Leaderboard

Popular Content

Showing content with the highest reputation on 06/13/15 in all areas

-

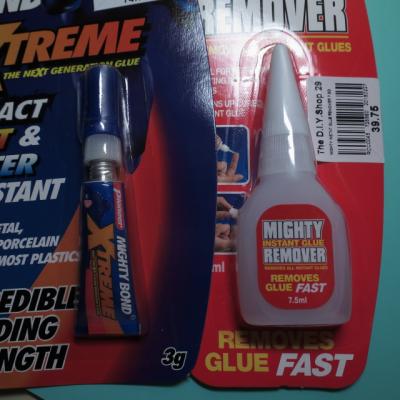

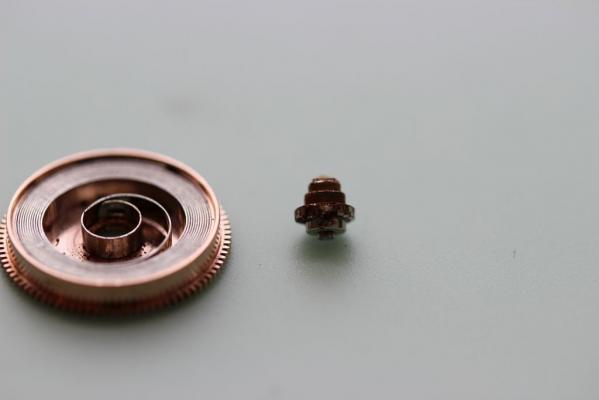

Thanks to this forum, I found about this technique. But initially, I was hesitant to use it. It sounded crazy! So I figured posting more cases of its use will give others confidence on the technique. The watch in this case was from a watchmaker. He himself wasn't able to open the back case - see all the scratches at the back. I used a superglue - remover pair from our local hardware store. It is best to center the nut as precisely as you can to facilitate easier turning. Otherwise, the pressure exerted on the case back threads won't be even. The glue remover turns the superglue into gel-like, allowing you to remove the nut after a few hours of applying it. ...and it leaves no mark. Not that it matters in this case. :D2 points

-

2 points

-

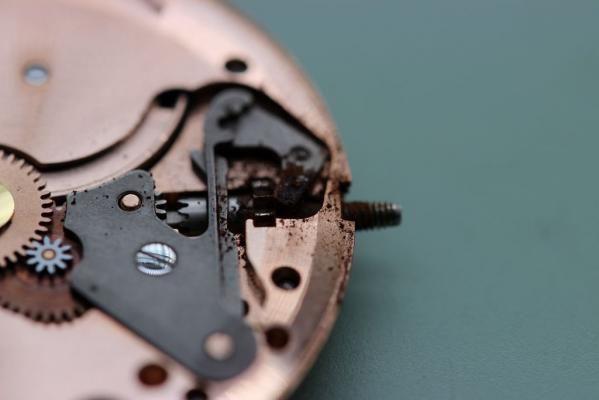

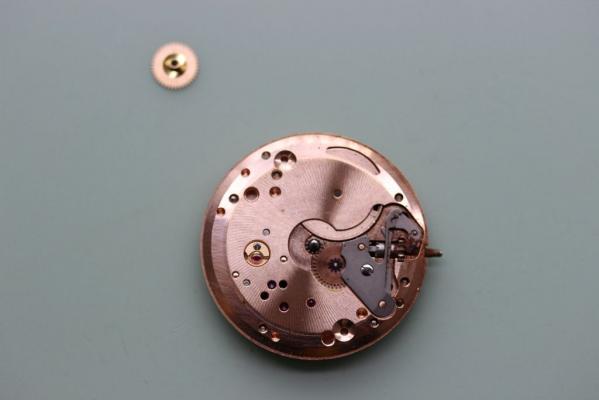

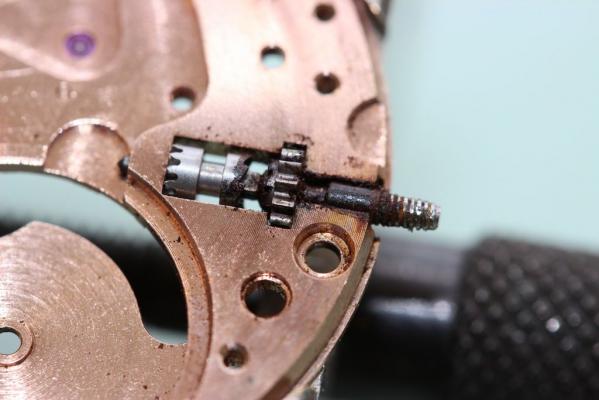

This nice Omega came in with a seized up keyless work. The crown could not be pulled out to hand set position and the watch could not be wound. I immediately suspected rust. Getting the movement out of the case was a challenge because the crown could not be pulled out. But luckily I could unscrew the crown from the stem as the stem was seized. With the movement out of the case, I can see evidence of rust. Time to get stripping (the watch). First challenge was unscrewing this dial screw which was rusted in place. A bit of oil and some gentle persuasion and it unscrewed. With the dial off I can see the extent of the damage which is quite bad - but not the worst I have seen. Off with the hour wheel: And the setting lever spring: And this is as far as I could get. That stem was not coming out, but I have an idea! ...1 point

-

I have had the same problem a couple of times with the hairspring bend right in at the collet. Not managed to successfully fix one of these yet. It would be enjoyable to see how some of the more expert watch repairers tackle this problem.1 point

-

So next off is the main plate exposing the wheels. I was half expecting to find rust in the pinion leaves or pivots but all seems fine. Off with the wheels... A teeny bit of rust on the escape wheel pivot but luckily not attached - brushed off and left no stain. Now back to this bugger of a stem. The oil did not seem to help... But after heating it up with my spirit lamp, I grabbed it with my pliers and gave it a sharp pull. It came away just fine. The barrel arbor was quite rusty so I decided to burnish it - easiest way is to use the lathe... And it came out quite well... Just need to clean up the rest of the parts and clean the watch now. To be continued.1 point

-

Well I decided that the first thing to do would be to dismantle the rest of the watch - can't risk damaging any parts. But first I drowned the stem and winding pinion with clock oil so it could start soaking. Then out with the balance... Then off with the ratchet wheel - does not seem to be any power there but I can't risk it so it's a good idea to remove the ratchet wheel and click work altogether. I don't like the ring of rust around the barrel arbor bearing... And the crown wheel... Now I am sure there is no power on the mainspring (but I was wrong) so I can remove the pallets... Off with the barrel bridge and surprise surprise... more rust :( Not looking good - but it seems to be surface rust so it should come off easy. Now to open the mainspring barrel. Remember I told you I was confident all the power was released? I was wrong: Yes - the barrel arbor was seized in the barrel and so the spring was stuck in a fully wound position!!! I have never seen that before. Time to improvise. I thought the safest way would be to put the barrel in a polly bag and push the arbor with my fingers. That way nothing flies across the room :) And that seemed to work well. With the tension off I am able to get the arbor out and inspect it. It's a bit corroded... More to come...1 point

-

1 point