Leaderboard

Popular Content

Showing content with the highest reputation on 04/26/24 in all areas

-

The plate is OK, thanks. It seems the answer to my question is that this is a 'hack' & for me another reminder that in general, one won't be the first person to be tinkering with an old timepiece!. As you day, I've been fortunate to have gotten some good advice and, just as important, encouragement. I've been lucky then not to have the balance spring break as a result of my novice 'ministrations' - but I did remember to 'stroke' rather than bend per se. The clock is of sentimental value to the owner so I'm relieved to have now got it running to time with the support & encourage of forum members like yourself.2 points

-

Hi. It’s always better to replace the coil but in the event of being unable to find one it’s nice to know that repairs can be effected. I prefer the conductive paint option because of the lack of heat and the chance of causing further damage.2 points

-

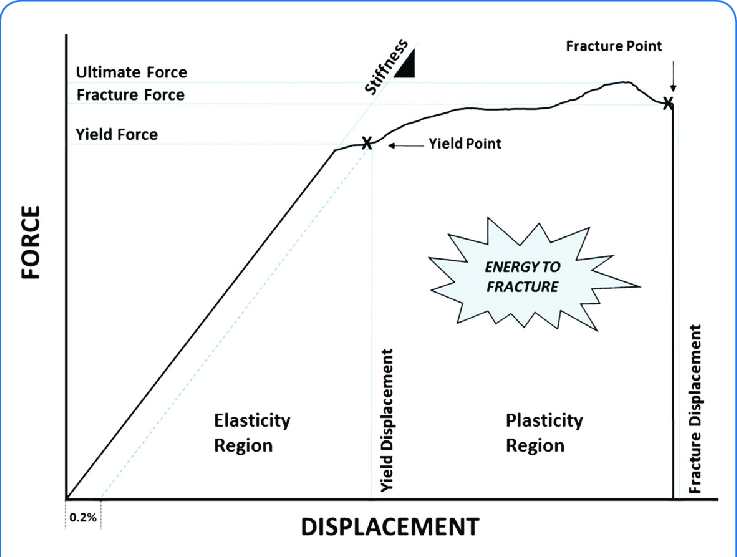

I would agree, in order to work harden something you need to exceed it's yield strength when it moves from the elastic zone to the plastic zone and you get permanent deformation and work hardening which is fairly close to its failure point, relatively speaking and dependent on the material/alloy of course. In theory you can load something constantly within its elastic range and not suffer work hardening issues.2 points

-

2 points

-

I didn't think pulling to set position would work harden the spring, in that position it is stressed where the arm starts. By work hardening i meant rapid polishing at that point, a bit like polishing a pivot work hardens as it compresses the steel. I doubt polishing by hand would achieve much in that respect though. Its finished, arm polished up mostly at the join to the bridge's main body. I'm ok with it, the screw holes aren't great as i had to open them up by redrilling and positioning it was difficult, I'm not much use with a loupe, opening up with a file might be a better option for me or i could just use the correct drill size . And the detent is way too deep, i had to guess that with the stem release out of position and sat on top, but i only took one measure and went for it, no slowly slowly catch your monkey . First go I'm happy , well sort of, it works and thats a big thing for me, next one will have a bit more finesse. Anyone thats interested, after filing, i used a 2000 grade home made diamond micro file and then 20 micron film, the film is much better than wet and dry, more stable to use and doesn't shed cheap grade grit everywhere , then auto polish on a sponge pad.2 points

-

Hi New. More of a get you out of a hole than a bodge. There is no substitute for a new coil.1 point

-

1 point

-

1 point

-

In think you are effectively shortening the coil by shorting out damaged tracks. In my case as long as the continuity was good and the resistance not too greatly affected it should be ok . One was on an era movement,1 point

-

Would the paint increase the resistance of the coil ? Effectively joining the wires that are painted. I imagine its important to only paint the smallest of areas to make the repair.1 point

-

Hi. In the picture not only does it depict that the wheel is bent but also the plate or is that due to th angle of the picture. Already received very good advise so I will butt out.1 point

-

There are some parts on Ebay for the seiko 6020A, it may just be a waiting game for someone to strip one down, NOS will be more scarce . K would strip your movement down to the module then start looking at other seiko movement to see if that coil is used, then seek out a seiko part dealer. Also Retrowatches youtube owner Mike may give you some advice try him on his site . He also hangs around amateur watchmaking groups.1 point

-

I discovered this last night when I printed my model, I'll try and tweak the design a little and re-post here1 point

-

That's very observant of you, Nev & that the 4th wheel is from another movement & has been dished to fit does seem a more likely explanation. Thanks for the education re calculating the rate & spring frequency. In the meantime, spurred by your earlier comnent, I risked a further tinker with the balance spring, cleaning it, fully un-kinking the last few cms (I'd been worried about breaking it first time round) & pinning it at the very end. The clock now seems to be running slow when the regulator is in that position so some progress at last.....Many thanks, once again!1 point

-

Snap! I recently finished my Gruen 510 movement - though the case for mine is in a rather sad state; I'm going to try re-plating it (in nickel, it's not a gold one). Re. the screws, I got a few of the one gram mixed batches from ebay. I've only needed a couple of screws for things so far, both rare, minuscule types - but both in the mix, after enough time sorting through them! The ones such as normal bridge screws are quite common in those lots.1 point

-

That's a good idea - shrinking down the nut and wrench size from the old casebook trick!1 point

-

OK, welcome in the world of alarm clocks... I guess the 4th wheel is dished because it is from another movement. If it was not dishet, then it would not mesh with the pinion of the escape wheel, am I right? The marks of wear on the 4th wheel pinion doesn't corespond to the 3th wheel table position, at list this is what i see on the picts. Calculating the rate is easy - there is a formula - BR = T2 x T3 x T4 x T5 x 2 /(P3 x P4 x P5) where T2 - T5 are the counts of the teeth of the wheels tables, and P3 - P5 are the counts of the pinion leaves. Vibrating the balance is easy - grasp for the hairspring where it should stay in the regulator with tweasers, let the balance hang on the hairspring while the downside staff tip rests on glass surface. Then make the balance oscillate and use timer to measure the time for let say 50 oscillations, or count the oscillations for let say 30 seconds. You must do the free oscillations test to check the balance staff tips and the cone cup bearings for wear. This kind of staffs wear and need resharpening to restore the normal function of the balance.1 point

-

Glue a nut to the barrel lid, insert a bolt, pull, disolve the glue. Maybe someone will have a better answer.1 point

-

I printed the base and it is a bit too large to fit on the base of the hand setter. The ring bumps into the column so it is unable to full seat on the central ring. I'm going to try removing some of the materal and see if I can't get it to go down.1 point

-

I looked at it like this, I've built a lot of stuff in my time, building structures and furniture,those are my creations and they will still be here way way after I'm gone. Traditional watchmakers felt the need to pass their knowledge on, ideas that they created . I assume with them as it is with me, leaving their mark on the earth, a way of being remembered. This creation of Mark's has brought thousands of people together to pass their knowledge around, ideas that will continue to be used for lifetimes. Ideas that should continue to be procured. If for whatever reason the forum ceased to exist, not quite like Ranfft's, that didn't disappear but much less usable. Then that is sad, such a massive loss of communication between good people and a wealth of knowledge lost. There should be something in place for when that happens which could be next week, next year or in 10 years. Might not be a topical subject for a lot of folk or boardering on controversy, i did say i talk about stuff other people dont. But if you dont talk about it and something happens then you've lost it and you ain't gonna fix it .1 point

-

Welcome to the forum, enjoy. It’s highly unlikely you will be able to purchase a new bezel look on eBay for a pulsar watch for repair to find a bezel.1 point

-

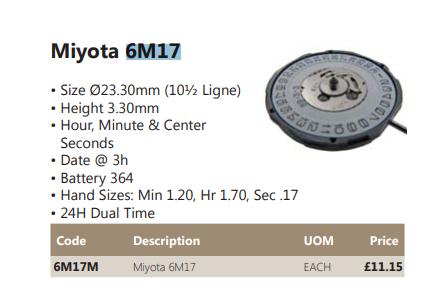

the problem with vintage watches and yes quartz watches can be vintage is availability of parts will be a problem. I have a link below where we can cross reference the coil and I was hoping for more. Another problem for vintage parts are everyone on the group gets used to ordering from online. Conceivably the physical material houses that still exist out there might have the part and you'd have to reach out to them and see if anyone has one. this is because they don't list every single part that they have online with the exception of cousins where everything they do is online work just doesn't exist but the other material houses can have stuff not listed. Otherwise just set up a search on eBay and sooner or later it will possibly show up if you're lucky. http://cgi.julesborel.com/cgi-bin/matcgi2?ref=SEK_6020A1 point

-

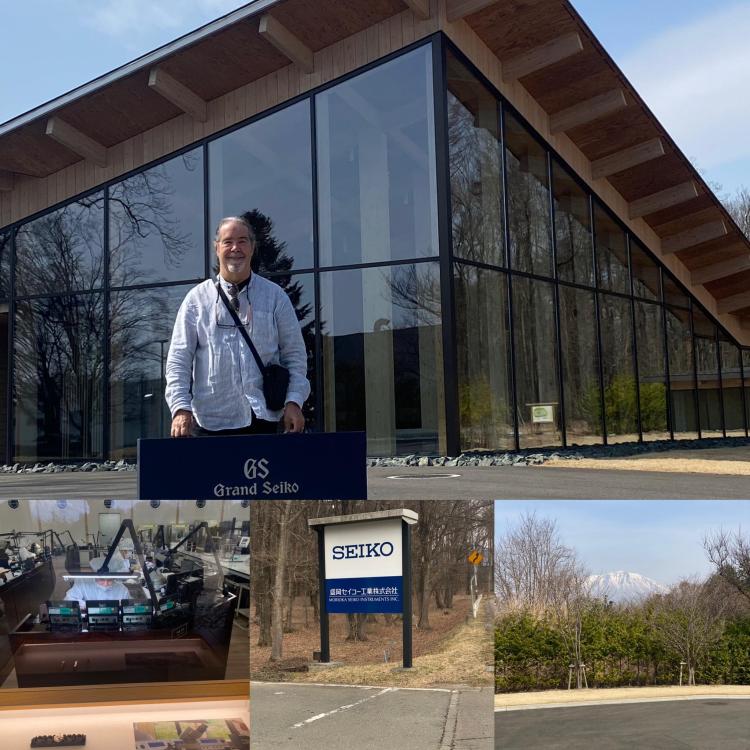

I am an Australian American living in the beautiful Gold Coast, Queensland Australia. I love Grand Seiko and Seiko watches, and recently came back from the Grand Seiko Shizukuishi Studio in northern Japan where I was blown away by the design artistry and technical excellence. More later on that (including photos, if interested!)1 point

-

I agree, the bezel needs removing. If there isn't a gap between the case and bezel for removal, it's probably screw on. If so you need to grip the bezel itself.1 point

-

Like losing Ranfft. That was a wake up call. We took his website for granted. Miss him terribly.1 point