Leaderboard

Popular Content

Showing content with the highest reputation on 12/13/15 in all areas

-

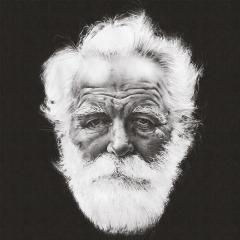

I started down the path of DIY watch repair after a visit to a local Watch/Jewelry shop to inquire about having my old Omega cal. 420 serviced. The shop did not service Omegas locally, and informed me that it would cost $1400 to have it sent in and serviced at an Omega authorized service center. Needless to say, this was out of the question as the watch is only worth about $300 - $500. I stumbled on Mark's YouTube channel while researching how to service a watch, I then proceeded to watch every video on his channel. Afterwards I had enough courage to try watch repair, just not enough courage to try it on the Omega, which was a special inheritance from my grandfather. I picked up an old Elgin 7 jewel grade 291 pocket watch that did not run but seemed to have a good balance (moved freely when rocked) at a local antique store. After receiving all the tools I ordered from Amazon (screwdrivers, tweezers, crystal removers, movement/case holders, and loupes) and Otto Frei (Rodico, oilers, Moebius oil/grease) I went to work disassembling the Elgin. While trying to get the front bezel off the watch, I dropped it! :angry: Needless to say the balance did not move freely any more. When I finally got the bezel off and the watch disassembled, the balance shaft had one pivot bent, and the other one broken off! Undeterred, I turned to eBay and bought another 291 movement (good balance but worn out fourth wheel bearing on the main plate). I disassembled the spare movement and scavenged the balance and jewels from it. After that, I cleaned all the parts in lighter fluid and rinsed them in alcohol (not the pallets). After watching a few of Mark's videos again, I reassembled the movement applying the oil and grease, following Mark's example. To my surprise, it ran after I got it back together. I fully wound the watch and let it run, after 24 hours and it only lost 3 minutes, not a bad result for an old pocket watch. ;) Still not ready to try my hand at servicing the Omega after my fumbling with the Elgin, I figured I would try servicing my old Ball-Waltham model 1894 pocket watch. I inherited the Ball from my grandfather as well. Over the years that I've had the watch I could only get it to run for a few minutes before it would stop. I disassembled the watch, cleaned the parts and reassembled the watch without incident. I fully wound the Ball and let it run, since it does not have any hands I cannot measure its accuracy, but I was impressed when it was still running over 40 hours later. B) With two watches under my belt, I felt it was time to take my chances with the Omega. I disassembled the watch without any issues, but after cleaning and inspecting the parts, I found the keyless works were roached. There was severe rust on almost all the steel components. I made a significant effort to scrape and remove the rust, I even resorted to a rust dissolving chemical. In the end the parts were rust free, but the surfaces were rough due to pitting and basically unfit for use. I managed to find an incomplete Omega 420 movement on eBay and I was extremely pleased with the condition of the movement when it arrived as I was able to source all the parts I needed from it. With all the parts on hand, I reassembled the watch. With assembly complete, I fully wound the Omega and it ran for about 6 hours... not a good result. :huh: I took the movement out of the case and removed the hands to make sure neither the case or hands were causing the movement to stick. This time it only ran for only 3 hours before stopping. After fully winding it again, I watched the balance closely and noticed that the balance spring was not flat, in fact, it looked to be hitting the balance wheel! I removed the balance and removed the hair spring, with the spring sitting flat on the bench, the end of hair spring was bent upwards, almost at 45 degrees. :angry: I was upset at first, but then I remembered... Mark has a video for that :biggrin: I re-watched his video on fixing bent hair springs and then spent the next 2 hours coaxing the spring back flat. When I reassembled the watch it ran for 48 hours, while only gaining 2 minutes over that time. I could not be more pleased! :jig: Overall the cost breakdown was: New crystal, hands, crown, stem, and band: $130 Parts movement for keyless works: $15 Tools from Amazon: $130 Moebius Oil/Grease: $100 Total cost was $375, well south of the $1400 the Omega certified service center wanted. I wanted to give Mark a very big Thank You :thumbsu: for taking the time to put all his information together and making it available to everyone here, and on YouTube. Jerry My Grandfathers Omega:4 points

-

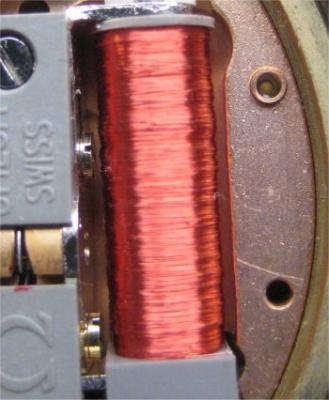

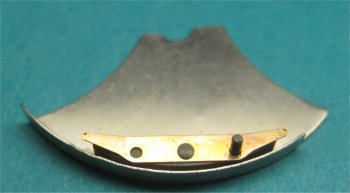

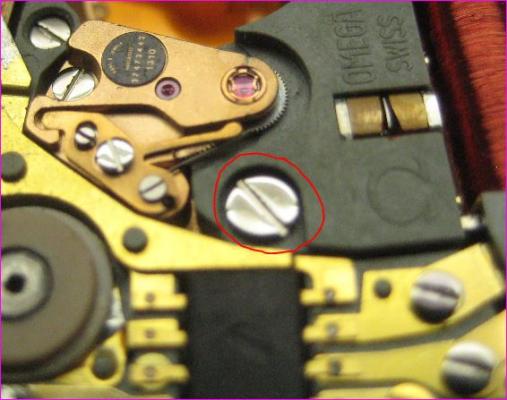

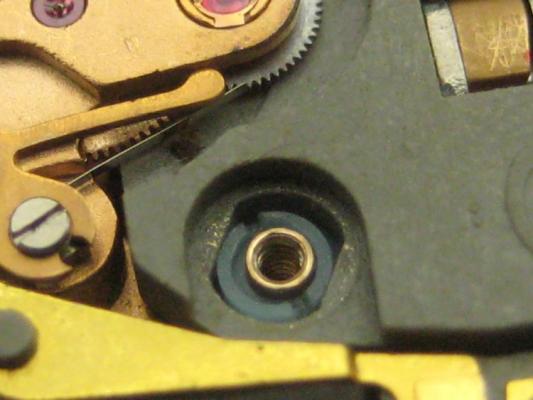

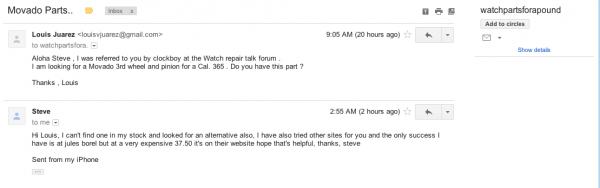

One of the things I really like about this group is your open to things. For instance quartz watches can be quite fascinating and very interesting to collect. But the entire world doesn’t necessarily understand that. For instance I collect electric watches including quartz watches. If I’m at a meeting of watch and clock collectors and asked what I collect a lot of times I skip over the issue. Other times I tell them I collect quartz watches just because I like to see the expression on their face as they run away. So there seems to be a perception that electric is bad especially quartz and mechanical is always beautiful. Except we have some very horribly made mechanical watches were not meant to be serviced. Timex watches pin lever watches zero jewel watches etc. so not all mechanical is beautiful. The early days of electric especially when they get into quartz a lot of very fascinating interesting ways to solve problems. Makes for a lot of just really interesting watches that can be quite beautiful. Then there is an advantage to collecting evil quartz watches. For instance the watch in the photograph the price tag indicates $20 it didn’t sell in this particular show the seller gave it to me because he knew I collect electric watches. A sizable percentage of my electric watch collection was given for free. Unfortunately to get some of the good stuff you do end up with a lot of crappy quartz watches but I didn’t have to pay for them. So for missing parts you’re missing one and the other is not missing it’s hiding possibly. So there supposed to be a magnetic shield it goes over the coil. On your Omega watch part of it is still there and the Tissot it’s totally gone. I’ve attached the image usually the little plastic pins break off I only have one there should be two. In the case of mine if you turn the watch over it just falls out which is why they’re missing. So the offset cam adjustment is hiding more than likely not missing. Notice the nice big screw and in the image I circled in red? Then nice close-up photograph of what's under the screw is what you should find which is the cam adjustment hiding not missing hopefully. Then special tool probably doesn't exist anymore so you can use a screwdriver that you grind out the center to clear the tube that the screw threads into. Make sure you read the instructions in the manual carefully you'll have to loosen the other screws so the entire motor assembly can move. The cam is made out of plastic it does not like to be forced..2 points

-

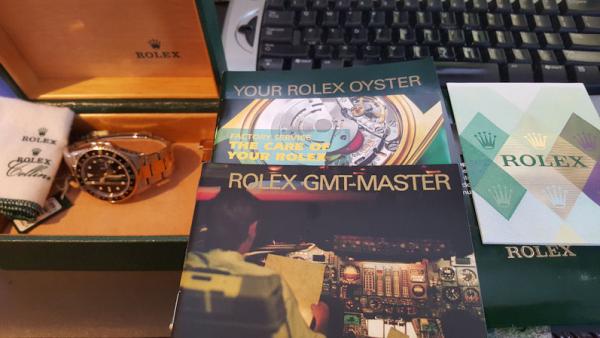

Take a look at this beauty guy's Sent from my iPhone using Tapatalk1 point

-

Great idea about the cigarette lighter spring, I also thought that it might be the black hole since it was the only one that stuck out to me as being different and would possibly fit a spring. I'm going to try and dig something suitable out and give it a try. I've seen someone on a youtube video dismantling a watch springbar and using the internal spring as a replacement, although that was on a newer g-shock and they had to drill the hole bigger.1 point

-

HI Vic, The superglue (not epoxy), as rogart sais, will work and will wash away with acetone. If I remember well in some cases there is like a left over discoloration though so maybe try in a corner or something? Also I think the Omega tool will fit those holes...but I don't know which of them (I haven't tried those but they look like they will fit). As you said, being pristine and a year old may be a problem...although worth case scenario it is replaceable (not a financially sound way to change a battery though). Maybe, it would be better to either let the guy know the risks you are running and/or advise to send it to a Tissot shop? I sure would hate to see you getting in trouble for a battery...just because it is a proprietary back! It would really sock! Other than that, I can't think of anything else...I hope something will pop up and you will be able to successfully accomplish this. Cheers, Bob PS. Omega tool:1 point

-

1 point

-

Well, the balance staff replacement went well. I trimmed down the rivet on my lathe, popped it into the staking machine and used a blocked stake to punch out the staff. I cleaned the balance a bit and then put the new staff into a slack fit hole on the anvil and then used the dome and flat stakes to set the staff. A quick check on the poising table showed it was pretty OK so back to the staking set and seated the roller table and the hairspring. I now have a watch running at +2 Secs/day, amplitude about 320 or so but a beat error that started at 9.1ms! I've now got that down to 2.6ms but that's too much for me so tomorrow back to the repetitious task of loosen the balance stud, remove the cock, remove the balance onto a soft wood block, tweak the hairspring collet, install onto the cock and nip up the stud and back on the plate. It's an arduous process and that little stud screw is a real little s***of a thing but Im determined to get it as close as I can so back to it tomorrow. I wish the Timegrapher would tell you which darn direction to turn the collet, I guess it's just tweak, check, tweak again, check for increase or decrease and then just TINY TINY tweaks. Although I eyballed the balance on a bare plate and could see the roller jewel dead centre in the pins it is still out so it may be a factor of the hairspring. Anyway, I've had enough so before I crack the ***** with it I'm off for a Guinness. A BIG thanks to Mark for the excellent videos that helped me immensely in the execution of this part of the work. More to come.1 point

-

1 point

-

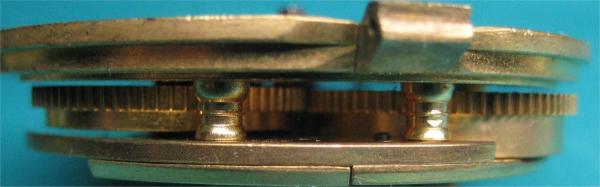

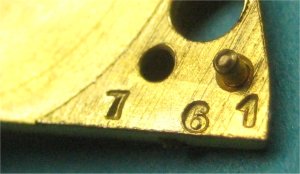

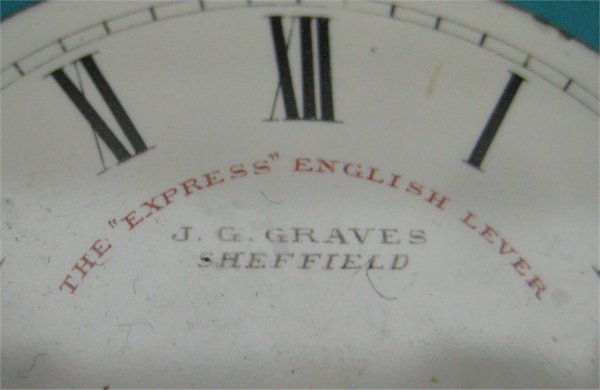

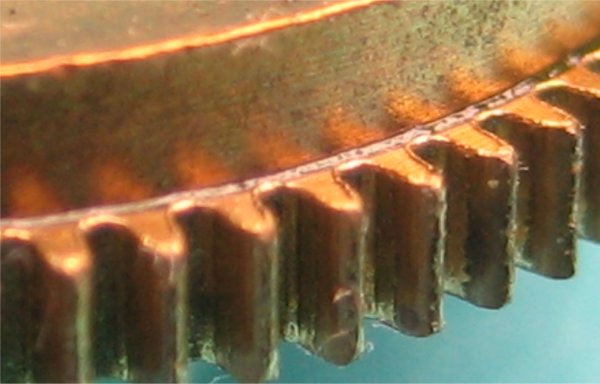

So was looking through my library of books and can't find any reference to watches like this yet I know they exist. One of the ways I knew they existed is I had to go through my watches and find them. Conveniently everything up until today had their fusee chains. Just needed to look at another location and came up with what I'm looking for. So lots of pictures three watches all conveniently look like fusee watches. The one on the left is not. This is just your standard single mainspring watch. Then the side view where you can see the single mainspring barrel. So the center watch and the one on the right-hand side casually look like fusee watches which is why I would have purchased them. You’ll notice that side view they appear to have two mainspring barrels? Then some mysteries and similarities. Similarities are they look very similar and at the same time do not. The one on the right-hand side looks older balance wheel and older style. The dial the second disc is a separate physical disk and in my case very separate because the glue is disintegrated and fell out. The finishing on the plates is outstanding but that’s also the final watchmaker would’ve done that. The dial feet the dial is pinned in place the same as with an older watch. The center watch gets disassembled the dial is one piece. Side dial screws. Then a mystery for this watch notice the dial says it’s in English lever but look at the escape wheel where the pointy teeth? Then the one on the right does have pointy teeth like it’s supposed to. Then your reference to donor watches what were you thinking? The reason for this question is at this point in time are these considered handmade watches or machine made watches? I think the reality is you going to find their little of both. It’s really not up until relatively modern times that you have 100% interchangeability. So the center watch the express English lever and I have no idea what the meaning of express is gets disassembled. Conventional T end mainspring. The serial number conveniently marked on all of the plates either the full number or the last three digits. Strange though the main plate full serial number on both sides. The balance wheel the serial numbers been scratched onto the arms the same as you find on American pocket watches. That is unless of course somebody has swapped your balance wheel which is quite common on American pocket watches also unfortunately. Then the for lack of better terminology phantom fusee barrel. Solid brass the arbors been pressed in and the gear appears to have been soldered in place rather than cut in place?1 point

-

1 point

-

Just finished a c1959 Smiths Deluxe A358 thats been on the back burner a while now: As was: Grubby case, badly scratched crystal, sticky out crown & to top it off a vicious expander strap good for torturing the hairs on your wrist. Movement fully serviced. Second hand straightened. Cleaned case etc. New strap & crystal. Crown set correctly & it now looks like this: The movement: Easy to work on (nice big pinions) & showing a good amp of 315 well up from its original 230. Running at +/- 8 seconds a day. Shown here with its older brother an A352 from 1956:1 point