Help me identify the correct mainspring for Bunn Special?

-

Recently Browsing

- No registered users viewing this page.

-

Topics

-

Posts

-

By Terrinecold · Posted

Hello, I am just starting to learn how to hopefully service mechanical watchs Right now I started by acquiring a bunch of tools and a first practice movement (ST36). Since I got it last week I have been practicing disassembling and reassembling it (I don't yet have the tools and products for washing and lubrication as I estimated that the first step is the manipulation required for assembly and disassembly). To be quite honest the result have been interesting. My first step was breaking the setting lever screw when I was trying to remove the stem (OK practice movement won't be able to set time, oh well). I did manage to mostly disassemble the movement (I kept the balance together, didn't open the barrel and didn't remove any jewels). I messed up the balance spring a bit when removing the balance (I think the impulse jewel was still in the fork or something). There was a small tangle. I reassembled everything and surprise the movement came back to life. I disassembled it again and decided I will try to fix the hairspring. So with lots of trouble I removed it from the balance and when trying to fix it I made more of a mess. After reinstalling everything the balance won't oscillate (likely the spring rubbing on things, either the plate or the cock). Right now I wait for my second st36 and continue practicing while slowly buying what I need to wash parts and lubricate them. Any of you think there is a chance I can repair that spring or find a balance complete for that movement which will cost less than the whole movement? -

By RichardHarris123 · Posted

Hello and welcome from Leeds, England. -

By Terrinecold · Posted

Hello, I am a software engineer and all day spent in front of my computer makes me want to do something more manual as a hobby. I like the mix of intricacies and basic technology of mechanical watches, the fact that such marvel could be built manually hundred of years ago fascinates me. So I decided to combine the two and learn "watchmaking" (between quote as I don't expect to ever be able to make a watch). My first goal is to be able to service a mechanical watch. My current status is that I am pretty good at breaking small parts in watch movements -

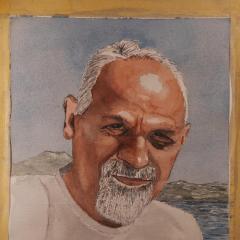

By eccentric59 · Posted

Nothing special to the horological world, but this is my travel watch. For whatever reason, this watch has accompanied me through airport security more often than my appendix and gall bladder. I feel as if i need this with me as much as my passport. -

Apologies for digging up an old post but I am thinking about doing the same. Can I ask the OP what medium he used on the wheel. Was it a sanding disc and polish and if so what grades. Thanks.

-

Recommended Posts