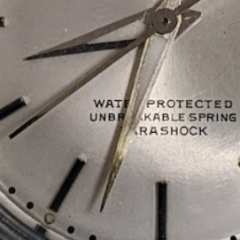

Tissot 28.5-21T Bumper Movement (Similar Omega 350?) Powertrain Issue

-

Similar Content

-

Recently Browsing

- No registered users viewing this page.

-

Topics

-

Posts

-

By coreymsnow · Posted

Hah! Well, California will have to do. Lived in TX for a brief period back in the early 70s, though, so maybe that counts. 🙂 Funny you should mention making vacuum tubes- I've actually tinkered with that! It's REALLY tough to do, and I've never made one more complicated than a simple diode that barely worked, but I have played around at it. But there's just no infrastructure for vacuum tube fabrication. I can get a lathe and learn how to use it to make complex parts, and while it might take a while to learn- and money to get the equipment, of course- it is possible to do more or less "off the shelf". But vacuum tubes, not so much. There are a few folks out there doing some crazy cool work with bespoke tubes, but they have setups that are far beyond what I can manage in my environment and it's mostly stuff they built by hand. I also have been playing with making piezoelectric Rochelle Salt crystals to replace ancient vacuum tube turntable needles- nobody's made those commercially for probably 60 years. I'm a sucker for learning how to do weird things no one does any more so I can make things no one uses work again. (I think this is drifting off the topic of lathes, lol). -

By LittleWatchShop · Posted

You shoulda been born in Texas. Tough to make a vacuum tube though. You can substitute with a MOSFET eq ckt I guess. I was playing around making a pinion the other day. More to it than meets the eye.

Recommended Posts

Join the conversation

You can post now and register later. If you have an account, sign in now to post with your account.

Note: Your post will require moderator approval before it will be visible.