-

Recently Browsing

- No registered users viewing this page.

-

Topics

-

Posts

-

So that is what the last person to work on this movement appears to have done. There was a "wad" of adhesive material in the vicinity of that hole when I took the dial off. I was hoping to take the high road and fix the issue in the work I did on this movement. I wasn't sure if I was imagining things or not when I looked at the screw hole, but it does appear to be somewhat distended. I had not considered the posibility that someone had forced a screw that too big in there. I had wondered about using a technique I've applied in other applications (where the screws are in the same scale as human hands) that involves counter drilling the plug with a reverse threaded tap. When I've had to do that in the past, the screw has generally caught and backed out from the torque on the tap (instead of yielding and letting the tap bore into it.) I don't like doing that, but it's saved my rear a couple of times, but the smallest bolt I've tried that on had a 5 mm head. This is an entirely different ball of wax. I am still contemplating disolving the screw with alum, even if that means I have to stick the dial down with double sided tape until I gain the skills to actually replace the screw.

-

Hi Thomas, you should be able to find the right (or on close to beeing) in a Ronda or DCN balance staff catalogue. Cousins uk have those available as a download.

-

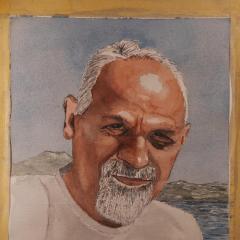

Hello everyone. My name is Cees (pronounced "case"). I have been working on watches for a few years now. Got down the rabbit hole when I started watching "how to" videos on watch repair when my watch broke while on holiday. I'm not interested in collecting watches, but purely in the technical side. I love fixing them and also love collecting the tools I need (or might possibly need one day...).

-

By nevenbekriev · Posted

The movement is FHF, something like this. But it will not help much to find stem. Sometimes making one is easier -

I think they all have their pros and cons, the one I suggested is a threadlock loctite product (Loctite is now owned by Henkel), In general I use the current one that is recommended on their Loctite page (link here) I use blue (243) for the actual crown the (stick is actually 248 which is the stick version of 243), like I said it is very convenient for using on stems. Blue holds the crown for everyday use, but can be removed if you need to with a little heat. I use the red 277 for things like stem extensions where I have no intention of ever removing it. The purple I don't use (but I have seen some youtubers use it) as I think the blue is removable so why take the risk on a weaker product. This is interesting, and a useful bit of information to know 🙂

-

Recommended Posts

Join the conversation

You can post now and register later. If you have an account, sign in now to post with your account.

Note: Your post will require moderator approval before it will be visible.