Leaderboard

Popular Content

Showing content with the highest reputation on 05/03/24 in all areas

-

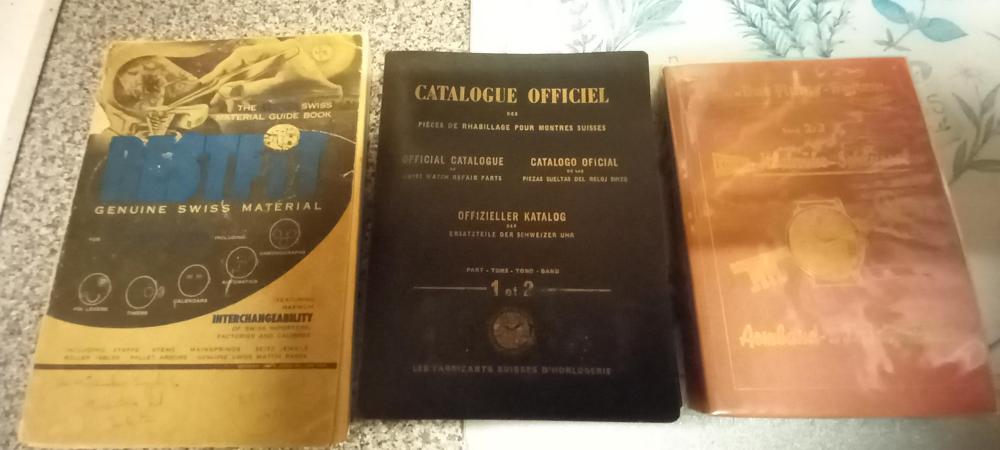

I should have done this a long time ago. I would like to say a big thank you to all my followers new and old. If I can help in any way just message me and I will do my very best for you.9 points

-

3 points

-

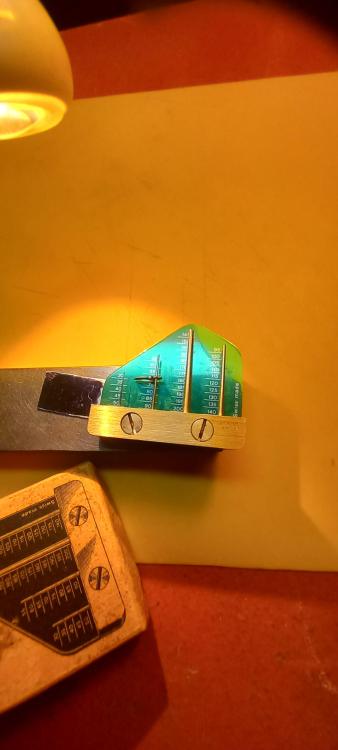

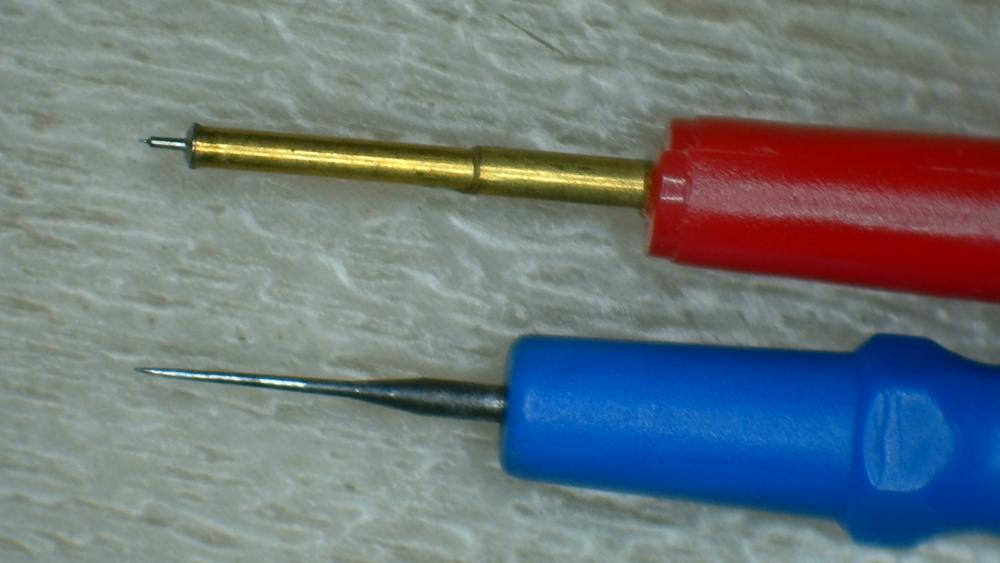

Yep, that's exactly how it should fit. The reamer shank is tapered and the socket in the spindle is also tapered so that the one centers in the other and is gripped tightly. If there is any wobble when the reamer is seated as far it will go then there is a problem. The cross hole in the spindle is to allow you the push the reamer back out again. If the reamer seated much deeper then it would limit the access for pushing it back out again. Here is one of mine for comparison.3 points

-

[SBGA405] Grand Seiko “Godzilla” Spring DriveI always enjoy coming back at the end of the week to my first Spring Drive watch which is a combined automatic mechanical watch and a high quality quartz — a Spring Drive.Impressive accuracy (10 seconds per month) and wears remarkably comfortable at 44.5 mm in diameter and 95 gm.Love the power reserve indicator, and the colour of the dial amd the watch band.One of my “perfect” watches!!3 points

-

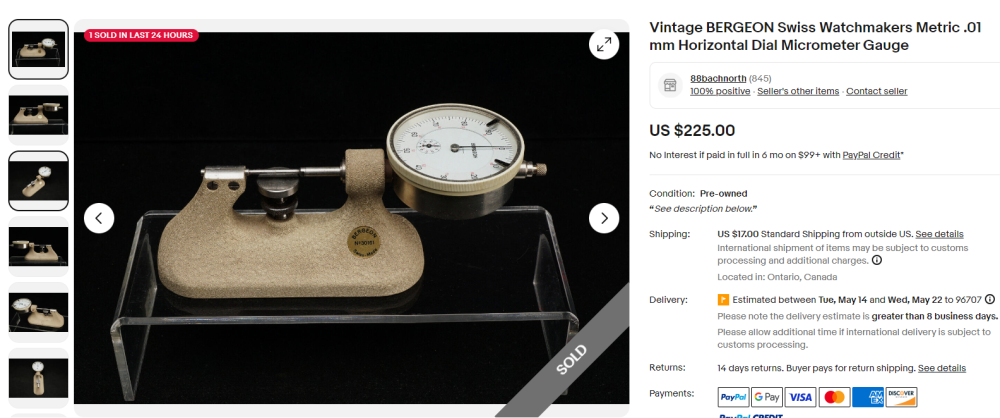

Thanks, ManSkirtBrew. I started looking for a setup like yours and ran across this. It was about half the price of the JKA Feintaster (depending on what auction you were in), and it's a Bergeon. I bought it because I thought the price was fair (eBay - Buy it now), and I'm a sucker for vintage tools. It also has a table, so it should be easy to use for measuring jewels. I wonder if the the contact points can be changed out. Bergeon seems to manufacture new tables and accessories for the contemporary dial version. What do you guys think of it? I'm sorry this post seems to have taken a detour. I'm new here so let me know if I should start a new topic.2 points

-

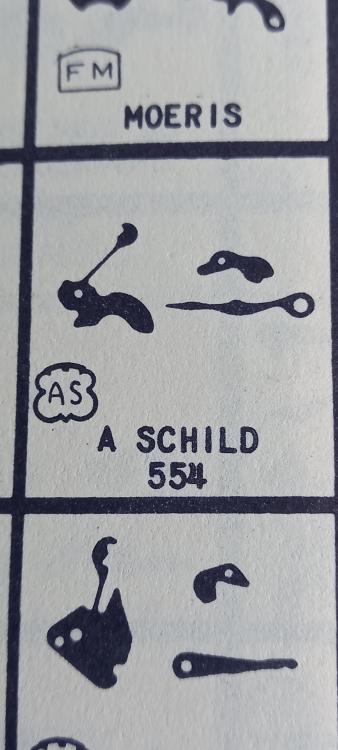

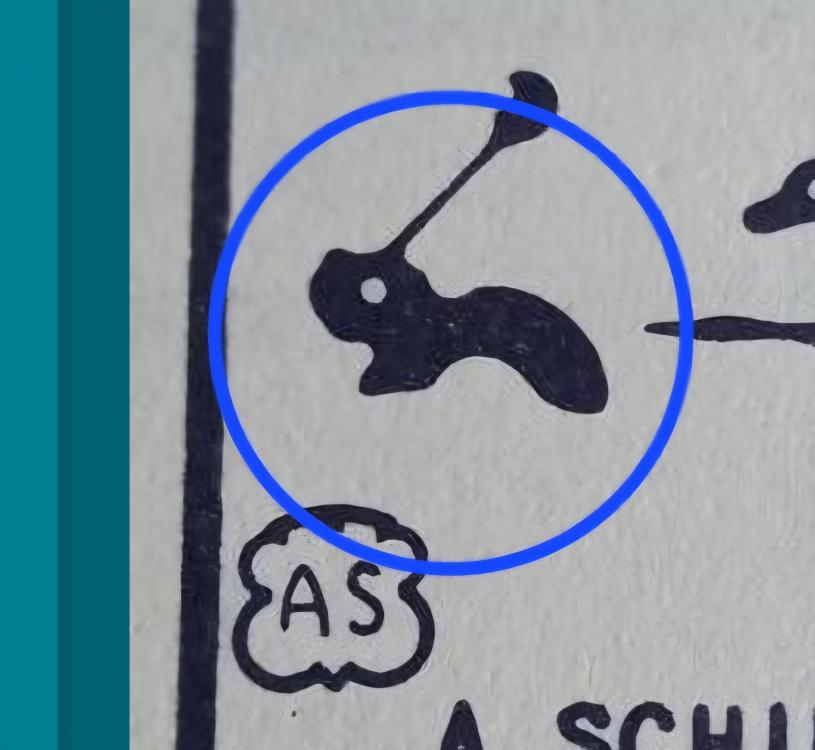

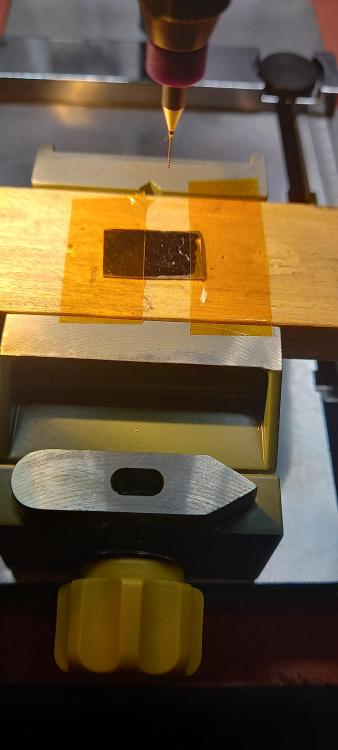

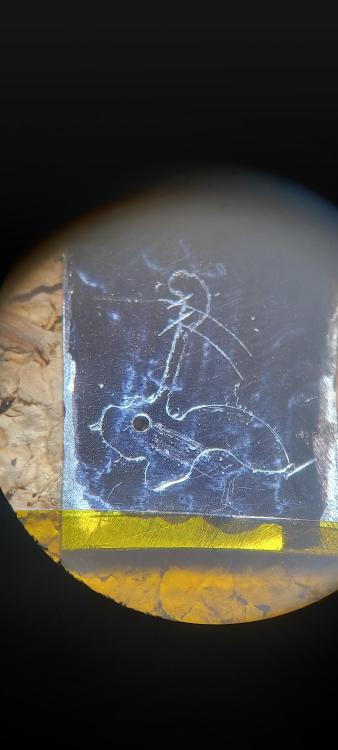

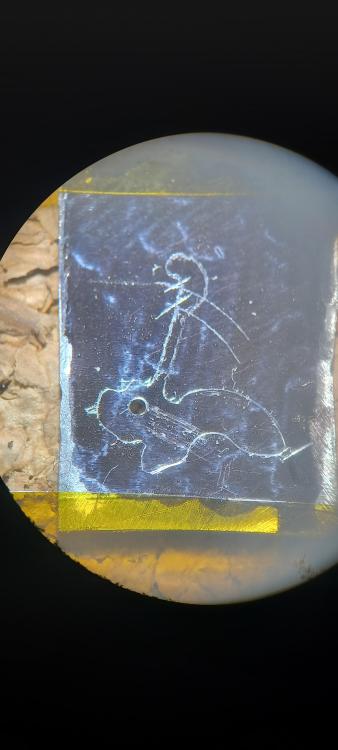

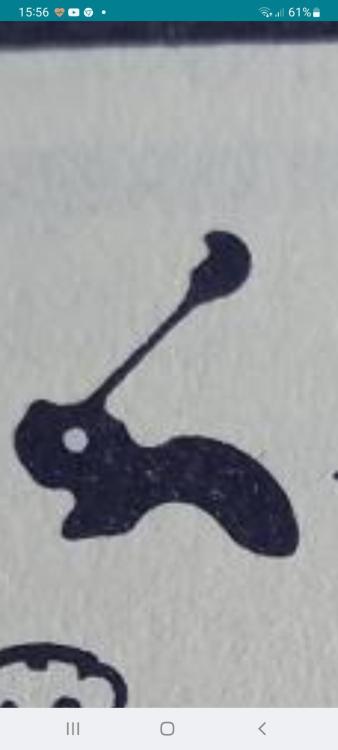

Next one up an AS 554, looks like a bit more to this one. First job is to check thickness, most springs are somewhere between .3 and .4, this one measures .35, that matches in with the .4 spring steel i ordered. So for marking up a permanent marker comes in handy to colour up the steel to be marked later with a scriber once its dry. Bestfit provide the extra bit of info for the jumper spring that is missing.2 points

-

2 points

-

I too got lucky with a JKA Feintaster for a bit under £200, they seem to go for around £400 which I find silly as a brand new one from cousinsuk is less money. Tom1 point

-

1 point

-

Whats not to follow OH ? You're every inch a pro and a true gent, i always enjoy reading your answers even some of the clock stuff that i dont have a clue about.1 point

-

1 point

-

Next is to drill the screwhole this then provides an anchor point so the bridge doesnt slip around while scribing the shape. A cork lid, a pin and a piece of gaffer tape ( ) keeps it all in place. The hole is measured from the broken part using a hand measuring gauge. Mark the hole, punch it and drill it off to size. The awkward bit is working out where the jumper should be and the detent positions. I remember watching a youtuber a while back do this with dividers, so i dug out my old school compasses and improvised a little. This bridge only has one hole and to find the detent positions you need two points of reference, so i just worked the second point from one of the corners, hopefully its near enough. Then scribe in the jumper using the two detent positions ( wind and time set ) that were marked and a big picture of the complete spring to look at that helps to give you a feel of where the jumper should be.1 point

-

1 point

-

1 point

-

We need to identify the movement to help you, but the oldest of these Rolco watches use Aegler-Rebberg movements that lack a calibre number and are very difficult to identify. You may end up having to make or modify a stem to fit . Post pictures of both sides of the movement when you have it and the size of the movement and hopefully it’s one that has a calibre number. Gruen used a lot of the same Aegler movements at the time and it’s worth comparing your movement with those if you can’t find it labeled as an Aegler or Rolex/Rolco calibre. Best Regards, Mark1 point

-

Thats insane Nev that you cut those tiny pinion teeth with a cutter you designed and made.1 point

-

1 point

-

Kalle Slaap said he is visiting London this week in order to see the exhibition. I was keeping an eye open, hoping to meet him.1 point

-

1 point

-

If you Google "site:watchrepairtalk.com Unruh" it should answer your question. https://www.google.com/search?q=site%3Awatchrepairtalk.com+Unruh&sca_esv=cd1cd8ba04cfc6b9&rlz=1C1BYYL_svSE993SE993&sxsrf=ACQVn08-tJuTdvkJ1CZdy5PcUR7BB6zDaQ%3A1714681373604&ei=HfYzZtTBJPf8wPAPnsySiA0&ved=0ahUKEwiUxLTx5e-FAxV3PhAIHR6mBNEQ4dUDCBA&uact=5&oq=site%3Awatchrepairtalk.com+Unruh&gs_lp=Egxnd3Mtd2l6LXNlcnAiHnNpdGU6d2F0Y2hyZXBhaXJ0YWxrLmNvbSBVbnJ1aEjfCVAAWABwAXgAkAEAmAEjoAEjqgEBMbgBA8gBAJgCAKACAJgDAIgGAZIHAKAHLQ&sclient=gws-wiz-serp1 point

-

1 point

-

Why do you doubt? It is a common current name for transistors with included base and base-emitter resistors. They are not „digital“ by itself but can be used in digital circuits without added components. Frank1 point

-

Just installed it on my iPhone (my only iOS device) and it appears to be intact and functional. I may have to go out and buy myself an ipad just for this app.1 point

-

The original database is available on iOS devices here: https://apps.apple.com/fi/app/ranfft-watch-movements-archive/id65020089391 point

-

The first one is an Unruh max stake for pushing out staffs1 point

-

Just a heads up that the CousinsUK branded replacement forks and pins fit the Bergeon tool and look/feel exactly the same. I damaged my Bergeon one and found that the replacement Bergeon parts were almost the same price as a complete new tool, so I decided to try the cousins own brand version. Out of curiosity I tried the fork and pin in my Bergeon tool and found they were exactly the same, and to buy the CousinsUK replacement parts individually is far cheaper than the buying a whole new tool. Hopefully is will save someone some pennies!1 point

-

Hisstoryman, it is always best to disassemble all capped jewel settings (if possible) to remove the cap jewel, peg out the hole jewel, put the parts through the cleaning machine machine and inspect them under magnification to ensure they’re clean and instant before thinking about oiling. The smallest amount of dirt or dried oil, particularly in a balance jewel setting can really impair the performance of a watch. If you look closely at the capped jewels of the (relatively few) movements where you can’t disassemble the setting, you will usually see little gaps around the cap jewel to allow cleaning fluids to flow through the setting during cleaning. These were designed so ultrasonic cleaning would clean out the setting without disassembling the jewel setting. If you encounter one that does not clean adequately, most are friction fit and can be pushed out, cleaned and then reinstalled with a Horia tool. Once the jewels are cleaned, if you choose to oil them using capillary action, you need a tool fine enough to pass through the hole jewel once you’ve placed a drop of oil on the hole with a normal stick oiler. Once you’ve drawn the oil into the setting by capillary action, check the size of the oil bubble in the setting and add more if necessary. The tool pictured above by nickelsilver, the HOROTEC 17.003, is excellent for this purpose and the tip is fine enough to pass through the jewel hole in almost all movements you are likely to encounter. The Bergeon 5423-A is also advertised for performing the same task, but I’ve found that the tip often isn’t fine enough to enter the jewel hole. You could file one down even finer, but the tool isn’t great for this purpose without modification. In the few instances I’ve encountered a hole jewel that the Horotec oiler can’t pass through, I’ve used either a hairspring pin as nickelsilver describes, or a replacement tampon for a cylinder escapement with a very fine pivot held in a pin vise. I know of people who use a balance staff they’ve replaced that still has one fine pivot intact, glued into a handle as a capillary oiling tool, and that should work well too. Hope that helps, Mark1 point

-

In other news, local man ejected from Waitrose Cafe for laughing like an old goat at that last comment. Apparently my guffaws were scaring the tea cakes. OK that might be a slight exaggeration, but I did get a look that would freezer your coffee from an old lady with a particularly heavy looking handbag sitting a couple of tables away. I felt an explanation might prove long, difficult, and given the size of the handbag, potentially dangerous.1 point

-

1 point

-

1 point

-

Heres my watch of today, a Smith 13'" RY . My missus bought me this for this Valentines day a bargain 14.99 with a reduction, the seller has occasional 20% off offers now and then so it was about 15ish with delivery. I love Smiths and i love bulleye dials, this is my first one. The watch arrived non working as stated and i knew what was inside and what would be against me, but i enjoy a challenge, we dont expect a lot if anything from pin pallet movements. A balance pivot was broken and i didnt have another staff but i did have another RY with a battered dial so i robbed the balance and tweaked it around to make it work apart from that mostly just a good clean and relubrication. Keyless works are pretty rough by design and the crown is a bugger to get in and out with the dial on, the setting lever hits the dial before it releases it, so a little mod is needed to help that along. Major problem was the pins on the lever were quite worn which make the old tg have a snow storm fit. Its a similar read for most pin pallets, these were brass as was the escape wheel. But perseverance is me, i didn't change the pins but i did spend some time dressing and polishing the worn areas which improved the trace a lot with some straightish lines and a beat error of .5 . Not sure what the lift angle should be on these and i Wasn't in the mood to work it out and who believes timegraphers anyway, but at the default 52° it runs with 260ish full 210 after 24 hours dial down , the verticals rates were pretty much all over place. So lets just put it in it's superlight aluminium case and see what happens. Been wearing it now for 3 weeks and it's consistently losing around 1.5 minutes a week winding each morning i think pretty good for an old pin pallet watch. I just love this dial, thanks wifey heres my Valentine's gift for yer sweetie x1 point

-

Five and a half years later I can confirm that a bit of silicon grease on the rubber seal makes a huge difference!1 point

-

1 point