Leaderboard

Popular Content

Showing content with the highest reputation on 10/03/22 in Posts

-

I am glad to see that my post on Reddit inspired Charette's version of the watch cleaner! I have since added a 3D printed L&R type holder for the baskets. I use a 200rpm DC gearmotor and I think the speed is just right. I did introduce myself back in March, I think. I have not posted very much because I am able to find most of what I need by searching.2 points

-

Thanks very much! The baskets are sold on Amazon as small task basket. https://www.amazon.com/gp/product/B0058ECYIY/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=1 I cut off the handles and fit one basket inside another. I have cleaned about 10 watches so far. Used the L&R cleaner and rinse. I specified ABS plastic for strength and hoping to have better chemical resistance. I do not really submerge too deep. The liquid just hits the bottom of the 3D printed assembly. Another Reddit user designed the 3D parts and I had them made at Craftcloud. Thanks! I would like to see your version with the Elma baskets when you are done.1 point

-

1 point

-

There are varying grades of naptha in lighter fuel. Yours has a medium carbon to hydrogen ratio which makes it a mid naptha. Less carbon light naptha , more cafbon heavy naptha. Also lighter fuel not a pure grade naptha, supposedly with additives to help it burn, strangely enough never listed in the ingredients and no one has yet given any information as to what those addatives are . As far as i know any benzine product will not affect shellac even with a long soak, i have done overnight before on some stubborn grime. On the other hand IPA will dissolve shellac if left too long in it.1 point

-

Thats a moot point, there are various opinions regarding lighter fuel (Benzine)and whether it effects shellac. Some say its ok to use others say not, I have used it with no problems but did not soak the parts just rinsed them with no effect.1 point

-

The Skagen I fixed some while ago had to be BLOWN out the front. Not pretty but it worked. Looks like yours is a screw back. With the stem removed, screw the back on air tight. Wrap painter's tape around the movement--not tight. Using a syringe, put the end on the case tube and quickly compress the syringe. If all goes well, the crystal will pop off and the movement will also come out. You really need a tool to put the crystal back on (assuming it does not break) after you make your adjustments. If those dial markers are glued on to the dial, some may come off. If they are painted on...you do not have to worry. Skagens are beautiful and classy and a pain in the @ss1 point

-

I wouldn't say it's too old. I certainly doubt it's easy, but you're probably going to be looking for broken watches that don't necessarily go into much detail as to what's inside. This part of the hobby seems to pretty universally move at a snail's pace... I have a small pile of watches in need of random parts that I'm honestly just too lazy to spend much time tracking down. At some point, I'll probably decide to specialize, and then I can use parts from a more concentrated selection of movements to keep other movements running. Meanwhile, I'm going to double down on the "spring". It's definitely not a lever, and I don't think I see a bridge at all in that photo. Not sure what that'd be referring to exactly if I'm being honest...1 point

-

You don't need to worry. The Kevlar will protect you!! I thought this topic had already been fleshed out on WRT, but I searched "radium" and did not find the thread. Bottom line...you need not worry...not for a moment. Do not lick the dial, nor the hands. I suspect that even if you did, it would have zero impact. I have several reports commissioned by the US government that provides an analysis of a variety of scenarios (professional watchmaker, amateur watchmaker, wearing in chest pocket, on the wrist, etc.). It is just not an issue. Moreover, my anecdotal evidence is that my father was a watchmaker working on watches from 1946 until 1990. I know he had and worked on many radium watches. He died at 93 of causes unrelated to radiation. Go read this thread. The documents I mentioned can be found there.1 point

-

These guys can probably help: https://midwest-clock-repair.myshopify.com/products/schatz-repair-rebuild-service-for-schatz-royal-mariner-ships-bell-clock-movement These guys specifically have a listing for the glass (but you'll need to know the diameter in mm): https://www.sheridanmarine.com/product/replacement-royal-mariner-clock-glass £13.30 for 84mm up to £20.95 for 146mm.1 point

-

1 point

-

1 point

-

That's normal truing work that would be checked and done any time a staff is changed .1 point

-

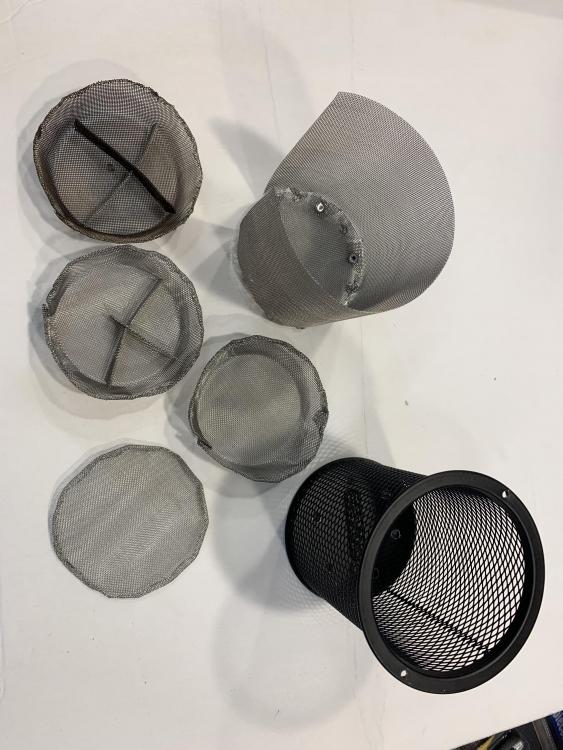

Hi all - here are some photos and description of my v1 diy watch cleaning machine. It is made of bits and bobs from the garage, dollar store, and amazon. I should first note that after much googling, what I made was directly inspired by a thread on reddit I came across by chance - here - https://www.reddit.com/r/watchrepair/comments/vk00i1/a_simple_watch_cleaning_machine/ Prices included below are in Canadian dollars. The frame of the machine is a lab support stand from Amazon. I was lucky to get this from warehouse deals for $18.89. Regular price is around $50, so a bit pricey. On the bottom of the stand I laser cut a holder from dollar store MDF (I think they call it 'craft board' to fit the jars I also got from the dollar store. I was hoping to use mason jars for the height and the nice sealing lids, as in the reddit thread, but the nice parts basket he used there was too expensive for me to order in Canada. I instead used wide mouth jars from the dollar store, I think they were $2.50 each. To load the parts, I have a pencil holder from the dollar store (~$1.50?) into which I have a bunch of pieces of stainless steel mesh ($20, amazon, for 5 sheets). I do not understand why formed products are so expensive (eg. the real baskets for watch cleaning machines). I cut a hole with a hole saw in a piece of wood and forced the mesh through with the cutout to make the rough 'baskets'. Not the nicest, but what I have at the moment for v1. Continued below as I think I can only attach 4 photos. Starting off here with the amazon stainless steel mesh product and the wood used to form the baskets. Some cut up pieces folded over inside to make compartments. I tried to solder these in place but that was a failure. So at the moment they are just set in there, and do move around. I think I will end up ordering some of those tiny little mesh baskets with lids - I have seen them for a reasonable price on etsy, of all places. Also I saw the parts basket used in the reddit thread on etsy for a more reasonable price as well, so may order to give it a try. The lab stand came with the clamp and gripper. In the gripper I have squeezed a 12v dc motor. Amazon, $15. It is 200 RPM. You can get these for extremely cheap on aliexpress, but I didn't want to wait for the shipping. I have subsequently ordered/received a 500 rpm motor from aliexpress - my thought was to use a potentiometer to slow it down, but have the extra speed to spin between wash/rinse/rinse. I think that the 200rpm is nice for cleaning but it doesn't do a good enough job with centrifugal force to get the first cleaner out, puts soap into my 1st rinse. Maybe my DIY solution just isn't the best. I have a flexible coupling, 4mm (on the motor side) to 5mm (approx diameter of the bolt I am using, I did have to add a bit of tape) to connect things up. At the bottom of the bolt there is a piece of aluminum, drilled so I can screw the pencil holder on, once loaded. A bit of a pain, but not like I am doing it all of the time. In a future version if I get that nice basket I may use little spring clips to grab its handle. Couple more photos of my current attachment method. I should note that I lost two parts from the basket when cleaning. One was the click spring - was at the bottom of 1st cleaner jar. So tiny it slipped through even the fine stainless mesh. The other was a spacer that Raketa uses on their balance bridge - it fell into where the pencil holder mesh meets the bottom and it was only luck that I happened to see it in there, shining a light. Another reason to switch to those little baskets with lids, I think. To control the machine, I have a pre-built controller, same as the redditor used ($20, amazon. I think it would have been close to the same price from aliexpress). It has multiple modes, but the one I found useful is where you can set time for direction one, stop time, time for reverse direction, and how many times this repeats. I have this on a little box I lasered, the redditor is just running it out in the open. It is dual power supply - a nice barrel plug for 5V, or can take up to 24v. When the DC motor stops to change direction, it is very sudden. I would like to get a litlte circuit for slow start/stop, but haven't been able to find if these exist. I don't have the know-how to build myself, only to wire up something someone else has built. I like how the mastermatic is nice and easy when it changes direction. I think that is all the detail I can think to note at this time. Hope this helps someone or gives some ideas.1 point

-

Hi I've worked on a tissot seastar and I get it close of course. Now I'm trying to close the back but I can't I cannot explain why just that it seems there is no room I join pictures Thanks for any advise I answer my own question I've inversed the movement ring so I came back to the picture and figured out. My advise for the beginner : take picture of the case and the rings before disassembling to avoid this experience it as much as important as the movement itself Thanks1 point

-

1 point

-

Ideally you have the correct size winders, with the winder arbor smalll enough for the mainspring. This isn't always possible - I only have a small set of winders. You have to improvise. The winder I use most is the 10.5 mm but the arbor is often too big for the inner coil of the spring. I use a bit of brass tube in the winder body, so that I can use the arbor from one of the smaller winders. If the spring does get distorted, use some round nose pliers to gently reduce the diameter of the inner coil. Once in the barrel, it's hard to do without scratching the barrel. DO NOT just squeeze the outside of the inner coil - it will kink and wreck the spring. Put something inside the inner coil to stop it bending too far.1 point

-

Don't oil the pins. Some 9010 on three (evenly spaced out) of the escape wheel teeth faces should do the trick. Sent from my iPhone using Tapatalk1 point

-

I would be curious where you got those numbers from just as a reminder were talking about a railroad grade pocket watch versus a Rolex watch as the timing specifications are a little bit different. If you look at Rolex timing specifications they will tell you what a maximum beat error is because they assume you have a modern timing machine. They're not concerned about amplitude except at 24 hours. But the watch companies are concerned about is whether their watches keep time over 24 hours. The problem with a timing machine is it tells you instantaneously what the watches doing now it does not tell you what your watch is going to do over 24 hours. But it does gives some indications like sounds like you have a poising airline your balance wheel then as you want your watch restored to factory specification timing I assume you actually have the factory specifications?0 points