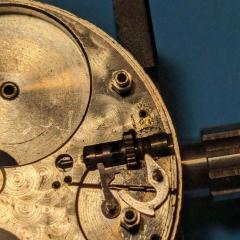

Clutch spring on a metronome (I know it's not strictly a clock) question

-

Recently Browsing

- No registered users viewing this page.

-

Topics

-

Posts

-

Learned a new thing today! 🤓 Looked this up and found this informative document: Watkins-MainspringGauges.pdf

-

By Neverenoughwatches · Posted

Correct one dip is expensive when the chemical is purchased as " one dip " which is why it is mostly reserved for these two small parts as far as information tells us it is mostly tetrachloroethylene. I use it bought as perchloroethyl used in dry cleaning processes, i cant say I'm overimpressed with it though it appears to me to be shellac safe. What may be a better solution for hairsprings is a high lab grade of pure benzine. IPA is mostly used as a rinse and water displacer and yes it does have the potential to dissolve shellac, personally i would not buy anything that has significant water dilution so 99.9% IPA is the way to go. And lastly the part you are cleaning dictates your choice of cleaning brush, delicate parts like a hairspring requires the finest artist's brush you can find. Plates and bridges can take a little more scrubbing, but always check to make sure the surface is being unharmed. And dont forget a stick of tip benzine soaked correctly shaped pegwood is your mate set up for cleaning dirty jewels and removing stubborn dried up lubrication. -

By Neverenoughwatches · Posted

Den / Dennison is a unit measurement of size this is actually a mainspring gauge . I haven't heard of a pivot been measured in Dennison before. Though the small thickness gauge is usually supplied with a Jacot tool and is more accurately known as a pivot destroyer. -

Could it be an abbreviation for Denier? "Denier (/ˈdɛniər/) or den (abbreviated D), a unit of measure for the linear mass density of fibers, is the mass in grams per 9,000 metres of the fiber. The denier is based on a natural reference: a single strand of silk is approximately one denier; a 9,000-metre strand of silk weighs about one gram." The pivot gauge looks interesting, however I wouldn't trust myself to drive a pivot into a wedge incase it jams and gets damaged/snaps trying to get it free. More a comment on my ability and incompetence than the quality or design of the tool 🤣

-

Recommended Posts

Join the conversation

You can post now and register later. If you have an account, sign in now to post with your account.

Note: Your post will require moderator approval before it will be visible.