Leaderboard

Popular Content

Showing content with the highest reputation on 05/08/24 in all areas

-

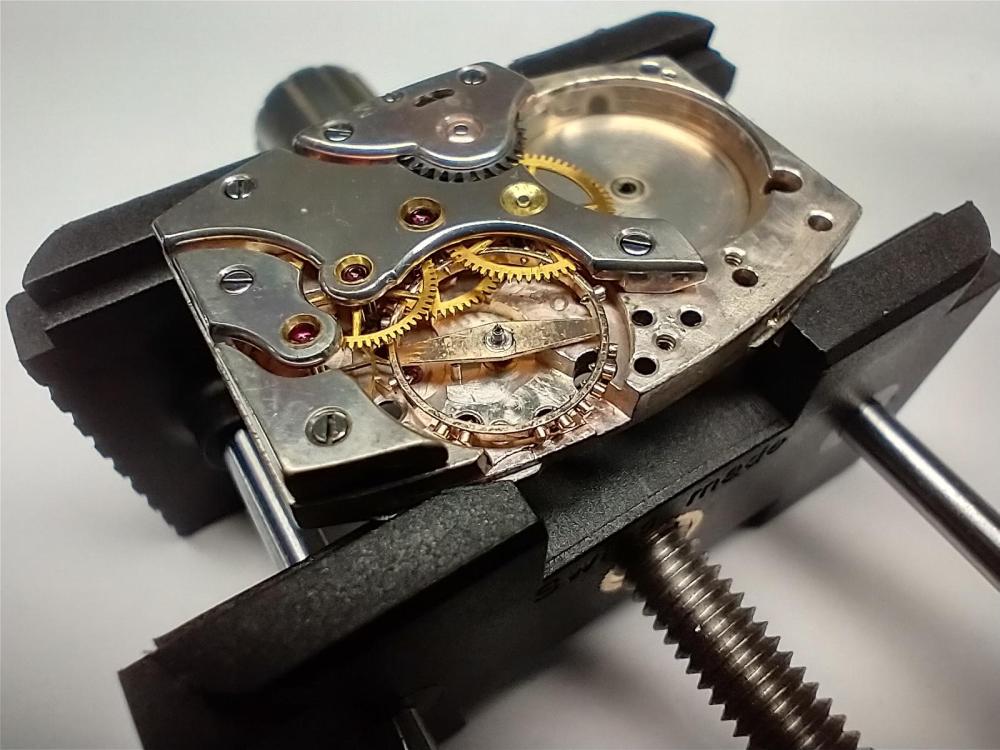

Hi, guys I got there in the end after several attempts using a screwdriver and Rodico, I couldn't wait for the tool to arrive and was getting pretty confident handling the stud screw without it flying away. At first, I was using far too much Rodico, and then realized you only need the smallest amount inside the screw slot. Putting the cock back onto the movement also helped as it gave me more to hold onto while my shaky hand tried to align the screw wobbling away at the end of the screwdriver Anyway, job done and I can move on. Thanks again for all the advice it's really appreciated for a beginner.4 points

-

4 points

-

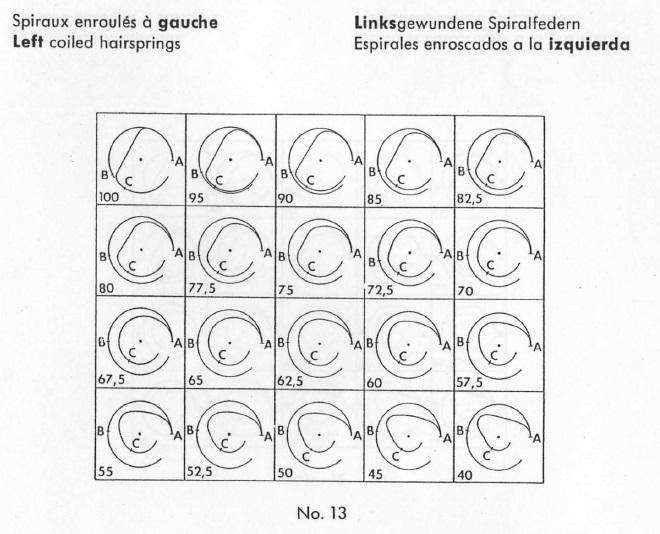

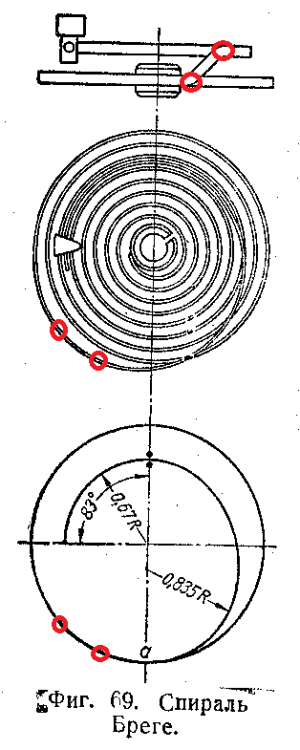

The overcoil can have a number of forms depending on where the stud is situated in relation to the spring. Here's a pic of the Phillips terminal curves. The pdf has all the curves in different scales, you can actually print it out and lay the spring over the one you determine you need to help in forming the coil. It's in 4 languages too! PhillipsTerminalCurves.pdf2 points

-

2 points

-

I was spitting out flowers and leaves for 10 minutes, fortunately 3 people saw it and promptly whipped out their phones to film the quick " nothing to see here " recovery1 point

-

1 point

-

I know I'm wierd as well, i tripped over my own feet today and landed face first in a huge heather bush with my gob wide open.1 point

-

1 point

-

1 point

-

How about using a magnetised screwdriver for picking-up and fitting screw, then run the assembly through a demagnetiser. I know magnetism is a no no, but this method is less fiddly, and has worked for me on several occasions.1 point

-

Find a plastic tube, cut longer than the K&D, put your tools etc in it and hold both ends. The plastic shouldn't have any effect.1 point

-

Here's a quick Gif I made to show truing the balance using callipers. This has such a slight wobble, but is within acceptable parameters. The important thing is the balance doesn't touch or rub anything when in operation. This is an Eterna Tank. Here's a pic of the balance freshly rivetted with a new staff in the movement1 point

-

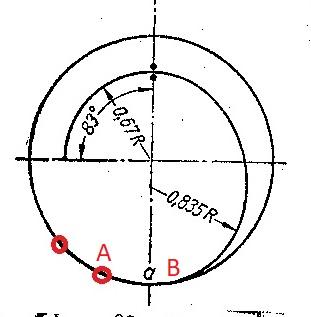

Yes, there are a lot of shapes and all of them are used in different cases. The one in Waltham A11 is one of the most spreaded and is what I have shown in the beginning. Of course, the radius of the final curve will depend on the distance between the hole in the stone and the regulator pins on the cock1 point

-

I'm currently 3D printing a new basket and trays for my Pearl machine - I printed one last week in PETG material and it worked well at first. I had taken a calibration cube and soaked it in old cleaning fluid for 8 weeks and then measured it, and there was no discernable swelling or shrinkage and the cube seemed mechanically intact. All went well after the cleaning cycles and then onto the drying cycle..... that's when things went awry. The heat was more than I was expecting and the basket and individual trays warped and deformed, I later found out that PETG is rated to 65°C working temperature (PLA = 54°C) I am now trying to print from nylon (working temperature = +/- 100°C, depending on the specific blend) - but it is extremely difficult to print with, my third attempt is chugging away now while I am at work - hopefully I don't go home to a ball of wool like last time! Assuming the heating compartment can't go higher than 100°C.... but not second guessing myself...anyone have any ideas or measured it? I also have a question on the trays, maybe I'm not seeing the obvious, but how do you use the ones identified with the arrow? they are called Basket_for_large_mainplate_and_mainspring.stl Basket_for_small_mainplate_and_mainspring.stl I can see the place for the mainplate, but how are you supposed to place the mainspring, you can't uncoil the mainspring to fit around the outer circumference of the tray or else you would damage the inner tight coils. Is the idea that you supposed to lay it on top of the mainplate?1 point

-

Yes, the general pat is this. On my diagram the points where the springs rises and levels are marked with red circles. This is only to show on all pictures (the ones that doesn't show this points as they are seen only from aside, not from above) where this points are. On You pictures, the pont where the spring rises is not marked. The point where it levels is marked with A. The point B is where the change in radius should start, but there is sharp bend there which should not be that sharp.1 point

-

This is such an odd Bulova. Off of the top of my head the only other mechanical Bulova that I can think of that has the 'Bulova' logo as an hour marker is the Golden Clipper 'J' (there must be others), one of my favorite dials. And then it has a solitary diamond, which is not unusual with Bulova, but paired with the 'Bulova' hour marker, that only leaves two quarter hour markers, and I can't think of another Bulova that has only two hour markers like that. You do you Bulova, no conformity here!1 point

-

I have some Gruen 510's in my donor pile if you need parts.1 point

-

I've been intrigued by everyone's input here...so I decided to give this a shot. I bought the"typical" Pearl watch-machine basket and trays, for about $65. The trays are good,..the housing is a nightmare ! Thought it would take the mixer off my bench at anything above about 200rpm. The housing is cast of course,..and it's not "true" at all...so the harmonic vibration was insane. So,..I bit the bullet and bought the Elma housing and top. Not the baskets though, as the Pearl one's fit the Elma. Saved a bunch there. The basket and lid came to about $80 with shipping. The opening in the Elma top is 8mm, and the shaft that came with my stirrer is 6mm. I bought a piece of steel tube, 8mm O.D., and 6mm I.D. Cut off about an inch of the tube, and drove the rod into it. Gives a really snug fit.... Lightly champfered the leading edge of the 8mm section, then lightly tapped it into the top of the Elma lid. Spins like a dream now So... I have about $240 total into this including jars and steel mesh for the wave breakers I'm pretty happy Best to you all Randy1 point

-

1 point

-

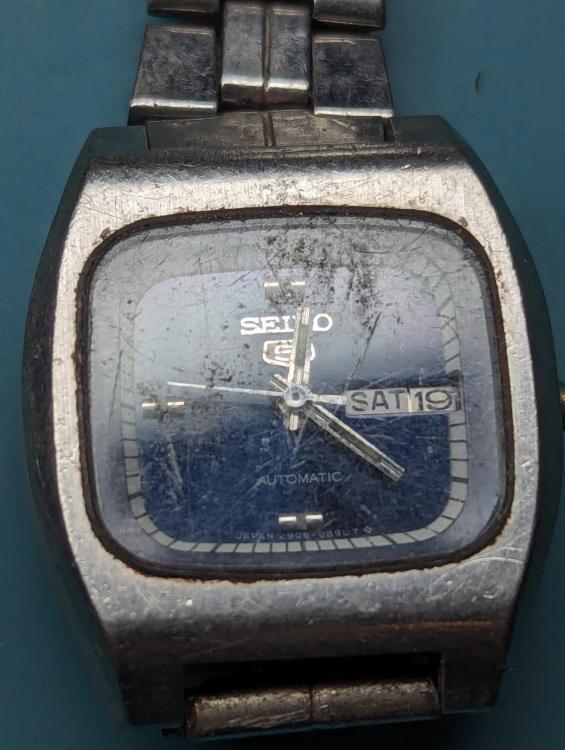

My newest 404 candidate, a late '60's / early '70's Waltham with a UTC 33 / Seiko 6601 17 jewel automatic movement. It needed a new crystal and I put on a strap from my Strap Graveyard. The timegrapher was a snow storm before servicing but it cleaned up nicely. I really like the funky font used for the hour markers.1 point

-

My second iteration. Cleaning to be underneath the towel rails. That makes sense. Moved the fridge and the maching/printing table around to the right. Changed the lathe to be used over the end of the bench. Not much room in front of the 3D printer, but you don't have to stand there while it is doing its thing. I may swap the fridge and the machining/printing bench yet. Not sure. And the 'doing' area. The power that was brought in for tha spa was 30A I think, so there will be more power than I need. I will have to check how level the benches are as well as find a spot for the movement testing rig to go. The tiles do have a fall toward the drain so I will have to work something out to be able to level the rig easily no matter where I put it. I'm also going to cut some slots in the bottom for pendulum clearance and some squares in the top section to be able to better see the movement. I'm getting more excited now.1 point

-

Looks like it is only dirt. If rust, then this means the strenght of the spring is reduced in places with rust, so the spring is damaged and useless. Only light surface rust, which is rather residual from other places activity of rust can be cleaned, and no chemicals that can etch the metals of the spring aloy should be used Be aware that this usually happens when the dial/hands have radium lume! One of the pivot looks little bent. Not that much to prevent the movement from working, but may be amplitude will be a little bit smaller when this pivot down, resing on the cap stone. Bent pivots always means the balance is out of poise, but it depends on the severity of the bent. Yes it can be straightened, but at this point I will advice to leave it as is and check how the movement performs.1 point

-

Lots of rust on that hairspring Nev, would you even try to clean it up ?1 point

-

1 point

-

Can you turn the cock over,looks like the stud fits into that cut out1 point

-

Newbie here too, but I’ve done a bit of reading around this subject. Looks like a Breguet overcoil. You’re right about A and B - A is just a minor tweak - but most damage is between B and the stud. Pivots can be unbent, but there’s a high risk of breaking it off. Take care, and probably see how it runs before trying. That’s really dirty. I’ve never found IPA to loosen Shellac. If you’re worried, put it in soapy water in the ultrasonic and then dip it in IPA as a quick rinse to displace the water and prevent rusting. As for the stud - does it wedge in the angle and the screw holds it there?1 point

-

I use these https://adjustingvintagewatches.com/tools-for-adding-weight/ I picked mine up from a watch fair years ago. Great for this type of work and for removing poise screws to fit timing washers. Cousins do a set, which aren't cheap, but I find that more than one size is definitely needed https://www.cousinsuk.com/product/balance-screw-holders-set Otherwise, if you have a really small pin vice that'll work.1 point

-

1 point

-

Thank you for posting this! I just found my grandfather’s watch which looks exactly like the third one pictured in the original post… although it has a bracelet instead of a strap. Can someone tell me what C.P.C. stands for?1 point

-

Hi and welcome to the forum. As you are already familiar with watches the attachment you may find useful Witschi Training Course.pdf1 point

-

welcome, sounds like you are on your way so far, you also might be able to help with gold/plated case repair for some .....1 point

-

1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement.1 point

-

1 point

-

Seems like ages since I last posted on 404, here is a ladies Seiko 2906A I picked up from Ramon in the Philippines as part of a job lot, so worked out to be $1.60. I did require a new crystal (£10.12) because the original shattered when I tried to remove it and it also needed a new winding stem (£2.00) and crown (from my spares) as it arrived without these, all of the screws for the automatic works were floating around inside the movement and the pawl lever for the auto works had one arm completely broken off so needed replaced (I had one from a donor) but apart from that it's all original. Here are the before and after pictures: Here is how it looked when I first opened the back...... and you get that "it gonna be one of those watches..." feeling And here is the finished watch:1 point

-

1 point

-

The 7620 with the black dial has been the only one I have seen besides mine. Could you please tell me a little bit more about the watch ? I looked up the serial number and it came back that it was made in 1945. But some things they had wrong about it like it said it was a 17 jewel and it's actually 23 jeweled. But if you could please help I'd be greatly appreciative.1 point

-

Really nice watch collection, and the diversity of bands makes each complete. JC1 point