Leaderboard

Popular Content

Showing content with the highest reputation on 09/19/22 in Posts

-

I worked through this refinishing issue and decided to post my solution for forum readers who may end up in this situation. During a routine watch service, I noticed a little surface oxidation on a pocket watch spring. It wasn't a lot, so I tried removing with a glass fiber brush. That removed some of the rust, not all, so I decided to go further. Then after some light work on a coarse diamond plate, the rust was gone, but it left a reflective, polished looked instead of the dull finish originally that all the other steel parts under the dial had. The two pictures below show how the spring looked after rust removal next to a part (yoke) with finish I was trying to match. It looked almost passable from one angle but from another (direct on top) not very close. I hadn't come across the situation before. Typically when I refinish steel it is to mirror finish. Never tried to match a dull or grey finish. First guess was that it would naturally dull over time and I shouldn't bother but after some thought I came to the opposite conclusion. I did a test to see if I could dull the metal to at least get something with less luster. Having some experince removing rust from old tools with vinegar, I knew that it changes the appearance- usually darkening steel. I decided to try it so placed the part in white vinegar. Perhaps a short soak would dull but not darken the metal? A few minutes gave the grey that I was looking for. The after photo is below. Looks pretty darn close to my eyes.6 points

-

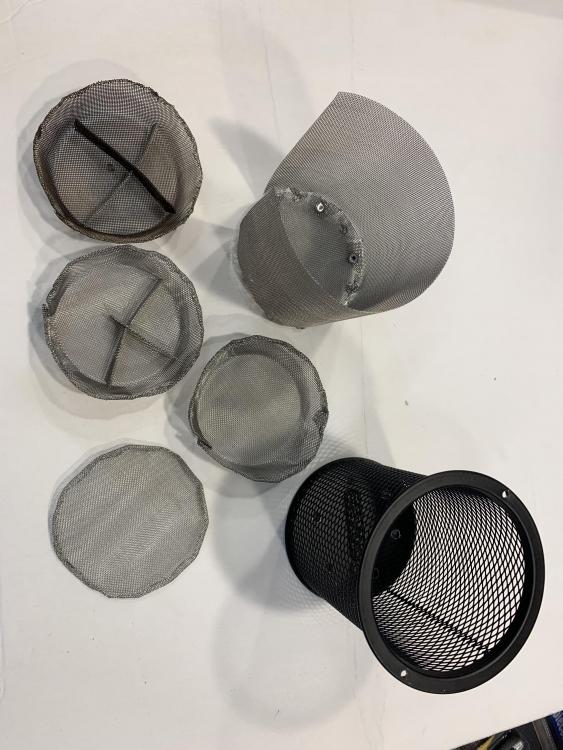

Hi all - here are some photos and description of my v1 diy watch cleaning machine. It is made of bits and bobs from the garage, dollar store, and amazon. I should first note that after much googling, what I made was directly inspired by a thread on reddit I came across by chance - here - https://www.reddit.com/r/watchrepair/comments/vk00i1/a_simple_watch_cleaning_machine/ Prices included below are in Canadian dollars. The frame of the machine is a lab support stand from Amazon. I was lucky to get this from warehouse deals for $18.89. Regular price is around $50, so a bit pricey. On the bottom of the stand I laser cut a holder from dollar store MDF (I think they call it 'craft board' to fit the jars I also got from the dollar store. I was hoping to use mason jars for the height and the nice sealing lids, as in the reddit thread, but the nice parts basket he used there was too expensive for me to order in Canada. I instead used wide mouth jars from the dollar store, I think they were $2.50 each. To load the parts, I have a pencil holder from the dollar store (~$1.50?) into which I have a bunch of pieces of stainless steel mesh ($20, amazon, for 5 sheets). I do not understand why formed products are so expensive (eg. the real baskets for watch cleaning machines). I cut a hole with a hole saw in a piece of wood and forced the mesh through with the cutout to make the rough 'baskets'. Not the nicest, but what I have at the moment for v1. Continued below as I think I can only attach 4 photos. Starting off here with the amazon stainless steel mesh product and the wood used to form the baskets. Some cut up pieces folded over inside to make compartments. I tried to solder these in place but that was a failure. So at the moment they are just set in there, and do move around. I think I will end up ordering some of those tiny little mesh baskets with lids - I have seen them for a reasonable price on etsy, of all places. Also I saw the parts basket used in the reddit thread on etsy for a more reasonable price as well, so may order to give it a try. The lab stand came with the clamp and gripper. In the gripper I have squeezed a 12v dc motor. Amazon, $15. It is 200 RPM. You can get these for extremely cheap on aliexpress, but I didn't want to wait for the shipping. I have subsequently ordered/received a 500 rpm motor from aliexpress - my thought was to use a potentiometer to slow it down, but have the extra speed to spin between wash/rinse/rinse. I think that the 200rpm is nice for cleaning but it doesn't do a good enough job with centrifugal force to get the first cleaner out, puts soap into my 1st rinse. Maybe my DIY solution just isn't the best. I have a flexible coupling, 4mm (on the motor side) to 5mm (approx diameter of the bolt I am using, I did have to add a bit of tape) to connect things up. At the bottom of the bolt there is a piece of aluminum, drilled so I can screw the pencil holder on, once loaded. A bit of a pain, but not like I am doing it all of the time. In a future version if I get that nice basket I may use little spring clips to grab its handle. Couple more photos of my current attachment method. I should note that I lost two parts from the basket when cleaning. One was the click spring - was at the bottom of 1st cleaner jar. So tiny it slipped through even the fine stainless mesh. The other was a spacer that Raketa uses on their balance bridge - it fell into where the pencil holder mesh meets the bottom and it was only luck that I happened to see it in there, shining a light. Another reason to switch to those little baskets with lids, I think. To control the machine, I have a pre-built controller, same as the redditor used ($20, amazon. I think it would have been close to the same price from aliexpress). It has multiple modes, but the one I found useful is where you can set time for direction one, stop time, time for reverse direction, and how many times this repeats. I have this on a little box I lasered, the redditor is just running it out in the open. It is dual power supply - a nice barrel plug for 5V, or can take up to 24v. When the DC motor stops to change direction, it is very sudden. I would like to get a litlte circuit for slow start/stop, but haven't been able to find if these exist. I don't have the know-how to build myself, only to wire up something someone else has built. I like how the mastermatic is nice and easy when it changes direction. I think that is all the detail I can think to note at this time. Hope this helps someone or gives some ideas.5 points

-

Indeed, I had bought up all of the tea strainers from the local dollar stores, none worked out shape wise. Also tried drain catchers, before bending up the mesh sheet myself. Funnily enough, on aliexpress you can get tea balls for ultrasonic cleaner that are quite expensive - or the exact same product sold as tea balls for cents each.3 points

-

Hi i have a skeleton clock it appears to be cast brass and hand made, it seems to be quite old and the materials it is made from seem to be of good quality, however the workmanship is very poor, e.g the plates have not been finished properly in corners the crossing out of the wheels is bad and there are tool marks left on some of the components. Has anyone got any ideas on the age or maybe the reason for the poor workmanship.2 points

-

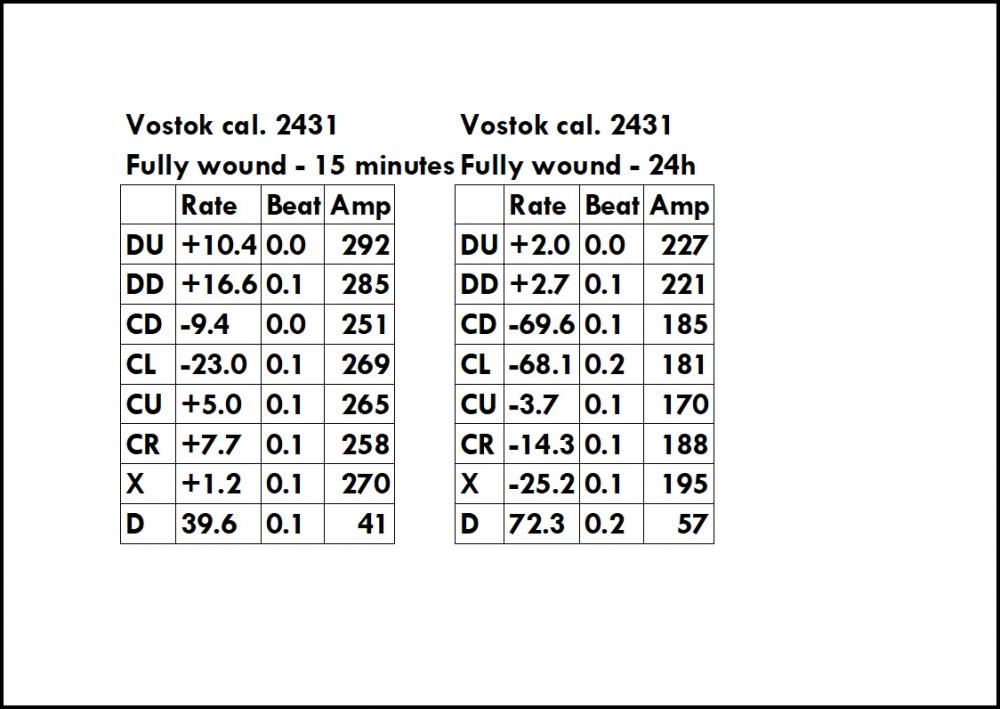

I find the wording interesting. Seeing as how I've done side-by-side comparison of the 1000 and the 1900 with my personal witschi watch expert two machine for the most part the Chinese machines do extremely well. So I have no problems people using these I always recommend them to everybody. So they're fine for timing. Although I really do get spoiled with the machine at work in no particular order of intelligence it be nice to have a picture of your watch on the timing machines I would like to see the graphical display of what it looks like not the necessarily go see anything but I am curious. you can see that there is a decrease in rates as all the amplitudes go down but not spectacular enough that you should do anything about it. I do find the amplitudes at 24 hours ago below 200 interesting. But unless we have a timing specification sheet for the watch that might be considered acceptable. then I think you are answering one of the questions I had which is if you didn't wear the watch for 24 hours and then went for walk it doesn't seem to be gaining as much. interesting about the Google translation. unfortunately I'm sure that adds to the confusion as translations are not always perfect especially in technical languages. Occasionally line now scour the Internet for other watch related stuff go to foreign-language words to try to find others discussions was looking at something related to timing machines that I don't remember the language but for some reason the word blood was scattered all through my translation and I'm still not sure how that related to a timing machine. So as good as it is it does have its issues but it does allow people to do things that they wouldn't normally be able to do like read other languages. Or people with dyslexia that can't write at least writing that you've never seen. I get set free with my dictation software but like Google translate it's not perfect. Doesn't make spelling mistakes but doesn't mean it's necessarily worded correctly and then when you add in the translation of things that aren't quite worded correctly it must be quite interesting. then yes I do go back through and try to edit things and fix the wrong words but it's time-consuming at some point time I just say the heck with it and send it. oh then there's the other problem I don't always give the answers I like people to explore their options small ask questions. What's the fun if I just gave you the answer although I don't actually have the answer to this question we still need more information. if you wind the watch all the way up until the mainspring should be slipping place it on the timing machine dial up or dial down that's your choice we don't need all the rest of the pendant positions are crown positions because I don't think that's a help you want to see it resting on the end of the pivots maximum amplitude wound up as tight as you can get it what is it show? Maybe even one is on the timing machine manually wind a little bit more can I go into the condition of Rebanking? Then just as a reminder for everyone else there is a video below that explains what that is. https://youtu.be/Rcqrb3_vin8 if you're standing for the timing machine with your watch on your wrist and you vigorously walk in place and move your arm back and forth and then very quickly put it on the timing machine what he we see? It's a shame we couldn't have a time recording of the watch on your wrist as to what the balance wheels doing. Then each day when you go for the walk does it gain the same amount of time or is different?2 points

-

@JohnR725 These numbers are from my Weishi 1900 cheap Chinese TM (X and D manually computed but double-checked, and gain setting adjusted to the best of my ability for optimal signal), and it's the watch that I've been talking about that momentarily can increase its average (extrapolated) rate to around 1400 s/d (fully wound + rotor installed) when swung in wide continuous pendulous motions over an extended period of time (+30 minutes or so), like when taking a brisk walk. Note that these rates are extrapolated, that is during the 30 minutes of walking it gains approx. 30 seconds. Once the walking is over the rate returns to the normal numbers as seen in the picture. Note that the rate increases more when fully or near fully wound (rotor installed) and less when fully wound minus approx. 10 hours (rotor removed), approx. 500 s/d. Hope you can make something out of it or raise some new questions! That goes for me too. I'm a thickie, not a pro, and not even an engineer. 55 years old (now 60) and in IT my entire adult life I had to begin by trying to figure out how screws and screwdrivers work. It's been quite a journey, to say the least. I really want to try to understand what everyone is trying to say. For example, John's sentences are sometimes a mystery to me but still immensely appreciated. I have the disadvantage of not having English as my native language, so I use Google translate more than you may think.2 points

-

2 points

-

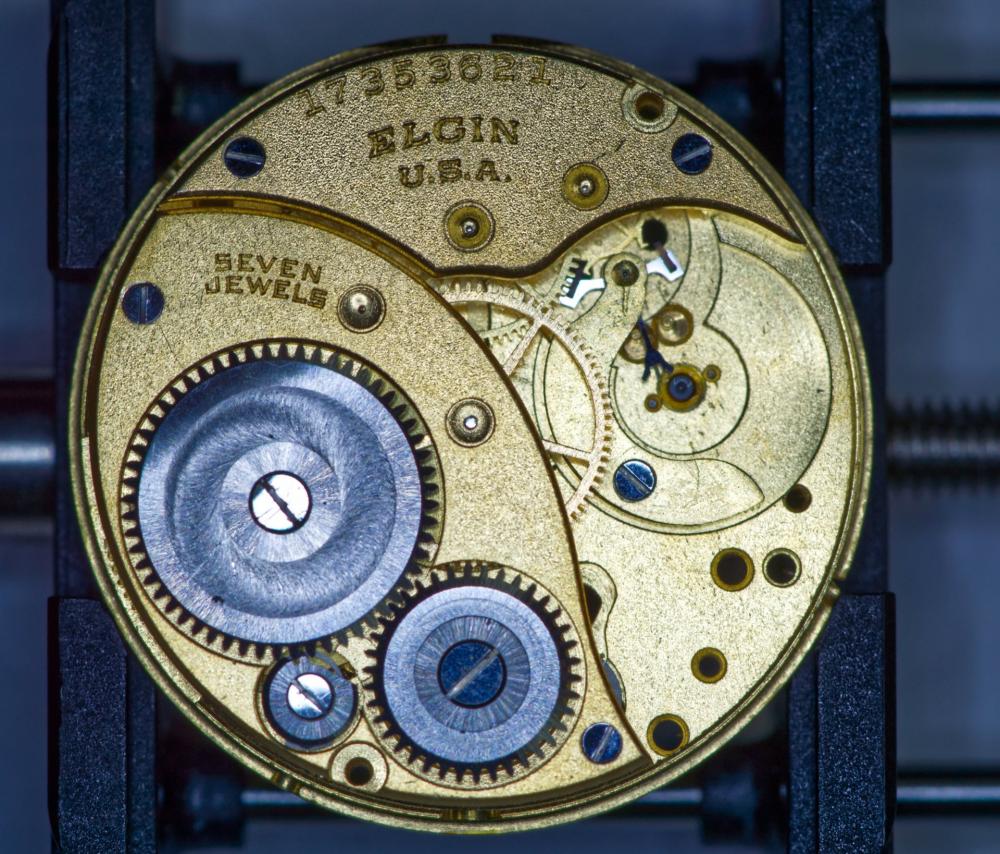

Hi all, Please find below some before/after photos of the 1st wrist watch that I serviced. After taking an online course I serviced two dollar pocket watches, then a swiss wrist watch before using this watch as my first try. I purchased this at the Aberfoyle Antique Market in Puslinch (outside Guelph), Ontario, not knowing much at the time. I knew that Birks was a Canadian jeweller, kind of like the Tiffany's of Canada. The crystal was spidered, assume watch was crushed down on at some point, but I had watched enough youtube videos at that point to know this could be replaced. Taking the watch apart and googling the movement, I was surprised to see that it was a Russian Raketa 2609ha movement inside. With further googling, I could not find any reference to Birks ever using a raketa movement. I know they often used eterna swiss movements. So, I am not sure if this is a true birks watch or if the dial was replaced and I have been 'had'. The dial itself was in pristine condition - unsure of the chances of the dial feet of a new dial matching up to the movement. In any case, it is a nice watch still, I thought. The case is gold coated, 10 microns. Lots of learning moments in working on this. At one point I thought I marked the dial slightly so I rubbed on it with rodico - learned it is a bad idea to do this on a matte dial. In the end result it is still hard to see unless looking from a specific angle with the light, but the area I rubbed is now shiny instead of matte. This movement had balance shock settings similar in shape to incabloc. There were also tiny springs on the escapement with cap stones. I managed to break both of these when trying to remove them. I also lost one balance spring that jumped away into the ether. The same happened with a capstone, I think from the escapement. I went a bit overboard and ordered parts movements through etsy from three sellers. One lot arrived from France within 4 days - I am still waiting on the other two. I will have enough 2609ha parts now to open my own store. The watch ran well before service - while reassembling I saw the escape wheel had both pivots broken - I thought I was careful but I guess this happened somewhere along the way. Parts movements to the rescue again. I may eventually change the band - this is the one that came with it and it is not too bad, I think. Changing the crystal was also a learning experience. I ordered the size I measured for and one size up, as I learned online. I have a cheap crystal lift from amazon. It is useless and will not grip anything - tried on 4 different watches. To install the new crystal I made some little wood domes to fit my chinese back/crystal press. Not knowing how much pressure to use to bend the crystal diameter smaller, and also trying to force the larger crystal in, as I was sure it was the larger 31.1mm crystal that would fit, I snapped it in two. The smaller 30.8mm ended up being the winner so I was glad that I purchased both at the same time. I also got a feel for the pressure required, not as much as I thought. Most of my kit has been purchased cheaply from aliexpress and amazon. I was hoping for a robur-style press for the crystal but the chinese have not copied this yet, hence my workaround above. I was hung up on having the proper equipment for cleaning. I have a cheap ultrasonic cleaner but really wanted a 'spinner' watch cleaner. Vintage was still out of my price range as I did not want to spend so much without knowing I would stick with the hobby. I found inspiration on reddit for a diy watch cleaning machine and built one using a timer/direction controller, small dc motor and various jars and misc from the dollar store and a lab equipment stand. My cleaner was also diy based on the SDS for L&R solutions. All in all, I am very pleased how this came out, for my first watch. My next project will be building a watch from parts using the eta6498 clone, Seagull ST3621.2 points

-

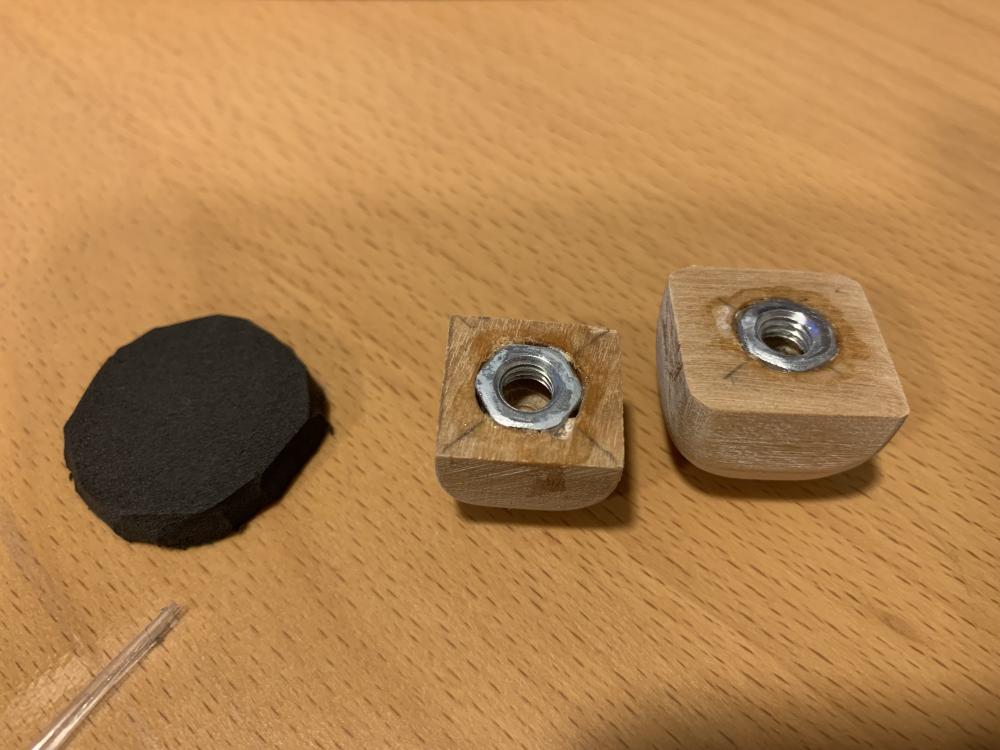

I actually did this a few days ago to put my 1st acrylic dome in. I have one of the cheap lever style chinese presses. I sanded down some scrap wood, put an M6 nut into the back and just used some super glue to hold it in. I put a small piece of foam over the dome when pushing on the crystal. Without the foam, I broke a crystal, but I chalked that up to also being too large and being the 1st time I have tried this, was using way too much pressure to make the larger size fit. The smaller size down is the one that ended up fitting.2 points

-

Introduction This service walkthrough is not a tutorial on how to service a watch movement. I made it for myself because I think it's fun and because it will make it easier the next time I service a Vostok 2431. I also think it feels nice to be able to share this walkthrough considering all the valuable information that many very talented members on WRT freely share. Many, many thanks! There is a lot to learn when servicing a watch movement that is not covered in this walkthrough. Therefore, I recommend, for example, watchfix.com, learnwatchmaking.com, or timezonewatchschool.com. I feel like I got the most bang for my buck at watchfix.com (I'm not sponsored in any way) but I've also had a lot of fun and benefited from the other online schools. Links to photos on my OneDrive Vostok calibre 2431 disassembly walkthrough. Please sort the images by name in ascending order. Vostok calibre 2431 assembly walkthrough. Please sort the images by name in ascending order. Curiosities I think it was in 2014 or possibly 2015 that I bought my Sturmanskie Open Space. I had just discovered that there were watches where the hour hand only rotates one revolution per day and at that time I knew absolutely nothing about watch movements, service and repair. The idea that the hour hand of a watch only rotates one revolution per day seemed not only completely logical but also different and fascinating. The earth rotates one revolution around its axis per day, so it should be obvious that the hour hands of our watches do so too. The fact that the letters on the watch were also Cyrillic did not make the whole thing any less exciting. I just couldn’t resist it and I’m happy I didn’t! Vostok claims that their movements only need a service every 10 years, and I think that's true because the tolerances are pretty rough and therefore large amounts of dirt are needed to stop a Russian movement or even cause it to run badly. It has been said that the amount of dirt required to stop a Vostok movement is enough to stop a hundred Patek Philippe movements However, the price for this endurance is a movement that doesn't come close to the precision offered by high-quality Swiss and Japanese movements, but it's still quite easy to get these Russian movements to run accurately as long as they're worn and used consistently. About the movement Russian watch brands such as Vostok, Raketa, and Poljot, to name a few, are known for using their in-house movements, but not this Sturmanskie which is instead powered by a Vostok calibre 2431, which is a 24-hour movement. However, it is not a true 24-hour movement. That is, the movement is not originally designed as a 24-hour movement. Instead, Vostok has modified the movement in its calibre 2416B so that the hour hand only rotates one revolution per day. Calibre 2431 is otherwise identical to Vostok automatic calibres 2416B and 2415. The motion work(/dial train) in Vostok 2431 The way that Vostok modified the movement so that the hour hand only rotates one revolution per day is by modifying a) the minute wheel, b) the bearing for the minute wheel in the main plate, and c), adding an intermediate date indicator wheel. The minute wheel has been modified so that it has two pinions that lie on top of each other. The lower pinion drives what I call the first intermediate date indicator wheel while the upper pinion drives the hour wheel and has been adjusted so that the hour wheel only rotates one revolution per day. The number of teeth on the hour wheel itself may have also been adapted, but this is not something that I have investigated. Normally the minute wheel is mounted on a regular metal post on the main plate, but in this case, Vostok has replaced the post with a beefy, jewelled bearing. I assume that this has been necessary to get the minute wheel, with its two pinions on top of each other, to rotate sufficiently smoothly and stably. The added first intermediate date indicator wheel drives the second intermediate date indicator wheel which is part of Vostok's regular (non-modified) calendar complication. And this is what it looks like with the hour wheel mounted. Cleaning I have found that it is all too easy to underestimate the importance of cleanliness when servicing a movement, perhaps because the parts are microscopic and therefore it takes time to get used to thinking microscopically, even though I have been doing this now for five years. Cleaning of pinions and pivots A type of watch movement part that is particularly important but also difficult to get completely clean is pinions, but @nickelsilver advised me quite recently that in its pre-cleaning you can dip and rub the pinions in pith wood that you have impregnated with an effective degreasing agent, for example, Horosolv. I've done it several times now and it works amazingly well. Speaking of pinions, independent American watchmaker Josh Shapiro mentioned in a podcast that he considered pinions to be the most difficult part of a watch movement to make perfectly. Whether it's true or not I don't know but I think it's likely. To get the pivots clinically clean, I have also started using EVEFLEX, but you have to be careful because the material has an abrasive effect. It is important to choose the right polisher and to be careful. I have summarized my experiences with EVEFLEX in this post and I mention it because EVEFLEX is easy and quick to work with and gives me very good results. End-shake If there's one thing I've learned this time around, it is that a Russian movement cannot be converted to a Swiss movement because the tolerances in Russian movements are generally much coarser. Experimentally, I adjusted the end-shake to 2/100mm on everything from the pallet fork to the centre wheel, with the result that the amplitude and rate became extremely erratic. I created a thread about this: "Can end-shake and or side-shake ever be too small?" As you will see if you follow the thread, once again @nickelsilver, @Shane, and @JohnR725came to my rescue. Many thanks! My recommendation is to let the end-shake be slightly wider on Russian movements. After I increased the end-shake to approx. 4/100 mm, the amplitude and rate returned to typical, i.e., still somewhat irregular but perfectly normal for a Russian movement. Side-shake In this video, Kalle Slaap from Chronoglide shows an amazingly simple and effective way to determine if the side shake is correct. Since there was a crack in the third wheel jewel in the train wheel bridge, I replaced it, and when I then used Kalle Slaap's method, I could clearly see the 3rd wheel pivot jumping back and forth in the jewel hole. So, I replaced the jewel with a hole that was 1/100mm smaller and the visual difference, just changing it by 1/100 mm, was nothing less than dramatic. I am incredibly happy that I got to learn this simple and exceptionally clear method. Many thanks to Kalle Slaap at Chronoglide! Vostok reverser wheels If you Google “Vostok reverser wheels”, there is a lot of whining going on. I don't think there are any major problems with Vostok's reverser wheels, but they are unfortunately easy to damage during service or modification of the movement, and I think that is the real reason for the whining. Next to Seiko watches, Vostok watches are immensely popular to modify in terms of dials and hands, and in addition, many people want to fix the seconds hand that sometimes stutters on these movements. The latter is done by bending the second-hand pinion spring illustrated in this thread. To make these modifications, the oscillating weight/rotor must be removed and when it is to be screwed back on, it is easy for the rotor pinion to end up on top of the teeth of the reverser wheels. If you tighten the rotor screw in that position, even just a little, the reverser wheels will inevitably be damaged. The result is that the automatic winding stops working or only works intermittently. An easy way to check if the reverser wheels are working as they should is to manually rotate the oscillating weight alternately about 20 degrees in both directions with a piece of peg wood while looking at the 1st reduction wheel which is large and easy to see. If the 1st reduction wheel continuously rotates in the same direction (counterclockwise, if I remember correctly), no matter which way you rotate the oscillating weight, you can be sure that the reverser wheels are working as they should. If, on the other hand, the 1st reduction wheel rotates alternately in both directions when you rotate the oscillating weight alternately, then you can be sure that the reverser wheels are damaged and need to be replaced. Servicing the automatic mainspring I find it difficult to service the mainspring on automatic movements. It is, in my opinion, a construction that leaves room for improvement and that is why I generally prefer manually wound movements. If the mainspring in an automatic movement slips too soon, it reduces the amplitude and the power reserve, and if the mainspring slips too late, there is the risk of re-banking and that the movement runs much too fast when you are physically active, especially when you take a brisk walk swinging your arms, and the oscillating weight rotates constantly. The effect is like continuously turning the crown of a manual movement with high pressure when the mainspring is already fully wound. Not good! What I learned this time anyway, long story short is that you can be quite generous with braking grease on the rim on the inside of the mainspring barrel. Even if some of the braking grease ends up where it really shouldn't be, I don't think it will destroy or affect anything negatively. Also, and again from Kalle Slaap at Chronoglide, I learned that you should press at the end of the spring at the bridle when it is mounted in a spacer, and you are about to push it into the mainspring barrel. In this way, the rest of the spring automatically follows down into the mainspring barrel. You can see it in this clip. Very smooth, especially in combination with my highly rated Master Craft mainspring winder which I wrote about in this post. Lubrication of cap jewels For a long time, I have had trouble getting the oil to stay in the centre of the cap jewels and not flow out after I oiled them and installed them, despite treating them with epilame (Fixodrop). I think it's because (and now I'm going by gut feeling) that I previously always installed the shock assembly in the main plate before installing the balance and that I didn't treat the jewel housing (chaton) with epilame. After several failures in servicing this movement, I decided to treat both the cap jewels and jewel housings with epilame and mount the shock assembly after having replaced the balance. It did the trick and also made fitting the three-legged anti-shock spring much easier. My theory is that the balance staff pivots stabilize the oil in the centre of the cap jewels when the jewel housing (chaton) is dropped into place, and better hold the jewel housing in place, which will otherwise slide around while installing the three-legged anti-shock springs. Have I just written the longest post in the history of WRT? Anyway, hope you enjoyed it!1 point

-

Today has marked the end of an era. The long and fulfilled life and reign of our Queen Elizabeth II. All of the UK and everywhere salute you ❤.1 point

-

The rest of the world can say what they like about us British, but no-one can top us when it comes to Royal Weddings and State Funerals. We are still the greatest when it comes to pomp. A great send off for a great Queen who dedicated most of her life to her country. She will be a hard act for King Charles to follow even if it will be only for a comparative short time compared to his mother.1 point

-

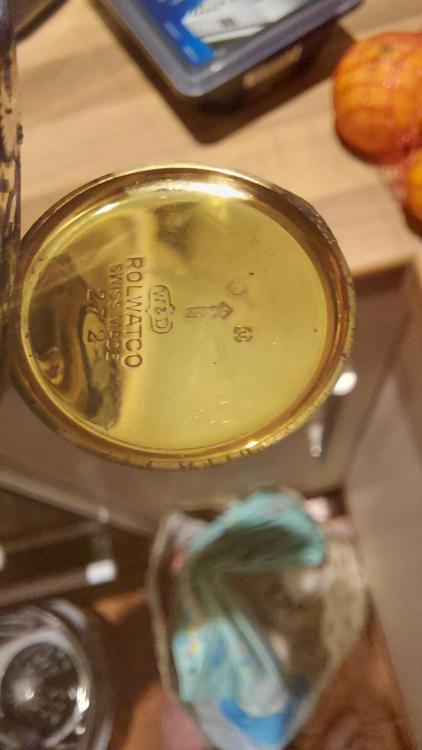

hello, not been here for a while, hope you're all well. I picked this up and wondered what you think of it? I've been able to find out that it was manufactured between 1922 and 1925 as that what when rolwatco was in existence. I know nothing more and can't find any info on rolwatco anywhere. It is a very simple but beautifully proportioned and if the date is correct, carries a relatively modern aesthetic. If anyone can fill me in I'd be very grateful. Frankie1 point

-

Of course, Rolwatco is short for Rolex Watch Company ! If you look here, you will see the same movement : https://www.worthpoint.com/worthopedia/1922-ladies-d-rolwatco-rolex-9ct-5156935221 point

-

Haha. No mate you are definitely not a thickie. Looking at the consistency of your timing and amplitude rates here you do amazing work on your servicing and repairing considering you come from a non tool use background.1 point

-

if I look at your picture it looks to me like to escape wheel is way too far down because the upper pivot is visible. It should be farther up in the jewel. if you did a escape wheel end shake testing in other words you attempted to move your escape wheel up and down I have a suspicion you going to find it has a heck of a lot of play. unfortunately to get a proper assessment you're going to have to take the watch a part. then you can look up the lower jewel properly and see if it looks like it's been knocked out of alignment. then an unfortunate problem of watch repair is the initial investment in tools and things is relatively inexpensive. But you do end up needing special the tools conceivably an infinite quantity of them that none of us can afford. So yes they do make tools to relocate the jewel if it's just been pushed down and it's not broken or something else.1 point

-

Unfortunately…. Nothing I found two movements for parts that look pretty much the same. I ordered them, and I hope that one of the second hands will fit…1 point

-

Hi Graham. I've decided to come back. Not unlike the Terminator. Upon reflection and some sleep i feel my quote and point making here may have been a little clouded through humor and attitude ( i do have rather more of both than the average person ). Everyone opinions ideas and thoughts are valid here, i always say this. Everyone gets something from everyone elses input. Some more than others, as we all sit in our own little niche of knowledge and intelligence. Its pretty clear that you are a very clever guy and like to delve deep into any subject you find of interest. The point I'm making I'm sure you have already worked out. A few hints here and there from a few of us will have helped you along. Your input is just as important as everyone else's so please dont take this the wrong way as it is by no means meant as any insult. I'm not the sort of person that beats about the bush, i never have been, i have absolutely no filter and say things as i see them and exactly as my brain processes them. So if you would be so kind matey can you possibly # dumb it down for some of us thickies # cheers. No offence meant to any of us thickies lol .1 point

-

Been exactly there myself. Trying to find smart ways to avoid getting more and more tools seems to be one of the biggest challenges Patience, and more patience, sometimes for years is sometimes required to find the right tool at the right price. Like my Mastercraft mainspring winder.1 point

-

for a whole variety of reasons were not going into their will always be conflicts in lubrication. enough conflict I will give you an answer but it may conflict with how I actually do things but I will give you the standard answer which should fit with just about everybody possibly. For fast-moving pivots the recommendation is a light oil. fast-moving pivots of the balance wheel and escape wheel. A light oil would be 9010. The rest of the gear train something heavier unfortunately HP 1300 is considered very heavy but it's a heavy oil the pallet fork needs its pivots dry no oil as they have to move very fast. The pallet stones they get the 9415 but not too much. There's a variety ways of doing this but the 9415 has to be evenly distributed across the entire escape wheel just not too heavy. Then your wording of pallet pins pivots? If that's the pivots and you are using 9415 there that would definitely be an issue as that's definitely not where you want to put the lubrication. in other words if you want to lose a lack of a lot of amplitude lubricate the pallet fork pivots with something really heavy that would be considered very bad. I have a link you'll notice a variety of PDFs possibly more than one may be of interest to you but for right now get number 40 https://www.cousinsuk.com/document/search?SearchString=working then you can get some additional conflicts in lubrication. I don't use all the recommendations of what they say and I don't use unnecessarily where they say but the document still has some really good information. Notice the trend on gear train lubrication you start off light and then you go heavier. but basically some general good information on how to lubricate where how much six a group there's some truth to this but? One of the reasons there are so much controversy with lubrication is for the most part you don't see spectacular failures. Because if people saw spectacular failures they would grasp that they shouldn't do this. So you get by with a lot of just about anything and the watch will run. of course whether the watch is going to run and run well for several years that unfortunately will take several years to discover sometime soon. there is one location of the watch where doing things extremely wrong will have a very visual effect on the amplitude. That is absolutely totally wrong lubrication on the escapement something is way too heavy or way too sticky. I'm reasonably sure somewhere on this group are somewhere else somebody had an issue because they used Molykote DX on their escapement's. You'll notice it's mentioned in the Omega document it's not used on escapement. this is always a hard one for newbies to see if there hairspring is even close to being perfect. In other words it's supposed to be flat and it's not supposed to touch the balance arms. But it can be extremely close to the balance arms as long as it doesn't touch and that is really hard to see. So unfortunately a lot of things can cause poor performance of the timing machine1 point

-

1 point

-

1 point

-

No rush matey but here it is . https://www.watchrepairtalk.com/topic/24066-diy-rotary-cleaning-machine/?do=getLastComment1 point

-

your hairspring does look like it desperately needs help. If you believe the book I have on fixing hairsprings the cone shaped isn't that hard to fix the rest of it would be depends on how much practice you have somebody that's really good could probably fix all of this. oh one of the problems with a book like this is the person who's doing all of this is extremely good as this means if you haven't been practicing on hairsprings and practicing means practicing learning how to fix them not practicing on how to destroy them then your success will vary by quite a bit then no it is not going to work at all. The easy way to find that out is after replace the balance staff put it in the watch and see what happens it should become apparent really fast it is not going to work at all.1 point

-

Evening all. Wanted to introduce myself. Only recently have gotten into this amazing hobby. I credit Marshall at wristwatch revival and Mike at my retro watches for this new obsession. Had a couple of their videos pop up on my feed and decided to see what their videos were. Ive restored cars( thus the name), small engines, ATVs and motorcycles. If its mechanical ive probably tinkered with it. After watching several of these fellas videos I thought I bet I could do that. The scale of the hobby really intrigued me. Bought a couple old seikos on ebay and started learning. This progressed to a restoration of a pogue then a ufo then a diver and now working on a helmet. Ive fallen for the quirky designs of the 70s seikos and im sure ill have tons of questions as I get deeper and deeper into the hobby. Cheers Chevy1 point

-

now a minor confusion flat hairspring versus over coil? I've attached an image over coil as tight as possible but the hairspring still has to slide when you move the regulator. Flat hairspring has to have a little bit of breathing room. This is why people who aren't familiar with over coil hairsprings may not notice that the regulator pin spacing that looks fine for a flat hairspring would be unacceptable for an over coil. Then the only way you can tell if you're centered is with no power. That will become obvious with some imagination and an example. For the example let's imagine that we have a watch with the etachron system. I'm assuming that were all familiar with that if not I can attach an image. The reason why for my imaginary example is this would work really perfect for demonstrating the regulator pin spacing without doing any permanent damage of trying to move the regulator pins which don't normally like to be moved dramatically. normally with this system you would with no power open the regulator pins up verify the hairspring is centered if not rotate the stud until it centered then you would close the pins but. this is where were not going to close them and you're going to have to use your imagination of how this is all working. Plus need to look at the chart below which was up above and pretend the pins are much much farther apart because it's going to dramatically change things. okay now with our imaginary watch with the regulator pins really far apart you barely wind the watch the balance wheel barely rotates and regulation will be at the stud in other words the watch will be really slow. Exactly what it shows on the chart below. Now if you very very slowly wound the watch up amplitude will slowly pick up. As the balance wheels oscillating the hairspring is opening and closing at some point in time much higher amplitude what the chart shows because the pins are much farther apart in this example they hairspring will just start to touch the pins. When that happens the regulation point will move away from the stud it will start to move towards the regulator in other words the watch will start to run faster. Now as the amplitude picks up they hairspring is going to spend more time touching the regulator pins as it does that the regulation point on the hairspring will move closer and closer to the pins. At some point in time it should stabilize like the chart shows below because it's spending so much time touching the pins with very little time in between. so this possibly confusing example shows that the regulation point with no regulator pins or pins are properly spaced apart other than over coil would be at the stud if they hairspring touches the regulator pins that more it touches them the more closely the regulation point becomes the pins themselves. This depends upon how much contact time they have greater amplitude the watch would run faster if they're far apart. If their space like the chart shows barely any spacing then like the chart shows it's much more defined. so hopefully this weird example makes sense. As I said on a pocket watch with the over coil hairspring pins too far apart especially if the watch isn't running well then you do see some dramatic timekeeping issues. As the amplitude goes down the timekeeping slows down because you're not touching the pins enough.1 point

-

I use a large oiler that was made from a small piece of aluminum rod with the end flattened. Delivers about a "drop" into the oil cups without minimal loss. Easy to clean up and maintain.1 point

-

Eyup Graham. How you doin ?. As regards to my understanding of isochronism, I was initially suggesting the force that was intended to make the movement tick. Ie. Energy released from the mainspring that travels through the train that reaches the balance wheel. But any exterior force such as magnetism, electrical ? Or a G force can act upon the balance wheel's mass to alter its swing so changing the movement's own amplitude for which it was designed. In which case i am thinking that the isochronism that was created for the movement is now out of the window. Which is maybe why Watchie is experiencing non isochronism rates .1 point

-

Hello @jdm Your post reminded me of a really fascinating talk given by Romain Gauthier at the New York Horological Society. Have you seen it? It's really fascinating. It's axiomatic precept is that the power reserve must be consistently released (Mr. Gauthier calls it "constant force"), or time accuracy of the device cannot be assured. Here's a link. Do have a look if you've not already. I thought it was great. I recently ca1 point

-

I blame Marshall at Wristwatch Revival, Mike at My Retro Watches, and Theon at Vintage Watch Services for getting me interested in the hobby. Once I found Mark's channel and courses, I was completely hooked. Excess funds are rapidly shrinking, but I've got a bunch of really interesting tools now! Such an enjoyable hobby to become involved with, and I find it encouraging to see so much support and advice within the community. Welcome to the hobby and to the forum. I'm a fan of the 70's Seiko's as well. I apologize for any past or future bidding wars on vintage Seiko's on eBay! Another excellent channel that really specializes in Seiko's is Spencer Klein. His videos are a bit different, as he sort of goes off rambling about non-watch things during his work, but it's entertaining to watch nonetheless. He seems to be an encyclopedia of Seiko information. He doesn't solely work on Seiko's, but they are definitely his specialty. Apparently he runs a business that specializes in restoring them. It's worth a look if you haven't found him on YouTube already. Here's my first three completed Seiko's as well. Seems that we're on a similar path.1 point

-

I remember @nickelsilver mentioning that the risk of denting very small pivots (<= 0.12mm, if I remember correctly) is imminent with a micrometre, so I always use my Seitz jewel gauge.1 point

-

1 point

-

SUCCESS!! I managed to separate the ratchet screw from the barrel arbor. I ended up soaking the subassembly in CocaCola overnight and with a couple of taps on my staking set with a punch collinear with the screw axis, it loosened up the crude holding it together. LH thread. I'm going to mark that screw head with three lines to indicate to whoever takes it apart in the future that its a lefty. Thanks for the tips y'all !!1 point

-

1 point