Leaderboard

Popular Content

Showing content with the highest reputation on 05/22/16 in Posts

-

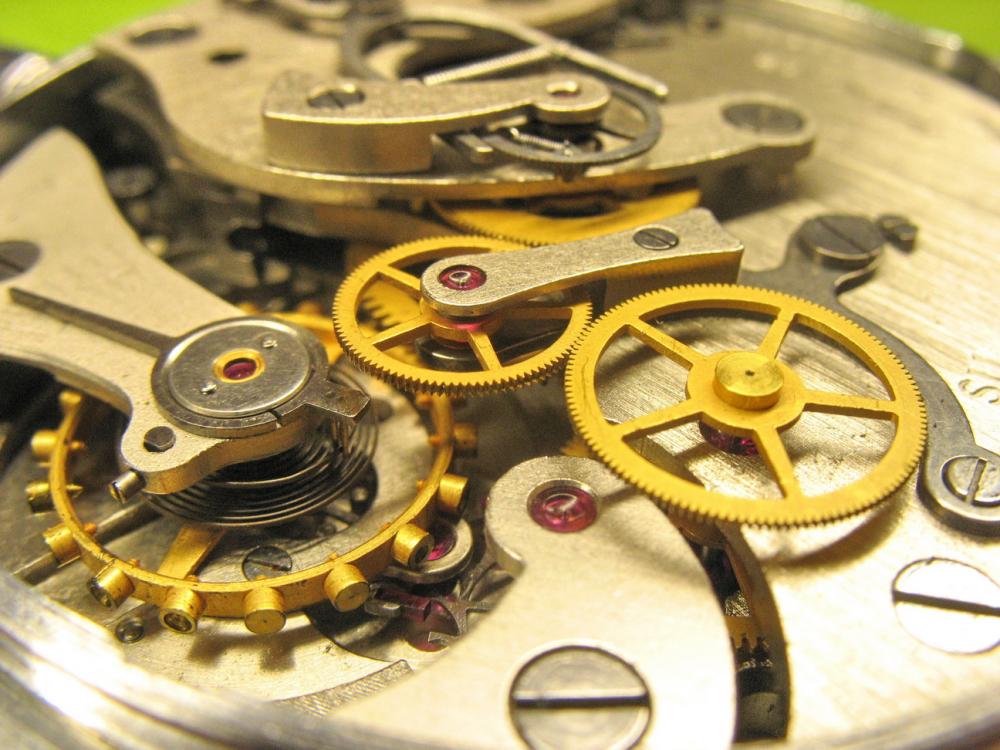

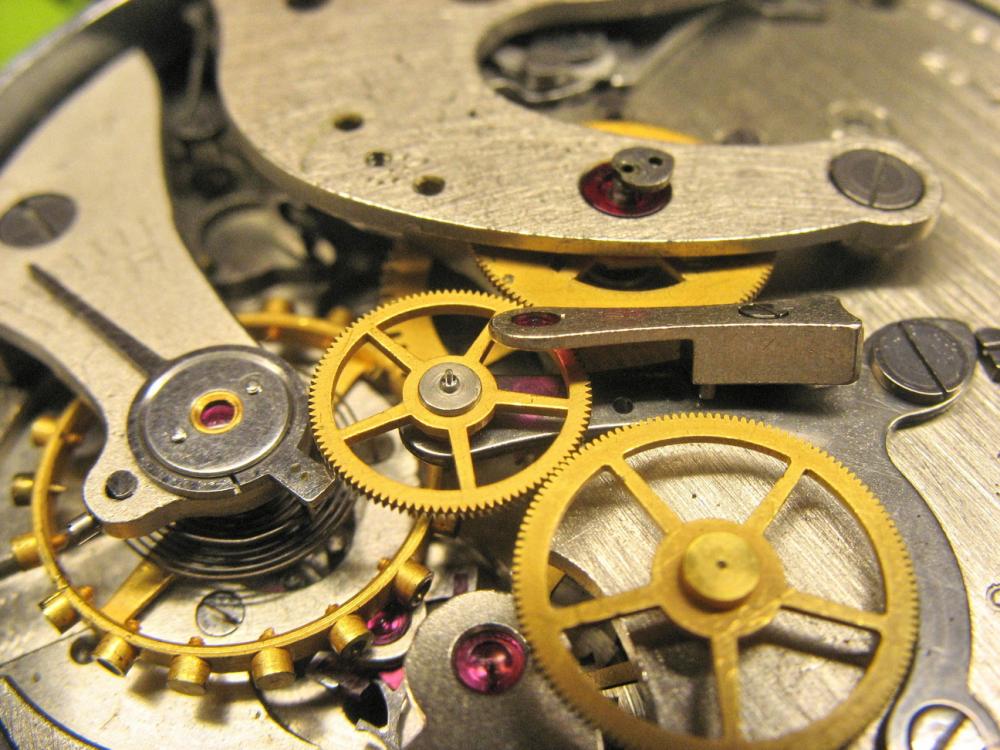

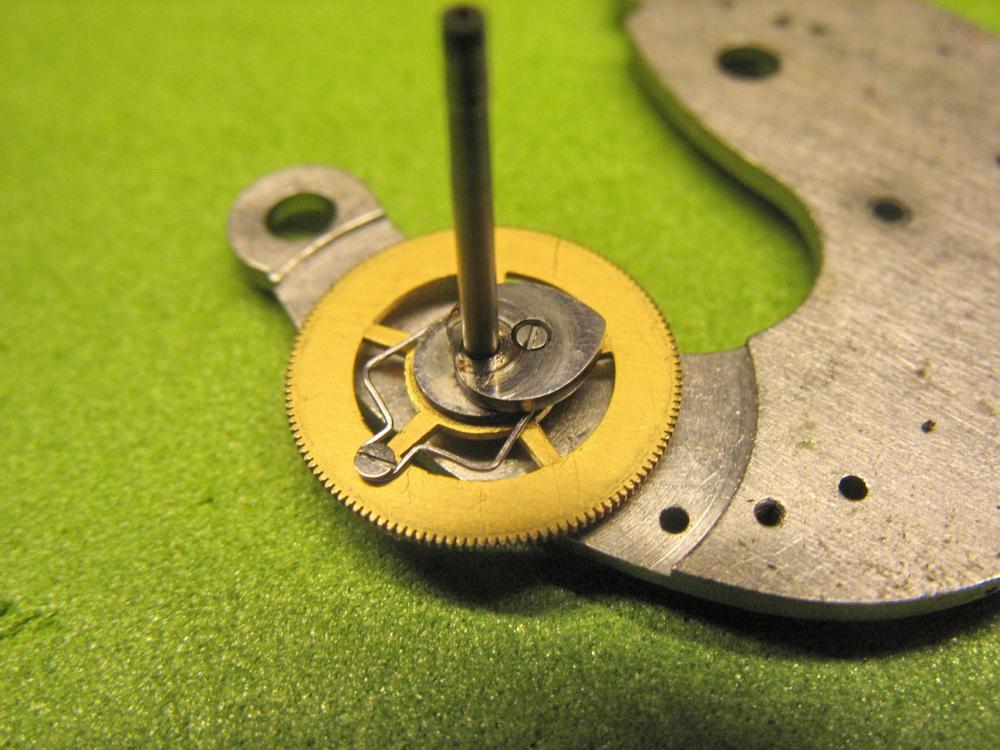

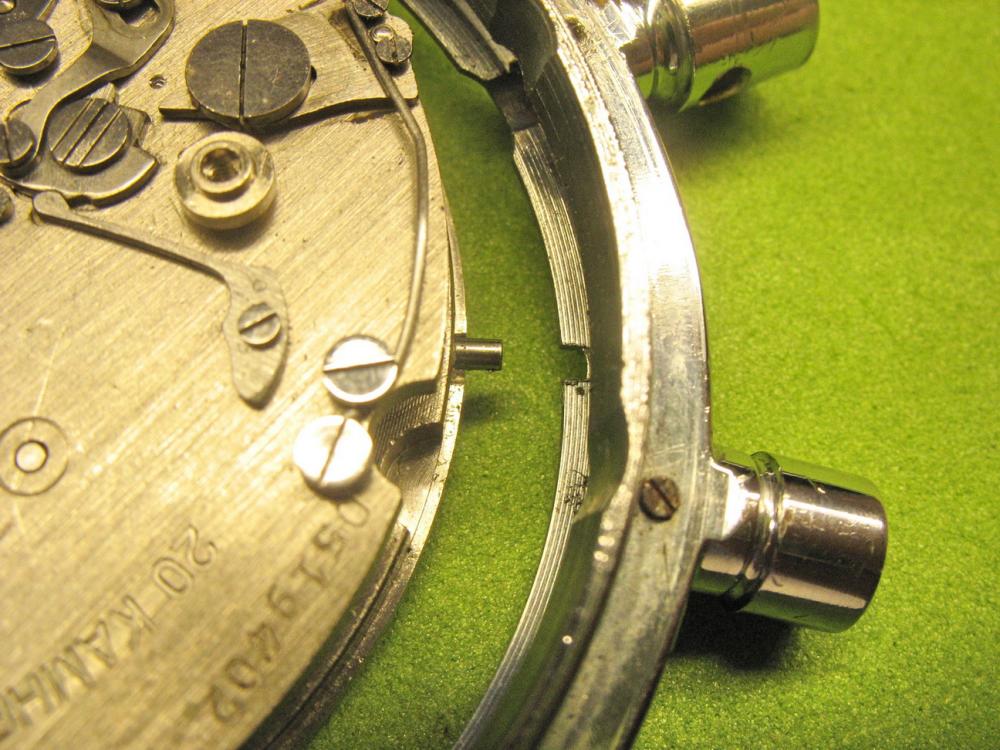

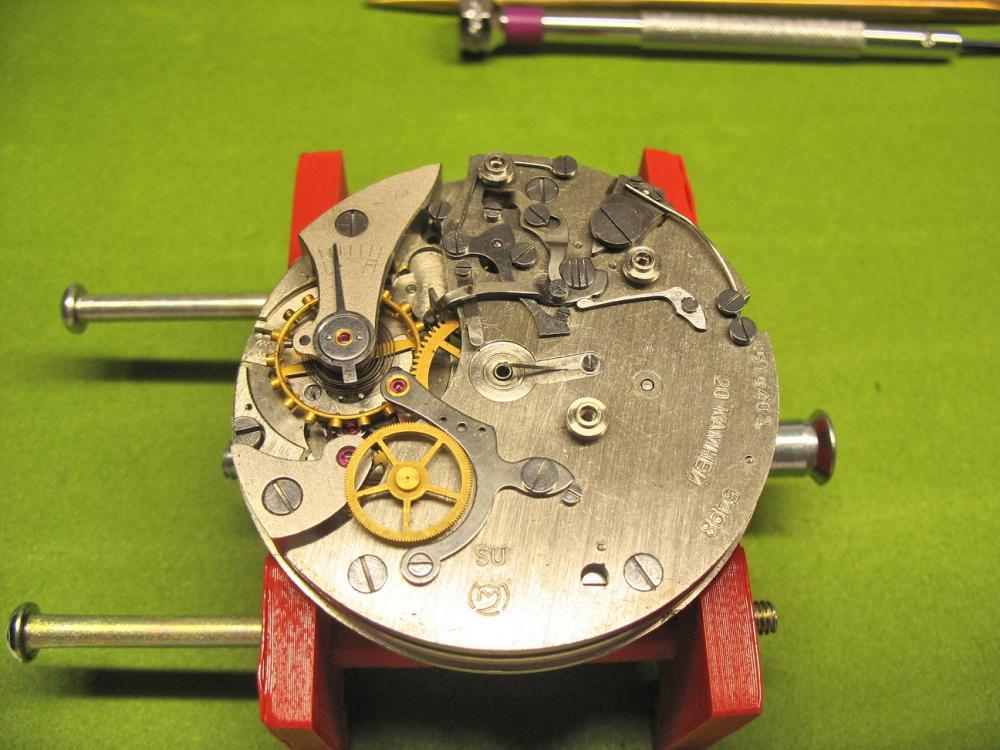

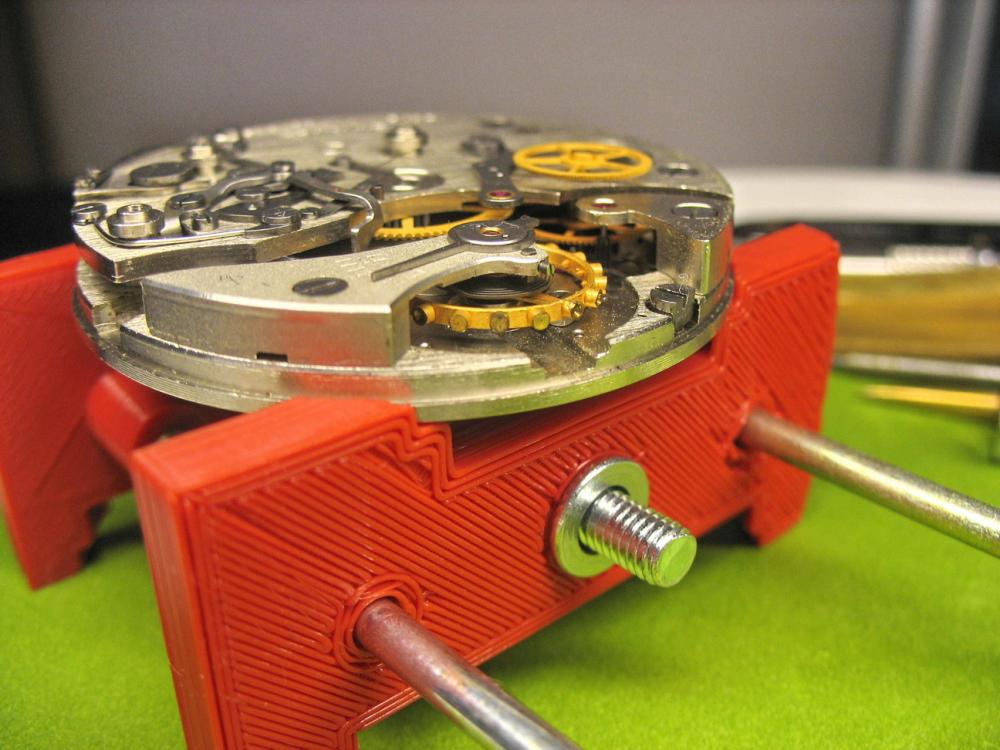

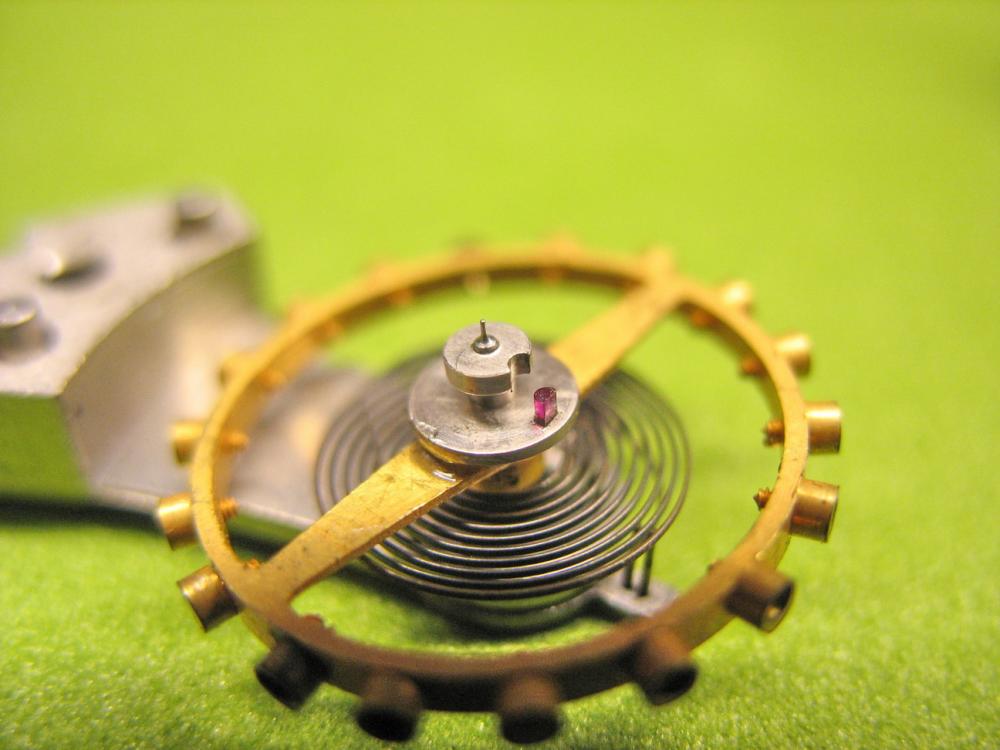

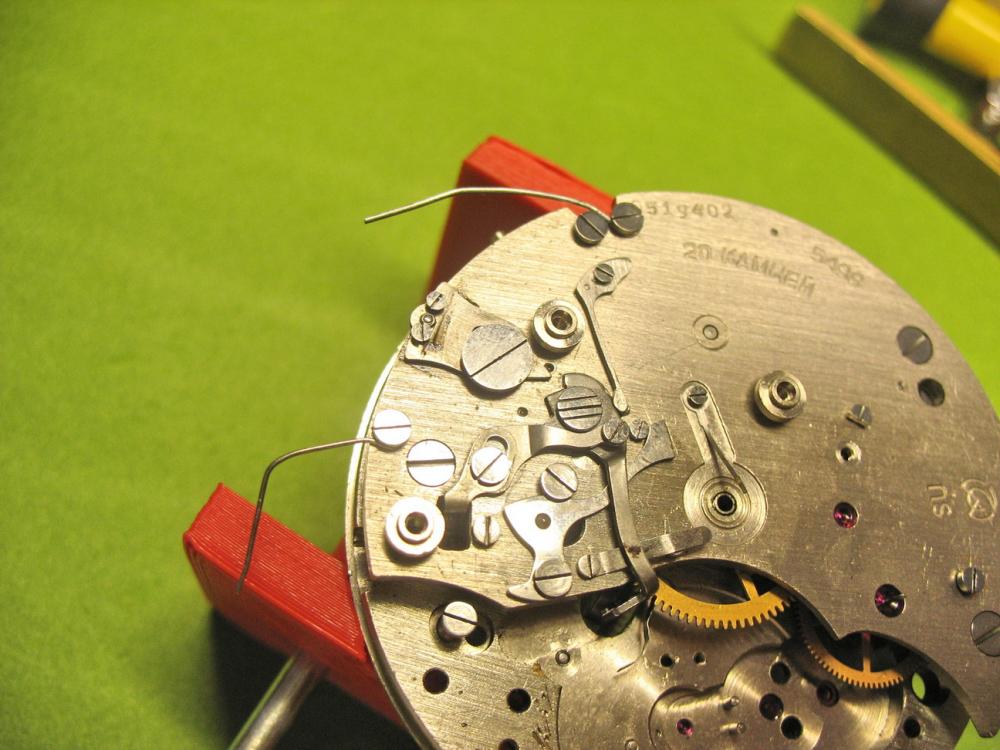

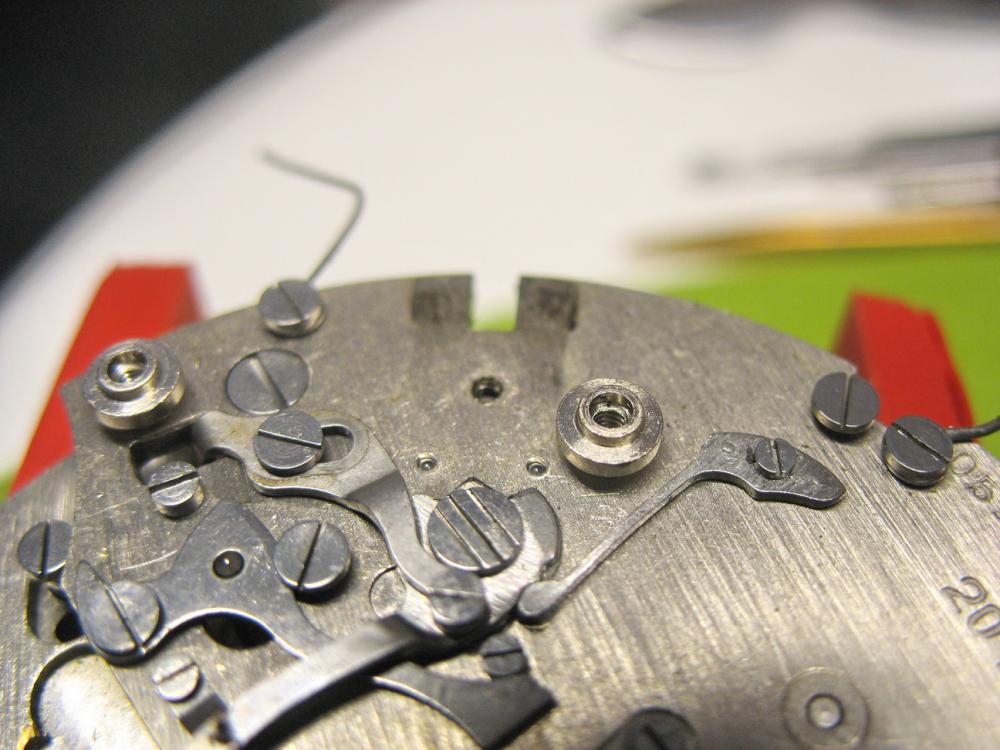

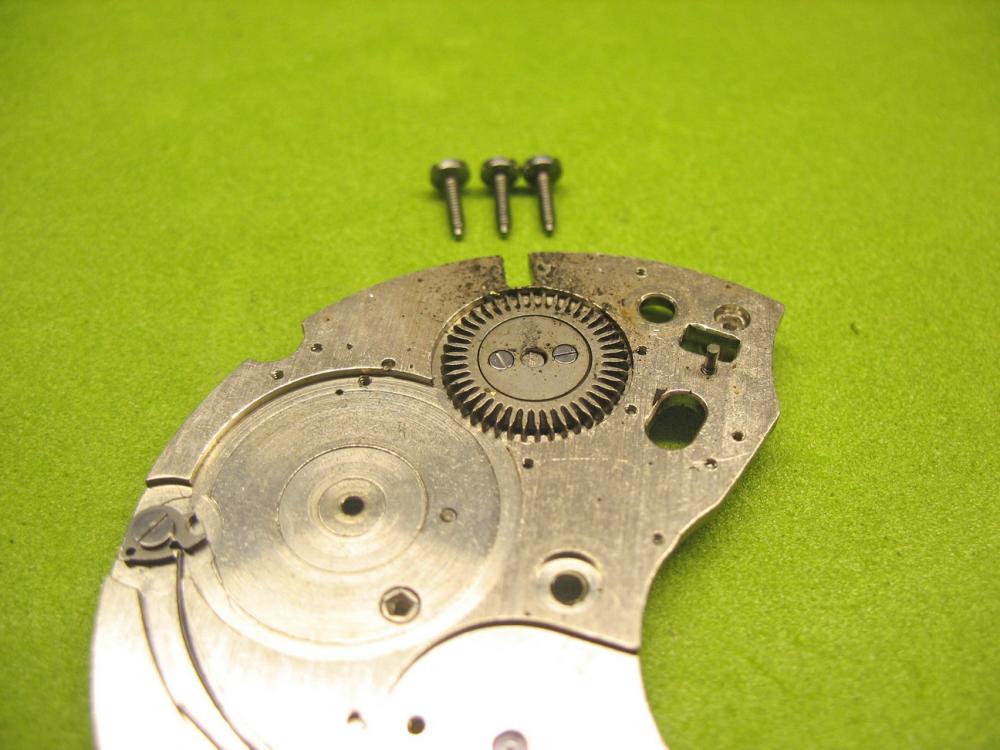

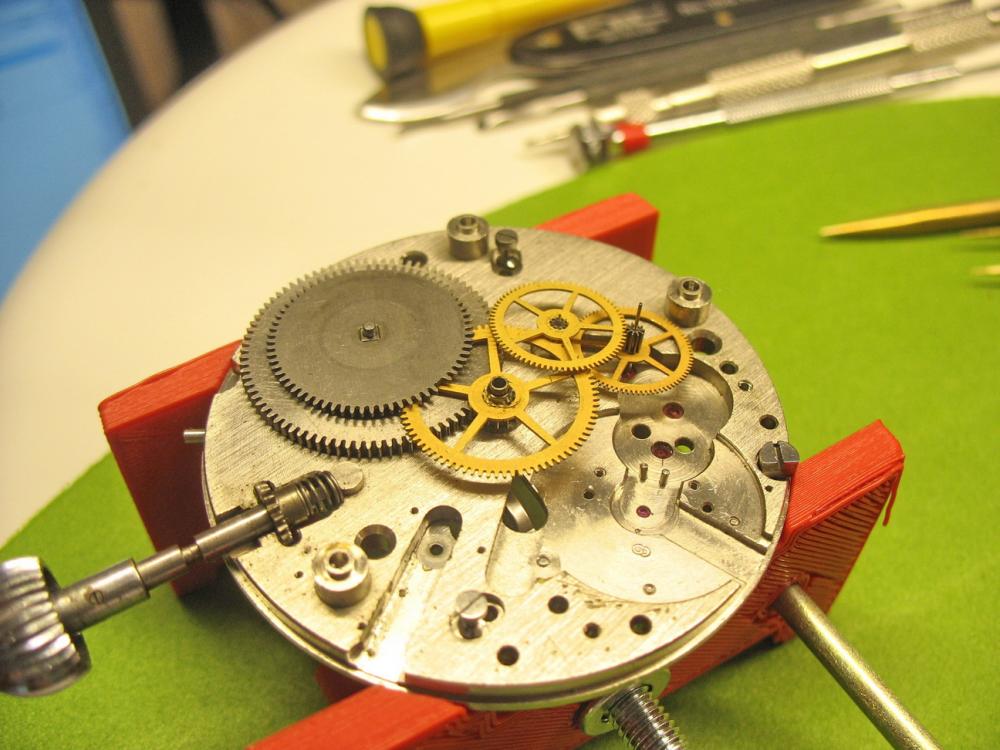

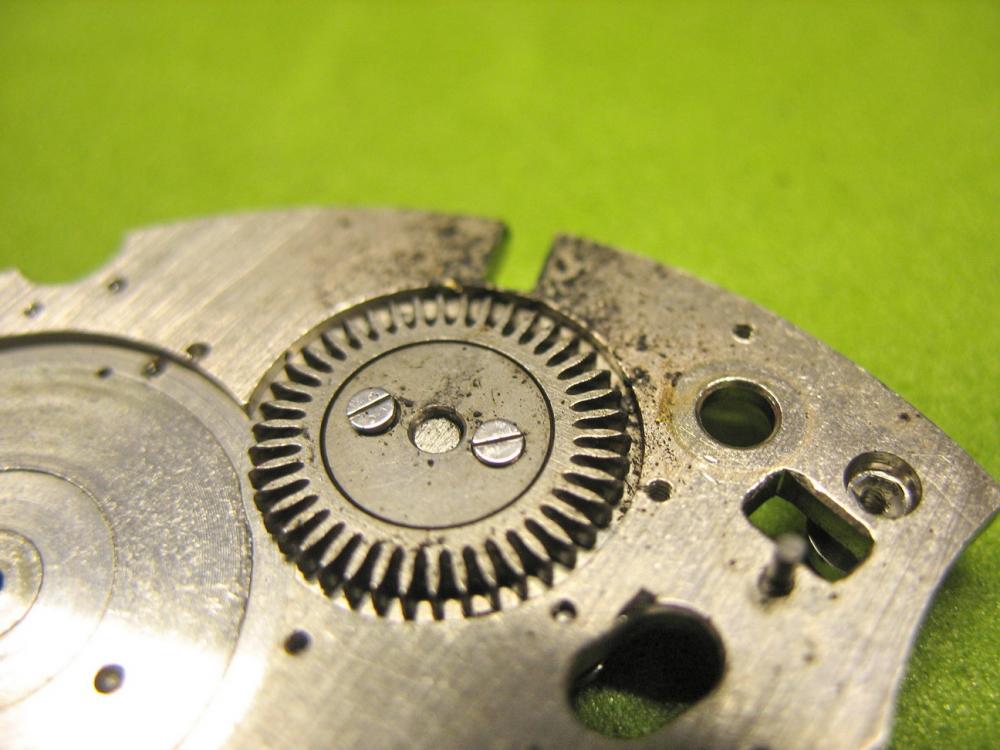

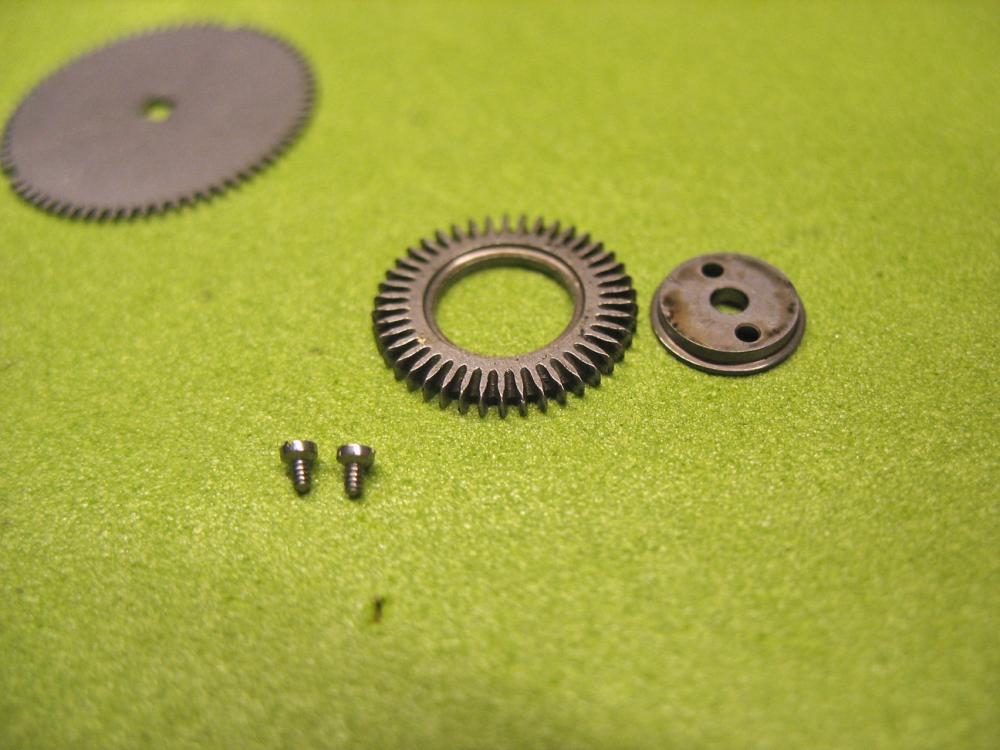

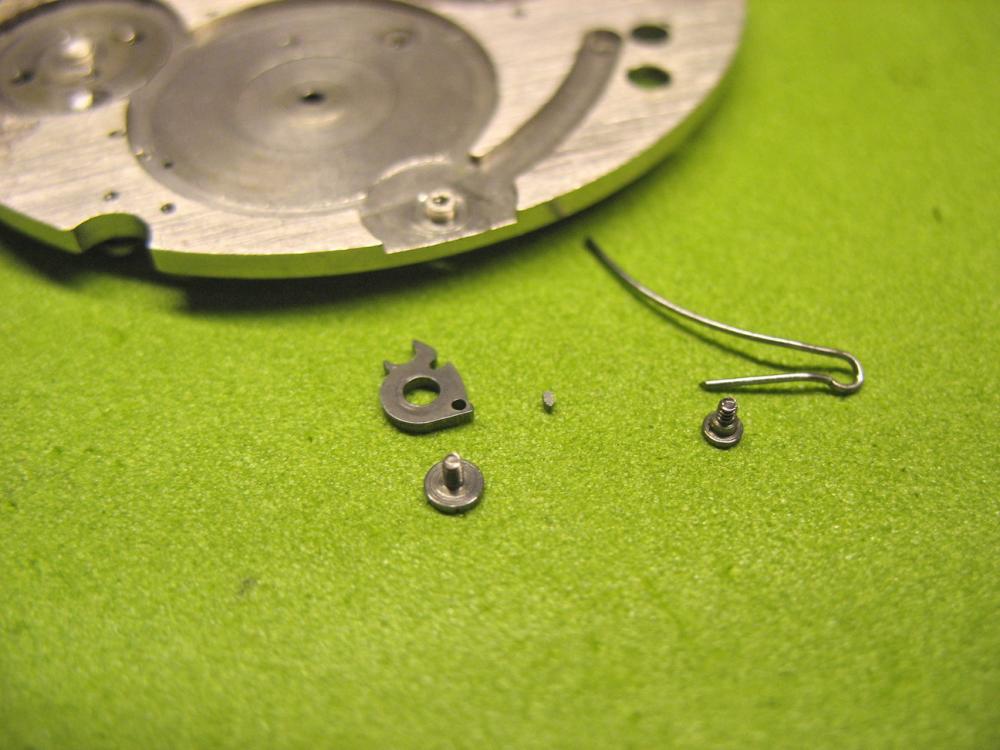

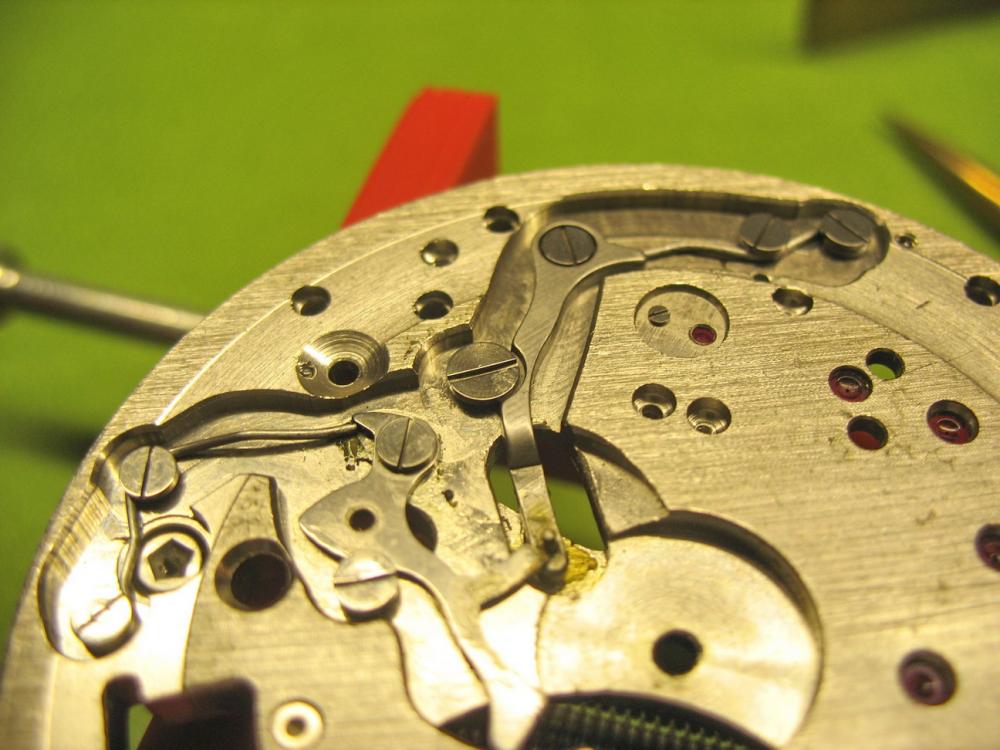

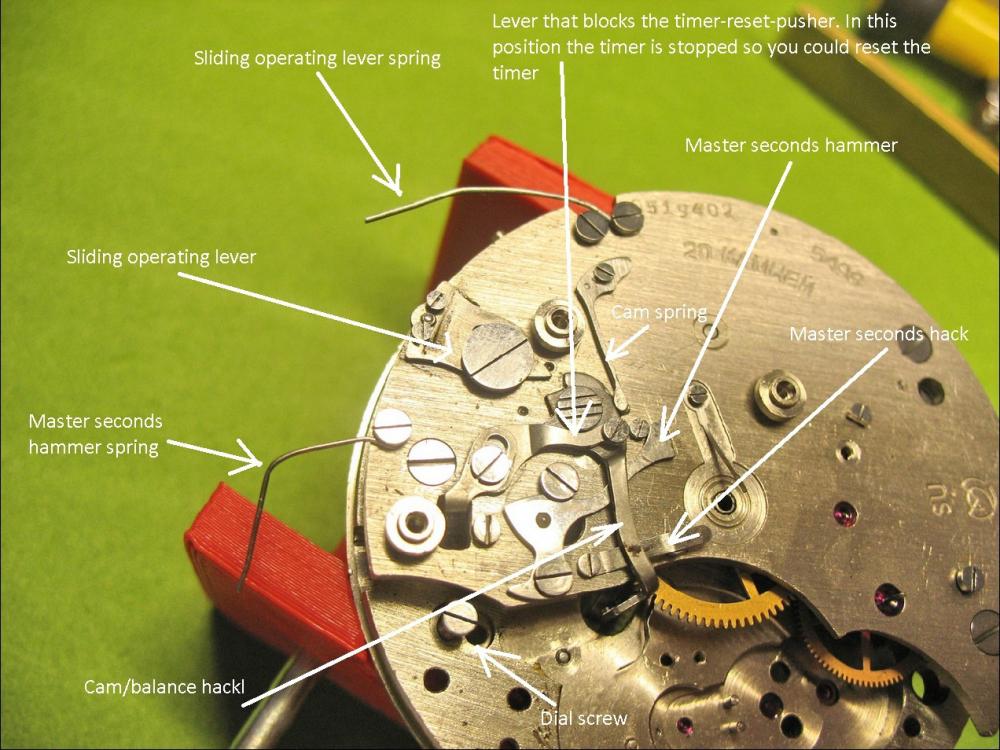

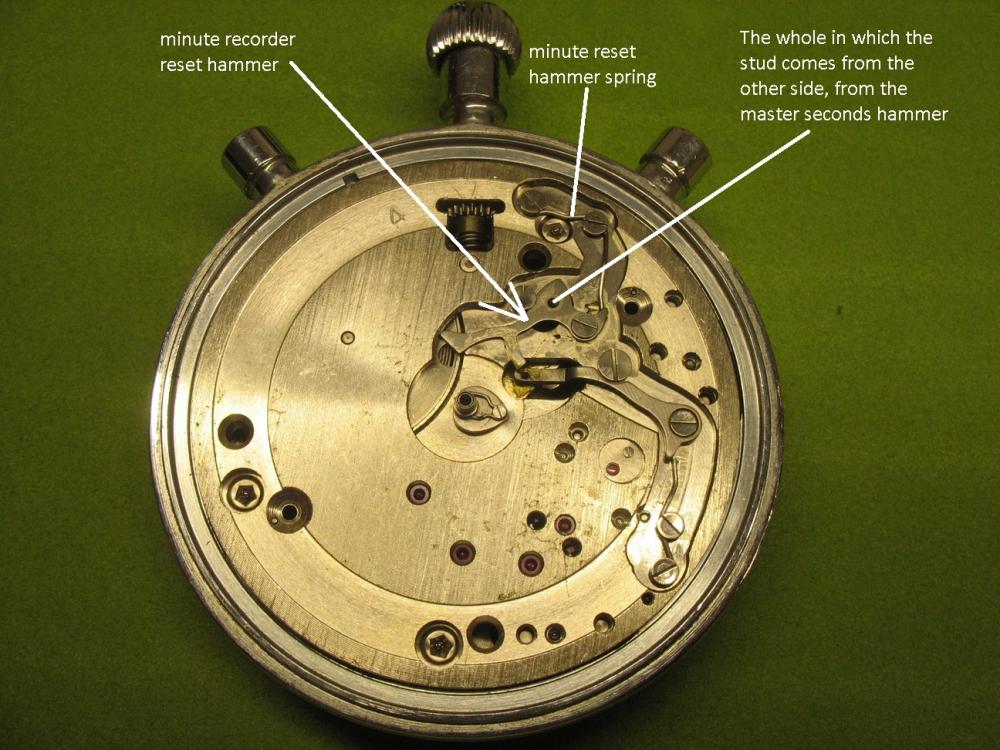

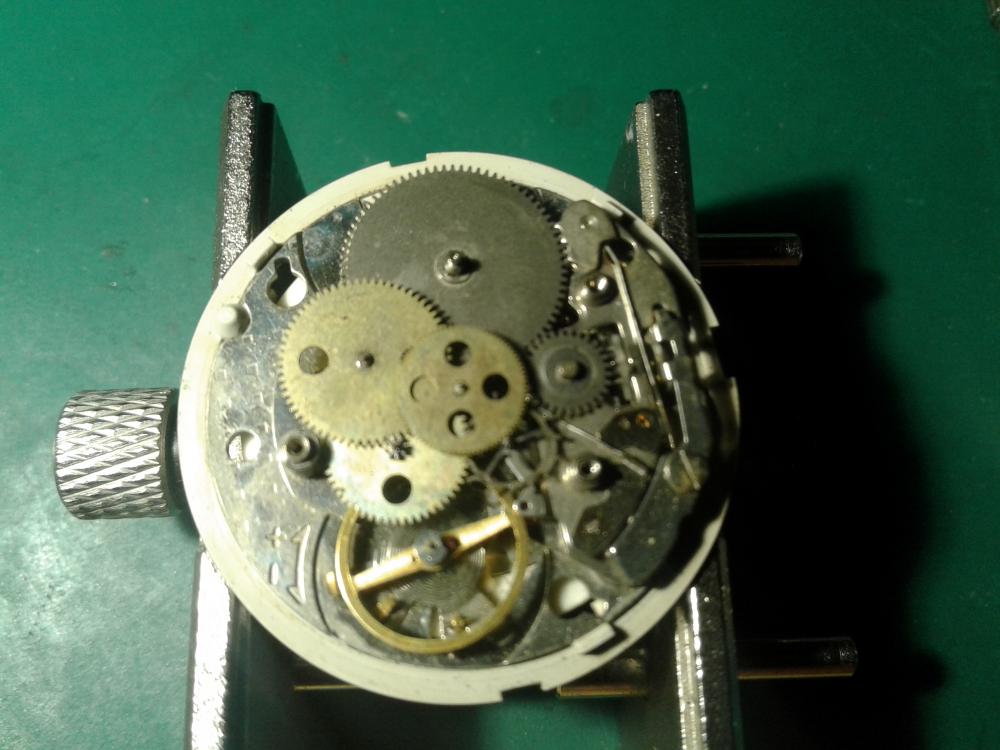

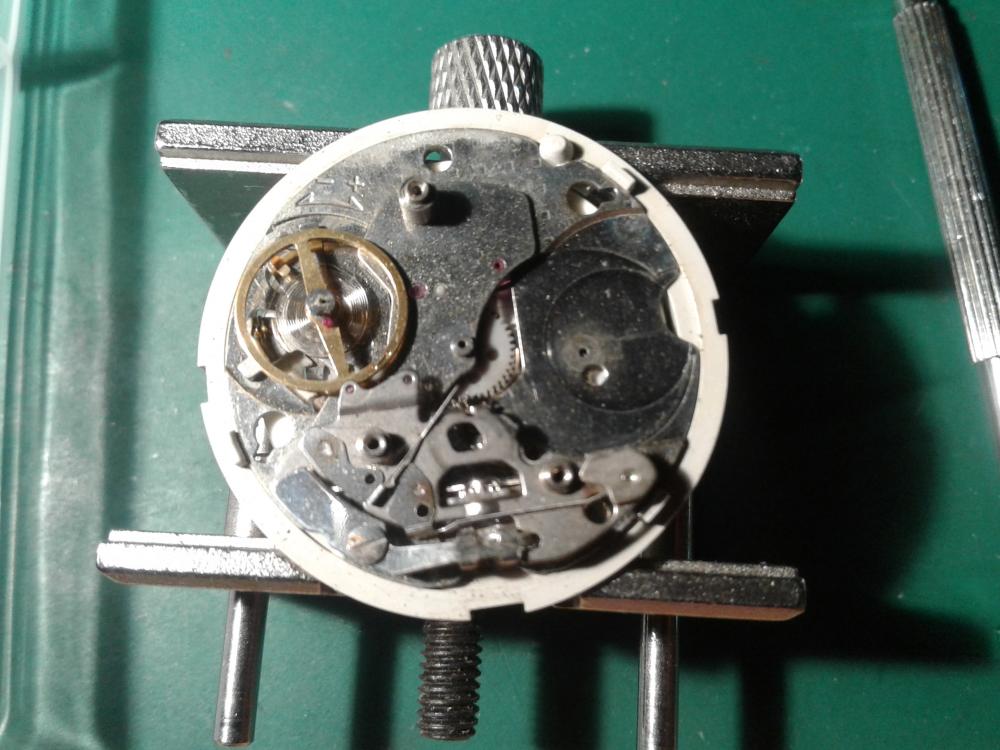

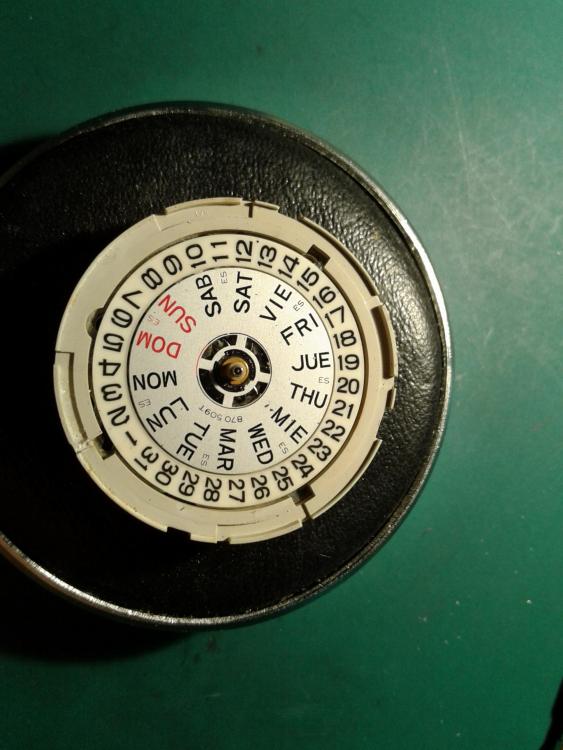

Hello all! I am doing this because I couldn't find any detailed information on this caliber, except some general photos. So I sort of explored it. Yes, I was an explorer, so please forgive the clumsiness! This is going to be more of a parts list presentation then a proper tutorial. I don't know what the parts are named, but I will try to explain what most of them do, from my understanding. Also this is the first time I opened a chronograph-like mechanism. It is a 24 ligne (55mm!!) russian rattrapante timer Slava 5498. Everything in it is huge comapared to any decent watch. It has 36000bph though so it is able to measure one tenth of a second, like a propper timer. It also has a Breguet hairspring on that huge balance wheel. I will call the two seconds as follows: the master seconds (or the second (2nd) seconds wheel, because it's at the bottom) which runs continously if you start the timer and the slave seconds (or the first seconds wheel, because it is at the top) which stops when you press the left pusher and hurries back after the master seconds when you push it again. Beneath both of these seconds hands lies the minute wheel which records 30 minutes. The middle pusher winds the timer. It also starts and stops the timer. When you press it, it both hacks the balance wheel and also hacks the master seconds wheel - it sort of needs two brakes to stop the beast . The left pusher stops the slave seconds wheel and, if pushed again, it allows it to quickly follow the master seconds wheel. The right pusher works only when the timer is stopped (via the big knob in the middle) and it resets all the hands to 0, except for the slave seconds wheel which, if stopped (from the left pusher), it stays in place. A couple of reference photos of the movement: The following two levers stop and release the slave seconds hand. They are acted by that column wheel (it certainly looks like one, but it has fewer functions then in a column chronograph). Next comes the spring that hold the column wheel in discreet positions, and the one that acts upon the lever that increments the column wheel: Next comes left pusher lever together with its piece that increments the column wheel: Next is the column wheel: I now take out the dial. For the picture purpose I leave two screwdrivers inside the movement to indicate the dial feet screws. I didn't take a photo when I pulled out the hands using a presto tool. Next I take out the slave seconds wheel and its cock. It sure is a long seconds hand axle. Beneath it you can see the lever with its spring which helps it follow the cardioid (heart piece) on the master seconds wheel axle. That lever has a rectangular jewel at it's end to minimise the friction - if you look closely you can see it is damaged. Also the cock jewel isn't hallowed but it is a sort of cap jewel that doesn't even touch the axle. Next I take out the intermediary chrono wheel: Next I take out the master seconds bridge - it is held by three screws. I do not disassemble the whole thing because I don't know how at this moment. To take out the Master seconds together with its bridge you need to stop the chronometer so the balance hack could get out of the way - so you could have access to the Master seconds hack screw to release it a bit so you could take the master seconds hack out of the way (long sentence!): Next I wanted to release the tension from the mainspring but I didn't know how to. So I cheated! I took the movement out of the case and looked at it from its side (I will show you how to get the movement out too). So there is a cutting on the side of the movement in which you can see a click appear when you wind the watch. You must hold that click with a 0.8mm screw and release the mainspring tension in a controlled manner - at least this is what I did: Now I show you how to get the movement out . It I expected two case screws but I was wrong. Russians used a simpler way: one screw combined with one stud. You can see the one screw that has its head cut in half near the balance - you unscrew it and release the movement. Now you can see the stud, diametrically opposed: I forgot to tell you that I 3D-printed a movement holder for this 24 ligne movement: Now you can better see the click: Now I take the balance out. That is one big balance wheel! And the pallets together with their bridge: Next I take out the intermediary chrono wheel holder (the equivalent of the coupling clutch). Carefull! It is hold only in one screw the one from its right. The bottom one is an excentric. I learned it the hard way - it was a 50/50 chance and I didn't win Next I take out the driding wheel. You can see in the photo that the escape wheel and its cock are missing - I didn't take a photo of those. Next I start on the main timer mechanism. I appreciate that all the springs are secured with a screw. It helps quite a bit! So you can see that it is a cam chrono after all, though the cam is also the balance hack. The column wheel is only for the slave seconds wheel operation. The Master seconds reset hammer has a stud between it and the minute reset hammer on the bottom side - you cand see it right about in the middle of it - I will show it to you later. I take out the sliding operating lever: Then the cam and the reset-blocking lever: Next goes the seconds hand reset hammer and the stud to the other side: I also take out the springs for the sliding operating lever and the master seconds reset hammer - carefully - the screws are not the same! I take out the train bridge. Check out the dirt! If you look closely, the ratchet wheel has two broken teeth - I didn't notice it before - the timer didn't present any problems during winding... russian stuff! Barrel and mainspring: I take out the crown wheel: And the click and its spring. You can see between them a ratchet wheel tooth I didn't tell you but in the mean time, on the bottom side, I had taken out the minute heart. It angages the minute wheel via a spring and it permits the recording of minutes and the reset of the minute recorder. It resembles a canon pinion with a different design and purpose. The bottom side: I take the hammer and lever out: Finally, the parts list: I will let you know how it goes when I will put it back together. Thank you, Bogdan1 point

-

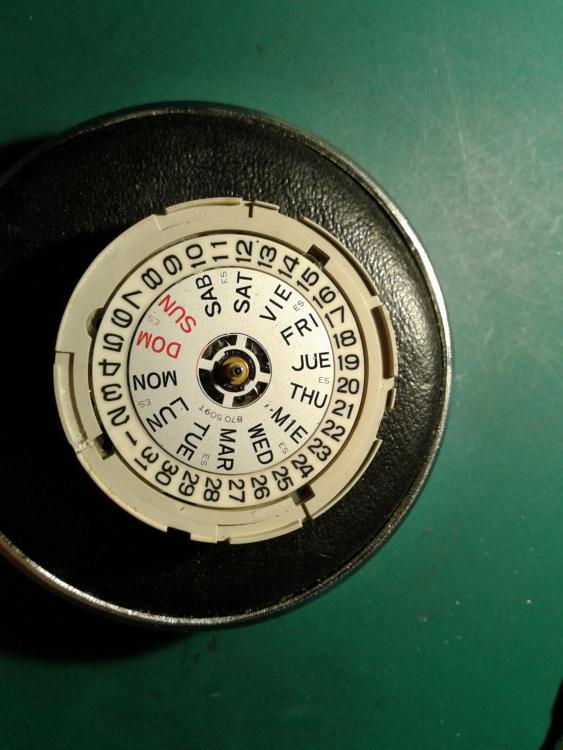

Hello a few months ago I picked a nice Helbros manual wind watch with a movement I hadn't seen before the hamazawa 5026 unfortunately it was missing its stem and setting lever.After checking cousins and other outlets without any luck I laid the watch to one side thinking I'd never find the parts needed. Then a month or so ago while trawling through our friend The watch collectors bay site for a couple of Seiko movements I spotted a set of 4 URIKA zombies with low and behold HAMAZAWA movements I quickly purchased these for a mead 8 quid plus his usually packing and waited not very patiently for them to arrive. One I've used as a donor for my Helbros which now runs beautifully and can be seen in watch of the day the other 3 I intend to bring back to life if possible. So here is number 1 a URIKA 56 auto 17 jewel 5026B. Oh and please excuse my photography I'm definitely not David Baily As you can see old battered and generally zombiefied. And with the back off we find a none running stuck 5036B movement I don't hold out much hope at this moment. Luckily once the plastic case ring was removed the rotor swang free it was just welded in with the green crud. Note the winding stem very unusual I haven't seen one like it before. Dail side bit crusty but ill just clean the parts the best I can I'm not going to try and find replacements. Calendar side bit better. First job remove the circlip holding the rotor in place. Rotor removed giving me my first idea of how much dirt I have to tackle. As you can see not the most complicated of self winding systems. Just a pivot point and an offset pivot on the rotor. Winding system removed time to remove the bridge and what looks like the balance cock Cock removed note that the balance adjustment lever is attached somehow to the main plate. Bridge off I like the way the wheels have corresponding holes in the according to there position in the train. Wheels and barrel removed I can't remove any of the setting system except the lever its all spot welded together very strange. The balance is removed and that's all I can do on this side. First remove clip from the center plastic pinion to free day dial. plastic setting wheels nice. Date ring and center plate removed and that's about it all parts were pegwood cleaned then ultrasonically cleaned before reassembly. I had no idea what the oiling and greasing should be as I couldn't find any tech sheets so I've oiled as you would an ordinary auto movement. movement cleaned and oiled and back in it case running smoothly with a beat error of .1ms and loosng 3 secs a day face down and 8 face up amplitude I think is a little low tho at 230 but that may rise after a day or so running. Glass polished nice surprise that its a prism type. Ida Dial and hands cleaned still a bit worn looking but I think it adds character. So that was an enjoyable service and clean I'll add a strap and put it in my collection. Mick1 point

-

I finally got the second watch of this kind. Unlike the first one with an ETA 7734 (w/ date) this one has an ETA 7733 w/o date. One thing I noticed when I tried the first one was the stop watch mechanism. I wasn't abel to restart the stopwatch after starting and stopping it. I thought that this might have been the case earlier. But... it wasn't. The watch with the 7733 I got today works flawless besides the fact that the big second hand is not alinged. Not a big deal. I looked at both movements and it seems that the 7734 has a problem with the setting mechanism of the stop watch. That's good, because I can repair it! I will start a thread in the walk-through section as soon as I start with this. If the weather is as bad as it is announced I will service a small "Anker" Ladies watch tomorrow. Before I start with the chrono, I will service five more movements, to practice. Cheers Alexander1 point

-

You know they can even custom make one, do you? !! Talk to Ann Marie, she is their glass cutter. Cheers, Bob PS. She is only there Tue and Thurs.1 point

-

Sorry to hear about the watch! It happened once to me on a nice 2496-2 brand new I had just received...and dropped right out of the envelope! Looking into the bright side back then I also thought it was meant for me to fix it anyway! Nice attitude! and good job...waiting for one more challenge! Cheers, Bob1 point

-

Hey Ry, Glad to hear you kept your cool. If all goes horribly wrong, the last time I looked Cousins had complete balances in stock for about £15. S1 point

-

My girlfriend dropped a WW2 Grana military watch which I had already agreed to sell... These things happen. Had to sell with a broken staff in the end.1 point

-

Oh no after all your hard work and the feelings you had when you did a fine job servicing. But look on the bright side you will be filled with even more pride when you've replaced that staff. As for your wife tell her your so upset you'll need a new piece to work on to get over it or some new equipment but if she's anything like my other half shell just say tough.1 point

-

anilv is correct on this, briefly it's done by what I can only describe as bodgers who know very little to take up or add end shake depends where the scoring has been made.1 point

-

Short Update: I must have jammed something with the date mechanism. After removing it, and assembling it again the movement ran for more than 24h. I consider this a success. Cheers Alexander1 point