Leaderboard

Popular Content

Showing content with the highest reputation on 04/26/17 in Posts

-

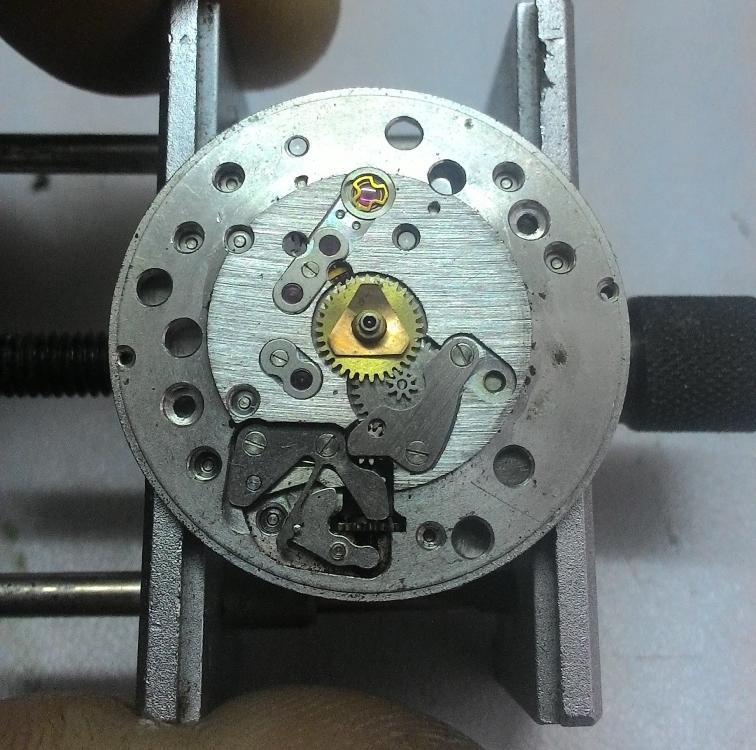

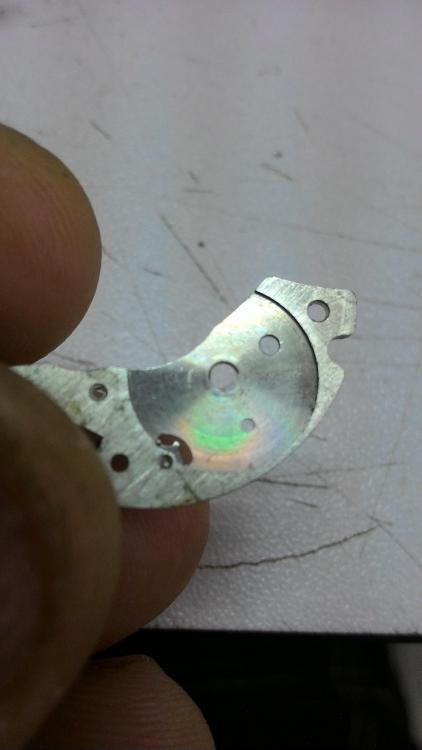

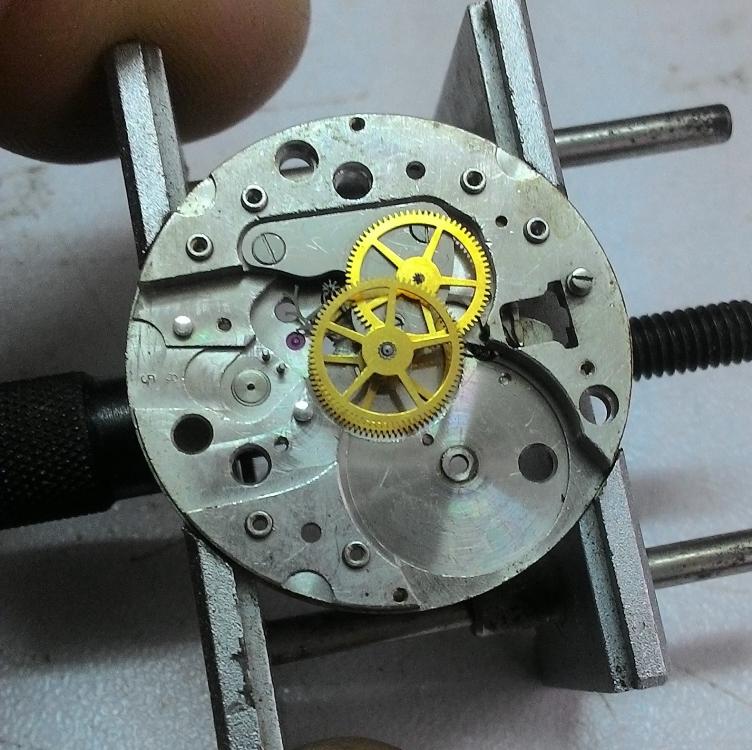

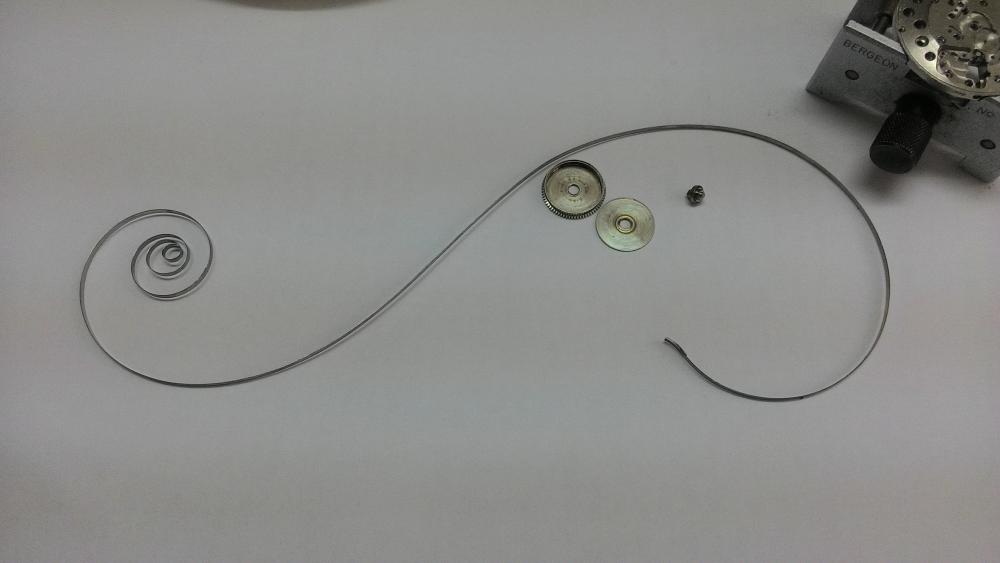

Seiko watches have been a personal favorite of mine because of the quality of the materials used and also the quality of the design. I recently purchased a hand-wind Seiko Cronos which was advertised as non-running and I thought I'd share my experience with it. As received, the watch was in decent cosmetic condition but not running. Caseback is in decent shape and the case itself seems to be pretty much unworn. Its Gold-plated but no indication of the thickness. Serial is the 7 digit type used in the 60s so this would be April '61? I popped the front bezel off as the movement comes out the front, you can see some damage to the dial where the hands have grazed the dial. Another pic of the damaged area. Its a shame as the dial is in good condition otherwise. The Seiko calibre 54. These came in 54A, 54B and 54C.. not to sure which one this is as there's not much info about these movements. Decent looking and 23 jewels for a handwind is pretty awesome. A full bridge for the balance-wheel no less...just like Rolex! One of the case screws is missing. The dial side of the movement with the dial removed... not as pretty as the other side, cap jewels present but in a simpler design. With the ratchet-wheel, balance-wheel and pallet-fork removed.. here we see the first sign of a problem. The barrel arbor hole has been 'massaged' to reduce barrel endshake. The underside of the barrel-bridge.. negligible end-shake on the barrel so it will go back in as it is. Some wheels...pretty similar to a lot of other Seiko movements. Dial-side dismantled.. It is at this point I realised that Seiko was not above playing the 'jewel' game. In the picture below, you can see that the jewel for the pallet fork has an oil 'sink' . In these jewels the endshake is controlled by the inner flat surface, rather than cap jewel which makes the cap jewel superflous. Compare this to the escape wheel jewel where the jewel is domed on the outside and the oil sits in the gap between the curved jewel and the cap jewel. Here the cap jewel serves to ensure minimal friction as the point of the pivot rides on the cap-jewel whereas in normal uncapped settings the pivot's 'shoulder' hits the flat inner surface of the jewel. I'm not sure if Seiko did this to raise the jewel count, pallet-fork pivots are not usually oiled so it could be that having cap jewels here MAY reduce friction in this case as endshake is more controlled. Below we see the other side of these jewels, the escape wheel jewel is the one with a flat side. Mainspring looks good. Ditto the barrel The cap jewels have been cleaned, The double jewelled one goes back in one position only as the cutouts match the holes in the dial where you check the pallet/escape-wheel engagement. Diafix settings with the spring in the open position and cap-jewels about to be removed... Dirty jewels.. And here we see the bottom of the train bridge. again we see another jewel which does not require a 'cap'. The fourth-wheel (seconds) jewel is flat on this side and has the oil-sink on the other. This wheel needs to be oiled and hence the cap-jewel is just a 'dustcap'. view of the oil-sink and 'proper' capped jewels for the escape and third wheel. All cleaned up and oiled. Fitting the diafix jewels went smoothly enough.. sometimes they cause problems but not today! Train bridge installed and checked for smooth runnig.. all good but......... The diafix springs were all over the place so I adjusted how they were aligned.. I think it looks a bit better now! (the upper left spring looks like it has one leg out of the groove but its actually OK). Everything running smoothly. Overall it was a nice movement to work on but the most difficult part about working on these watches is getting the clearance of the hands correct. I had to remove the bezel twice before it ran without hands snagging on each other and I believe that it wouldn't take much to get them out of alignment. This movement was used as the basis for some early Grand Seiko watches and while I haven't timed it, it has been running well for the last few days. I really think that the 2 cap jewels I mentioned above are unnecessary and it would have been better to jewel the barrel arbor but even with 21 functional jewels it still is a nice running watch! Hope you enjoyed reading about this as much as I enjoyed working on it! Anilv Ps.. while outwardly clean, the initial rinse in lighter fluid showed how much of dirt was in the movement. Here the balance and pallet fork was removed, the mainspring given a few turns and it was left to unwind in the fluid. I find that this helps clean the pivots but you have to prevent the wheels from turning (I used a sliver of pegwood) until the movement is submerged in the lighter fluid otherwise the wheels spin too fast and could wear the pivots unnecessarily.3 points

-

2 points

-

1 point

-

1 point

-

The work being done at 2:57 through this video might be of interest... https://www.youtube.com/watch?v=FdxbysUSSAM Looks like a (permanent) ink is just loosely applied across the lettering. I then assume excess is wiped away immediately ... and/or after drying some isopropyl alcohol is used to get any excess off the bridge surface.1 point

-

Nice watch, nice movement and an excellent write up Anil. You have reminded me that I have GS needing serviced!1 point

-

Here is a way but it is a dangerous practice so be warned. To stop wheels moving around and dropping out of there holes. Start to screw the plate down so it doesn’t move around, but be very careful not to screw it down to much if you do you will break the pivots off the wheels, with the plate in its correct position you should be able to use your tweezers and move the wheels into their correct position. This way is much better and safer and is the way I used. Hold the plate in position by putting a finger with a little pressure to hold the plate and carefully move the wheels into their correct place using your tweezers. When it is all in place and screwed down go over the plate using Rodico to clean off any finger marks.1 point

-

Not really a good tool for this. To de magnetize the watch it needs to be inside a alternating field like the coil in the picture posted. This tool is for getting rid of polarization in a recording head. The magnetic field is really small and the probe end has to touch what you want de-magnetize, this would make it worse with a watch spring. Just so you know a DC powered coil will magnetize things and a AC powered coil will de-magnetize them.1 point

-

Good old pith is the answer as Geo has said. The set of oilers I had came with covers, I always put the cover back on to stop dirt getting to it, don't forget to cover the oil when not being used. Good luck with your quest.1 point

-

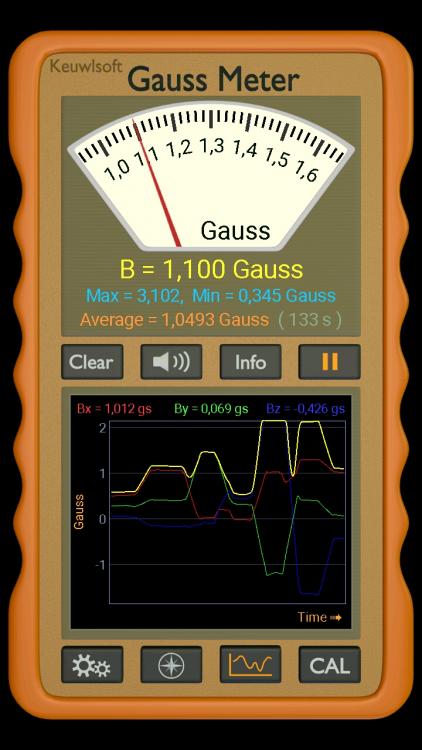

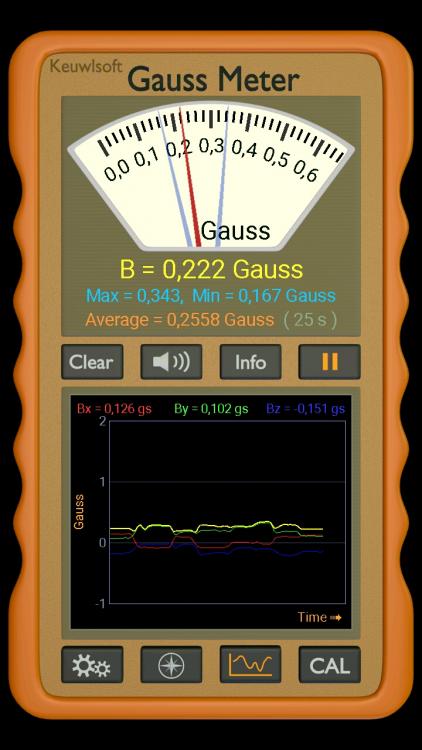

I am working with an NMR spectrometer which is 94000 Gauss Sure my watch was magnetized, it even stopped once i forgot to take off before going close to the magnet. Since i had a suitable transformer and remaining wire from generator rewireing decided to put together a demagnetizer yesterday. Used the middle of an empty bottle as the coil shape, it is big enough for all sized watches, even for my Roskopf pocket watch The 230V/60Hz main current is transformed to 12V/60Hz with a toroid transformer. The wire is 0.7mm in diameter and four layers were wound. It is connected directly to the transformer... well, burned some 800mA fuses when connected to quickly with a switch but working fine with a crocodile forceps. The copper layer under it is for cooling. It is heating up over 60 Celsius in 30 seconds. Before demagnetization the gauss meter (android app) shows up to 3 Gauss. The peak is only 0.34 Gauss after demagnetization The rate increased by ~10 s/d, amplitude is the same and it is more stable in the different positions. Finally demagnetized all of my steel tools. Never again sticky screws1 point