Leaderboard

Popular Content

Showing content with the highest reputation on 10/01/24 in Posts

-

3 points

-

Well not my solution I found a little watch and jewellery shop that advertised watch repairs available. So I went in and thought maybe I can get some advice The old chap took it into his workshop area which I could see from the counter. I saw him turn on his desk lamp and put his magnifying headset on and pick out a tool but that's all. 30 seconds later he came back with the end links removed without a mark on the watch or links. Even the spring bars were undamaged. It was like magic I don't know what he did but he didn't even charge me. I gave a donation to my favourite charity, cancer research, of £20 and e-mailed him to let him know.. He replied to say "anytime"2 points

-

2 points

-

2 points

-

Hello again, thanks for the help and advise. I found out that the problem was the endshake of the escapewheel. After I adjusted it, the watch runs very nice and at this moment for 48 hours.2 points

-

Hi Dmitry, I can guess that may be You have decided that the banking pins were bent out and have straightened them, may be just a little? Now the 'run to the banking' on exit pallet is not enough and the tooth that is higher than the others (yes, always one is higher, no mater they are the same), can't pass. Or may be the exit pallet has moved somehow a little out, or may be the pallet fork cock has free play and it's legs doesn't fix it in one exact place reliably...This can be solved by several ways, and long conversation is which way is the correct one. If the cock can be shifted, then slightly untighten the screw(s) and press the cock to direction as to enlarge distance between the fork and escape wheel, then tighten again. If the cock is well fixed (as it should be) and don't move, then the simplest thing You can do is to open a little the corresponding banking pin (if You look from watchmaker side, the balance is down and escape wheel up, then this is the right side pin). Do You speak Russian? It will be much easier for me to write such things in Russian...2 points

-

1 point

-

Hi Murks, I talk about normal copper wire from electric cable. Cable with many thin wires inside. You need wire thin as 0.2mm or similar. Just unscrew a little the screw, enough to wind one coil of the wire under the screw's head, then tighten the screw and cut the excess wire with sharp office knife, that's all. It acts same as washer. You can use thinner and thicker wires, as needed.1 point

-

1 point

-

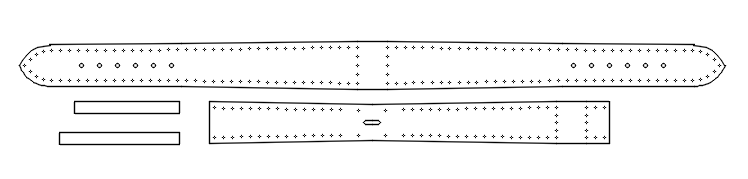

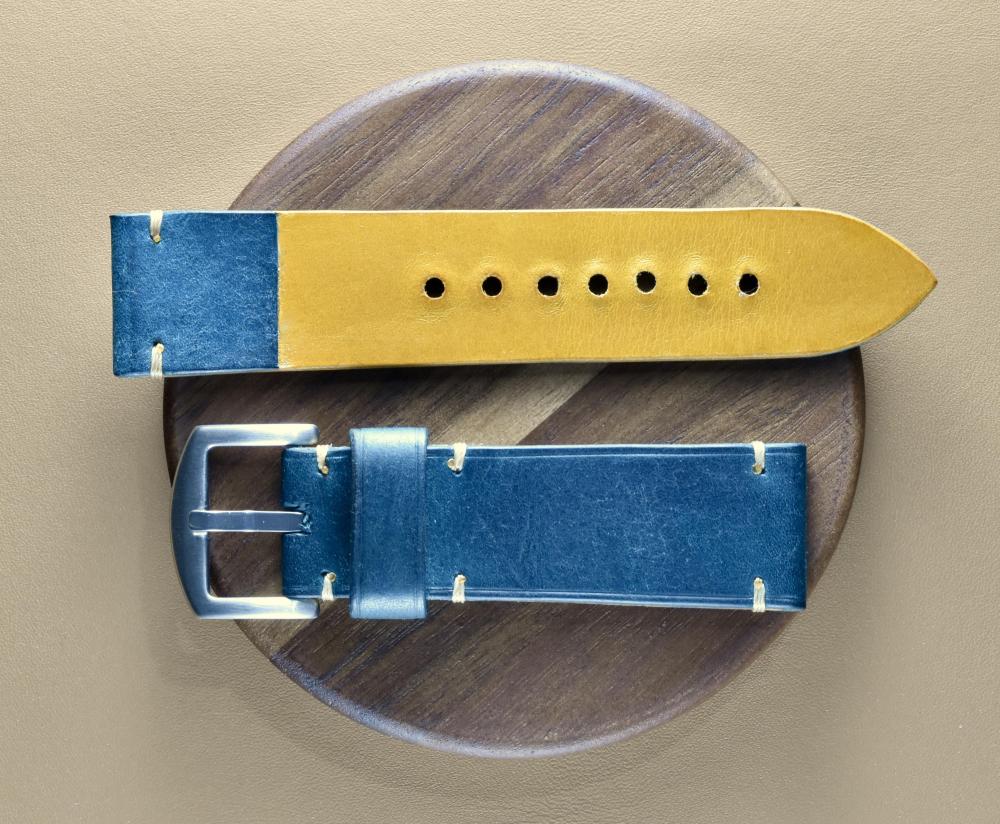

LOL! If only I wasn't gluten intolerant! I can normally get a couple of straps out of 1 sheet of A5. The straps I usually make are 120/80 or maybe 125/75. For the tail end of the strap (the longest section), the longest bit of leather I need is about 150mm length - (125mm for the strap, and about 25mm to fold over and skive to make the loop for the spring bar). For the buckle end of the strap it will be 75mm for the body of the strap, 25mm for the fold over at the lug, and 35mm for the fold over at the buckle - so about 135mm total length. If you are going to make the straps using the pattern in one of your images you need to be careful. If you make the tail of the strap by folding in half one very long strip of leather you can run into problems when trying to fit it to the watch - you may find there is not enough clearance between the spring bar and the watch head. Hope this makes sense. Ps 4mm stitch width should be ok to start with but it can look a bit chunky on a smaller watch. Straps for large watches such as panerai I use 3.5mm. Normal watches I use 3mm, and for vintage watches I normally use 2.5mm. 4mm is good to learn saddle stitching with tho. Good luck mate - strap making is a massive rabbit hole - don't even get me started on creating the ultimate burnished edges!1 point

-

1 point

-

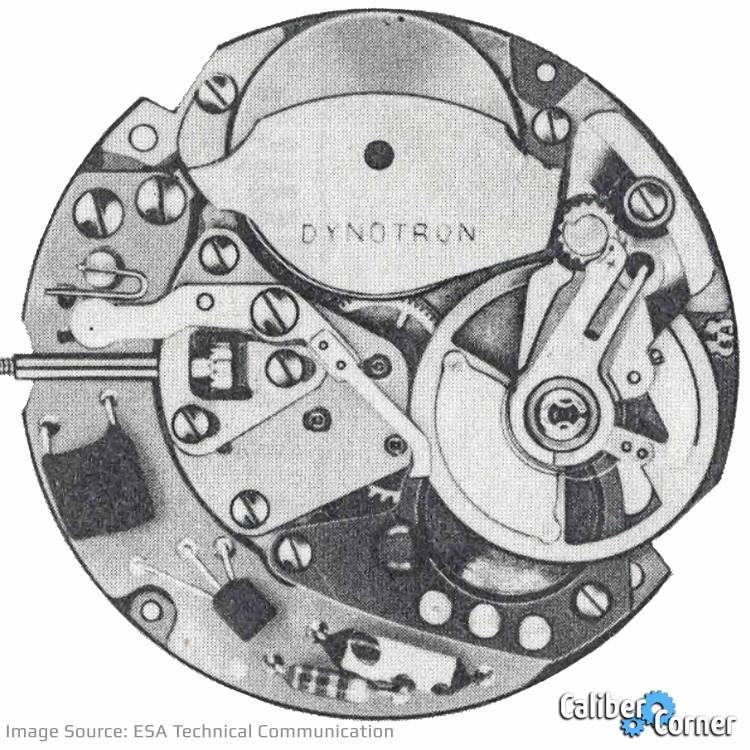

Another oddball 70s vintage on its way to me. This time a Benrus Electronic Citation. No pictures of the movement, but I bid an amount I was comfortable being scammed out of, and what do you know I won the auction anyway. I found a thread suggesting it should have an ESA 9154 movement inside, which looks pretty neat. Taken from calibercorner.com:1 point

-

If you have a look at the straps you have in your first photo, you will see that the long end of the strap is not made out of a single long piece of leather. The hole for the pin bars is made by folding over a cm or 2 of leather and skiving it so it blends into the rest of the piece. Here is a very simple strap I made for a Panerai with no edge paint so you can see the construction of the loop. It was just made for myself so its a bit rough around the edges! The tools that are most used. If I can find time ill explain each one and why I use it.1 point

-

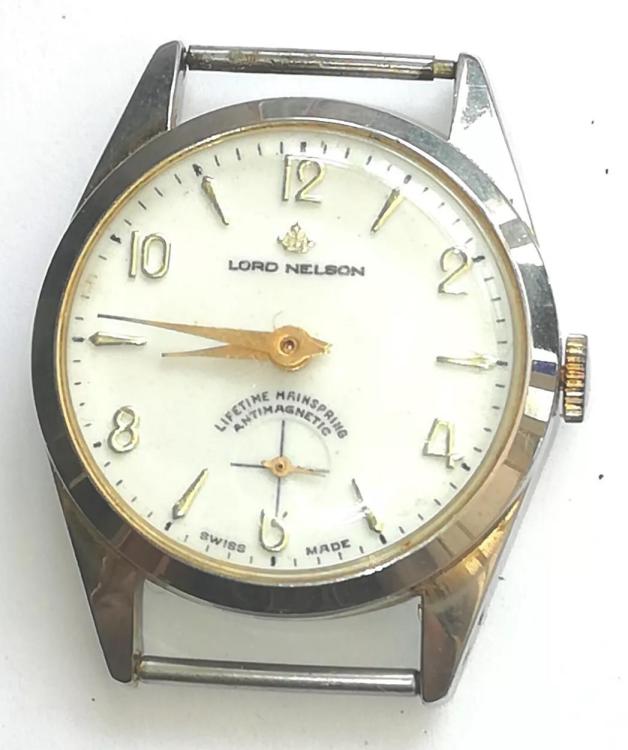

That was my thought too. "Jewels" is conspicuously absent from the dial, but I love these gilt numerals.1 point

-

I've got this lovely Lord Nelson watch being delivered! Unfortunately to my fathers address as I forgot the change the delivery address on Ebay and for the low bargain price of £13 including delivery I'm very happy with it. I have had a quick google and haven't been able to find much about the maker/brand but I think its a stunning little watch for the price!1 point

-

What about using timing wire instead of timing washers? I use wire, for many years, it is free and available in plenty of sizes.1 point

-

1 point

-

Yes, and they've got a nice clearance range at the moment. https://www.cousinsuk.com/category/watch-buckles1 point

-

Sure, ill try and take a photo today for you. My advice would be to avoid assortment bags of unknown leather. Leather requirements for watch straps are quite specific. You may end up with 5 kg of unusable rubbish. That's how companies get rid of the crap no one else wants!1 point

-

Wave breakers in the rinse jars are not essential. I found Elma always very helpful and they are still in business! But you have to decide in the end. Frank1 point

-

HI, relatively new hobbyist here in New York. Have been at this for 2.5 years and am going deeper down the rabbit hole. I love restoring antique pocket watches and vintage wrist watches and sometimes record my work as an educational tool for beginners and admirers of these timepieces. Looking forward to talking watch repair with you all! Cheers! Jimmy https://www.youtube.com/@WatchRestorationCottage1 point

-

Check that the pivot holes have not worn out and become elongated.1 point

-

From what little I see, it's a low jewel movement (no jewels on the escape wheel)? Have you checked for wear ( side- and endshake) on the train? With the pallet fork removed, it's easy for the wheels to spin as there is little tension on them creating friction. That changes with the pallet fork in place. If there is too much play, wheels and pivots are pushed sideways or up/down causing a loss of power.1 point

-

Thanks! And yes, I'm rather obsessive. Which sometimes turns a hobby I love into and pain (if things aren't quite as I want them). Certainly rare, but not really particularly expensive (within the range of triple calendar + moonphase watches). I bought it for myself and have no plans to sell it. And once you service a baby like this, you grow a connection..1 point

-

1 point

-

1 point

-

I primarily use Badalassi Carlo Pueblo, Badalassi Carlo Wax, and Walpier Buttero (standard or museum). I usually buy these in A4 sheets of 1.2 - 1.4mm thickness. I buy mine from Artisanleather or Leatherforcraft. make sure you use the correct needles and thread. Not many people talk about this but it is crucial. I use Amy rose polyester thread in 0.45mm with an either a 3mm or 3.5mm stitch gap. I also use John James small saddles needles (size 4 if I recall correctly). I will post some photos of the sort of results I'm getting.1 point

-

I make all my own leather straps. I use Ecostick 5019N. It's a water based contact adhesive specifically designed for leather. Its the strongest glue in the Ecostick range and was designed for shoe making if I remember correctly.1 point

-

And how much included your work hours for making, assembling and maybe fault finding? You will get a top used Elma for that money that usually last for ever. I would take the automatic. They were made for pro’s use and will also last. A bit service and grease may be no bad idea. Frank1 point

-

Hi Rixy, See, the balance is on a separate platform, but the lever is not on it, it is on the movement together wit the escape wheel. The special thing here is that there are banking pins, and they are on the balance platform. The problem You describe is because the banking pins are shifted (together with the entire balance platform) from their correct position that will allow normal work of the lever. Now it is clear seen that when the lever top is moved right and has rested on the banking pin, the downside pin is still on the impulse surface. This means that the entire balance platform must move a little right, just enough to allow the pin to leave the impulse plain. So You must untighten the nuts that fix the balance platform, find the platform correct position that gives normal lever action (this is when 'run to the banking' is equal in both sides) and then tighten the nuts.1 point

-

It decreases friction. Depending on which braking grease you use will make a small difference to when the spring slips, as well as how much grease is used and the barrel material. I always use 8217 and have never had any real problems on a multitude of barrels from modern to vintage. I believe it is how much grease is used rather than which braking grease which makes the spring slip earlier or later, but that is my opinion and experience based on many barrels and springs1 point

-

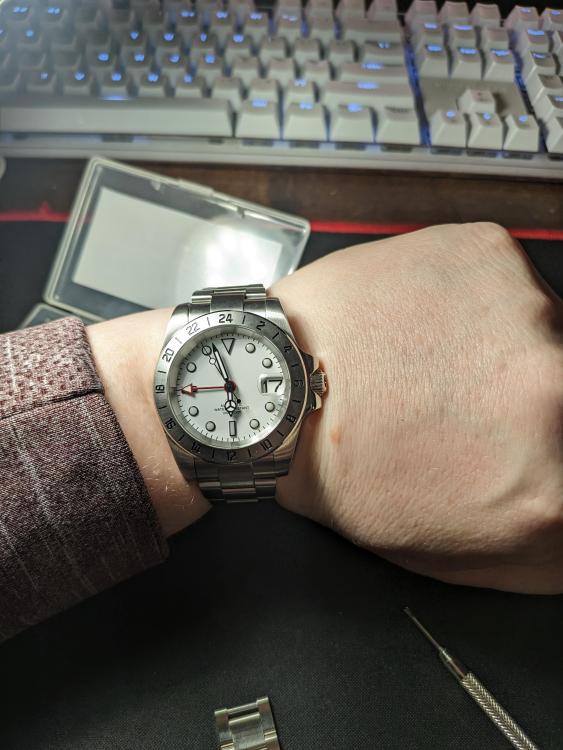

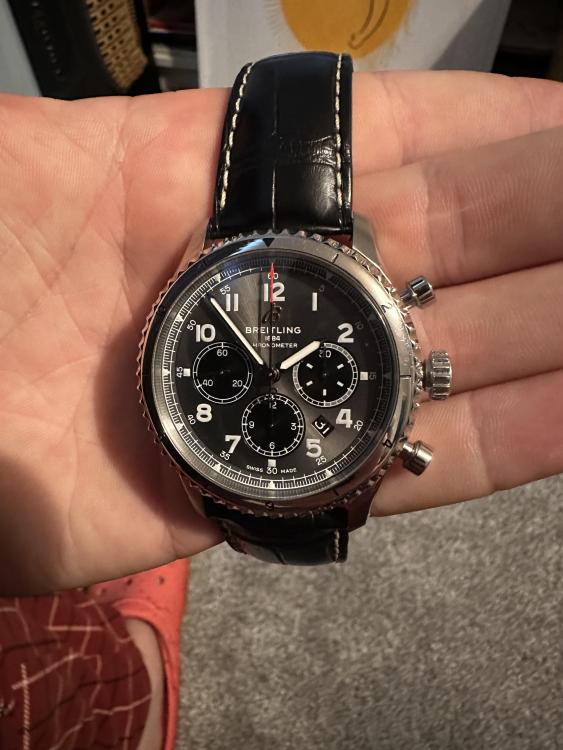

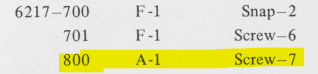

A few of my favorites. Mostly wear the 1016. Still haven't landed on a dive watch. I ended up selling the seamaster as it was too thick. I like my explorer 2 build, but the hands weren't quite right so I have a few sets coming. I might have to pick up an explorer 2 in the future. Secondhand markets are coming down pretty well.1 point

-

Quite sure these hands are (nickel-)plated. A bit polishing will not remove the plating. You need pure unplated steel (not stainless steel) or iron for blueing. If cheap or not doesn't matter. Frank1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)