Leaderboard

Popular Content

Showing content with the highest reputation on 06/19/16 in Posts

-

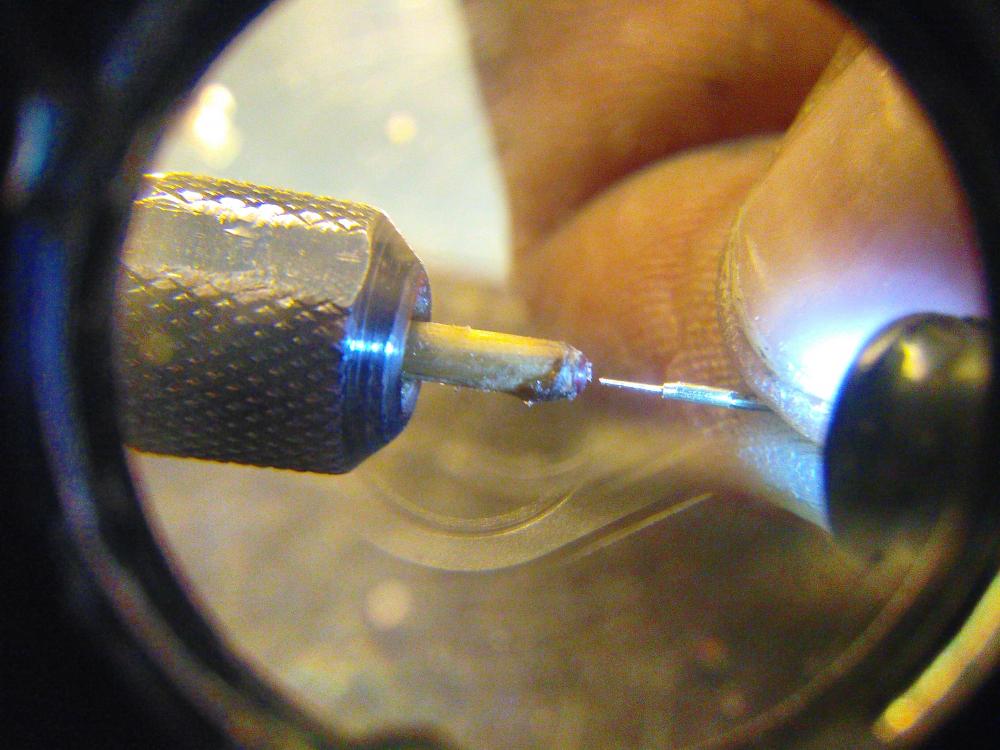

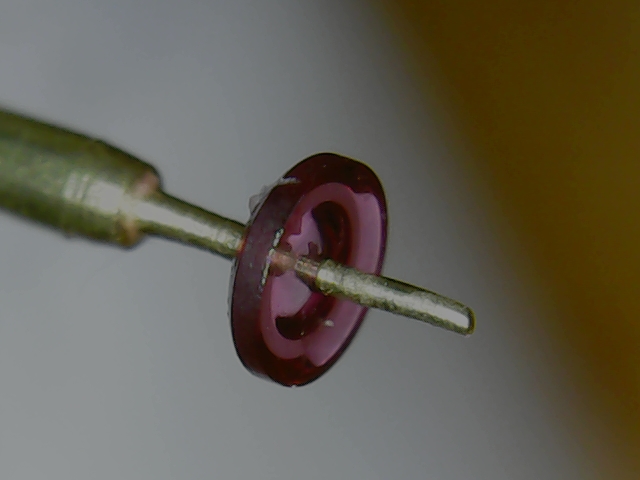

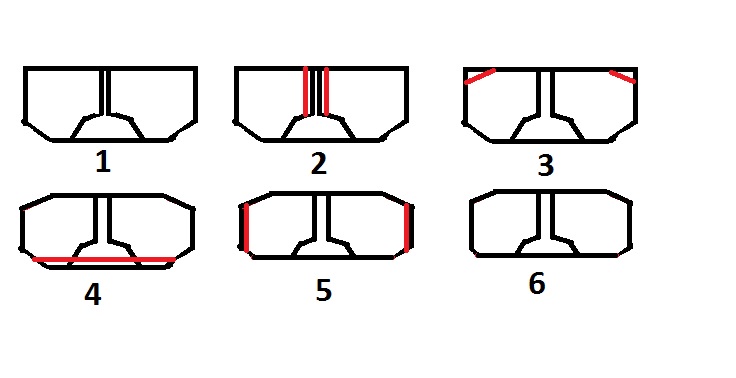

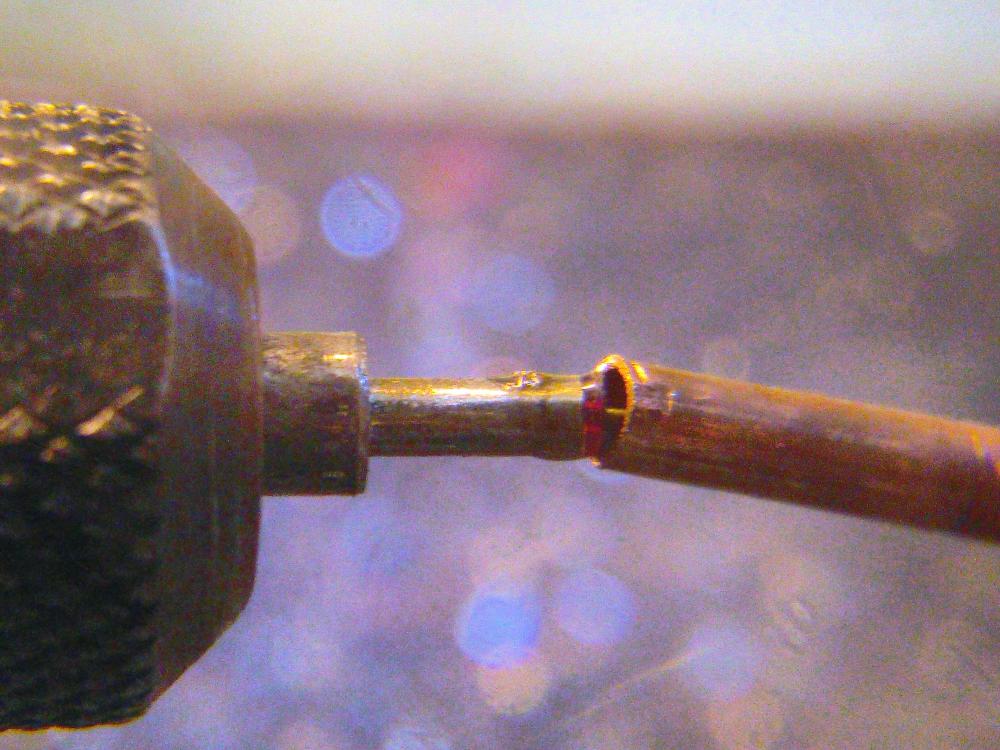

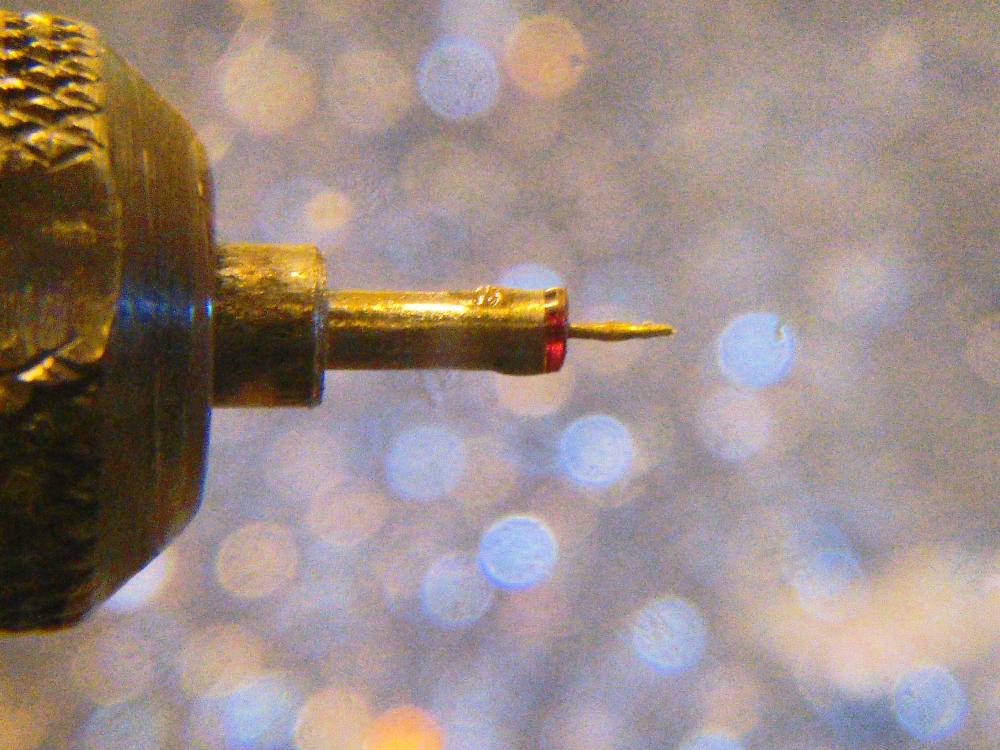

Just a quick report about my first jeweling adventure. Recieved a lot of jewels from my friend but it turned out most of them are for wristwatches. There was however one that seemed ok in diameter for the 3rd wheel pinion. The hole was 0.1mm and the pinion is 0.27mm so tooled up for jewel hole drilling I was asking Steffen Pahlow for the proper method. First, 0.2mm brass stick tapered to 0.27mm was turned in the Dremel from 0.7mm wire. The jewel was hotglued first on a turned tootpick mounted in the Dremel, later on 2mm brass wire. The jewel was centered while holding the lighter near the glue and turning with brass tweezer toothpick. The brass stick was dipped in polishing paste and simply pushed against the jewel hole while turned in the Dremel with around 5000-1000 rpm. It was really slow when i realized that i was using the finest paste After changing to coa rse one it was quick. Almost through. At this point the jewel still sticked to the pinion bottom. After polishing the hole with fine paste it was moving freely on the pinion. Now it was time to mount the jewel into the movement plate. It turned out that the jewel is not for such a setting. It is a friction fit jewel. So several modifications were made to the jewel. The flat bottom had to be tapered a bit taht i can rub the brass setting over the edge. Moreower, the thickness, and diameter had to be reduced a bit. Have no pictures from all steps but made a shematic picture showing all modification steps. Reducing external diamater. 3mm soft steel nail was reduced to 1.4mm. The jewel is 1.5mm. 0.8mm hole was drilled in the reduced end where the jewel hole drill bit was hotglued. The jewel was simply pulled over the brass stick and glued and centered as mentioned above. Another 2mm brass wire was drilled to 1.5mm and added some co**BLEEP** (5000grit) polishing paste on the jewels and the brass tube was pulled over the jewel. The tube was moved back and forth while the jewel was turned 5000-10000 rpm. Diameter was reduced to 1.38mm. After altering the jewel it was perfectly fit in the setting. A setting closing tool was made (according to the setting opening tool in my earlier post) but it turned out that a simple female cone end-drilled steel wire is perfect for closing the setting. The gear staff is vertical with a small degrees of free tilt.2 points

-

1 point

-

Bit of a long shot this but does anyone have a Pallet Fork for an HMT manual wind Watch? it has a Citizen 0201 based movement see this http://17jewels.info/movements-en/movements-c-en/movements-c-citizen-en/413-citizen-0201.html Also need the the top balance shock jewel as mine went ping. These Watches don't command huge ammounts of money very little infact but I enjoy getting them going as they make good practice for a novice so any help would be appreciated. Thank you and regards from Jon. P.S At some point I plan to do post on strip down and rebuild.1 point

-

1 point

-

Rotary case parts don't show up on any of the usual material house sites. You could try calling the number on their page for service and materials http://www.rotarywatches.com/en/service/rotary-watch-servicing S1 point

-

Look for wear in the train wheel bridge and movement plate? Where the arbor is. That is a place where Seiko is usually worn. To much movement and the barrel will lock when you have the movement in different positions?1 point

-

guessing, but i'd say balance assembly or pallet/jewels incabloc, dirty, cracked, worn or bent pivot(s), too much endshake or not enough, seen this on pocket watches, takes a pretty hard knock to get Seikos out of whack, balance staffs and roller jewels are usually robust unless they are dirty. hope that helps1 point

-

I just finished working on the 2472. Everything is in place and it's running fine. Here are a couple of pictures. Some are just for the sake of having them. Not necessary to assemble the movement but nice. Assembly of the date mechanism proved a challenge for someone inexperienced, like me. Mounting this part took me quite a while to figure out. Usually the silverish part sticks out further and cannot be inserted. This is how the part should look like prior to assembly: The spring proved to be another challenge. During assembly of the driving wheel / lever slide the spring has to be pulled back. This is the situation where the lever slide has to be slided under this guide post: After 30 minutes of trying to figure out how to assemble it, I eventually succeeded. You can see the the lever has been slid unter the guide post and that the spring is nicely in place. I first assembled the date jumper and date jumper spring but it turned out that when mounting the date indicator, I cloudn't get it done. So assemble the date jumper AFTER the date indicator is on place. The driving wheel has to be positioned so that the notches of the date indicator fit through. The date jumper is not properly in place in this picture. Done! Yet another picture of the other side with the movement in motion on the timegrapher.1 point

-

Hi stroppy, As a collector, there is a point where all watches become "valuable" and "good"...my own experience, since I want them all! The truth is, no matter the "pedigree" of a watch, if it makes you tick -- pardon the pun -- you should get it -- if at all possible -- since the satisfaction of the watch lover is fulfilled that way. On the other hand, if you want a "true" watch -- considering we have cells and other gadgets that tell time -- you should focus on history and quality of the brand. Example: an Omega watch, no matter how cheap the components inside, it will never be even comparable (as of today), with and Aldi watch no matter how much care it has been put into the building of the later. Omega being better of course. Then, some exceptions exist to make our life more difficult but this type of example, IMHO, is the general rule. There is some more to the above: SEARS used to sell some stuff. Among them there were cheap pocket watches. Those watches were mechanical (ETA 6498 movement inside). They can still be gotten cheapish and they are the original UNITAS built. Nevertheless, nowadays it is, for most of us hobbyists and even watchmakers, a heaven of quality stuff...some 50+ years later! And what is best, newer ETA 6498-2 interchange, successfully, most parts with them. That said, I doubt there will be any quartz watch worth the trouble as we usually go about restoring mechanical movements like those. The beauty of quartz is that in most cheap watches -- and not so cheap ones -- we just change the movement when it breaks (if available), substitute the movement for a "compatible" one or simply thrash and buy new. One more reason to go the time honored -- and quality -- way. Also, about Aldi, we had them in the mid west -- maybe still do, it's been a long time -- here in Miami, they are not in my area so I wouldn't be able to have an opinion of their products...back then, in my home town, I never saw watches in their flyers...I don't even remember the flyers! But, I believe as a rule of thumb that quality and "expensive" workmanship (without the price tag), is something of the past (SEARS example, back then, it was cheap, now it is quality) and the more time goes by, more poor quality and run-of-the-mill products will make their way into our everyday life...the quality, reliability and durability are being dissolved in time! IMHO. I hope my opinion is not too far from the truth and if so, will be an eye opener to the watch lover/collector as far as what to wear on their wrist. Bottom line: if you like it, get it no matter the procedence but if you are picky about it, get whatever quality/good name is still being made...before it all becomes cheap garbage with inflated price tag! Cheers, Bob1 point