Leaderboard

Popular Content

Showing content with the highest reputation on 08/03/23 in Posts

-

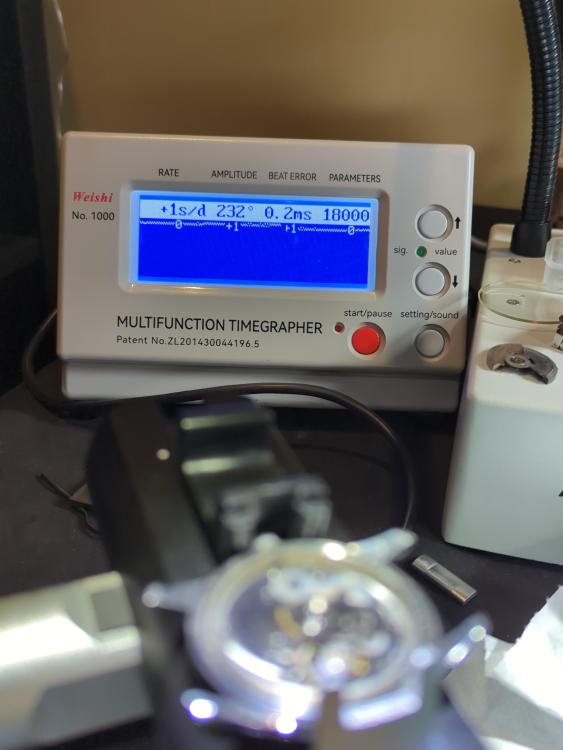

Hi there, I got home early from work and needed a watch fix! Started work on it around 5:00 and then looked up and it was 11:15. This is a Zodiac that I got on eBay and the case was a wreck, strange scratchings on the bezel, the picture below doesn't do it justice. The watch was running quite well and fairly clean inside, well compared to some of the other watches I take on! I took a quick time graph footprint before I started and the rate was +10 s/d, the amplitude was 235° and the beat error was 2.0 ms. After I finished the full service I took the following timegrapher snap: All better, except the amplitude, but this was already pretty good and I expect it to improve over the next 24-48 hours. I worked on the case and got most of the damage out but had to stop before I over polished and changed the shape of the case. Apart from the crystal and strap everything else is original. Here is the finished watch: Let me know what you think.3 points

-

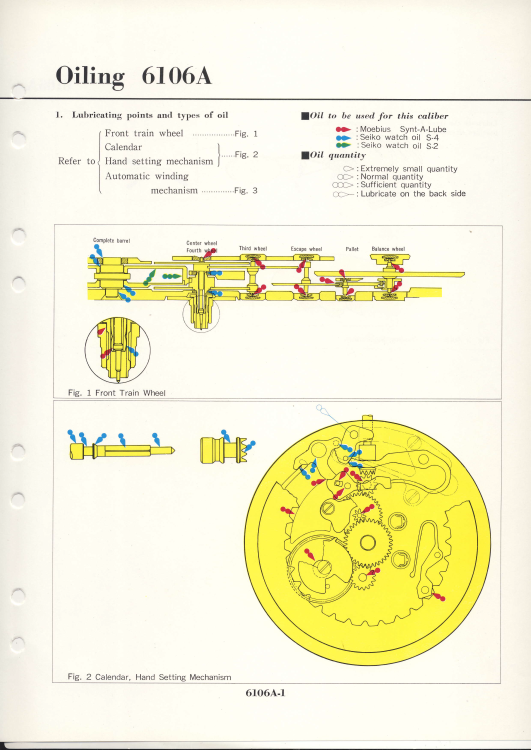

Started this at the weekend, but got side tracked with a 3D printing project my son was working on. I suppose this is one of the advantages of doing this as a hobby instead of a job in that you can pick and choose when you do it, or not. Anyway, I finished this September 1981 Seiko 6309 last night and I must admit that it came out well and is performing excellently... So far. The watch was a non runner and is all original apart from a new crystal and a screw that was missing on the plate on the dial side. Here are the before and after shots, first is the before dial side: Here is the movement including the crusty green corrosion on the rotor - a pure nugget of green! And here is the timegrapher result, note that I did a quick check this morning and amplitude is continuing to improve as the new oil and cleaned parts settle in: Here is the finished result:3 points

-

2 points

-

Yes, that is a bona fide Illinois Watch co grade 274 model 2, let me see what I can scare up2 points

-

Elgin did not make the Burlington watch, Illinois did, and sorry, i did not see you had provided the info. If I can find out, i will,2 points

-

There are several uploads here for the witschi training materials which outline timegrapher anomalous traces and the likely causes, I would search for them and they should give you a good start on initial assessment. Tom2 points

-

no need to apologize as it's sometimes hard to find things on the message board. yes a timing machine manuals over time are interesting. The usually have the this is this kinda sheets they don't always explain what they mean though in detail. The Greiner manuals tend to be one of the best as a really go into detail. Some others actually published a book and someone around here but I can never figure out what I did with it I have a reprint of a bunch of manuals including one that I'm convinced somebody was on drugs because their interpretation of the waveforms is quite interesting.1 point

-

1 point

-

Well, since you offered, will you kindly see if you can find a house under my watch pile, and if yes, then grab a walkie talkie and a st. bernard, and I will direct you to what this man needs from there.1 point

-

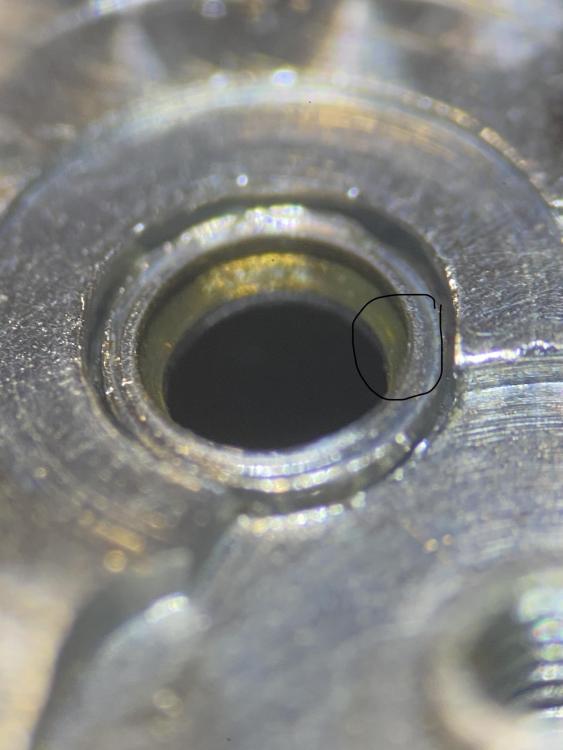

You might be lucky , i hope so . But there are 2 sides i think. Finding the correct jewel size i very much hope in your favour. Like i said JohnR725 is the man for you .1 point

-

The rim seem to be intact, so I am hoping I can close it with one of the special tool, if I get one. If not, the blame is definitely on me.1 point

-

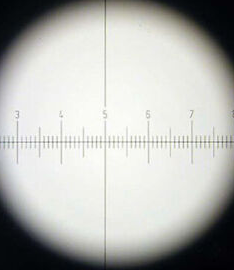

I always like to do a preassessment on the timing machine of all incoming watches at work. That is providing they can run. Sometimes the balance staff is broken like a watch I had earlier. So I'll replace the balance staff then verify the watch can run before I go ahead and clean the thing. I don't want to have a clean watch that has a major timing issue because then the balance wheel may come in and out enough times it basically F to start over for cleaning a lubrication. If the watches really sticky and doesn't want to run at all you can insert your tweezers into the hairspring rinse closed and it will pick up the hairspring rinse and you can drop that on the watch. Usually I can free up things enough that I can do some sort of assessments. Otherwise I just don't worry about it go ahead quickly that and hope for the best which doesn't always work out as vintage pocket watches can have lots of issues as lots of people of played with them. so what you're really asking is you'd like to have diagnostic information for timing machine results? It's already been discussed before somewhere but I'll attach a PDF. Then a link to a timing machine with a really good users manual. This was written at the time when the watchmaker didn't know what a timing machine was so it explains a lot of things http://www.historictimekeepers.com/documents/Micromat.pdf1 point

-

See? The greatest show on earth, I think i am moving on to hot dogs.1 point

-

basically if you look at most watches you'll find that the side that you can see the backside will look nicer than the dial side for instance the jewels will usually be physically bigger things we finished nicer. Or in the case of pocket watches jewels on one side none on the other occasionally. the unfortunate problem of vintage watches are getting parts including mainsprings. If the watch was relatively common there is probably an aftermarket mainspring. But I notice as you go down in size for a lot of the American watches small pocket watch is getting a mainspring becomes much more difficult. Sometimes you can look on eBay and someone will be selling an old spring. Otherwise I just go through the list of other American pocket watch springs and see if anyone else as anything close that will work which is probably what happened before1 point

-

What are you saying, good god man, i am dizzy. Why would i look it up since you already did, and I do seriously believe everything you say, and you do know everything... Incidentally, I thought it was fiercely clever of you in the very first place to spot those marks on the movement, and in the end, what did the OP pull out? The mainspring john said would be there, even though every source there is tells us it should not have been there! So from the top...1 point

-

1 point

-

At low amplitude machine's print out is invalid anyway, so if you get good amplitude, then yes definately good practice to make a habbit of. I guess in your profession any amplitude is good news. Rgds1 point

-

1 point

-

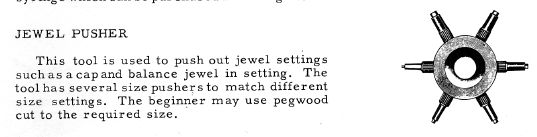

Yes, I have replaced and adjusted friction settings a couple of times, on a bit more modern Swiss watches. Edit: I decided to push it out with my Swiss jewelling tool. Indeed it was ”rubbed in”. It wasn’t really obvious to my untrained eye before I pushed it out. Did any of the old American pocket watches use modern friction settings?1 point

-

If hou can see it folded over in places then it more than likely is rubbed in. Have you replaced a friction jewel before ?1 point

-

1 point

-

A rust removal product called Rustins, it has a high concentration of phosphoric acid.1 point

-

Yes! Depending on how well it is running, it might give a clue to any problems.1 point

-

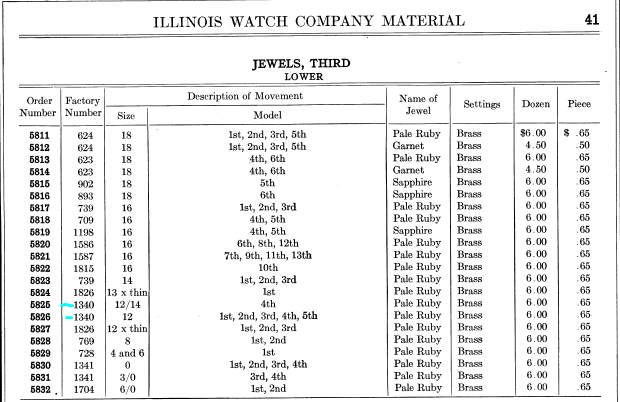

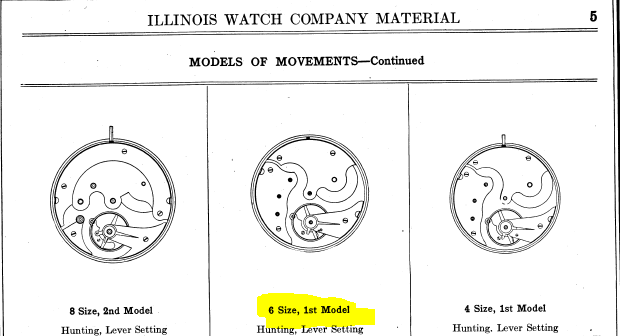

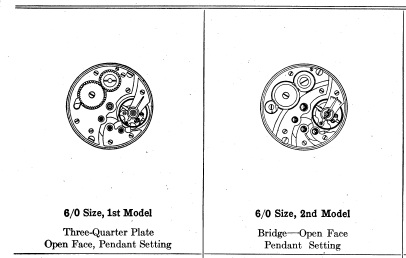

always nice to start the day off with a laugh. if you click on the link to the pocket watch database goes the parts on the left-hand side. Scroll down the list until you get the Springs. Go down that list until you get to mainspring no picture part number 171. Then go up higher in the discussion where I posted the picture out of the Illinois parts book and part number 171 corresponds to mainspring for a six size watch. yes about that? let's look what else the parts book has for us initially in the parts book they'll help you are try to help you identify your watch and one of things they do is drawings of plate layouts like this as you can see from the drawing up above it looks like the picture from way up above versus this one that doesn't quite look the same does it1 point

-

It's a great idea to do a pre and post timegrapher footprint, then you will know how well you did - any improvement is an improvement and the watch is better than when you found it... if its the same or worse then ermmmmm.......... you didn't do such a great job. To be honest its more about the differential in the readings than the absolute number that counts. An absolute number sounds like a good idea and for a watch right out of the factory this makes sense. But a 40 year old watch that has had a hard life, you can't expect to hit those numbers again so the absolute quoted values are essentially meaningless. All you can do is get as good a difference as possible, as my mechanics teacher used to say "perfection is expensive to approach and impossible to achieve".1 point

-

This is going of track. Please keep it to what the original poster was talking and asking for.1 point

-

This Croton with an ETA 2472 automatic I have shown before. Recently replaced the tension ring crystal and regulated the watch and added a basic black leather strap. Nice everyday watch. Lug width 18mm, lug to lug of 42mm, and case wdith of 34mm. No way to know for sure because the movement was made from '55 to '74, but seems late 60s or early 70s with the chunky hour markers and case shape. Not sure what the dial CHP is about but over has a nice patina. The case is all SS with drilled lugs which I have not polished (yet) so has a few marks. Working on the rate and the amplitude could be a bit better but so far it is not telling me it needs a full service quite yet as on the wrist it is less than 20 seconds a day fast and everything seems smooth. Edit to add that I like the slightly inset crown which can still get a purchase on with a manual winder and with this ETA you can manually wind as well. I also like the way the crystal sits in the case, seems UFOish and more 60s I think.1 point

-

1 point

-

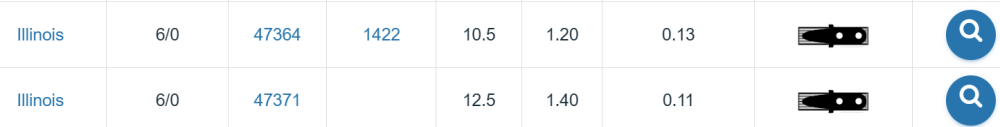

I was wondering when someone would bring up the PWDB, great site and great people Well, they do make the occasional error, and I can ask. There is about half an inch difference between the two sizes, should be easy to tell. regardless, and also ... PWDB list no illinois mainsprings for a 6s, but two for 6/0, one 2" longer.. here, neither with a T... If this is not solved yet I have another idea, which is I can look through my illinois catalogs and also through my stock, I am bound to have one, or more.1 point

-

There is nothing special about that screw, they are common amongst a lot of Seiko movements. Try these guys for any Seiko movement 6309 or 7009 etc. You should be able to pick one up cheaply. https://www.ebay.co.uk/str/speedtimerkollektion The other option is to buy a bag of random screws and you should find one that is close enough, CousinsUK sell them by the hundreds for just a few pounds: Best of luck!1 point

-

That part is the Holder for the transmission wheel & pawl lever and it's Seiko part number is 022252. I did a check and could only find it here. https://gleave.london/screw-seiko-022252/1 point

-

No valves, probably a big bunch of TTL ic. This style was trendy in the 70s. Frank1 point

-

1 point

-

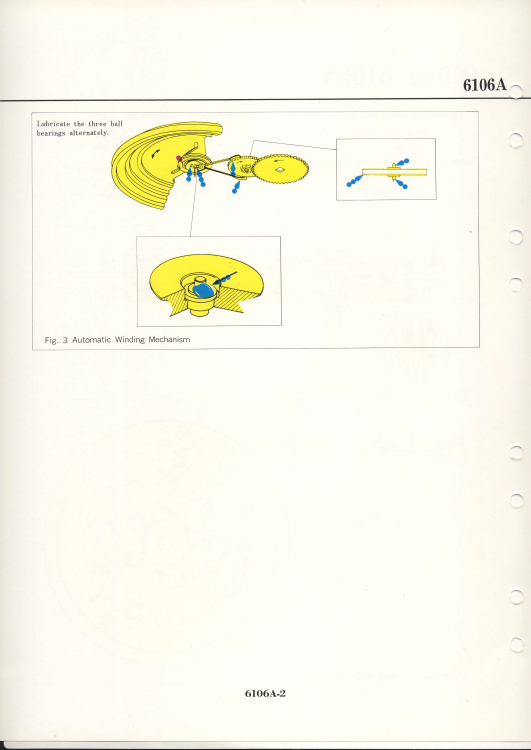

I've attached the parts list for 6119 and the base caliber that goes with it that might help you to figure out which screw you need Seiko 6119B.pdf Seiko 6106A.pdf1 point

-

it looks like your standard wristwatch before the nifty shock systems were invented. Then a book well worth reading and skimming through. But if want to skip ahead page 131 talks about servicing your watch. https://archive.org/details/TM9-15751 point

-

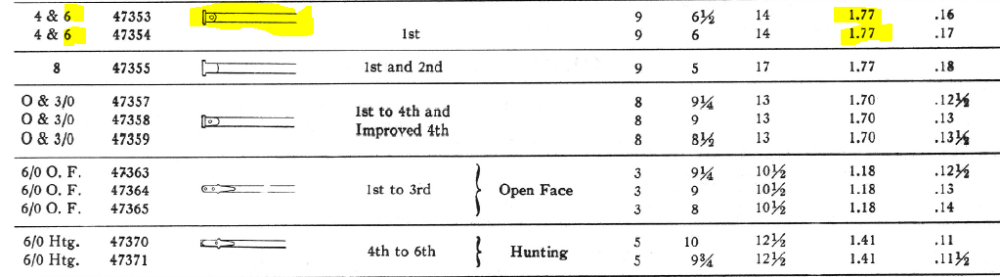

another source for figuring out what you have is the pocket watch database https://pocketwatchdatabase.com/search/result/illinois/644615 where we have a interesting problem? database claims that it's a 6 size and you have 6/0 size which is not the same thing. fortunately we have a size I'm attaching a PDF which confirms six size is the correct size. I wonder does that change my assessment of the mainspring? now I have to question the mainsprings size because this is what the listing says. That may explain why someone was filing on it because they did change the size. But this would answer my confusion over the type of end. without a very interesting to see how well your mainspring fits versus what I perceive should go in there and I be curious what the actual dimensions of the spring was that came out if the dimensions you have up there or the spring they came out. typically on American pocket watches when you remove the screws the jewels will not fall out. This requires you to go to the other side and pushed them out with a tool designed for that or you can make something with peg wood. Then we do reassembling you push the hole jewel in first followed by the end stone wouldn't try to push them both at the same time not recommend make sure you get the end stone aligned with its scruples and be careful the little screws like the strip is they are really tiny. watch-ligne-size-chart.pdf1 point

-

Thats one of the last professions i would have thought. Certainly no money worries, I wonder why. yeah not good to be stuck in a room by yourself. We are sociable creatures that are meant go be in groups. Doesn't make sense to me though, i don't like people1 point

-

Yeah, I think it's true. I thought it would have to be psychiatry, considering all the depressing patients and the stories they bring. I had a friend, one year my senior, who took his own life. You would never have guessed from his happy-go-lucky personality that he would do something like that. He had an identical twin brother who was a little weird and had a real gloomy personality. I would have thought he would be the one. In my 36 year career, we have lost 4 dentist to suicide. I don't know what it is about our profession that drives us to suicide. I would think horology would be a more suicide prone profession. You know, you're stuck in a little room, surrounded by things that go tick tock and cuckoo all day long.... Take care of yourselves and talk to friends and God if you are feeling down.1 point

-

Can also remove rust. Weak to strong Lemon juice ( ascorbic acid ) vinegar ( diluted acetic acid ) Cola ( heavily diluted phosphoric acid ) then proprietary products, some contain high concentrations of phosphoric acid. I used a well known one that dissolved an escape wheel in six hours .1 point

-

1 point

-

This is my Keystone Standard Watch Co specimen. (Not to be confused with Keystone Watch Case Co) It is a 9ct hand engraved case front and back. The Keystone Standard Watch Company was started by Abram Bitner with the purchase of the factory and production of the Lancaster Watch Company in 1886. Almost 9000 Lancaster watch movements had been completed but not sold when Bitner assumed control of the company, and these were sold by Keystone Standard under the Lancaster name. Keystone continued to produce a relatively small number or watches, about 48,000 in total, until their sale to the Hamilton Watch Company in 1891. This watch is one of the Lancaster watches.1 point

-

1 point

-

Nice info! I just checked that my stirrer can do max 3000 rpm but there's no way to adjust the speed accurately. I run the wash cycle so that the liquid doesn't foam too much.1 point

-

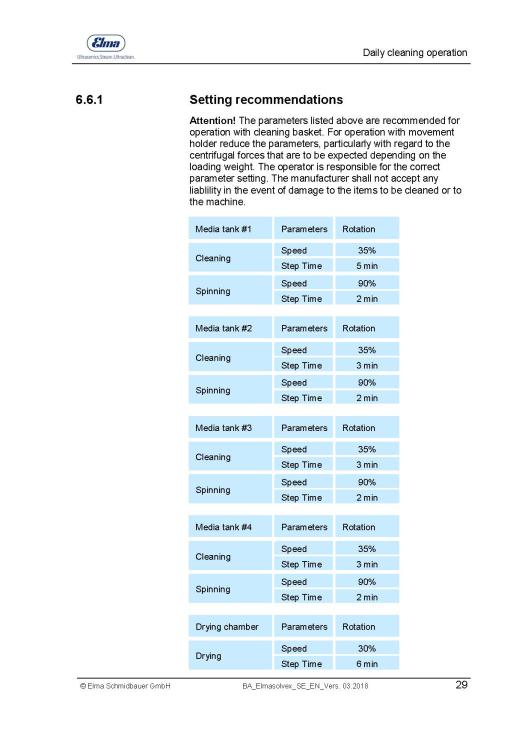

After a bit of further research, the recommendations from Elma are given below, FWIT. Bearing in mind they quote percentages of their machines' maximum which is 1200 RPM and will optimise their settings for their chemicals. For the novice watch homogeniser, this will vary according to the ambient temperature, relative humidity and type of cleaning / rinsing solutions used. So a visual inspection to see there is minimal frothing and central cavitation is probably the real world scenario.1 point

-

That seems to be the same basket I have. My stirrer has an 8mm motor shaft and the hole in the Elma lid is 8mm. So there's a 8/8 shaft coupler and an 8mm shaft that I cut from a beaker holder that came with the stirrer. Those jars are just some kitchenware but the lids are metal and there's a rubber seal. Not the tightest one around so you can smell the 566 if you sniff the jar close. The shaft goes through a lid that slides up and down and acts as a splash guard while spinning the basket. It also keeps most of the flammable fumes and odours inside, which is nice. The jars are not very uniform, there's a little deviation in diameter and roundness so one jar fits the base better than the other but I just stick a piece of cardboard in if there's too much space. What or who is Mr. Kilner? First I was about to buy an Indian basket but I read and saw some bad things about the randomness in quality so I went with Elma. The machining is precise so the basket doesn't wobble in the shaft. The wobble I experienced is due to high RPM, jar not supported properly, long shaft and the shaft going through a tight hole. But no problem if I support the jar with hand. I have no idea about RPM, still experimenting myself. The Elma wavebreakers seem to work fine so I can go a little higher speed. I went with 10 min wash and 5 min rinse, and finally 30 sec rinse in IPA. I guess you can do a longer wash cycle when not using ammoniated cleaner? The results are very satisfying. I haven't tried using ultrasonic with L&R 566 but before I had hard time getting all the gunk off pinion leaves. Now they come up all clean and shiny with no precleaning.1 point

-

I second the watch paper. Frankly though, once I do the rinse in the IPA, I have found they dry very fast even without a food dehydrator or anything. The IPA just evaporates very fast I have found.1 point

-

1 point