-

Recently Browsing

- No registered users viewing this page.

-

Topics

-

Posts

-

Yes they all used to chop marks but this guy was so over the top and passionate about it that it still stands out in my memory so vividly.

-

By RichardHarris123 · Posted

On a different post we were discussing units of measurements. Not wanting to highjack the post, I thought we could discuss here. What is the origin of Dennison's. @Waggyonly one lecturer insisting on units of measurement, all mine did. -

I used to have a lecturer during my Engineering classes who was always beating a drum about quoting units, I remember one day he was so exasperated with our class he said "quote your units!!!!...I don't care what units JUST QUOTE THEM!!!" My next assignment I calculated the velocity and quoted the units, something along the lines of: "Thus the velocity of the body will be 0.00345 furlongs per fortnight" He graded my work as an F, then crossed it out and gave me an A+, turns out he had a sense of humor after all.

-

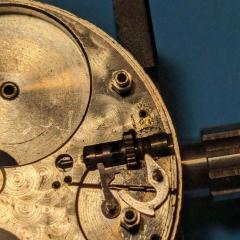

Just to add to what @Neverenoughwatches says, the impulse jewel on the balance wheel is also held in by shellac, so avoid exposing the assembly to IPA as well - as stated the one-dip and generic tetrachloroethylene equivalent is safe with shellac so you can use this for your pallet fork and balance assembly. I agree, but worth noting that IPA readily soaks up water, even from the atmosphere: "IPA exposed to the air will absorb moisture rapidly until it reaches an equilibrium value of 65% IPA to 35% water." So you need to refresh it regularly.

-

By Neverenoughwatches · Posted

The width is otherwise known as mainspring height and strength as thickness for us more modern guys.

-

Recommended Posts

Join the conversation

You can post now and register later. If you have an account, sign in now to post with your account.

Note: Your post will require moderator approval before it will be visible.