Search the Community

Showing results for 'accutron' in topics.

-

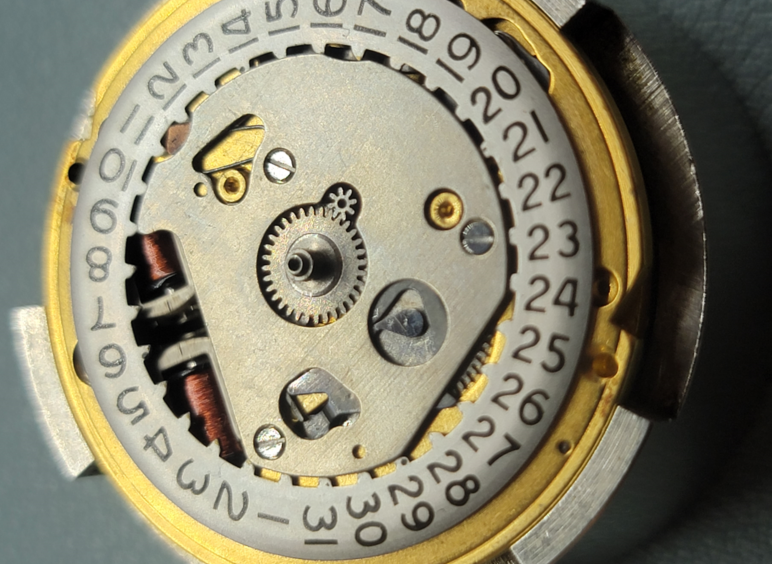

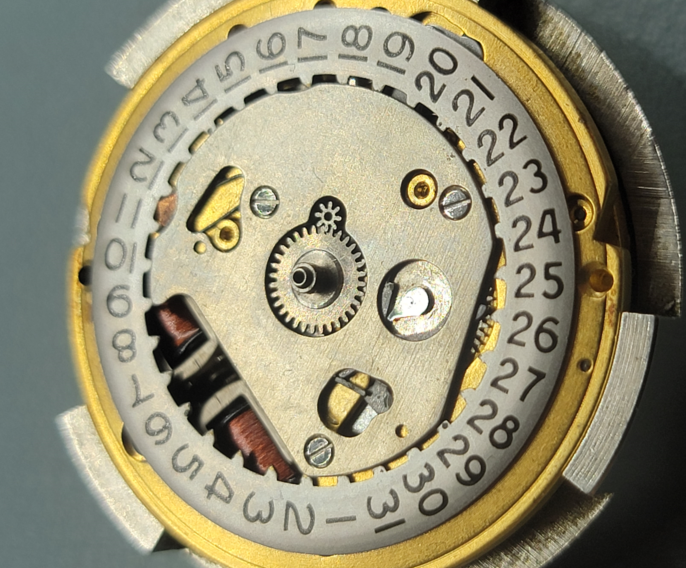

This is the same watch I have posted about under different topics. After assembly, the date does not advance. In the pictures I show the Date Trip Arm and the Date Trip Wheel in different positions. What is happening is that the hook on the Date Trip Wheel is releasing the Date Trip Arm BEFORE it moves far enough to grab the Date Indicator. Everything moves freely and I have lubricated according to the manual instructions. I wonder if the Arm or the Wheel have worn to cause this problem. BTW, before I opened this watch up for service, I noticed that the date was not working. Thoughts?

-

I'm sure that this has been covered before but, I have one of the Accutron watches, I seam to remember that there was a movement that could replace the 218 movement. I have one the movement is no good it's just too far gone. I'm hoping that someone will be able to help me, I'm sure it's been done before. Thanks in advance.

-

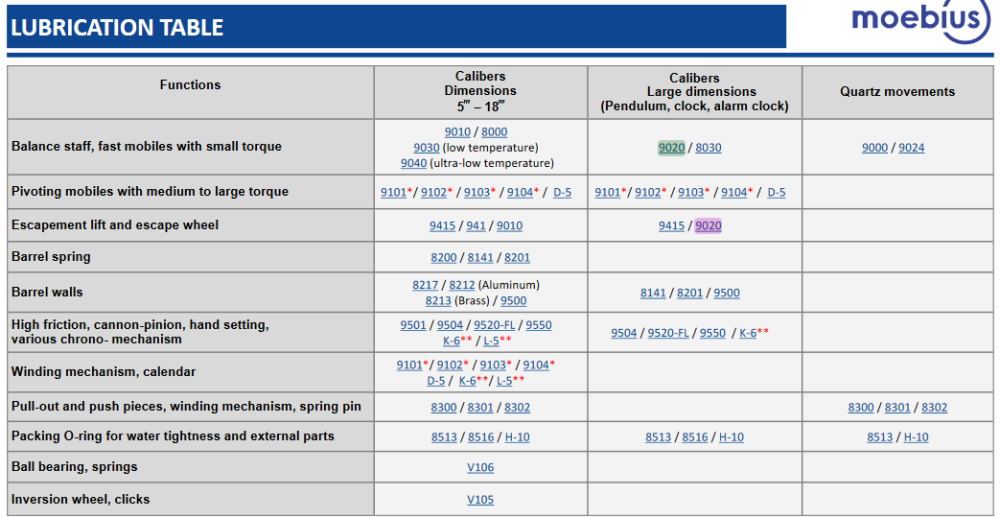

The service manual calls for only 2 lubricants: Moebius OL219 - Synta Visco Lube Moebius OL207 - Special Lubricant with Molybdenum Disulfide I understand that they are now Moebius 9020 and 8201, respectively. Unfortunately, I don't have either in stock. I do have 9010, 9104 (HP1300). For greases I have 9501, 9415, and Kluber P125. The manual recommends OL219 on the train jewels where I'd normally use 9010, and looking at Moebius' lubrication chart that seems reasonable. In Mark's chronograph course he also notes that 9010 can be an acceptable substitute for 9020. The grease is a little more tricky. The manual uses it in some places I'd normally use 9104, like the minute wheel post, but also where I'd use 9501 like the stem and sliding clutch. I thought the Kluber P125 might be a reasonable substitute for the 8201, but I think the Kluber is thicker. Basically I'm wondering if there's a compelling reason to buy the lubricants specifically called for, or if I can use what I have here. I don't mind spending the money if I really should, but if I can get away with what I've got and not have to wait with parts on my bench, I'd love that too.

-

According to the patent at least, the Accutron wire is 0.6 mil which is about 15 microns. I will try to find some info about the quartz coil wire. I pulled a quartz coil and measured it with my JKA and got between 15 and 18 microns. The JKA resolves 10um tic marks, so I am interpolating to get this number. Thus, the quartz coil and Accutron coils have comparable wire diameters. I never worried about measuring quartz coils, so I will no longer worry about measuring Accutron coils. A further experiment might be to measure the fusing current for a quartz coil. A test for another day!!

-

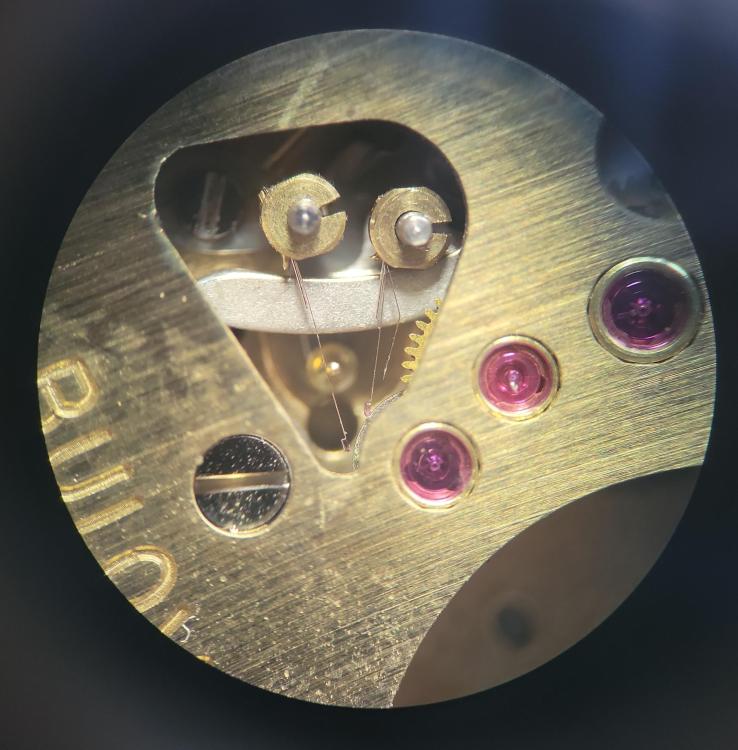

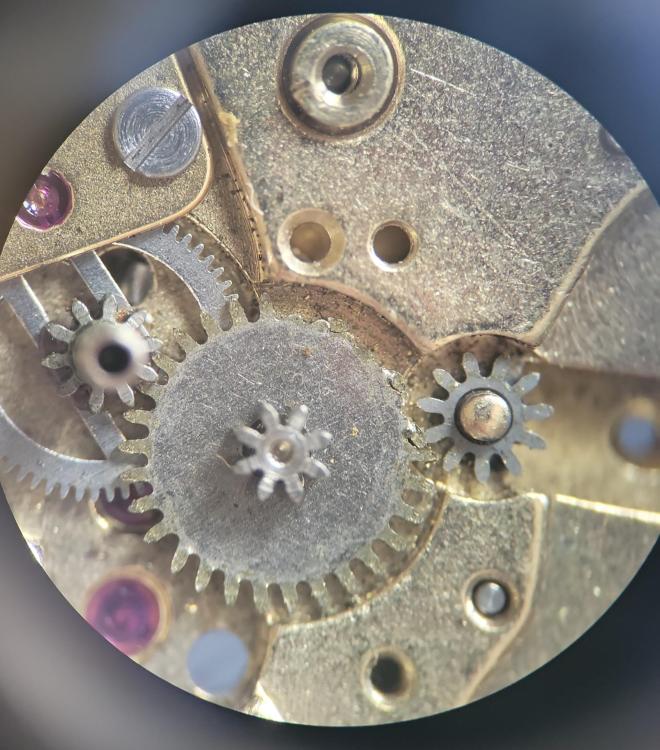

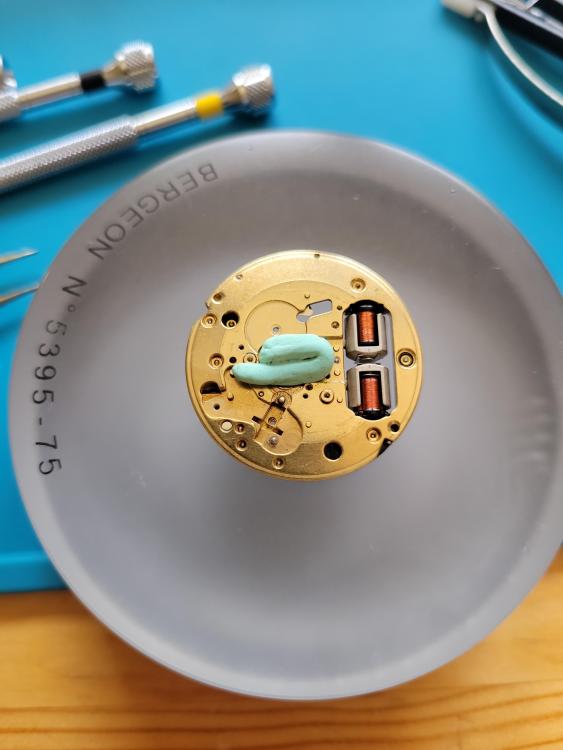

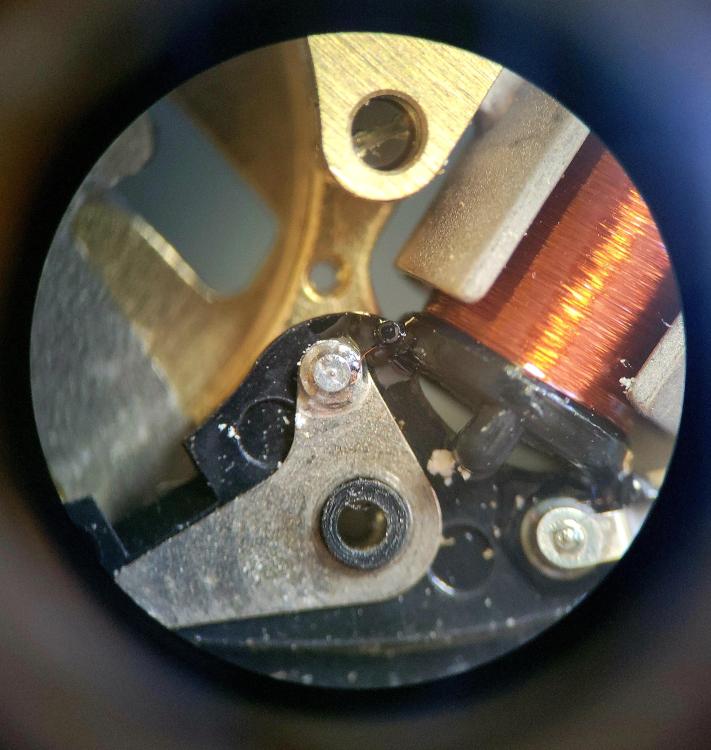

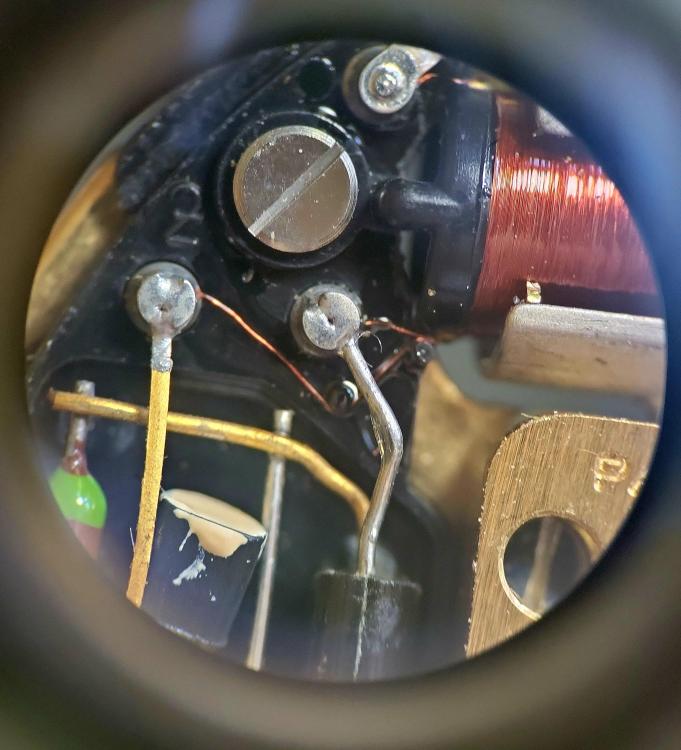

Hi All, I thought I would share where I am up to with my latest project. While doom-scrolling Ebay I came across a soon-to-end auction for tidy looking Bulova Accutron 2181 and chanced a bid. The seller was upfront that the seconds hand turned but the minute and hour hands did not move. I had already read elsewhere that this was a common problem and figured I should be able repair or at least replace the seized parts. This is my first Accutron... The project is a simple stainless steel dress watch with a silver face and simple baton hour markers. Should look nice on a black leather strap. On first inspection after opening the case it is obvious there has been a battery leak. It looks mostly contained to one area and Im hoping it will clean up. I checked the "fingers" and while dirty, they look ok. So far so good! I started by disengaging the fingers from the index wheel - apparently any rough handling during hand removal can cause these to break. Once I had stripped the dial side down I came across the reason why the hands were not moving. Indeed the canon pinion had seized - and properly so! The minute wheel teeth had been striped! After wrestling the centre wheel away from the movement it was clear it had rusted solid and the previous owner had attempted to free it up using force applied to the crown. I used a bit of Rodico to clean up the rust and teeth before proceeding as the forks are magnetised and will attract any ferrous material. Also of note virtually all the components were magnetised to some degree or other so will need to deal with that. A couple of shots showing just how thin the coil wires actually are! I finally made it down to the tuning fork and got stuck trying to remove one of the two screws holing it to the plate. I was putting significantly more force in to turning that screw head than I was comfortable with so decided to place a drop of penetrating oil around the screw in the hopes it will have loosened up by the morning. Now I need to start looking for some replacement parts...... I will update this thread as I progress!

-

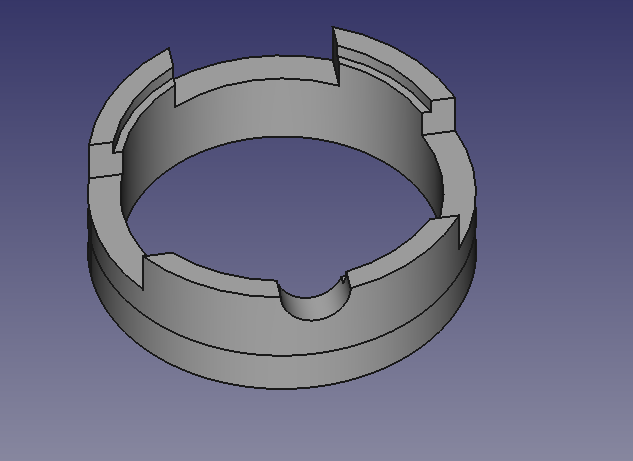

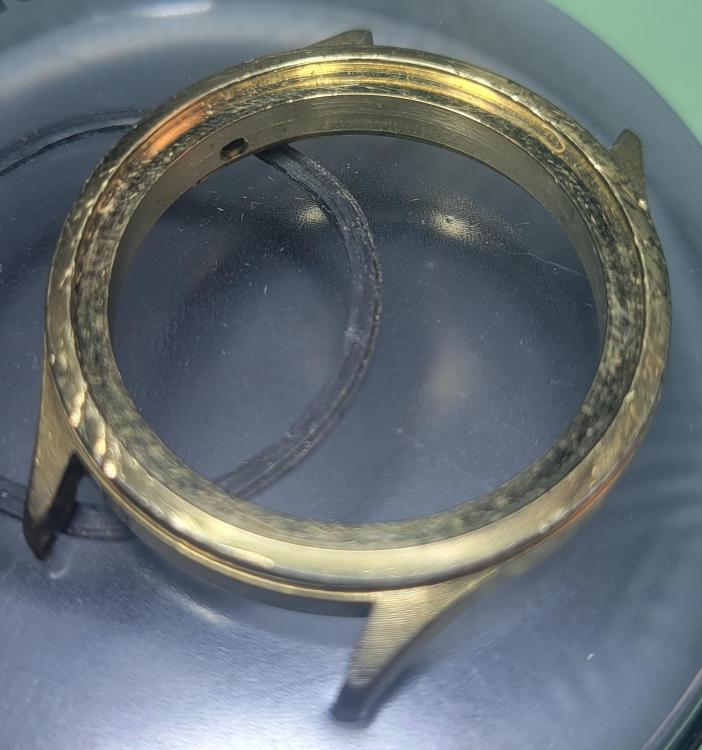

I have an issue with this as well. The bi-directional friction bezel on my 1970 Accutron Deep Sea 666 was turning a bit firmly. I needed to clean the case anyway so removed the bezel. The spring was left surrounding the upper portion of the case, but I don't see how it does much good there. There's a groove around the inside of the bezel that seems designed to hold the spring, but the spring is too small in diameter to fit into it. When I try bending the spring into a larger diameter it just springs back to its original size. It seems too thin, and so possibly fragile, for me to bend it excessively. Does anyone know how this is supposed to go?

-

Started talking about this guy in the "what watch have you got coming in the mail" thread, and thought I'd add some more pictures and info here. Here's how it arrived to me: @JohnR725 noted that it's supposed to hack, but the mechanism is finicky and best left alone if I'm not doing a full service, which I'm not yet. It runs with a modern silver oxide battery as-is, so I'm going to run it a few days and see how she goes. I took a peek inside to make sure it had the correct hacking movement (214H), which it did. It also had a ton of organic matter all over it, so I de-cased it and gave everything a good cleaning. John also noted that the caseback gasket and grime could contribute to the hack not hacking it, so I replaced the hard plastic gasket that came out with the correct toothed rubber one. It really cleaned up nicely. I notice now when I lift the setting bow that I hear and feel an intermittent buzzing, which I assume is the movement trying to hack but just barely failing. I suppose I'll have to take it apart at some point. For now though, new wrist candy!

-

It's been a long time and I rarely work on quartz stuff, but had one for a friend I suspected a coil was bad, grabbed my trusty Radio Shack (Micronta) digital meter I bought as a teenager, thinking it should have a low enough output. From memory, you want less than 2v to be safe with quartz coils. I recall we had meters in school with a resistor across the leads to drop the voltage. Turns out the Micronta puts out 4v, which is common. Didn't have a resistor on hand, so didn't test (ended up not being the coil- but at least I didn't kill it!). I don't know the difference in the coil wire diameter between common quartz and Accutron; my gut says the Accutron is a bit heavier, so probably doesn't mind the extra voltage?

-

Greetings all, I've been working on a few Accutrons of late. It started with one that was gift to me. I find them very interesting, and marvel at their engineering. Who wouldn't, right? Of the two that are on my bench right now, one needs an index wheel, the other needed the index and pawl jewels cleaned better than a dip in One-Dip. Of course I didn't realize that until I put it (A 2242 Accuquartz) back together and it wasn't staying running and I looked at the jewels under higher magnification. Despite some advising against putting the fork/index finger/jewel and pawl-bridge/finger/jewel in the ultrasonic, I was told by an Accutron expert that it would be OK, so I did so. I definitely cleaned off the gunk. I used fresh cleaner and ran a rare earth magnet through the cleaner before putting the parts basket in. The issue I'm dealing with now is that the pawl finger got bent. It must have been sitting too low, or the upper fork screw was sitting too high. When I spun the finger around to avoid damaging it, it hung up on that screw. Then it somehow got lifted over the hack pin as I was trying to get the index wheel in position without high enough magnification to notice it happening. Anyway, I am now working to straighten the finger. It's not terrible, but I guess it needs to be rather perfect to work properly. First the jewel wasn't squaring with the index wheel. Then it was riding over the index wheel. Right now it will get the watch running slightly but it won't stay, at least at lower phasing voltages. It looks pretty square now, and isn't riding over the index wheel. The only obvious issue is that the stress limiter on the pawl finger is not engaged with the finger at all. Since the jewel was sitting so squarely with the index I decided it was worth at try, but the stress limiter may be more important than I hoped. These fingers are so fragile, and manipulation has to be done under pretty high magnification, I just want to know if I should give it up and buy a replacement or keep trying. Any help is appreciated. Thanks ahead of time. I'd include an image but I don't have a good way to do so with my microscope setup. Cheers.

-

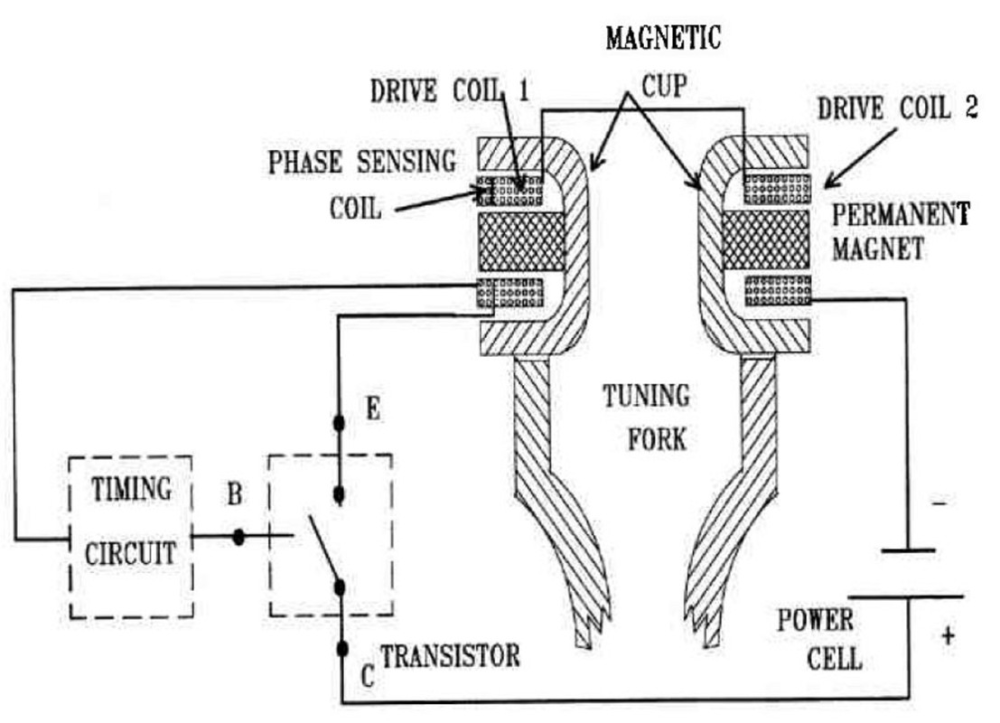

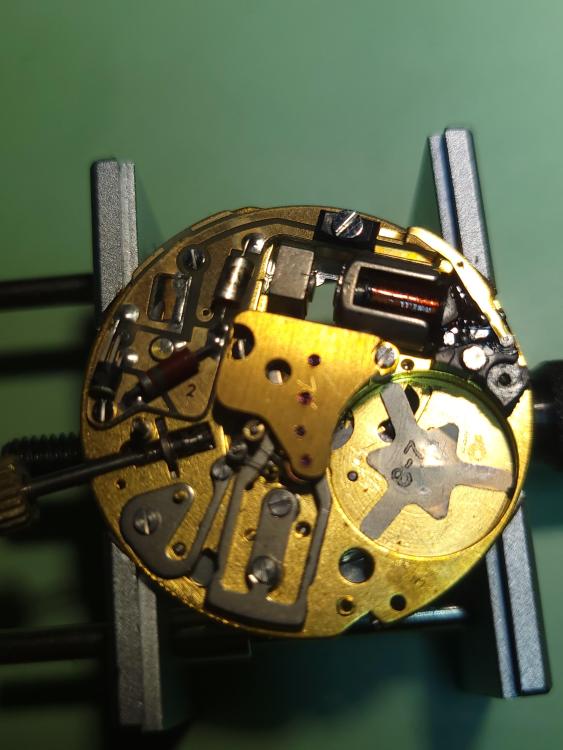

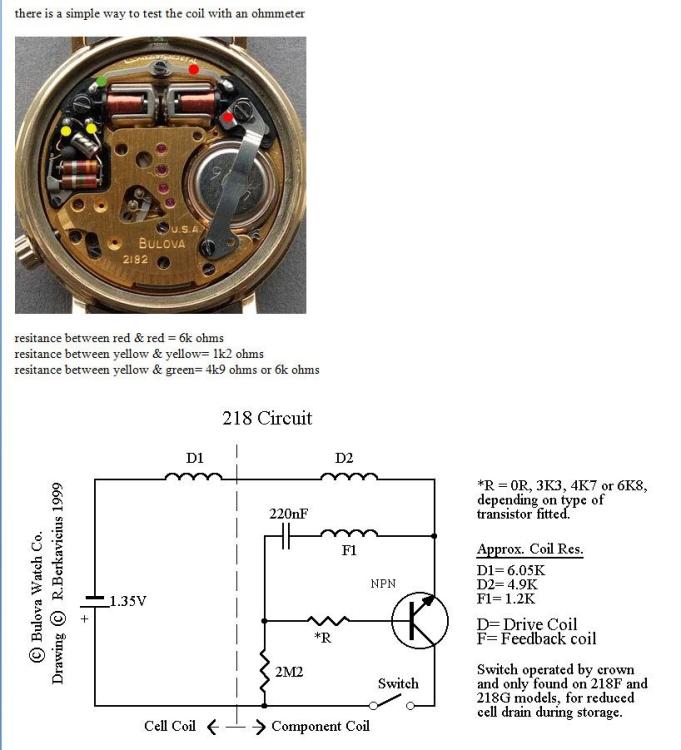

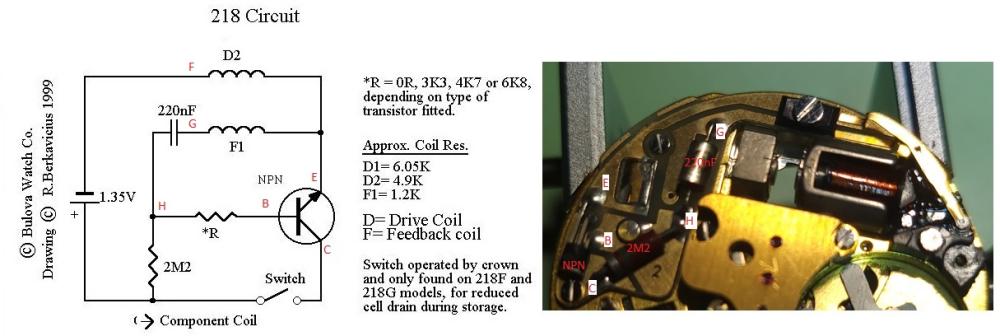

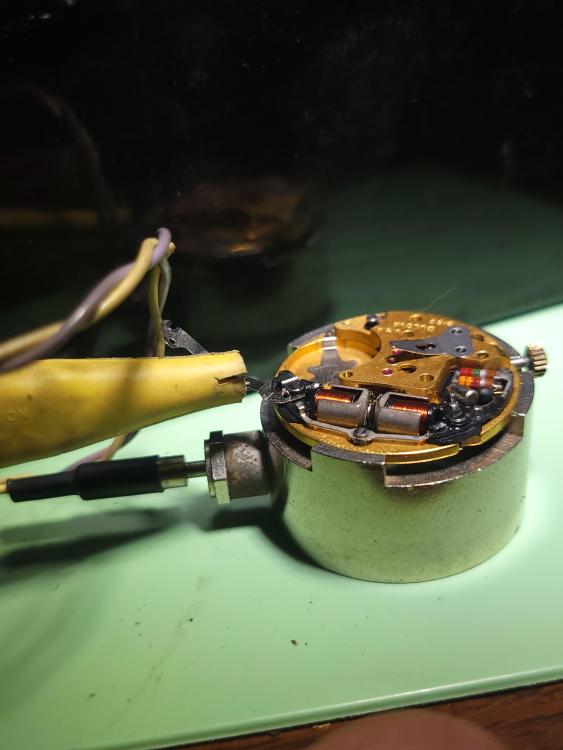

I've got a 219 that I'm playing with. When I hook it up to the 700 test set, it pegs the ammeter, so I'm trying to determine if I need a new coil. I first determined that the previous owner had screwed the battery strap to the main plate, causing a dead short. After I fixed that, it still doesn't run, regardless of how much tapping I do on the side. The ammeter needle stays all the way to the right. My understanding is the 219 uses most of the same bits from the 218, with the obvious omission of one coil. And this is what my 219 looks like: Testing resistance across the two brass prongs of the coil only gives me 900 ohms, where I'd expect 5-10k. But because there's only one coil here, I can't be sure I'm testing the right bits. Is the feedback coil included here? Where are the contacts for it? Are there any diagrams for the 219 out there? I do see that Cas-ker has coils and circuit boards available for $50 each, but I'd love to know if this is bad first. Plus I love learning this stuff. So assuming they just removed the cell coil and left the rest of the circuit the same, this is how I matched my 219 to the schematic: I was measuring between E and G, so across F1. 900 ohms makes a little more sense. I'll try tomorrow between F and E. To tired and too much Scotch to do more tonight

-

Accutron 214 service . Do you know anyone in the not to far from Sweden that does that . I thought electric watches did accutron . But not any more.

-

Hi All, I have just picked up a nice little Bulova Accutron 218. It is humming away but the minute and hour hands are not turning (apparently it could be corrosion on the cannon pinion) so it is likely in need of a service/repair. I have found a (grainy) copy of the service manual on line and a quick read through identifies the required lubricants as: Moebius OL219 - Synta Visco Lube Moebius OL207 - Special Lubricant with Molybdenum Disulphide Im struggling to find any information regarding these lubricants. Does any one have any specs they could point me to? Or alternatively, does anyone know if there are modern equivalent lubricants I can use for this movement? Cheers, Bob

-

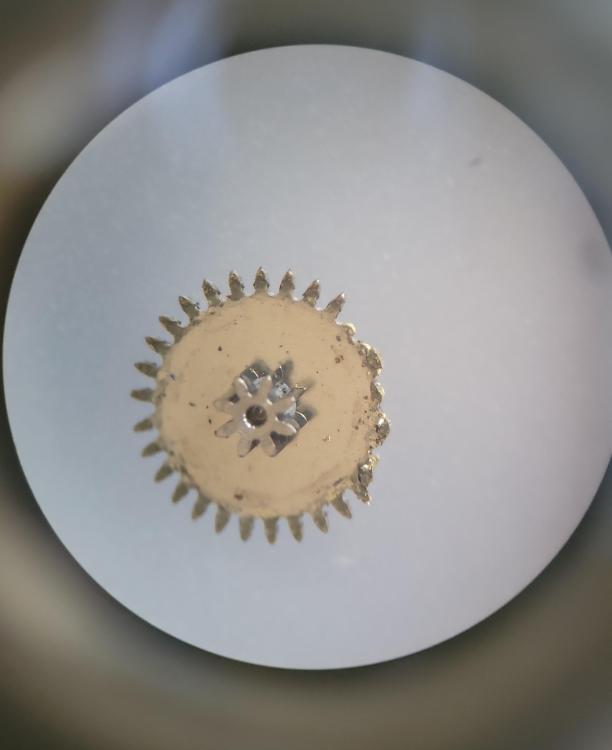

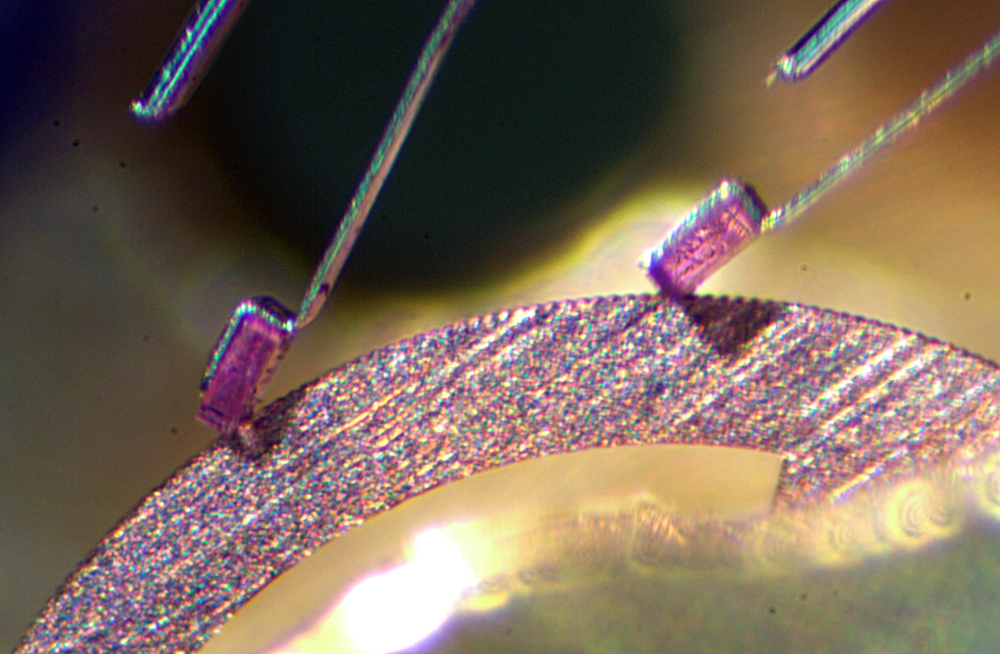

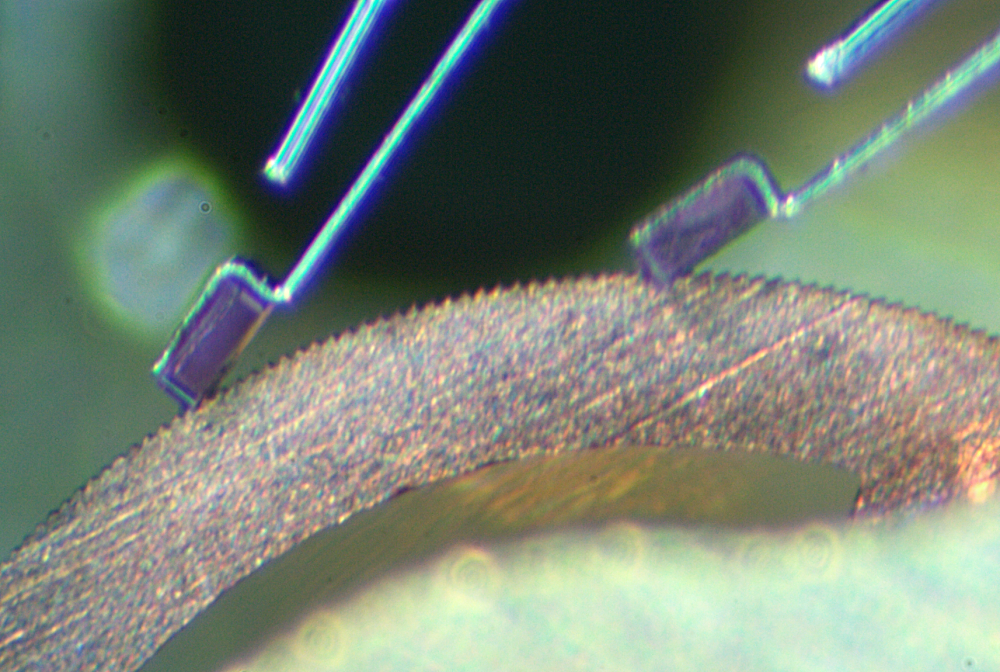

New forum member @ChrisMcKeith saw my previous thread about fixing the electronics in my 219 movement and was foolish trusting kind enough to send me his to work on. It's been an interesting journey and I thought some folks might find it useful or interesting. The capacitor, resistor, and coils were all within spec, and a little pluck got the fork humming, so we were off to a good start. Full tear down, clean, oil, rebuild. Got to break out the Horia clone when the second wheel jewel surprisingly popped out of the main plate. After depthing the wheel, I inly had to tear it down twice more because I forgot to put the hacking lever under the train wheel bridge...then forgot to put the fork under the train...good practice, I keep telling myself. Then I started phasing it. Adjusted the tension on the index and pawl fingers by the manual, applied voltage from my power supply, and it ran...for a half revolution of the index wheel at a time, no matter how I adjusted it. After some more diagnosis and manually moving the fork, I had the hunch that the index wheel has some bad teeth. 45x is as high as my microscope goes, but it sure looks like those teeth are rounded/flattened: I compared it to the index wheel on the 219 I have that runs: Seems like a big difference in the sharpness of those teeth. Literally as I took this picture, I got a message from our friend @LittleWatchShop, who generously offered to try re-pivoting the 4th wheel on my 219. Since it didn't work, he's sending me a spare 219 movement! Hopefully we can use the 4th wheel for my 219, and the index wheel for Chris'. The kindness and generosity here does not cease to amaze and delight.

-

Sorry for the multiple threads. I'll be honest--I just noticed there was a separate forum for tuning fork watches So I'll keep my posts here. I don't have the 344 silver oxide cells yet, so I'm adjusting with the 1.35v Accucell and the model 700 test set, per the service manual, to get a feel for how things work and to have a good starting point. This is really a learning experience. The index pawl is even more sensitive to tension than I expected. So the first question is regarding the last few steps in the process: I'm a little confused on the momentary hesitation part. Are they saying it's permissible while rotating the cam after it stops the first time, but before it continues to run consistently? The other thing I'm wondering about is trueness of the index wheel. I noticed that the one on this movement is noticeably out of true at the rim. Is that normal? I did my best to take a close-up video, and you can see the index and pawl jewels moving back and forth. Edit: I was also using Henny Frystack's excellent video on the 214 here as reference, but it looks like the actual phasing part is cut out of it. He talks about the theory of it, but the practice seems to be cut off at 43:00. Anyone know if the rest of it is out there on the internets?

-

Which Watch Have You Got Coming In The Mail ? Show Us !!!

Zandr replied to SCOTTY's topic in Your Watch Collection

On the way, the tiniest Accutron, and my first 404 club-eligible project (since I've learned about it, anyway). "Untested", so expectations are low. -

I am about to start the journey into Accutron service and came across this thread after reading the Accutron service manual. I will bite the bullet on 9020, but it seems to me that a molybdenum disulfide grease is a reasonable substitute for OL 207 (8201) because when you read the marketing data on 8201, it is recommended as a breaking grease (MDS): "This special purpose Moebius grease contains Molybdenum disulphide to enhance it lubricity and resistance to pressure. It is designed for use on automatic mainsprings, to ensure proper functioning of the bridle. It is also recommended for use on the Bulova Accutron watch movements. Moebius 8201 natural watch grease lubricant Contains Molybdenum disulphide Black color Drop point: 32°C Viscosity: solid at 40°C Viscosity: 22 cST at 60°C Viscosity: 13 cST at 80°C"

-

I know how to measure and fit an acrylic crystal, but how does one choose the type if the watch came to me without one? Can you tell if it needs a gasket by looking at it? Since it has a gasket for the case back, should it the crystal have a tension ring for extra waterproofiness? Low-dome? High dome with step? Without step? With faceted edge? If I choose one with a calendar lens, is there any way to know if the lens is wide enough for the day/date, or are they really only designed for the date? Basically I'm trying to figure out what is an aesthetic choice and what is important. My instinct is to just get a plan ol' low-dome for $3, but I don't want to end up getting something that won't be water resistant if that's what I need.

-

fortunately when I post things I usually put them in a particular folder so I can find them for uploading so conveniently they were together. oh and yes you really would need the stem thing if you are installing this for the first time. If it's already in an existing watch it by theory should be much easier to do unless you change the back gasket. In other words on a 214 the location of the crown versus the back gaskets and the movement the back casket will of course move things around. then while I was remembering this that's why I uploaded this to some other group somebody was having a running issue on a 214 with a hack although unless you disassemble you won't actually know if you have a hack or not sort of. So I uploaded to comment on if it has a hack it could be an issue in these would be the issues why. In other words the crown is on the back if dirt gets under the crowd that changes spacing if the back gasket thickness should change. Which unfortunately will occur today as you may not really get original 214 gaskets and they have replacements and of the thickness is different it can be an issue. Oh and then if you are installing this for the first time you'd need the thing on the stems because you would have to change those to get one of the right length. I very distinctly remember when I installed one of these I was a student in school which was quite a while ago and I do not remember being a pleasant experience. Because as you can see with the instructions you have to set everything up and put it all together and if not right then you have to yes they can be a fun experience. I don't think I've ever done a 214 after that that had a hack though Accutron 214 hack.PDF Accutron 214 stems.PDF

-

Last week, I bought a bunch of stuff from an NAWCC member. Lots of junk quartz watches, but a few accutron tuning fork watches and some accutron quartz watches. I think whoever worked on this accutron quartz accidentally switched out a solid gold back where a gold filled one probably was. I have seen lots of accutrons where the wording on the back says "gold filled" whereas this one just says "gold." I think it is 14K solid gold. Opinion?

-

I doubt ESD would be able to destroy a coil. The problem of open Accutron coils has always baffled me. Even if 1.55V were to be applied directly to the coil, it shouldn't be able to fuse the wire. And if anyone noticed, it's always the cell side coil that fails. So is it a design fault that's causing that coil to burn? Maybe as the components age, the waveform changes and creates more back EMF? Maybe @LittleWatchShop could investigate the cause of the failure and solve the mystery.

-

LOL Yes my first VOM was a Triplett Model 630, 1970. However, I am not a luddite...my best meter is a Fluke 87V. I made the measurements with Cen Tech P35017. This morning, I measured the current output of the CT with my Fluke. When measuring resistance with the CT, I get 484uA. When in diode mode, I get about 800uA. I know you have lots of Accutron experiene...I take it you have never knowingly popped one of those coils via measuring?? ---non sequitur--- the going train on these things continue to amaze me. I was initially deathly afraid of it because of the index wheel. No more. About 20% of the time, the wheels just jump in place as soon as you drop the plate down. The rest yield quickly with a few nudges with my modified oiler. I only wish Bulova used similar engineering on their cases. Yes

-

I finally feel like I have the confidence, tools, and fine motor control to tackle these tuning fork movements. I've got my 700 test meter here (in beautiful shape with the original box, I might add!) and it seems to work as it's supposed to, at least with one of those 1.35v diode batteries in it. I'm planning to phase the watches for silver oxide cell voltage at 1.65v, so what I'd like to do is use my low voltage power supply to supply the test meter, and so I don't have to keep buying cells. I feel like I saw a thread where someone made a dummy 343/344 cell with power leads on it. Anyone have pictures or a link to that?

.thumb.png.e3ea96bbff95e4995053f85304262add.png)