Leaderboard

Popular Content

Showing content with the highest reputation on 09/02/24 in Posts

-

My first foray into the 404 club is an accidental one. My girlfriend's 13 year old daughter picked up this cute little Timex at a thrift store for $1. She'd been wearing it semi-ironically as a fashion statement and I asked if she'd like it to work. "Sure." So I took it home, tried a battery, and it lit right up! So of course I had to clean it up, polish the crystal, and lubricate the stem. Not bad for $1! I made a little video of it functioning: Then while searching for an instruction manual for her, I found this: And this was her response via text:7 points

-

Well it worked, because I was sitting here trying to figure out how I could see the carpet through the back of the watch.5 points

-

The pallet stones can easily be resized. Of course, You will need bigger (wider) stone and grit 1000 or so flat surface diamond disk or file. You put the stone on the disk and press on it with finger, then move the finger with the stone forvard-reverse on the surface to grind the stone. 4-5 movements and try if it will fit in the slot. May be it is clear without mention, but never grind the rest surface, grind only the opposite one, which is never in contact with the escape wheel teeth PS Chipped stones (if chipping is small) can be repaired too. Rotating brass flat surface is needed and diamond paste about 10 microns particles. You can easy shape and change the impulse surface angle. The stone gets shorter, but usually it is not a problem3 points

-

3 points

-

You'll need to insert a thin lever to release the clips as shown in the video around 5 minutes.3 points

-

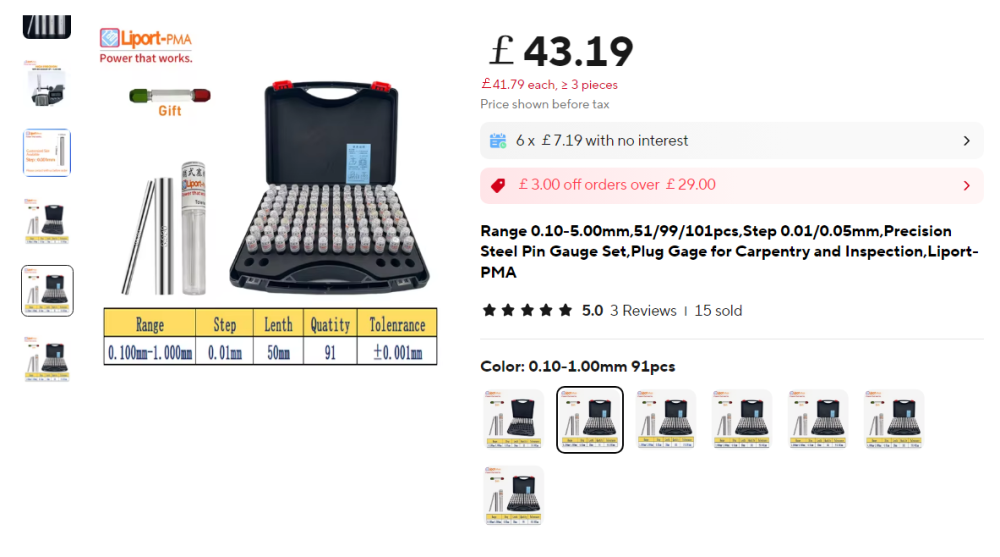

I have that set Rich, I have randomly gone through about 20 of the guages and they have all measured correctly using the Feintaster. Don’t put the smaller ones down on your bench, they make click springs look big and thick Tom3 points

-

Picked this up today for £7.59 or $10 if you are in the US (as I am). The seconds hand was off and wedged. Damage looks worse in pics as the scratches don't go to metal. The gasket is actually on the movement holder and did it's job and still had grease! The stem gasket also did it's job. Doesn't look like anyone has touched this movement (7005a). Reattached the seconds hand and gave the case and caseback an ultrasonic cleaning. Looks like a high dome gold armored crystal will work. Runs okay but needs a servicing as it is a 1974 model, I think.3 points

-

I would not solder it. Just prepare tapered pin from iron wire, then mark to where it goes in the hole and cut smooth the front part so it will not touch the axle, then press it in the hole (+locktite is OK), cut the excess, smooth and polish Poor thing...3 points

-

Hi! If you plan to work on more old pocket watches, you will end up using it on every project for a variety of tasks. Lots of things need pushing, driving, staff replacing, closing.2 points

-

I bought the 0.5 to 1 mm set, as well as the 1 mm to 2 mm and the 2 mm to 3 mm set. The bigger pin gauges are great for barrel arbor holes in mainplates and barrel bridge when boring to create an even hole from an ovaled one before bushing. They are mentally accurate, as my JKA Feintatser tells me. I bought all my sets from these guys https://www.aliexpress.com/item/1005005362640246.html?spm=a2g0o.order_list.order_list_main.246.44ba1802PTiHEm I have my Bergeon pin gauge set for the small stuff. 0.07 to 0.5 mm2 points

-

I understand that John , i dont think its a bad thing when necessary. But if something is repairable then that is something more that i can learn from. I could have swapped this part in seconds, as it was it took me well over an hour fiddling around setting up a drill and organising the a drill bit that would work, that was an hour of learning for me.2 points

-

I'll try that nev Ordered the vice Jon but I'll still read your review . What i like about it , you can make a series of your own clamping plates with different profiles to hold anything you want. I keep looking out on ebay for the BHT ( same brand as the trupoise ) vice, sell for around 30-50 quid, i think this Chinese one will have more application. Toys you say........ i wouldn't dare describe them this way if my missus asked what it was for, " Its an essential tool that i can't do without darling, whats that you're running out of that perfume you like "2 points

-

I really should label the little marks down below but I'm just doing something really fast. Where the spring has been bent out that's just about where it's bent sort of its also bent at the stud the classic place where things get bent hairspring. Day choir practice movements and go in and just gently pull out in the exact same location you would even need to grab it with the tweezers just push it out and see if you can simulate what you see here then you can try pushing it back in again. Now the reality is you may have to grab the tweezers and gently squeeze the whole thing to get it to go back but try some techniques and if you have a few spares deliberately destroy one just because. Then you'd you got that out of the way it now you can go back to practicing. The other thing you'll notice is the cause of that bent is the opera Mark notice how much spacing of the hairspring coils versus the other mark? This is because of just what's there has changed the centering of the hairspring. As I said it should be relatively simple to fix but try simulating on the practice watches try fixing on the practice watch and then you can Come back to this one with better idea of what's going to happen. Plus you can also try twisting the hairspring at the stud to see how it knocks it out of level you can try twisting it back again. All things that might somehow accidentally occur when you removing a balance wheel. Then yes classically the stud is the most popular place to have a problem with the hairspring1 point

-

Yes this is why the watches running fast. That's because they hairspring is not straight and The spring gets pulled out has artificially shortened the spring hence the reason is running fast so that needs to be straightened out if you wanted to keep time The problem with how your learning watch repair is your learning on live patients. Just think of doctors did that instead I going to school they go straight out the clinics and hospitals. You might be the first patient they decide to do surgery on I wonder what the worst that could happen would be? Maybe a better approach would be practicing on something that's disposable that you have no intention on repairing. There usually is a lot a cheap junkie watches on eBay that you can purchase movements whatever balance wheel sometimes practice bending hairsprings we get good at anything in watch repair is practice and the best practice is repeated practice on stuff that's disposable not live patients. Then that bent part of the hairspring is relatively easy to fix. Versus all sorts of other bad things you could have done but it really would be nice if you practice on something else.1 point

-

1 point

-

@Eliminator you will need a decent staking set, most of the Chinese ones are soft and not worth the postage or the pixels on the website. Safe way it too look out for a decent vintage set, plenty of information in the tools section here with lots of good advice. You will also need smoothing broaches. A ball bearing and reamer is most definitely not the way to go. Tom1 point

-

No, I haven't had as go at it yet, but I like your idea of making a custom axle to fit the hole once I open it up. I know a bush would be a bit of a dodgy proposition, but I'll give it a go first and then try your idea. Cheers @nevenbekriev1 point

-

Red cover Band 2/3 the caliber listing is easier to handle than bestfit, choose the pallet design, then holes per set lever then the size. I'll get that link. https://www.aliexpress.com/item/1005003664177054.html?spm=a2g0n.order_detail.order_detail_item.3.3eb7f19cQtqUzy1 point

-

1 point

-

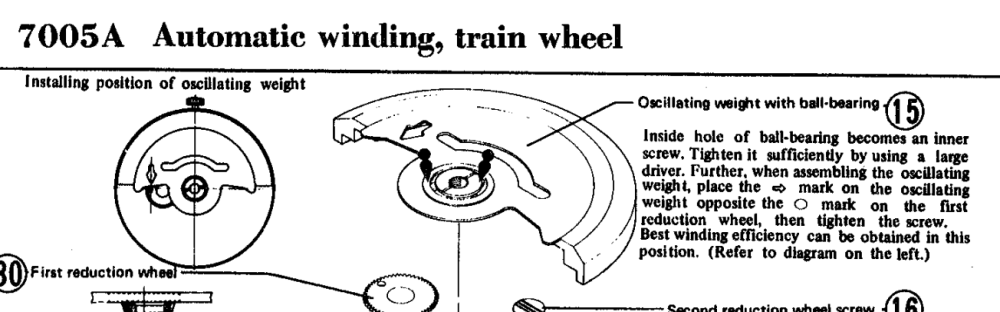

I wonder what the deal with is with the arrow on the rotor. Knee jerk was that it winds only in one direction, but then I see the magic lever pawl there... Why did they spring for that extra detail in the stamping die? Edit: And then I took another sip of coffee. And then I remembered there's something about aligning the arrow with the dot on the wheel in the automatic works to balance it all out somehow... I think... More coffee...1 point

-

1 point

-

1 point

-

1 point

-

Oh my heavens, @JohnR725 this fellow scared me a few times. I happen to have a cylinder Breguet (which is either one of their more modest offerings or may be a souscription - it does not have a ruby cylinder, just a steel one like the above watch, but the construction is Breguet). My movement is identical to this one, but the case is silver and not gold. The difference? - I have serviced cylinder escapements before, and they do behave a little differently from levers. It is also best to have the extra, needed tools - the special weird-looking punches that reach into the cylinder to push at the tampons, and the stumps to support the balance properly. Watching this guy just jump in with both feet, without apparently reading a little bit about them so he'd know what he was getting into, that made me wince. That poor watch. There are several things that can cause a cylinder watch to misbehave or not run at all. And many of them are the same issues that would also stop any other kind of watch: dirt, congealed oil, wear, damage caused by carelessness or accident, or damage caused by inept repair, etc. But one thing that comes up is *inadequate* lubrication. Each of the escape teeth needs just a tiny smear of oil. It's a friction-rest escapement and one must mitigate some of that friction. And it is best to service it yearly if you are going to carry it and run it throughout that year. Friction and wear are much more of a bane to cylinder escapements then to any other kind. Another problem with bar movements that have this kind of suspended, hanging mainspring barrel: misalignment. I had to bush the hole in the bridge of my Breguet because wear had caused it to tilt and bind against the center wheel, and rub the underside of the hour wheel on the other side. Once I got it back at proper height and alignment it ran very well. Seeing that video reminded me; I started out a little ahead of this fellow. I'd already read quite a bit about cylinder escapements and how they worked before I was confident enough to work on one. I was prepared for the surprises. The poor man in the video was not. Clearly the movement did things that surprised him. Surprises can be a bad thing in watch repair. I am holding out hope that this experience does not discourage the man in the video from learning better practices with regards to cylinder watches. His videos are very watchable, and I'd like them to improve.1 point

-

Whel it is a cylindre. First of all, it is not enough to have it running with no stopping, but amplitude should be at least 90 degr to be sure that it runs confidently. After disassembling, put only the balance with both the cocks on the plate and do the free oscillations test. There should be no difference in both horizontal positions and at least 50 oscillations are expected. If this is not so, then pay attention to the pivots and bearings. As this is cylindre, the axial free play of the balance (if it is big) may cause the teeth of the cylindre wheel to go away from the correct trace on the cylindre mouth, so this is one of the important things to check. Lubrication of cylindre is important here to achieve good amplitude. My experience is tat the best results gives very small amount of moebius 8020 grease only on the trace where teeth make contact with the cylindre. It is a lady's watch and they usually wore them as a pendant on their necks.1 point

-

Just to solder the hole now, it isn't so bad, i used a cut down 0.4mm carbide bit, man those things are brittle. If the drilling machine you use has some run out ( i used an old minicraft tool in it's drill stand ) the whip on the tip snaps the full drill bit flute as it hits the workpiece and flings it across the room, i found a dead moth later that had been speared . Shaving the carbide down to 2mm helped a lot, dont know why they have around 8mm on them. The cannon pinion will be packed inside with something easily removed, probably sponge, piece of leather maybe to stop the solder running inside. I'll let you know how the fire goes It had some grip on the inside so it may not have spun while drilling .1 point

-

Me thinks... there is no cap at all, this is one whole part. Yes Rich, what You did is the only solution. The broken part is loose inside and will turn when trying to drill. It is hipoteticly possible to fix the piece with shellac and then drill it, then dissolve the shellac, but what You did is easier and safer.1 point

-

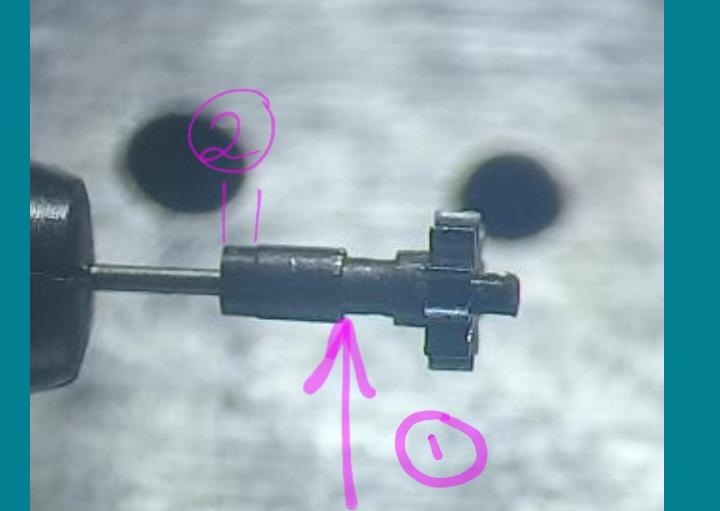

I noticed these vices a couple of months ago and really like them, they're down for next months buying only 27 quid. I've spend a shed load this month on watches some tools and something to make a semi auto watch cleaner. The hole in the top seemed safe, if the top section is tight,tapping the arbor further in to pop the cap off .....risky me thinks. The join at 1. At 2. the thickness of cap end i had to drill, thicker than i expected .1 point

-

I've got one of these tools, which are great for holding crowns for removing and replacing gaskets, as well as drilling out old stems and closing up watch hands. I'll do a little review on the tool in the next day or so. In fact, I've got half a dozen new toys... I mean, tools, so could do some reviews for them. I even got some boxwood tweezers from AliExpress for about a tenner, which are mind-blowingly good for picking up bridges and the like1 point

-

1 point

-

Would alum not also just dissolve the pinion being made from the same steel? I've only ever used alum to remove a broken stem from a crown.1 point

-

I thought I would give the link to the offending video which by the way is the second video. But six days ago he is doing it again and yes five minutes of research but does it matter? He has close to 1 million subscribers he makes happy videos on how easy watch repair is and he definitely does not do things right but apparently those things really don't matter. Memories making entertainment videos try not to pay attention them as actual service videos then I can't say the cylinder is my favorite watch to work on at all. Very definitely always remove the power and be extremely cautious as breaking things on this watch will be very bad for you. In fact I would actually stay away from cylinder watches as their vintage they're not usually made in outstanding quality although? There are some outstanding quality cylinders including those that have rubies cylinders. I would also stay away from those they're well out of your price range if something breaks as there will be no parts for those and fixing anything on the cylinder watch getting parts is just a big pain in the ass. okay now to the watch video that definitely do not follow his practices1 point

-

A small update for those who are interested. Last Friday I finished the disassembly and for those of you who are interested, I have added new pictures to the link I published in a previous post (please sort by name in ascending order). It was over 300 pictures. In the long run, I plan to create a service walkthrough and then I will have plenty of pictures to choose from. I was a bit unsure whether I should dismantle this cannon pinion-like part on the "Cover mechanism" because Rolex explicitly writes "Do not dismantle". But, since the whole movement is covered with metal debris, I chose to do it anyway. However, I had some headaches because it did not work with my trusted cannon pinion remover nor with some of my presto tools which were all too big. I tried to pull the tube off by clamping it in my staking set and pushing the tube up with brass tweezers, but that only resulted in the tip of the brass tweezers breaking off (easily dressed) but better than damaging the tube. After looking through a bunch of videos I finally found a video where @Markshows how to do it. Many thanks! The parts are now soaking in a degreaser (Horsolov) and I will brush them all off before it is time for the cleaning machine. Getting everything perfectly clean will be a challenge considering the service neglect and damage made by the loose rotor.1 point

-

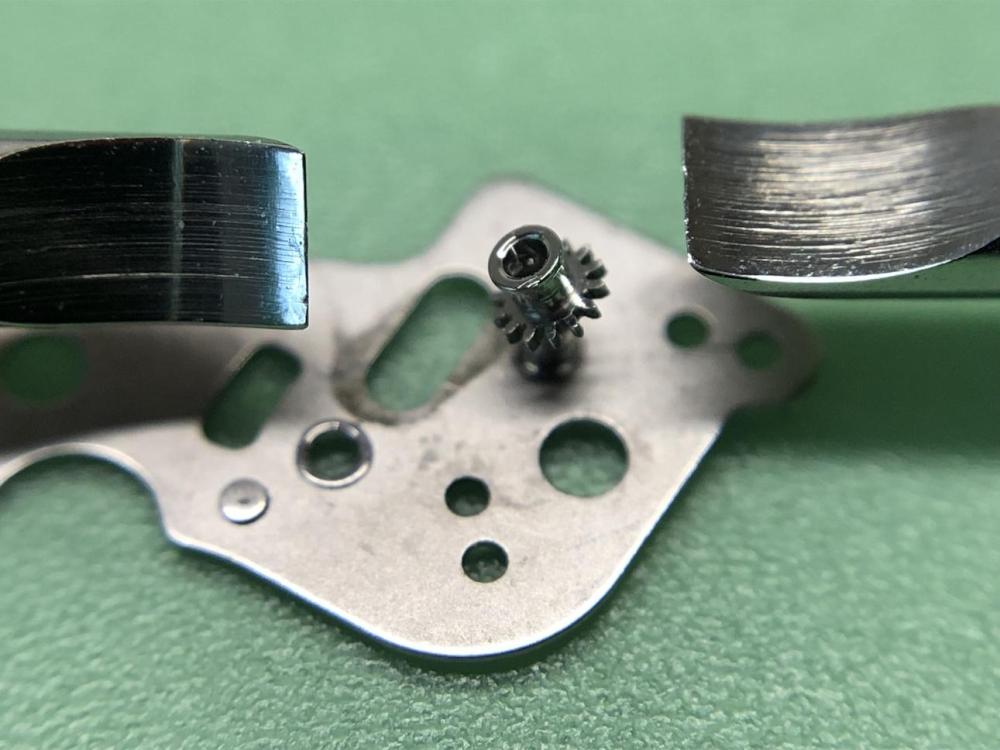

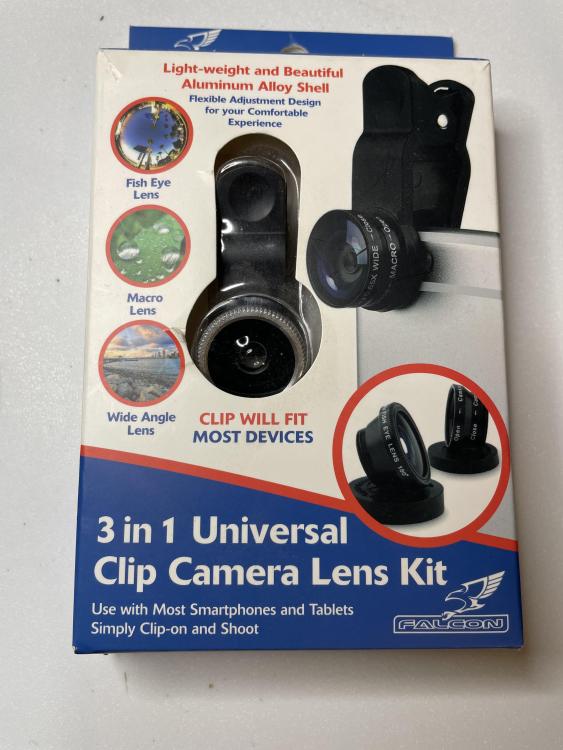

I saw a mention in one thread with the OP saying they could not take good photos of a watch movement they were asking about, so I thought I'd post my ultra-cheapo method: A local second hand shop had a stack of the nasty looking "clip on" lens kits for smartphones; they were priced at 50p so I got one out of curiosity. I didn't even try they for weeks, until I was struggling to take a high enough magnification of a damaged piece of jewellery, for a friend. The "macro" lens in these kits is actually amazing, it's very effective - and the full kits around only around £3 to £4 on ebay. The first photos are the particular 50p lens kit I got, and the lens I'm using from that, then examples photos, using my iphone with the macro lens in the clip and approximately centred over the camera lens. It does need a good light, and finding the exact height for best focus can be tricky sometimes, but the results are worth it. The movement is a Junghans calibre 73 from ebay:1 point

-

I love my Russian watches. The Vostok Amphibia and Komandirskie... maybe not so much. They are rough but robust. Can take a lot of abuse, unlike my Swiss Army watch which uses a quartz movement and just dies sitting on the shelf. It's like an AK47 compared to a M16.1 point