Search the Community

Showing results for 'accutron' in topics.

-

HI. Does anyone know how to remove the coil coating on an accutron? I tried leaving it in pure acertone for a whole day: the coating softens but does not melt. Thank you

-

Bulova Accutron 2181 Repair

HectorLooi replied to bobtheterrible's topic in Your Walkthroughs and Techniques

Unfortunately I don't. He was using a Chinese industrial digital microscope. The software was entirely in Chinese. And my Chinese has regressed to nursery school level. I'm am working on that and keeping the technique I've developed to myself for the moment. And as @nickelsilver mentioned in another post, the 218/219 is much easier to phase to a silver oxide battery than the 214. But unfortunately, the Accutron collector community has a preference for the 214, as evident in the prices on eBay. -

Bulova Accutron 2181 Repair

bobtheterrible replied to bobtheterrible's topic in Your Walkthroughs and Techniques

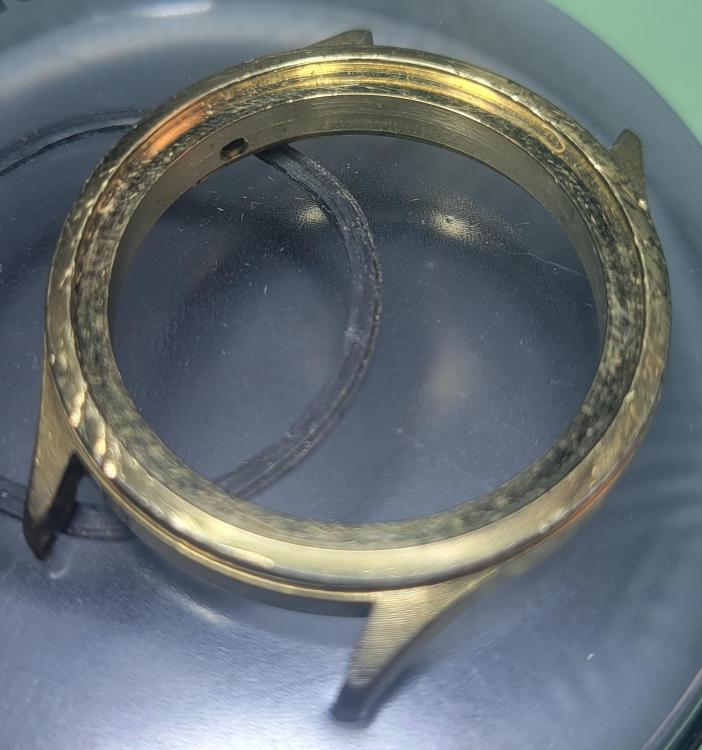

That is a very interesting idea - do you remember what sort of frame rates the camera was using to achieve aliasing? My question from this is; what do you do if the index finger travel is out of specification? Is there anything to do or are you looking at replacing the fork? In the end, my watch was about 7 seconds out before weight adjustments. Im pretty sure I did not "phase" this thing anywhere near correctly (thanks everyone for the discussion!) so perhaps I lucked out. I did buy a few more accutron projects before realising what I had taken on - I am both more and less confident I know what I am doing going forward now... My next project is to find a case for this movement I found in a lot of other movements. Again thanks everyone for the discussion. -

Bulova Accutron 2181 Repair

markr replied to bobtheterrible's topic in Your Walkthroughs and Techniques

Sounds like a Accutron service center to me. -

Bulova Accutron 2181 Repair

JohnR725 replied to bobtheterrible's topic in Your Walkthroughs and Techniques

It happens when the watches not say used correctly. We also get some minor discrepancies between the users mail instructions and the instructions there were taught if you took one of their classes. When the electric watches came out Elgin, Hamilton and the Bulova had training classes because electric watch was a newfangled thing that the watchmaker didn't understand. Bulova studied Hamilton's failure at education and enhanced their advertising and training they learned from the mistakes of others. The problem though with Bulova is the tuning fork is so much different than anything else it definitely would be a confusion problem so they would have a training class that you could take for the basic course was two days and then later on they threw in a quartz class so would be a half day so for 2 1/2 days you to take an extremely intense and yes everyone there said it was the most intense class that ever taken. The two day class to learn how to phase 214 watches. So I do remember that we crossed out some items in the book that they don't do and one of them is with one of the index fingers where I think it says half a tool thickness you basically just adjusted so it's off the index wheel's that's all it needs is basically a reference point where lifts off Now maybe another way to look at all of this is a PDF of some light reading. So there is one of the instructors who was teaching the class of oh and the Bulova class unlike others had a written test and a practical test for which a few past you got a certificate. Where a lot of training classes from watch companies you got a certificate that you attended the class but here if you past you had a certificate with a number. Taxi a very impressive certificate consists laminated to piece of wood it looks really impressive So it understand what's going on I have a PDF. 1996-08-web horological times Accutron silver cells phasing.pdf -

Bulova Accutron 2181 Repair

HectorLooi replied to bobtheterrible's topic in Your Walkthroughs and Techniques

I think all of us who have attempted servicing an Accutron are familiar with this phasing diagram. But all that assumes that the amplitude of the tuning fork is such that the index jewel travels a distance of between 1s and 2.5s over the entire useful voltage range of the battery. But what all the literature out there doesn't explain is how to make the index jewel travel between 1s and 2.5s. All they say is that there are some tuning forks out there that cannot be phased properly. There doesn't seem to be any test equipment out there that is capable of measuring the actual travel of the index jewel. I think it is important to be able measure this travel distance before even attempting to do phasing. It's like the amplitude of a conventional watch. If the amplitude is too low or too high, proper regulation cannot be achieved. I was at my mentor's workshop and we were playing around with his digital microscope and noticed that if the frame capture rate is adjusted, it can actually make the index jewel appear to move in slow motion. And the travel distance can be actually seen. If anyone out there is into high speed photography or stroboscopic photography, I hope this information is useful to you to develop a "timegrapher" for tuning fork watches. PS. I am tagging @LittleWatchShop here. If you are planning on developing an Accutron service centre, please read this. -

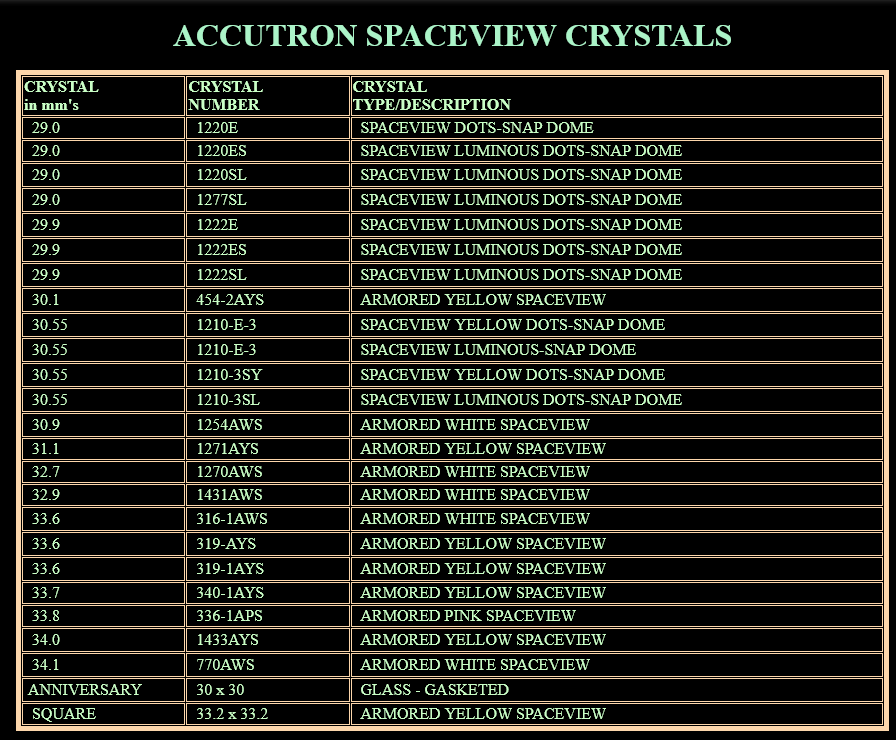

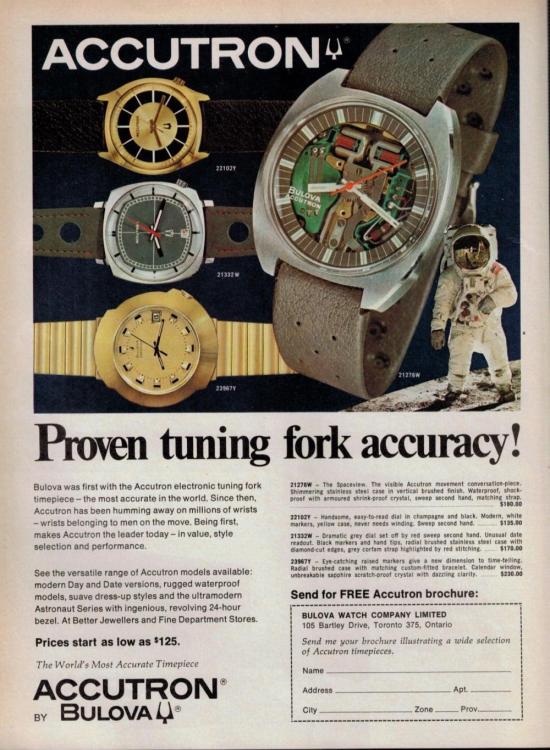

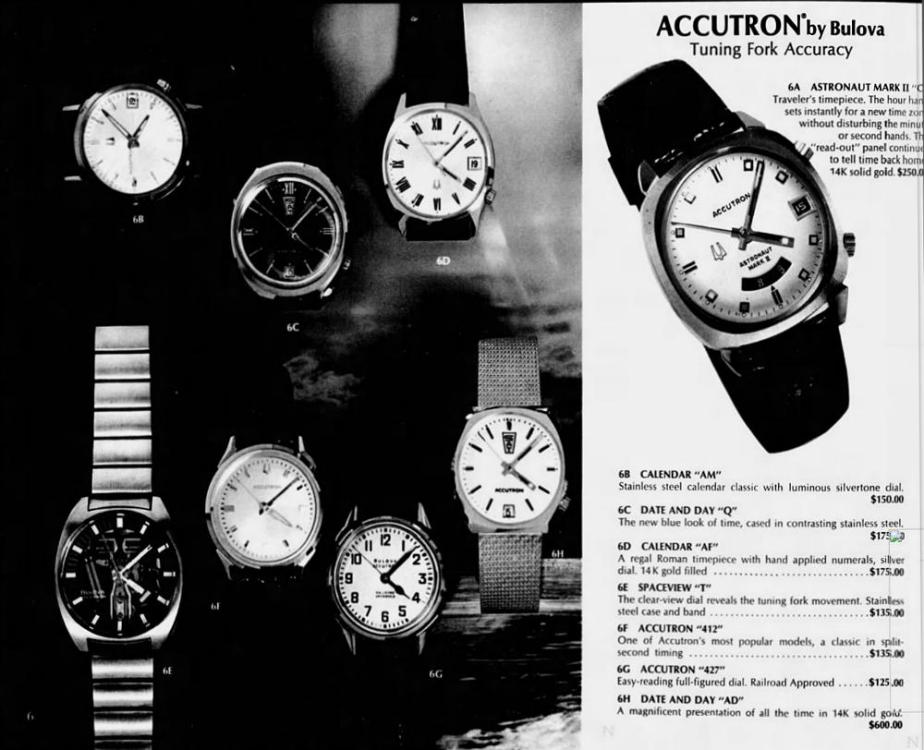

So I'm looking to get a replacement crystal for my 1971 Spaceview, case # 2531. According to Jules Borel, the replacement is Bulova part # 1271AYS. This is the crystal the watch came to me with: Searching around eBay and other suppliers, I'm finding variations for the same part number. Also, the logo looks green in a lot of the pictures. Is that because it's lume, or are some of them actually green from the factory? I would think that'd blend in with the green plastic behind it. Here are a few of the photos, all sold as 1271AYS. I would think the NOS one in the first picture is the definitive correct one, but it also has the green looking ink, so I figured I'd ask around. I also dug around on myBulova.com in the hopes of finding a catalog with pictures, but no luck. Sadly, it seems that accutron214.com has gone down, but I found the Wayback machine gives us access to a lot of great stuff. The two genuine Spaceview pictures they have show the Accutron tuning fork logo at 12 o'clock instead of 8. This ad from 1972 shows it without the tuning fork at all. Look at those prices, though! That's a lot of money in 2023 dollars. 1970, again without the fork. I know none of this is really important--it's my watch and I can do what I want--I just like knowing the history. Advertising puffery! 1969.

-

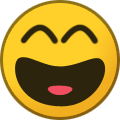

Started talking about this guy in the "what watch have you got coming in the mail" thread, and thought I'd add some more pictures and info here. Here's how it arrived to me: @JohnR725 noted that it's supposed to hack, but the mechanism is finicky and best left alone if I'm not doing a full service, which I'm not yet. It runs with a modern silver oxide battery as-is, so I'm going to run it a few days and see how she goes. I took a peek inside to make sure it had the correct hacking movement (214H), which it did. It also had a ton of organic matter all over it, so I de-cased it and gave everything a good cleaning. John also noted that the caseback gasket and grime could contribute to the hack not hacking it, so I replaced the hard plastic gasket that came out with the correct toothed rubber one. It really cleaned up nicely. I notice now when I lift the setting bow that I hear and feel an intermittent buzzing, which I assume is the movement trying to hack but just barely failing. I suppose I'll have to take it apart at some point. For now though, new wrist candy!

-

1971 Bulova Accutron Spaceview 214

ManSkirtBrew replied to ManSkirtBrew's topic in Your Current Projects and Achievements

While cleaning up the case, I polished out the crystal, then gave it a wipe with a paper towel. And that's how I learned that despite being on the inside of the crystal, the Accutron logo wipes right off with a little soap and water I should have been more careful, but live and learn. I'm not too heartbroken, as the crystal has some pretty bad cracks and deep scratches, and I was planning to replace it anyway. I have to say, I still love the results of a quick polish on the wheel with red rouge. Here's a before and after of two Accutron crystals. This was all of 5 minutes' work. Cleaned up and back together. Unfortunately, the lugs measure 17,mm, while all the straps I have are 18mm. I have a suspicion this watch was treated roughly and the lugs may be bent, but I'm not brave enough to try bending them back. -

Which Watch Have You Got Coming In The Mail ? Show Us !!!

GuyMontag replied to SCOTTY's topic in Your Watch Collection

You've been bitten by the Accutron bug! -

Which Watch Have You Got Coming In The Mail ? Show Us !!!

ManSkirtBrew replied to SCOTTY's topic in Your Watch Collection

Another Accutron 214 found its way into my shopping cart. Not sure how that keeps happening... I've always liked the railroad dials, and I'm a sucker for the blued hands. This one was sold as running, for a nice change of pace. -

Just got this guy from the eBay. Purchased as "for repair." First thing I notice is the contact spring in the battery hatch is missing. My dad recently asked me to repair his non-running Spaceview and it turned out that was the entire problem with his, so I put the world's tiniest ball of tin foil in there and what do you know. Looks like a good service is all it needs! One more quick note: according to the list from myBulova, this is a factory Spaceview. Nice!

-

Which Watch Have You Got Coming In The Mail ? Show Us !!!

ManSkirtBrew replied to SCOTTY's topic in Your Watch Collection

Continuing my trip down the Accutron rabbit hole, this non-running Spaceview is on its way to me. The seller made me an offer I couldn't refuse. I haven't been able to cross reference the serial #, but it looks original enough for me. -

…you all find some lovely 404s. Here in the US it is a challenge to find this kind of potential. Perhaps our elders sported too many Timex and Accutron and other things with plastic movements. Bradley Mickeys with pin levers and maybe 1 jewel…but well above the 404 I’m afraid…

-

Bulova Accutron 2181 Repair

JohnR725 replied to bobtheterrible's topic in Your Walkthroughs and Techniques

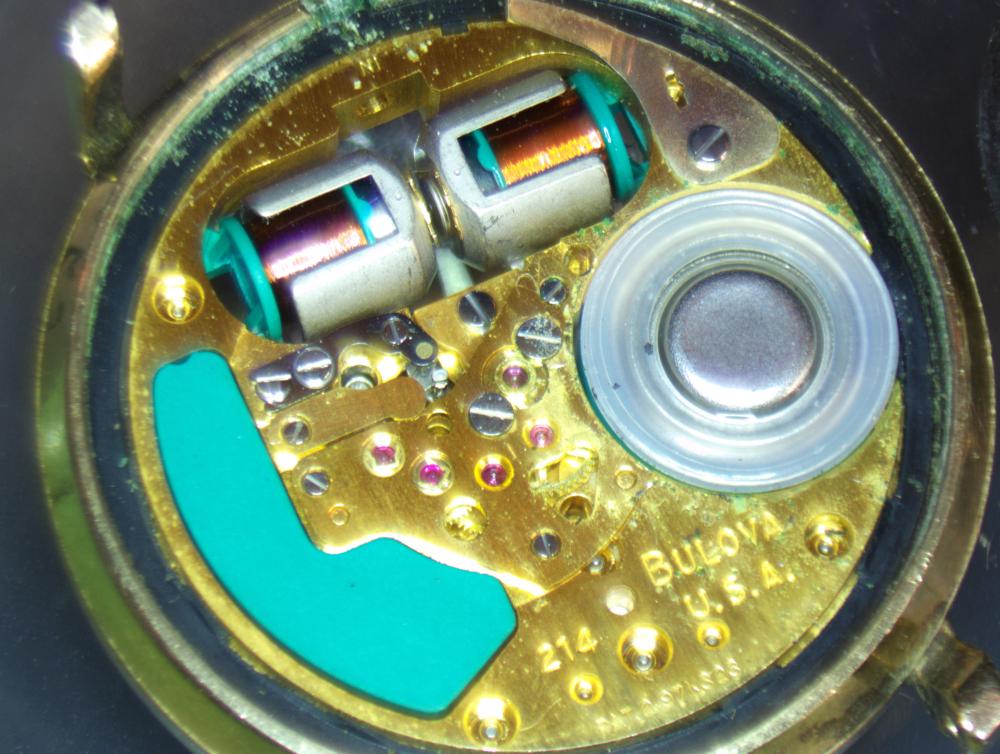

The classic problem of the center wheel assembly has rusted itself to the post. Then a minute and hour hand no longer turn the secondhand churns the friction part of the center wheel assembly is totally destroyed. Occasionally can flip the wheel over and buy yourself a little time but typically you'll have to replace the wheel. Then if you have really enthusiastic user you'll end up with a minute wheel stripped also. I would recommend not following the lubrication specification of whatever they say for the center wheel to avoid this ever happening again. I really wouldn't worry about the magnetized components unless you get rid of the magnets on the tuning fork. Basically magnets on the fork everything else is going to have a problem with magnetism typically is not going to bother anything at all unless of course you have steel tweezers. Oh and when you finally get the screws off and remove the fork be very careful because typically underneath our spacing washers. The color-coded to refer to their thickness. But I find it's usually best to just put the screws back in once you've lifted the fork out of the way that way you don't have to worry about which washer is where and basically is random whatever you going to find. The purpose is to tilt the fork so it agrees with the circuit. In watch repair yes you're supposed to pay attention but this is example of where you really have to pay attention otherwise well at least the fingers can be replaced. So they have to be at least one of them rotated out of the way to get the fork out. Then typically I rotated back and after the wheels are out I put the bridge back on to protect the finger when it's in the cleaning machine. Then when you're putting it all back together of course you remember to rotated out of the way and put it back etc. oh and remember to rotate it back before you put the screws in for the tuning fork because typically it sticks up too high and he can't get it past the screw head. So basically there's a lot of rotating that finger around to do things and it has to be in the right place or else, did I mention they can be replaced? Phasing on silver cells is interesting. Then yes you really should have a variable voltage power supply but there is something amusing about all of this. For instance is a technical specification for their watches and notice I marked something? As we know running on a silver cell has too much voltage out of the package brand-new without a load you can get almost 1.6 V and they are originally designed for Mercury batteries so obviously that is way out of specifications but if that is true why on the technical sheet is there the high-voltage run check? Which by the way is not mentioned in the service manual because normal service manual relies on using the normal meter and your source of power would've been the Mercury battery which cannot get to the voltages listed here One of the amusements and watch repair is service manual versus the factory? Or sometimes service manual versus other technical documentation that you typically don't have. In one of the other discussion groups is somebody who worked at the factory and she had pointed out that they use a variable voltage power supply and they did test the watch at a higher voltage. Then I'm attaching a PDF an interesting article about the problems of silver cells. 1996-08-web horological times Accutron silver cells phasing.pdf -

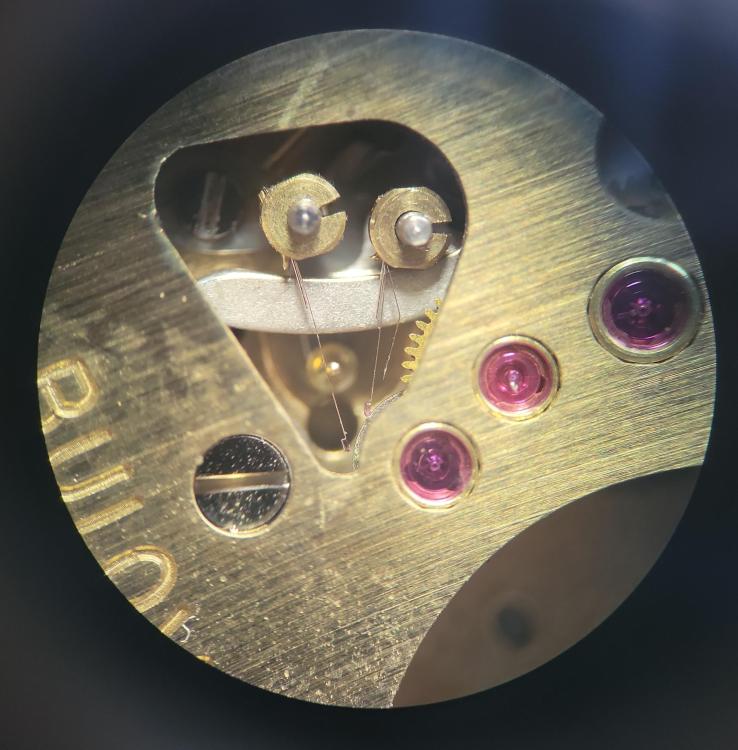

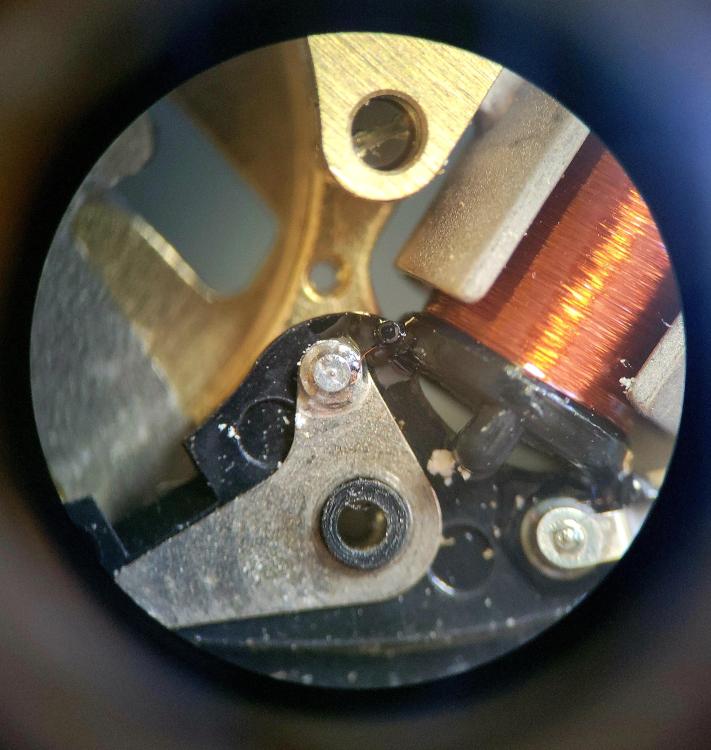

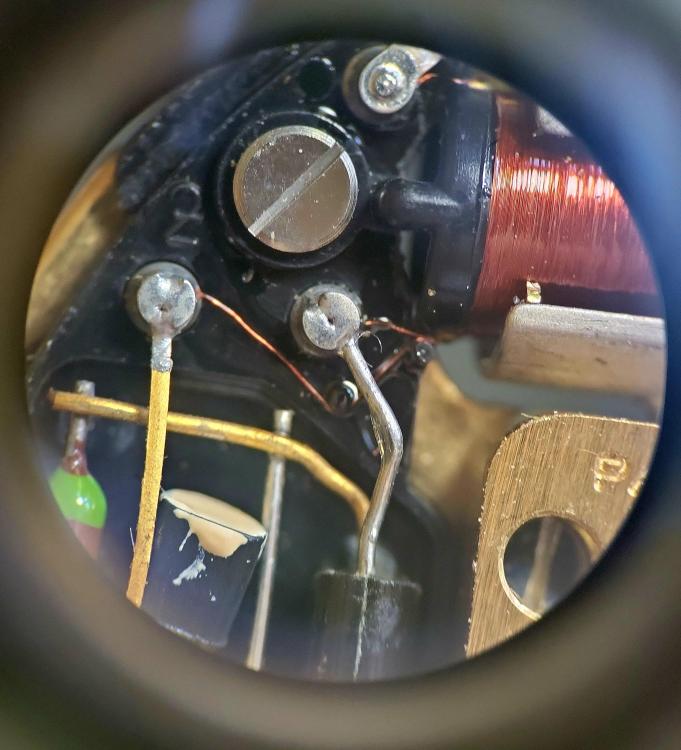

Hi All, I thought I would share where I am up to with my latest project. While doom-scrolling Ebay I came across a soon-to-end auction for tidy looking Bulova Accutron 2181 and chanced a bid. The seller was upfront that the seconds hand turned but the minute and hour hands did not move. I had already read elsewhere that this was a common problem and figured I should be able repair or at least replace the seized parts. This is my first Accutron... The project is a simple stainless steel dress watch with a silver face and simple baton hour markers. Should look nice on a black leather strap. On first inspection after opening the case it is obvious there has been a battery leak. It looks mostly contained to one area and Im hoping it will clean up. I checked the "fingers" and while dirty, they look ok. So far so good! I started by disengaging the fingers from the index wheel - apparently any rough handling during hand removal can cause these to break. Once I had stripped the dial side down I came across the reason why the hands were not moving. Indeed the canon pinion had seized - and properly so! The minute wheel teeth had been striped! After wrestling the centre wheel away from the movement it was clear it had rusted solid and the previous owner had attempted to free it up using force applied to the crown. I used a bit of Rodico to clean up the rust and teeth before proceeding as the forks are magnetised and will attract any ferrous material. Also of note virtually all the components were magnetised to some degree or other so will need to deal with that. A couple of shots showing just how thin the coil wires actually are! I finally made it down to the tuning fork and got stuck trying to remove one of the two screws holing it to the plate. I was putting significantly more force in to turning that screw head than I was comfortable with so decided to place a drop of penetrating oil around the screw in the hopes it will have loosened up by the morning. Now I need to start looking for some replacement parts...... I will update this thread as I progress!

-

Unfortunately, I found the tool I bought didn't actually work for the 218 series, so the particular tool might be for the 214 only. I wished in one hand...again. JohnR275 is correct about that tool for the phasing of 224 series Accuquartz movements. It looks like a movement holder with a couple of thin probes built in. If you have one of the Bulova series 300(?) movement holder with the removable probes and nylon sizing pegs, it may work even better. Good luck with your Accutron. Sorry about the late response. Cheers.

-

I bought the 16mp camera for my AmScope trinocular microscope, and I have to say, it's fantastic. While it is a luxury, I do post a lot of photos, and holding a loupe to my phone is less than ideal, and the ability to get close up video will be fun for the Accutron repairs I've been doing. Additionally, I bought the calibration slide to go with it, and the software lets me measure things to within a fraction of a mm. For example, trying to find the diameter and width of a flat case gasket when I don't have the original. It's just super cool and thought I'd share.

-

Hi All, I have just picked up a nice little Bulova Accutron 218. It is humming away but the minute and hour hands are not turning (apparently it could be corrosion on the cannon pinion) so it is likely in need of a service/repair. I have found a (grainy) copy of the service manual on line and a quick read through identifies the required lubricants as: Moebius OL219 - Synta Visco Lube Moebius OL207 - Special Lubricant with Molybdenum Disulphide Im struggling to find any information regarding these lubricants. Does any one have any specs they could point me to? Or alternatively, does anyone know if there are modern equivalent lubricants I can use for this movement? Cheers, Bob

-

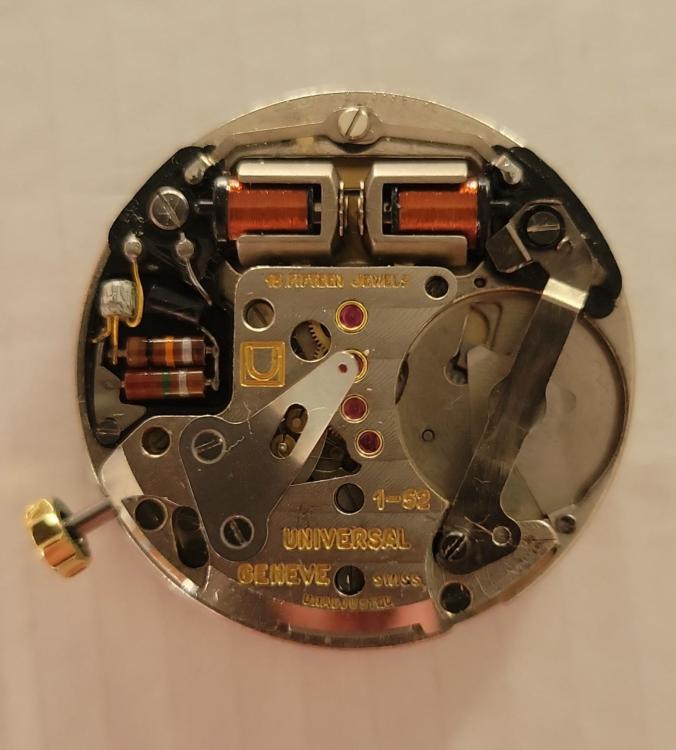

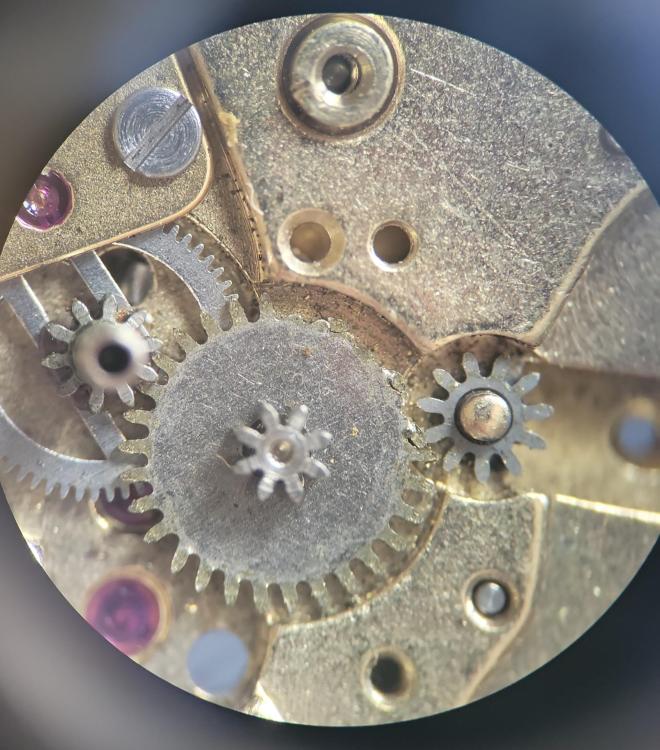

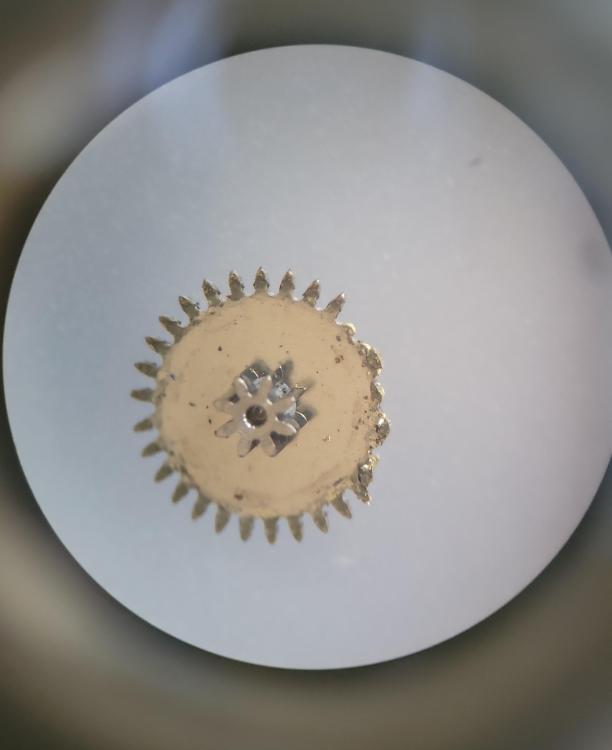

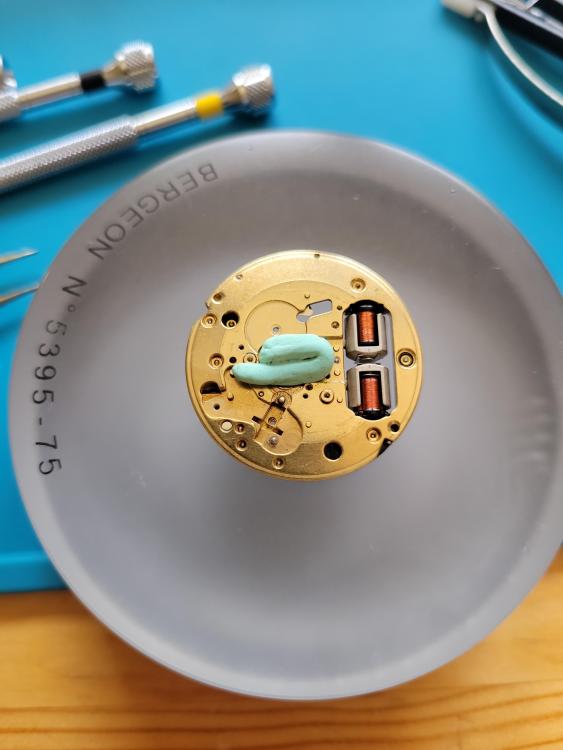

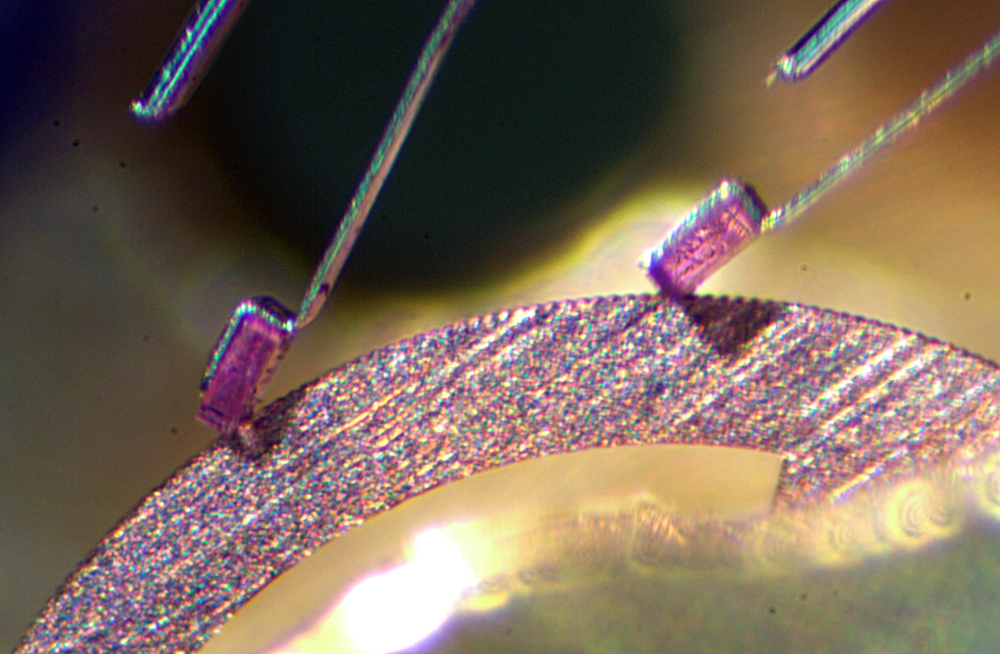

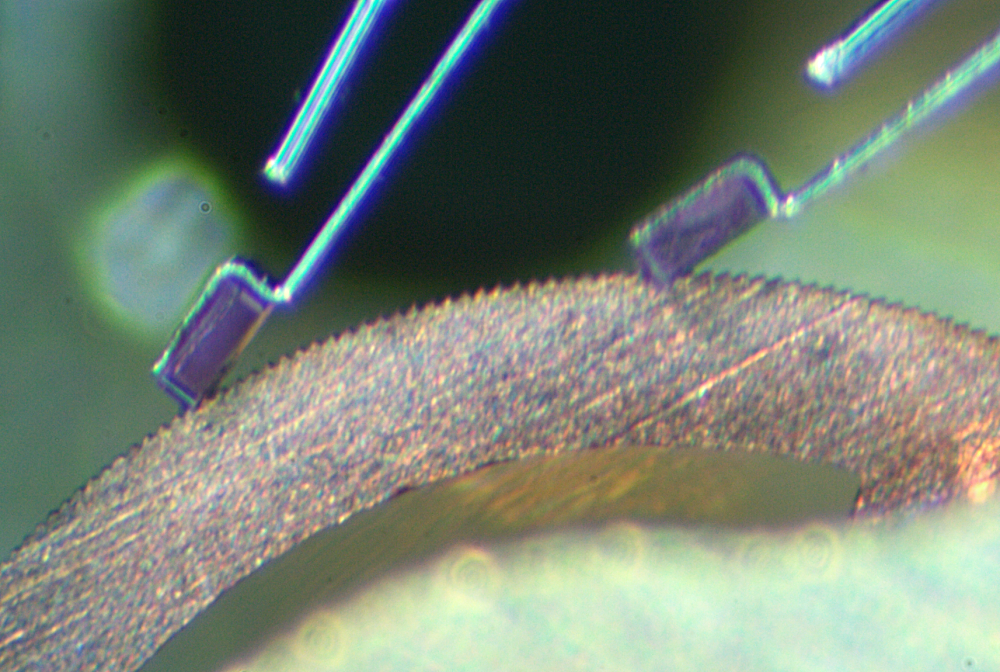

New forum member @ChrisMcKeith saw my previous thread about fixing the electronics in my 219 movement and was foolish trusting kind enough to send me his to work on. It's been an interesting journey and I thought some folks might find it useful or interesting. The capacitor, resistor, and coils were all within spec, and a little pluck got the fork humming, so we were off to a good start. Full tear down, clean, oil, rebuild. Got to break out the Horia clone when the second wheel jewel surprisingly popped out of the main plate. After depthing the wheel, I inly had to tear it down twice more because I forgot to put the hacking lever under the train wheel bridge...then forgot to put the fork under the train...good practice, I keep telling myself. Then I started phasing it. Adjusted the tension on the index and pawl fingers by the manual, applied voltage from my power supply, and it ran...for a half revolution of the index wheel at a time, no matter how I adjusted it. After some more diagnosis and manually moving the fork, I had the hunch that the index wheel has some bad teeth. 45x is as high as my microscope goes, but it sure looks like those teeth are rounded/flattened: I compared it to the index wheel on the 219 I have that runs: Seems like a big difference in the sharpness of those teeth. Literally as I took this picture, I got a message from our friend @LittleWatchShop, who generously offered to try re-pivoting the 4th wheel on my 219. Since it didn't work, he's sending me a spare 219 movement! Hopefully we can use the 4th wheel for my 219, and the index wheel for Chris'. The kindness and generosity here does not cease to amaze and delight.

-

After 21 Months

Neverenoughwatches replied to rossjackson01's topic in Your Current Projects and Achievements

I love your updates Ross, you're making good progress. Do you have any immediate plans to learn some repair techniques involving staking and jewelling tools ? Many years ago now but It was my first time for having bacon eggs and honey pancakes on the same plate, i remember thinking # what the hell is this all about # You can do it Nessie, organise that space , set up the scope, lay out the tools, crack your knuckles stretch out them pinkies and off you go. Is this the single eyepiece accutron scope ? -

I know how to measure and fit an acrylic crystal, but how does one choose the type if the watch came to me without one? Can you tell if it needs a gasket by looking at it? Since it has a gasket for the case back, should it the crystal have a tension ring for extra waterproofiness? Low-dome? High dome with step? Without step? With faceted edge? If I choose one with a calendar lens, is there any way to know if the lens is wide enough for the day/date, or are they really only designed for the date? Basically I'm trying to figure out what is an aesthetic choice and what is important. My instinct is to just get a plan ol' low-dome for $3, but I don't want to end up getting something that won't be water resistant if that's what I need.

-

EvergreenParts supplier...interesting

HectorLooi replied to LittleWatchShop's topic in Chat About Watches & The Industry Here

Hmmm.... I wonder if they can machine Accutron index wheels? -

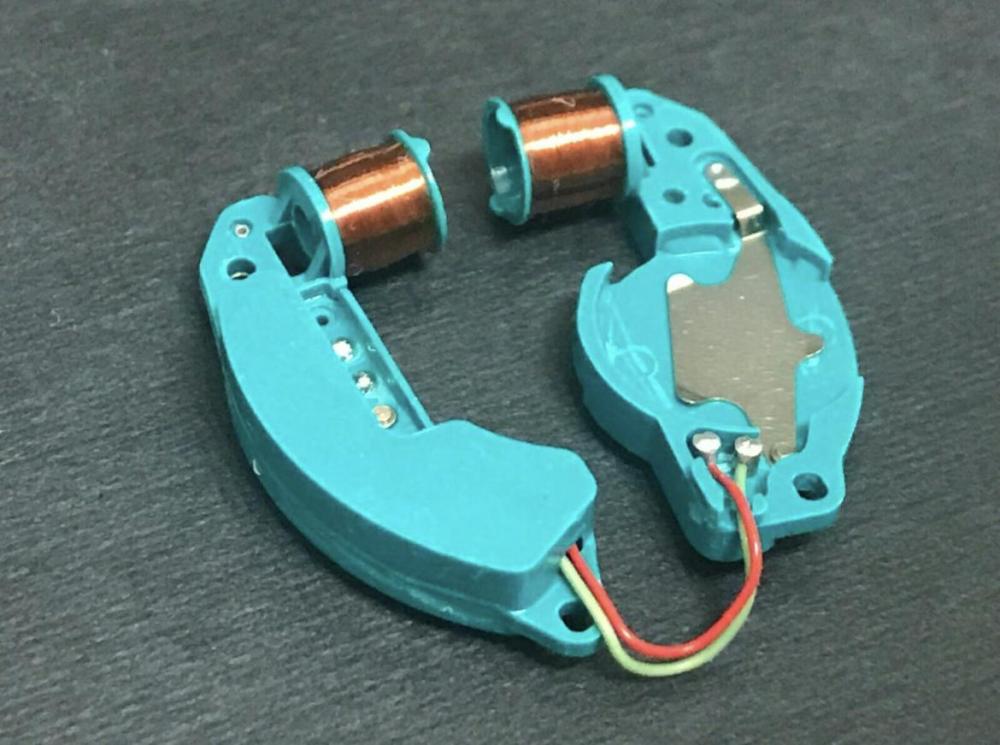

I came across a replacement motor from Cas-Ker recently but it's a little pricey to just buy and try. https://www.jewelerssupplies.com/accutron-242-step-motor-20-510-900.005.11.html I wrote about my adventures with a Bulova 242 last year. I just bought an untested 242 movement off eBay and am praying hard that it works. You might find it useful. Apparently, this twitching problem is quite common with the 242 stepper motor. I haven't really looked into the cause.