Search the Community

Showing results for 'accutron' in topics.

-

After 21 Months

Neverenoughwatches replied to rossjackson01's topic in Your Current Projects and Achievements

I love your updates Ross, you're making good progress. Do you have any immediate plans to learn some repair techniques involving staking and jewelling tools ? Many years ago now but It was my first time for having bacon eggs and honey pancakes on the same plate, i remember thinking # what the hell is this all about # You can do it Nessie, organise that space , set up the scope, lay out the tools, crack your knuckles stretch out them pinkies and off you go. Is this the single eyepiece accutron scope ? -

I know how to measure and fit an acrylic crystal, but how does one choose the type if the watch came to me without one? Can you tell if it needs a gasket by looking at it? Since it has a gasket for the case back, should it the crystal have a tension ring for extra waterproofiness? Low-dome? High dome with step? Without step? With faceted edge? If I choose one with a calendar lens, is there any way to know if the lens is wide enough for the day/date, or are they really only designed for the date? Basically I'm trying to figure out what is an aesthetic choice and what is important. My instinct is to just get a plan ol' low-dome for $3, but I don't want to end up getting something that won't be water resistant if that's what I need.

-

EvergreenParts supplier...interesting

HectorLooi replied to LittleWatchShop's topic in Chat About Watches & The Industry Here

Hmmm.... I wonder if they can machine Accutron index wheels? -

I came across a replacement motor from Cas-Ker recently but it's a little pricey to just buy and try. https://www.jewelerssupplies.com/accutron-242-step-motor-20-510-900.005.11.html I wrote about my adventures with a Bulova 242 last year. I just bought an untested 242 movement off eBay and am praying hard that it works. You might find it useful. Apparently, this twitching problem is quite common with the 242 stepper motor. I haven't really looked into the cause.

-

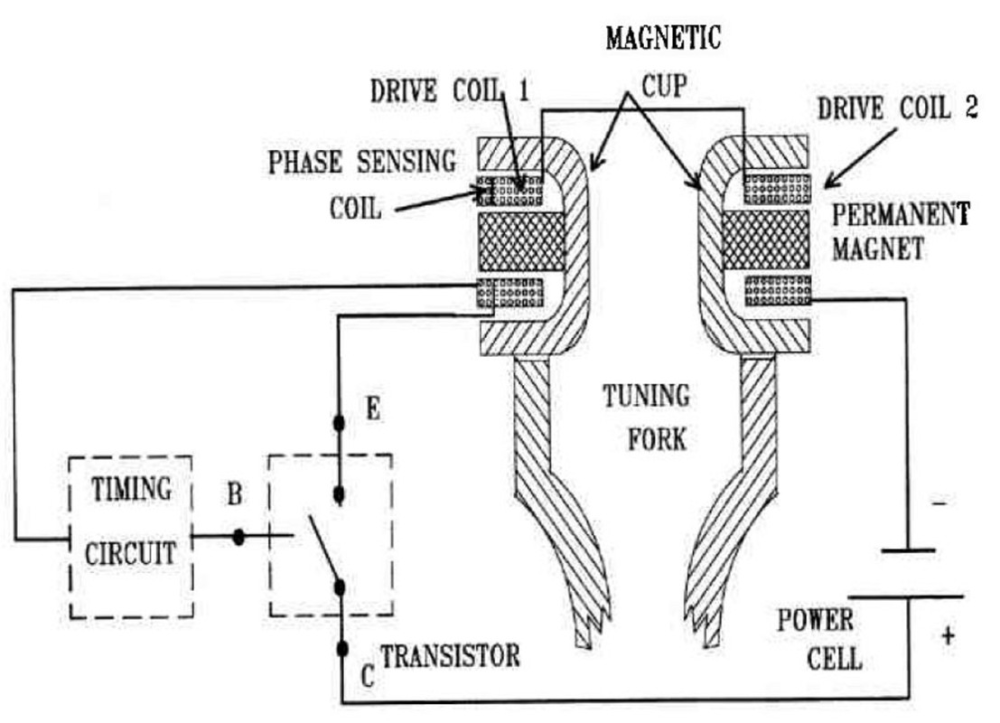

Yes they figured out things easier with time for instance the ESA 9162 Phasing is interesting. They give you a little test plug you put it in and you just the fingers to be in the proper place for the plug you remove the plug you put the watch together and if you're lucky it might just run otherwise you barely tweak the phasing screw. Plus the electronic part is separate from mechanical part Oh thinking about phasing I've attached a couple of things. The article on basically where the factory way back when was servicing the watch to run at a much higher voltage so silver cells for the most part shouldn't be a problem. Even the specifications sheet shows that the high-voltage phasing voltages much higher than it says in the service manual itself. 1996-08-web horological times Accutron silver cells phasing.pdf Accutron_Specifications.pdf

-

For unknown reasons the 219 service manual is incredibly hard to find. But I was sure that I had a PDF in the computer doing a search revealed A two-part PDF and the quality sucked. So I was thinking what would be the chance that I could figure out where my physical copy is and find it without searching the entire section. Fortunately I guessed correctly. That's now been scanned and attached as a PDF and much more readable condition than the previous thing I downloaded. I think it will answer the questions you have testing the various components etc. Accutron 219 ServiceManual.PDF

-

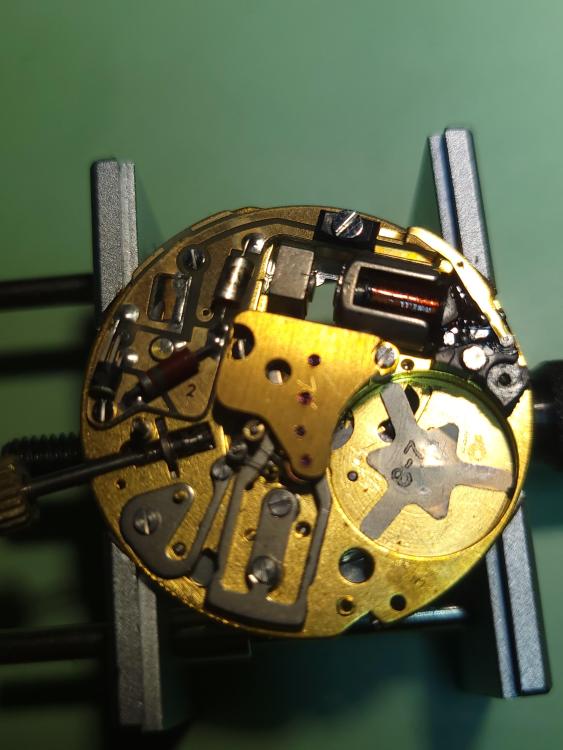

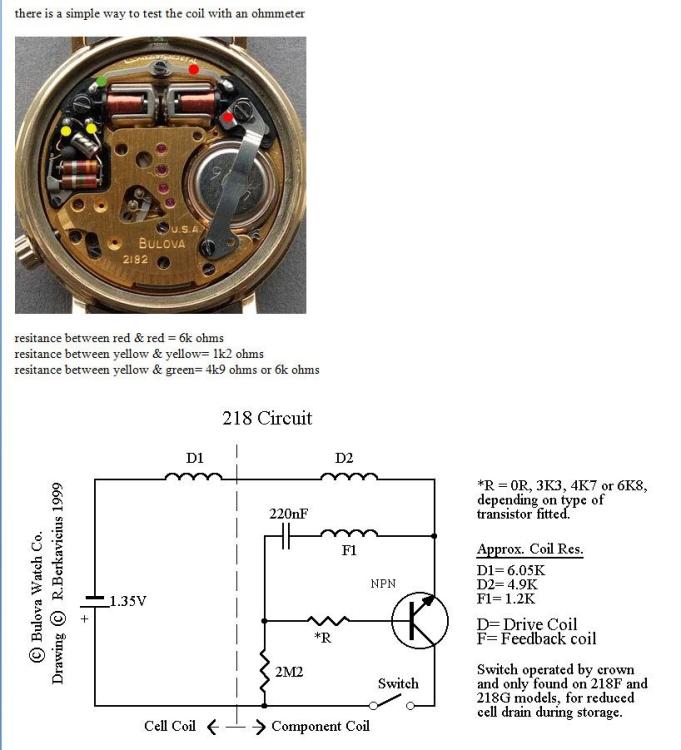

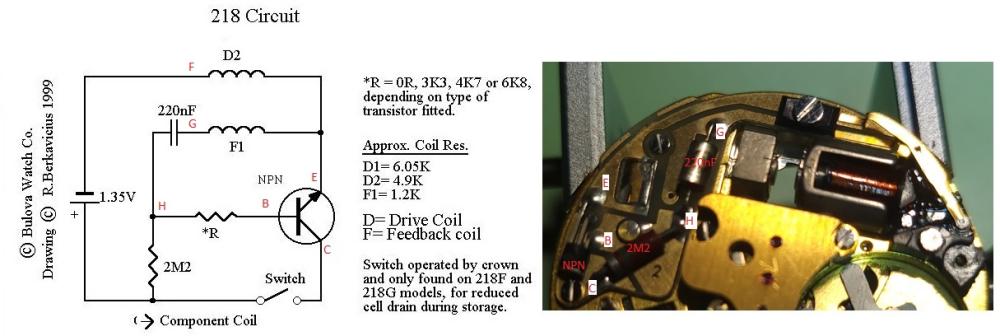

I've got a 219 that I'm playing with. When I hook it up to the 700 test set, it pegs the ammeter, so I'm trying to determine if I need a new coil. I first determined that the previous owner had screwed the battery strap to the main plate, causing a dead short. After I fixed that, it still doesn't run, regardless of how much tapping I do on the side. The ammeter needle stays all the way to the right. My understanding is the 219 uses most of the same bits from the 218, with the obvious omission of one coil. And this is what my 219 looks like: Testing resistance across the two brass prongs of the coil only gives me 900 ohms, where I'd expect 5-10k. But because there's only one coil here, I can't be sure I'm testing the right bits. Is the feedback coil included here? Where are the contacts for it? Are there any diagrams for the 219 out there? I do see that Cas-ker has coils and circuit boards available for $50 each, but I'd love to know if this is bad first. Plus I love learning this stuff. So assuming they just removed the cell coil and left the rest of the circuit the same, this is how I matched my 219 to the schematic: I was measuring between E and G, so across F1. 900 ohms makes a little more sense. I'll try tomorrow between F and E. To tired and too much Scotch to do more tonight

-

Looks like it's to adjust if you have drift in the seconds hand. From the Accutron 242 service manual found over at Watchguy:

-

Accutron 214 service . Do you know anyone in the not to far from Sweden that does that . I thought electric watches did accutron . But not any more.

-

The index wheels all seem to have a strangely large amount of runout. As long as the teeth are intact they just seem to work though. When phasing, I do as in the quote above, but I don't want to see any hesitation- smooth running only. That's a shame they skip the actual phasing part in the vid! Henry was actually a guest instructor when I was in school to teach us Accutron work- interesting guy and he really did know his stuff. You could check with AWCI, the American Watchmakers and Clockmakers Institute, who made the video; if you are a member you can check out books and videos from their library.

-

Sorry for the multiple threads. I'll be honest--I just noticed there was a separate forum for tuning fork watches So I'll keep my posts here. I don't have the 344 silver oxide cells yet, so I'm adjusting with the 1.35v Accucell and the model 700 test set, per the service manual, to get a feel for how things work and to have a good starting point. This is really a learning experience. The index pawl is even more sensitive to tension than I expected. So the first question is regarding the last few steps in the process: I'm a little confused on the momentary hesitation part. Are they saying it's permissible while rotating the cam after it stops the first time, but before it continues to run consistently? The other thing I'm wondering about is trueness of the index wheel. I noticed that the one on this movement is noticeably out of true at the rim. Is that normal? I did my best to take a close-up video, and you can see the index and pawl jewels moving back and forth. Edit: I was also using Henny Frystack's excellent video on the 214 here as reference, but it looks like the actual phasing part is cut out of it. He talks about the theory of it, but the practice seems to be cut off at 43:00. Anyone know if the rest of it is out there on the internets?

-

Accutron train bridges are very easy to assemble because the jewel holes have something like a funnel to guide the pivots in. Just put the the bottom pivots into the bottom holes, gently drop the top plate on and tap the holder. The plate will just drop in. It's really satisfying. I suspect it's because your bottom holes have pegwood in them that you can't get the plate on.

-

Accutron 700 meter

JohnR725 replied to ManSkirtBrew's topic in Watch Timing & Testing Equipment / Timegraphers

There used to be somebody out there that didn't do this but I think he got overloaded and work and doesn't do it anymore. Then when you're making a machine for winding coils about a machine to make index wheel's. Then I figured out where I put the information on phasing for silver cells. I'm attaching a PDF on that. 1996-08-web horological times Accutron silver cells phasing.pdf -

So first of all: yes, I'm a dummy. Yes, I learned my lesson. While cleaning my Accutron I pegged out the jewel holes as usual, but realized too late there were burnished-in cap jewels on the other side and managed to get bits of pegwood trapped between the hole and cap jewels. I was able to clean one out through the hole jewel with a sharpened oiler, but the other is not budging. I've been soaking the bridge over night in hexane, but it's no better this morning. I'm worried about chipping the edges of the jewel hole if I keep it up. Any other suggestions on what might soften/dissolve pegwood?

-

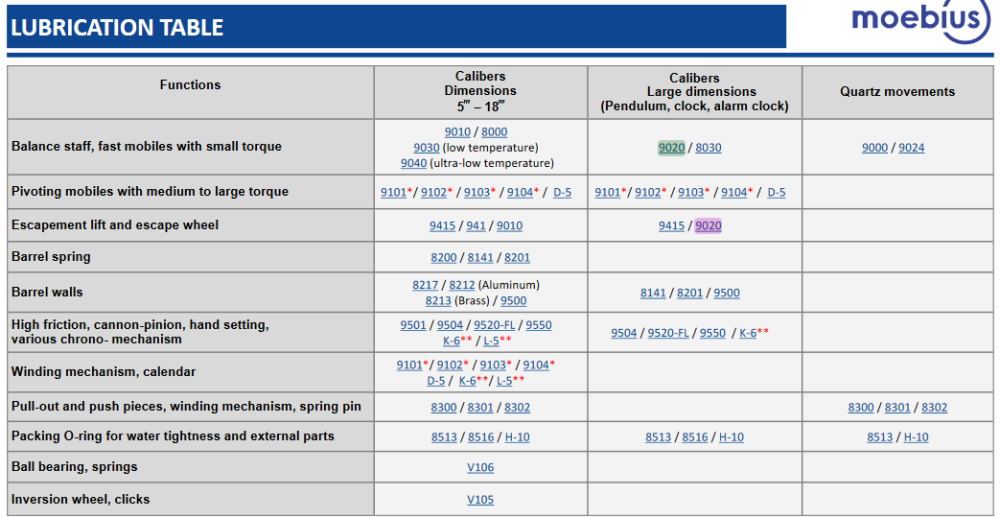

The service manual calls for only 2 lubricants: Moebius OL219 - Synta Visco Lube Moebius OL207 - Special Lubricant with Molybdenum Disulfide I understand that they are now Moebius 9020 and 8201, respectively. Unfortunately, I don't have either in stock. I do have 9010, 9104 (HP1300). For greases I have 9501, 9415, and Kluber P125. The manual recommends OL219 on the train jewels where I'd normally use 9010, and looking at Moebius' lubrication chart that seems reasonable. In Mark's chronograph course he also notes that 9010 can be an acceptable substitute for 9020. The grease is a little more tricky. The manual uses it in some places I'd normally use 9104, like the minute wheel post, but also where I'd use 9501 like the stem and sliding clutch. I thought the Kluber P125 might be a reasonable substitute for the 8201, but I think the Kluber is thicker. Basically I'm wondering if there's a compelling reason to buy the lubricants specifically called for, or if I can use what I have here. I don't mind spending the money if I really should, but if I can get away with what I've got and not have to wait with parts on my bench, I'd love that too.

-

Accutron 700 meter

HectorLooi replied to ManSkirtBrew's topic in Watch Timing & Testing Equipment / Timegraphers

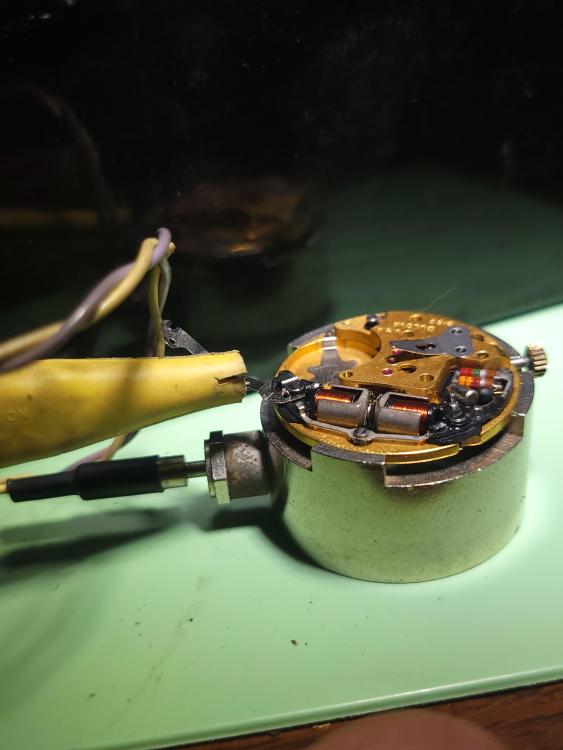

Is that a 218 movement? 218s are a good starting point to learn Accutron repair. They are infinitely simpler than 214s. The uA are an indication of the amount of current drawn. It should be within the current range for the movement. An abnormally high current could indicate a faulty circuit, a dirty gear train or a high amount of pressure of the pawl/index fingers on the index wheel. A high current draw will result in short battery life. The adjustments to the index finger that we are talking about here are incredibly small. My 218 just died on me after two years. I found that it's due to an open cell coil. Looks like it's time to build a jig to do coil rewinding as working coils are getting really hard to find. -

I finally feel like I have the confidence, tools, and fine motor control to tackle these tuning fork movements. I've got my 700 test meter here (in beautiful shape with the original box, I might add!) and it seems to work as it's supposed to, at least with one of those 1.35v diode batteries in it. I'm planning to phase the watches for silver oxide cell voltage at 1.65v, so what I'd like to do is use my low voltage power supply to supply the test meter, and so I don't have to keep buying cells. I feel like I saw a thread where someone made a dummy 343/344 cell with power leads on it. Anyone have pictures or a link to that?

-

That is an Accutron tuning fork watch. I wouldn't advise a newbie to attempt this. The repair would require a microscope, an Accutron tester, a multimeter, a variable power supply and specialized tools. There are a lot of articles and videos on the web explaining the inner workings of an Accutron. Absorb everything you can and then decide if you are ready for it. If you are looking for a battery watch to dabble with, perhaps a modern quartz watch would be a good starting point. Or an electromechanical watch like a Timex Electric, Hamilton Electric, Dynatron, Cosmotron.

-

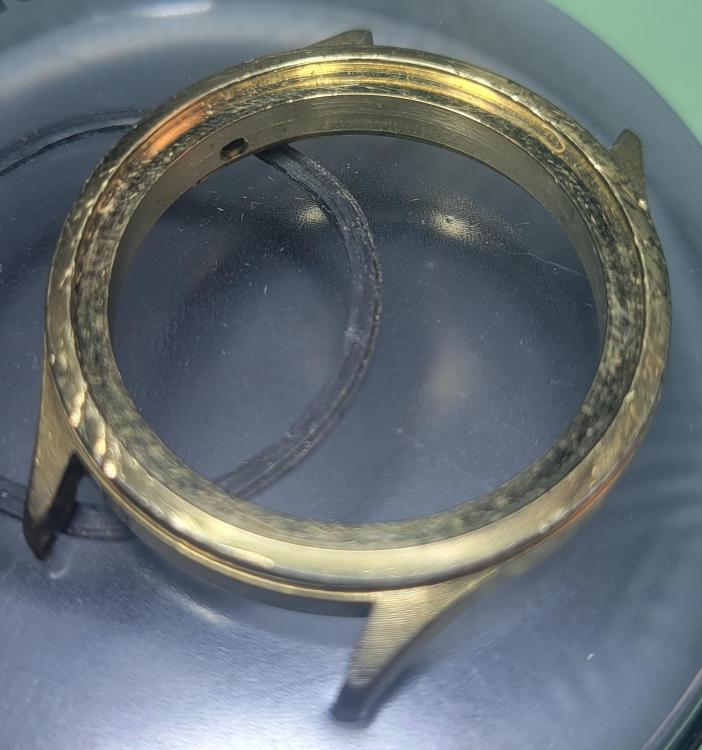

Last week, I bought a bunch of stuff from an NAWCC member. Lots of junk quartz watches, but a few accutron tuning fork watches and some accutron quartz watches. I think whoever worked on this accutron quartz accidentally switched out a solid gold back where a gold filled one probably was. I have seen lots of accutrons where the wording on the back says "gold filled" whereas this one just says "gold." I think it is 14K solid gold. Opinion?

-

2x Barlow lens yes/no ?

spectre6000 replied to Endeavor's topic in Eyeglasses, Loupe's, Microscopes and other Optics

I have both 2X Barlow and 20X eyepieces, but I don't use either for watchmaking. Accutron movements seems like a good application for the eyepieces, and I'm sure there are occasions when you really want (though probably not strictly need) to get as deep on a mechanical movement, but that seems like a wait until the need arises sort of thing. That scope looks like it's from the same factory as the AmScope, et. al., so I wouldn't worry about inexpensive eyepieces getting hard to find any time soon. -

2x Barlow lens yes/no ?

HectorLooi replied to Endeavor's topic in Eyeglasses, Loupe's, Microscopes and other Optics

Try it out for yourself. Do you find 22.5x sufficient to oil a pallet jewel? Is 3.5x wide enough to see the whole watch? Like I said, the only time I need higher magnification is when working on Accutron watches. Possible upgrades that you might want to consider are a led ringlight for shadowless lighting and a tiltable microscope mount, so that you won't need a step ladder. -

2x Barlow lens yes/no ?

HectorLooi replied to Endeavor's topic in Eyeglasses, Loupe's, Microscopes and other Optics

I think most of us use a 0.5 barlow lens, giving a magnification of 3.5 - 22.5 X. The 0.5 barlow lens halves the magnification but doubles the working distance. When I want higher magnification, I use a 20X eyepiece. This gives a magnification of 14 - 90 X, but at a more useful working distance. The only time I wished I had higher magnification is when working on Accutron watches. The teeth on an Accutron index wheel are so small, that even at 90X magnification, they are still hardly visible. But higher magnifications with optical microscopes become impractical because of the shorter working distance and shallow depth of field. I'm still trying to convince myself to get an industrial digital microscope with a magnification of 200X.