of them you can physically walk into their establishment and purchase things or you can telephone them or email them but they have no online presence at all. So more than likely there is quite a few of those spread across the US where you have to reach out to them somehow and a course these ones will probably not ship out of the area. then let's look at a problem I see a specific request for specific mainspring then you go to this page it has your watch and it lists the mainspring. Yes it's a generic replacement but still he gives us a number it also means that you could probably order that exact same mainspring from cousins because they distribute the same mainsprings. Is the problem today of limited quantity of people manufacturing mainsprings. http://cgi.julesborel.com/cgi-bin/matcgi2?ref=SEK_6309A then you get this link the mainspring and it's part numbers in which watches has the same mainspring. http://cgi.julesborel.com/cgi-bin/matcgi2?ref=T`ZF]EX then they go to the homepage looks like you have to use the Seiko number the mainspring number doesn't seem to work? That's always the fun on the websites of trying to figure out which number you're supposed to use because to a certain degree of all the websites suck http://www.julesborel.com/products/watch-parts-mainsprings/0401615 cousins is being a pain but all share the pain based on the link above I know how wide the spring is so ended up at this link and you can scroll down and you'll eventually get the right number which is just same number he got the website above but with the spaces taken out. basically looking for GR2534X now let's see if I can do a search for that can get an exact linkthe second link does have yet it's not as informative as going through well I'll snip out a image of you go through the first link and find it versus the second link which just as a place and isn't overly helpful but at least you could purchase it https://www.cousinsuk.com/product/up-to-105mm-height https://www.cousinsuk.com/search?searchTerm=GR2534X1 point

-

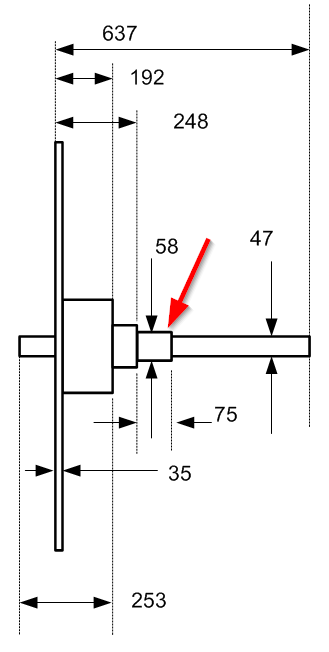

Well, an update. I must confess my sin. When I turned down the rest of the post before drilling and inserting the new one, I failed to notice the diameter of the pivot that rests in the bushing (the shoulder) was greater than the rest. I illustrate what I missed below. The arrow points to the additional diameter that I missed. So, rather than turn a new one, I stole the pinion and shaft from a donor (the wheel on the donor was broken in half). This was not as straightforward as I hoped. The dimensions of the replacement part were larger and as a result, there was ZERO endshake (perhaps negative). I had to turn down the part of the shaft that rests on the bushing to make it fit. Live and learn.1 point

-

1 point