Leaderboard

Popular Content

Showing content with the highest reputation on 04/07/23 in Posts

-

I also made some . Toothpicks dipped in contact adhesive, the type that's used to stick laminate strips to kitchen worktop ends ( Evo stik impact ) I have to say they work rather well, maybe a little too soft and squishy but ok. Bit of trial and error to get the blob right. Shaping the end of the toothpick changes how much it can pick up. Also double dipping in the space of a minute increases the size, then hang them upside down until they are set. And as nickelsilver says ready to use in around 30 mins. Not super sticky but enough to easily pick up hairs and debris from a dial without scratching, same for the movement and can remove smudges. I actually prefer them to rodico. When dirty just pull the ends off and redip them.4 points

-

Very gentle application of a small propelling pencil eraser and this is the improvement. I didn't want to rub through the silver plating or remove any of the printing, so it took a little while. I was afraid I might improve it worse. It looks even better close up, as that engine turning shimmers nicely as you move it around, and the twelve dial divisions are much more apparent. I also cleaned up the back of the dial, although nobody is likely to ever see that except me. In case you are curious, I'm fairly certain the Tavennes movement that goes with this dial is actually a Cyma 216, which put the date of the watch around 1930 which makes it around 93 years old.3 points

-

OK I'll be the first to admit it is far from perfect, but this is simply by removing the dial, applying white vinegar manually to the worst bits with a soft brush, then dipping the whole thing briefly in white vinegar, and finally rinsing off with diluted dish soap followed by rinsing with copious amounts of clean water. The dial is a little tired, but no more of the print came off while cleaning, and I was surprised to see that the mechanism wants to run. The hands are good. It needs a stem, but nothing else so far as I can see. The original stem is still there, but snapped off flush with the edge of the movement, so I should be able to match it with something from my stash. This all assumes I have a suitable case in the junk box of course, but I'm fairly sure I will have something. This is what we started with.3 points

-

I've been working on getting myself a workbench put together. The kitchen island was not going to cut it for the long term. Seeing as I wanted to save as much money for tools as I could, I wanted to do save some bucks on the watch bench. I took a 2nd hand desk that I got for cheap, refinished the desk top, installed a LED light bar, added a power strip, and created some storage in the otherwise useless keyboard tray pullout. The hutch is good to store some tools and accessories. I've got a couple of drawers to store parts, supplies, and project watches. I put a chair pad down over the carpet, to hopefully keep some flying parts out of the carpet. Hadn't used this much yet, but so far it seems like it will work. Eventually, I would like to add a binocular microscope to the mix.2 points

-

The hook on the arbor will show you which direction the mainspring needs to be wound2 points

-

A little bit of history for the Tavannes Watch company can be found ->here<- Tavannes is in a French speaking canton so the 'es' at the end is silent: it should be pronounced ‘ta-van’.2 points

-

2 points

-

actually if you have a lightning strike nearby timegrapher would be the least of your problems. Depending upon where it hits you might not have to worry about anything ever again. Or you blow out all of your electronics. Even with surge protectors they're not designed for a lightning strike in close proximity. I remember one of my electronic magazines back east were electrical activity like this was quite common he had his own generator and he would just disconnect the main power grid to avoid blowing out all the electronics. Of course if you still have a lightning strike even that's not going to help you out if it's really really close. if it's a Chinese timing machine there actually quite sensitive to audio noise's the Swiss machines like witschi are better sort of. I was once doing a comparison of the Chinese 1900 and the witschi watch expert number two and I happen walk into the room with my battery-powered shaver and noticed the Chinese machine was very unhappy. So that's why the shavers in the picture the witschi machine is immune the Chinese machine is unhappy. But that's not necessarily true with all the witschi machines at work the ultrasonic is about 3 feet from the primary machine and most the time it just won't time a watch sometimes ill do my pocket watches you make it synchronize the pocket watch that it isn't is concerned with the ultrasonic. The other machine that's about 6 feet away if the ultrasonic is on it won't work at all so even when she gets unhappy about ultrasonic machines producing a heck of a lot of noise that they pick up. Which is why anything resembling instructions for timing machine will typically tell you to place them someplace that's quite away from things that make noise like ultrasonic which we might not here but the timing machine will.2 points

-

A one sided razor blade is the best thing with this type of barrel. Most case knife blades are too thick and will damage the side of the barrel.2 points

-

You can find them in either 3mm or 4mm. I bought a 4mm set, and had to sand down flat a couple of the anvils as they had a few pieces from the casting still attached, but since then it's done a wonderful job. I've done several jewel replacements and adjustments with mine since receiving it. I find I use it quite regularly. Now that I have one, I've been meticulous about checking and adjusting end shake. It was my first purchase from Ali Express. While it took a couple of weeks to arrive, I certainly don't regret getting a clone tool in this instance. This is the one I purchased: https://www.aliexpress.us/item/3256802886227821.html?spm=a2g0o.order_list.order_list_main.5.1e041802MHfxnd&gatewayAdapt=glo2usa&_randl_shipto=US2 points

-

That's interesting....I'm surprised it even works wehre i have it. I have my pc tower, two monitors, speakers and a gigantic wacom tablet right there on my workdesk.2 points

-

First... are we in the right forum? Second. Have you done this kind of stuff before? Third. Are we talking about a CRT, LCD, LED, Plasma?1 point

-

I was able to get the mainspring out of the barrel. I used a utility knife and held the barrel with my cut resistant "no cry" gloves. Just in case I slipped, I didn't want a visit to urgent care. I would like to say that it went without incident, but once I opened the seam a bit with the utility knife, I tried popping off the top. Well, there was an explosion of the mainspring out of the barrel. Fortunately, I was able to find the arbor. Glad that I got a chair pad; otherwise, I would have been digging through the carpet for it. Unfortunately, I don't know which direction the main spring was coiled. Well, live and learn. Next time, I'll use the utility knife to get the seam to open up a bit and then a thicker blade (like a pocket knife or case knife) to open it up the rest of the way.1 point

-

1 point

-

I haven't tried it but I watched a video of using lazer transfer paper to customise dials. The numbers could be reapplied. The results were quite good.1 point

-

A good question. The short answer is I don't know, I've never tried. I guess it rather depends on how you set about re-silvering it. I would guess that it would be extremely tricky to re-silver, and you might end up with a patchy finish. Also given how small the dial is, and therefore how small the lettering and markers are, there is a big risk that any attempt to re-silver may damage what remains of the printing. You *might* get away with brush electo-plating with a very fine brush, but it would be very tricky, and might end up patchy. Rubbing silvering powder into the dial might be too abrasive and remove the printing. If the dial was etched like a clock dial, and the lettering therefore was wax in the etching, then silvering powder might well work, but given the design on this dial is pad printed on top of the engine turned surface, I would say anything remotely abrasive is likely to end in disaster. Has anybody got any experience of this?1 point

-

On those types of dials a rubber will only remove the dirt it will not harm the dial. That has come up very nicely.1 point

-

The cement will prevent dust getting under the glass. Watch cases that are not round are more likely to let dirt and dust in.1 point

-

1 point

-

1 point

-

Not sure if he will be honoured but i was thinking of calling them Nicklesilver's toothpick condoms Its a prophylactic on some wood1 point

-

Thanks for all the replies - all really helpful The extra holes do make sense - as I put in the original post my colleague was convinced it was (once) an automatic. I can post a few more pics when I strip it down if it would be of interest to anyone.1 point

-

1 point

-

Update on the contact adhesive swabs. After 12 hours the adhesive has set quite hard making them more usable imho. They still pick up fibres and debris just as well , but might lend themselves to dial cleaning as well as the consistency is similar to a hard rubber. Just be sure to put enough on to keep the toothpick covered, it doesn't need much as the adhesive is pretty tough. Heres a gross shot before lunch .1 point

-

If the watches concerned are Wostok Amphibia's then this is perfectly normal. For more info try Googling "amphibia wobbly crown".1 point

-

realistically it looks fine but if you want to be obsessed about it wait 24 hours and run your timing again and see if there's any problems there. Then ideally you should run the timing compared to a master clock over several days. The timing machine just points you in a direction of it looks really good. But if are aiming for a chronometer standards or really precision standards then you time over several days. Or if you're like the watch companies run at several days at whatever temperatures they were testing the compensation at. But still it looks really good I would just leave it alone.1 point

-

1 point

-

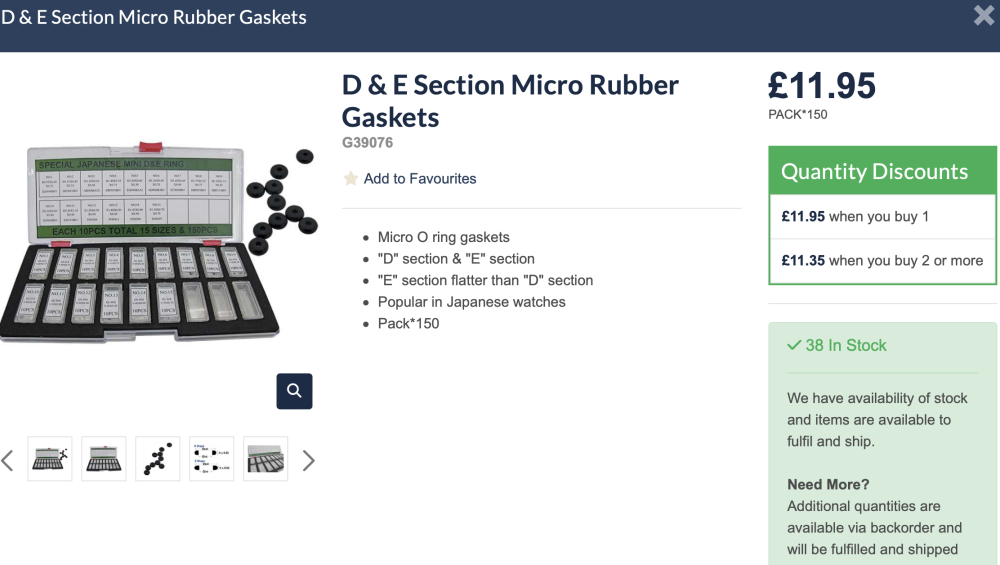

This is a great set, especially if you work on a lot of Japanese movements. #10 in the set is the DJ0060B01, and you'll use 2 of those for every 1 of everything else. I ordered about 20 more of just that size just for stock, which isn't bad at all at only around 0.20 per, compared to $5 to $7 per from eBay or other supply houses for a factory gasket.1 point

-

Is the balance amplitude low or high? One possibility is If the balance amplitude is very high it will begin to knock and the rate will be very fast. If you listen to the sound of the escapement knocking will sound like galloping instead of the normal tick-tock.1 point

-

Hi kd8tzc I will dig out the information and post here shortly. Apologies for the delay in replying, I haven't been on here for a while. I did have a spring liberate (haha) itself too but used my neodymium magnet to summon it back into this dimension - worked a treat. Doesn't work for broken screws though! If you search for ST36 case and the right size dial - thats a good start. I have to say that getting the seconds hand on was a real pain in the butt. The dial is an Aviator style. Watch this space. Jon Correction to the above - search for 6497 case and dial but make sure to select the dial to suit the seconds hand at the 9 o'clock position, not 6 o'clock (assuming thats the movement you have), just check before ordering. Also - the advice I was given here is just to buy another movement rather than try and find a part, which was good advice to be honest. I now have a spare movement minus a screw and the broken part in the barrel bridge! Case: https://www.ebay.com.au/itm/373527847827 Case & Hands: https://www.ebay.com.au/itm/385140205713 Watch band: https://www.ebay.com.au/itm/293941450235?var=592641354006 The watch is still keeping great time by the way! Cheers and good luck (let me know how you go) Jon1 point

-

If the old gasket has hardened, the only way to get it out is to cut it. Attempting to dig it out with a metal instrument would result in damage to the crown tube.1 point

-

I just recently bought this. I am away from home now so cannot answer specifics, but I am impressed with the quality.1 point

-

The gasket is not glued down, but hard to get out of the deep groove in the crown without inflicting damage (at least with my novice skills). For a new gasket, first I went to http://cgi.julesborel.com/ and searched for my case number. For my watch, I searched for SEK CS#7S26-01H0. Then click on the link for Gasket, Crown/Stem. Part number for my gasket was DB0055B01 (yours may be different). You can order gaskets individually from Cousins (or other vendors). I chose to order an assortment that included the gasket I needed. Best of luck!1 point

-

Ok my pro watchmaker friends from another group gave me the go ahead to finally....finally close this thing up. They said the only thing they could think of i could still do is tweak teh regulator pins to fix the crown down deviation but taht it's so risky with these old type pins that they told me not to do it. 2 days on the wrist and it's gained 15 seconds and i haven't even done my final regulation so i'm confident it's finally done. Today the sun finally came out so i could get some proper beauty shots of it. I'm just in love with this dial. The blue is just stunning.1 point

-

Ok, I gave this a shot. I have to say it worked out pretty well! Thank you for the great tip!1 point

-

I spotted a cool looking Wittnauer diver style electronic watch on eBay and said yeah I want that. Of course it is listed as not working and right off I see two big concerns. First was the bezel ring insert is missing. Second the dial has clearly bee broken off its feet. So here it is, broken feet and all. The fee are still in the movement and it does run. Dial dots? maybe but it looks like there is very little flat surface to use. Lets see how this goes! I found one to compare to. sure is a great looking watch.1 point