Leaderboard

Popular Content

Showing content with the highest reputation on 12/19/23 in all areas

-

10 points

-

Thanks to all for the good words. The tools I used - yes, angle grinder and bench grinder, and some diamond disk used as a hand file for the finish of the tips, then some sand paper 800 grit to smooth the grinded edges. Actually, not special skills needed, just cutting, grinding, filing. Do not take me wring - I can afford buying tools. I just like making my own tools. I mostly use ordinary general purpose lathe, but have made by myself all the milling attachments and utilities that I use to cut gears and make all parts needed. Long time ago simple servicing watches by cleaning/oiling/parts replacing stopped being interesting to me. Then I started making parts, restoring antique movements. Skills are needed for this and skills mus be kept alive exactly this way - by practicing htem all the time..4 points

-

Well, here I am again. Doing an update. It's been 24 months since I began my journey on this watchmaking hobby. Where am I at, what have I achieved? Looking back, time has gone quick. Covid has been and gone...ish. Although I, like others of my age group are still reticent about mixing in a large community situations. This hobby has been a godsend. Something to do, but most of all a change of life direction. Achievement is the name of the game, and to do something that uses acquired physical and mental skill gives great well being. That's what it has done for me. The internet has allowed me to study and to practise physically from visual and audio stimulation. Like most beginners, I started without direction. Youtube videos, 'I've only been doing this two weeks and I fully serviced this vey intricate watch with many complications'. Oh bloody ha ha. I believed it and started. Ebay sold me a cheap kit (still use most of it) and I purchased watch movements that needed repair (idiot). If they need repair it's because they are broken and if they are broken how can you fix them if your don't have the skill? They are still there in my storage. I had no idea what I was doing. I do like Seiko's so I tried unsuccessfully to repair some. But I did watch Mike's 'My Retro Watches' who suggested that a course would be a good base, and mentioned Mark Lovick. I was lucky and got a 40% Christmas reduction. At last, guidance!! How did he know that everything I had been doing was wrong? Hmmmm. I have mild dyslexia in that I have great difficulty in assimilation of written instruction. I react to physical and visual stimulus. Exactly what Mark offers. So began the extended learning curve. Overcoming the history of broken pivots, springs , lost items and other breakages, I learned system and most of all the skill to practice. An hour or two every day gives a good depth of skill in use of tools. Where am I? I can disassemble most watches with basic complications, day and date, not yet chronographs. I can assemble all the watches and service them to be better than prior to disassembly. I have a plethora of tools and thanks to members even know how to use them. Am I where I wanted to be after 2 years. No. I was going to do a service on my own Breitling chronograph purchased by me for my 18th birthday in 1966. But I don't want to do so just yet as confidence is not there. Soon. Maybe. Am I enjoying the hobby? Oh yes. Will I continue? Oh yes. The biggest help has been 3 fold. 1. Me, getting off my backside and making the effort. 2. The internet. Courses and YouTube. 3. The membership of this forum. Made good friends and got good guidance. 24 months on. Merry Christmas and a Happy New year to you all. Ross3 points

-

2 points

-

With all due respect to everyone else... this is probably the most impressive thing I've seen on this forum since I joined2 points

-

I'm pretty good with my hands, but I'm not a professional craftsman. I will make a simple jig or hand tool myself, if it isn't otherwise available. What I don't have is the ability to make tools, from simple ones up to machine tools, which perform as well as or even better than the market leaders, from what otherwise would be scrap. That's a big difference, and I don't know anyone else who can do it either.2 points

-

Before the ‘Iron Curtain’ fall, in my country was not possible to buy watchmaker tools. There were no any. So, if one wanted to have, then he would receive them by inheritance or make them. And, my father was (unknown) poet and writer… This is my first lathe, I was 14-15 years old when I made it. The base of it is a Vernier caliper I am OK with Nev. No problem, will show pictures. Will make new tweezers to show how. Will try to do before the holidays2 points

-

Listen to this knebo. I promissed to show my watch collection when first joined back in may 2018 and still plan or hope to do so in this lifetime .1 point

-

Makeshift parts dryer if anyone wants a cheap hack . Just until the dc windscreen motor i ordered arrives to knock something better up. I normally use a food dryer but this is much quicker. A 2 pound travel hairdryer from a carboot that runs at 1000 watts and a microphone stand for 7 quid off ebay. The dryer is on low so just a good steady heat about 4 inches below the basket, within 10 seconds the basket of parts start to swing, that aids the drying. Obviously put all small parts in mesh baskets and check that the height and heat output below the basket suits requirements1 point

-

1 point

-

Thanks to all for the welcome to WRT. It's been very absorbing going through all the info and posts over the last week or so! My profile picture btw is of my Dad (Bert), at watchmakers' school back in 1946 when he was 16. Thanks again and I hope to be able to make contributions of some interest in due course. Martin1 point

-

Glad the guy has taken this up, but I liked the old advanced search better.1 point

-

1 point

-

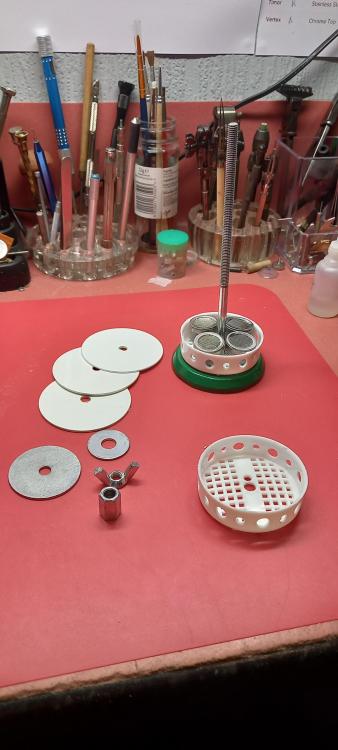

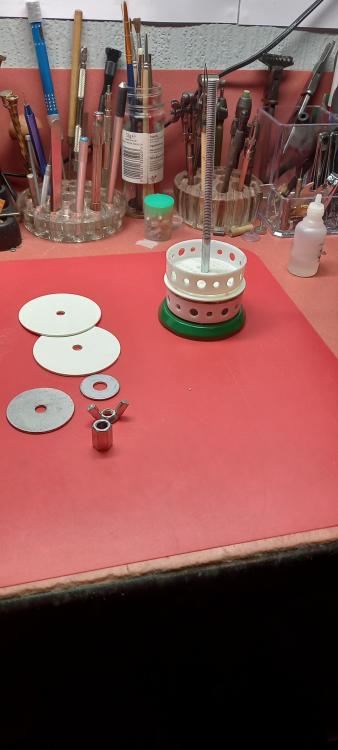

Another upgrade for you Ross. The little plastic baskets from cousins, the center post is too flimsy to spin the basket outside of a neatly fitting tin as per previous post. So i did a little customising to make it more stable. Remove the center post of the basket completely and drill out a 6mm hole in its place. Add in some more holes around the side of the basket to your liking. The base is just the lid off a sauce jar, i might change that or do away with it altogether but it does make the assembly more stable and creates a stand for the basket, you could add some holes to it if you wish, i probably will. The driveshaft is a bolt that connects kitchen worktops together it was just the right length and is an m6 thread size,you will need an m 6 wingnut for the top locknut. The plastic disks are cut from the outer skin of an old upvc door panel, just cut with a holesaw and then spun in a drill to clean them up, probably add some holes to these too. I think the pictures are self explanatory, i have some bits and pieces coming in the mail plus some odds and sods to make up the drive for the basket and a heater. Ideas are an electric drill with a seperate speed regulator, a striped down 2 speed cooling fan, these are great if you can adapt one to fit into some kind of jig ( very quiet induction motors and they run forever ). Also in the mix is an old drill press, a cheap laboratory stand with holding arms and dc car windscreen heater. Enjoy , i have too much time on my hands at the moment so theres more to come For some reason the pictures didn't add here they are.1 point

-

So Nev, lets just call you Neville after my uncle Nev if thats ok with you ? You can call me Richard or Rich or I'll even let you call me Dicky or Dick when we get to know each other better . Ok so my mind is also blown and Intrigue has grasped me by the short and curlies. We all need to see a picture of your kitchen/ tweezer combo if you please.1 point

-

The British Horological Institute have a list of accredited watchmakers, so you could check there to see if anyone is nearby.1 point

-

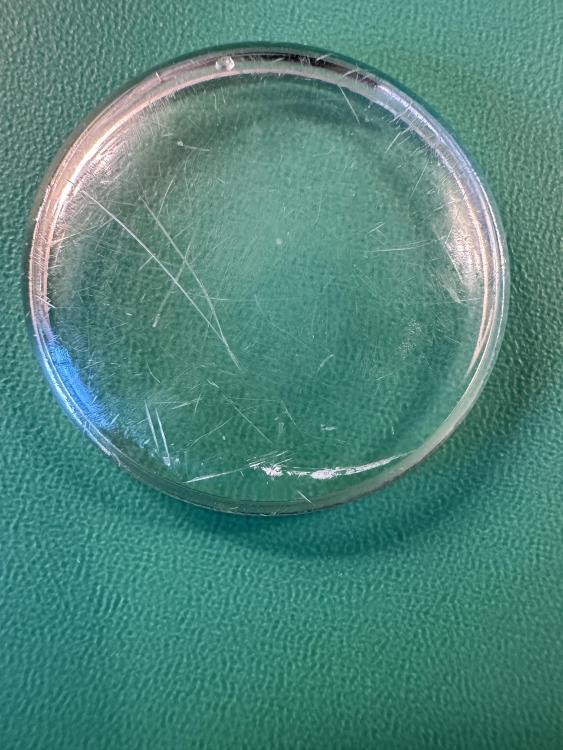

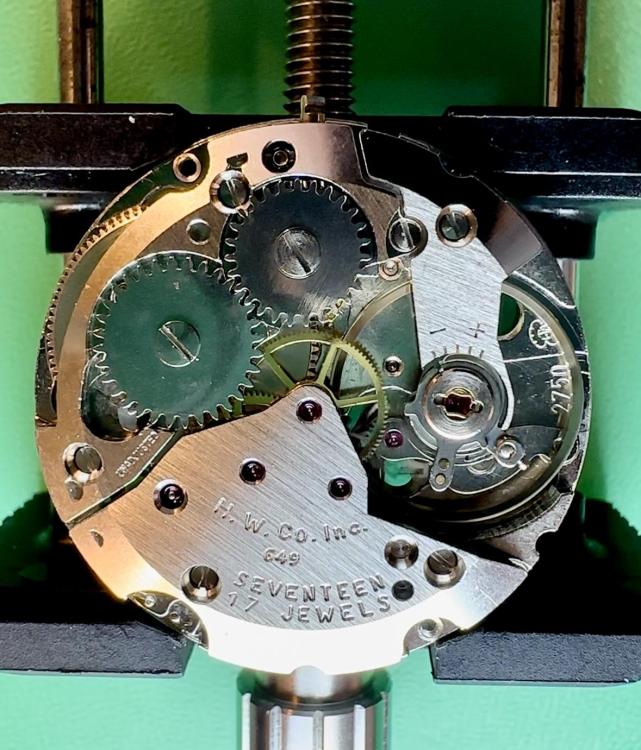

…so its looking good. No issues with the crown removal or the movement. No rust and looks to have never been serviced. Dried gunk. There’s that greenish glue holding the hairspring in the stud. The hole in the barrel bridge has been tidied a bit… …I’m waiting on a new crystal as the old one was cracked and not just scratched. A special Stella 24 1/2 says the interwebs. There's extra importance to the crystal here as it holds everything together so hopefully it’s the correct size…1 point

-

1 point

-

1 point

-

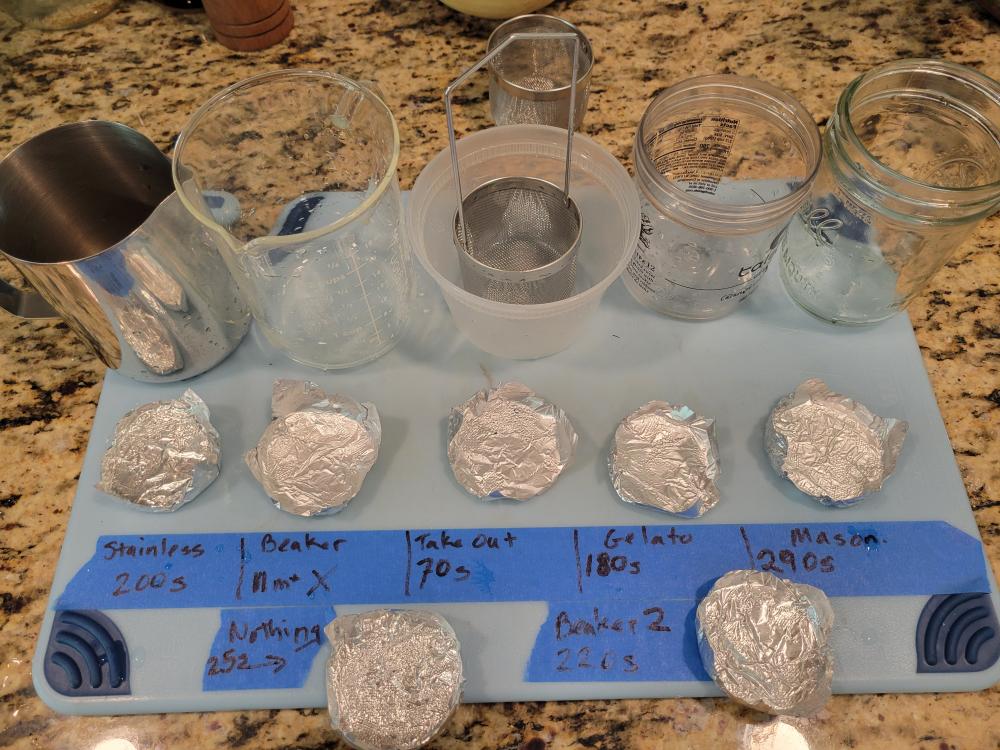

An excellent proposition. So my methods were: Square of foil pressed into the bottom of a cleaning basket Steel nut on top just to keep the foil from floating Basket goes into test vessel (or directly into the ultrasonic for the control) Test vessel is filled with enough water that it sits on the bottom of the ultrasonic's basket. Run ultrasonic until first evidence of holes in the foil Each test vessel was run by itself to try to keep things consistent. Results were interesting: Directly in the ultrasonic: 25 seconds Thin-walled stainless milk pitcher: 200 seconds Thin-walled glass beaker: over 11 minutes and zero pitting Thin-walled plastic takeout container: 70 seconds Thicker-walled plastic gelato container: 180 seconds (have not tested other flavors) Thicker-walled glass Mason jar: 290 seconds The beaker was the surprising outlier, so I tested it again, and this time came up with 220 seconds. Maybe a weird piece of foil, no idea. I should do more runs and get more data, but I already stared at my ultrasonic cleaner for an hour. The test is, of course, a VERY coarse one, and there are definitely questions about its overall usefulness. That said, I think it's interesting to see. I haven't been super happy with the effectiveness of the 5 minutes in Mason jars I've been doing, so this tells me maybe I should switch to the plastic containers or just clean for longer.1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)