Search the Community

Showing results for 'accutron' in topics.

-

fortunately when I post things I usually put them in a particular folder so I can find them for uploading so conveniently they were together. oh and yes you really would need the stem thing if you are installing this for the first time. If it's already in an existing watch it by theory should be much easier to do unless you change the back gasket. In other words on a 214 the location of the crown versus the back gaskets and the movement the back casket will of course move things around. then while I was remembering this that's why I uploaded this to some other group somebody was having a running issue on a 214 with a hack although unless you disassemble you won't actually know if you have a hack or not sort of. So I uploaded to comment on if it has a hack it could be an issue in these would be the issues why. In other words the crown is on the back if dirt gets under the crowd that changes spacing if the back gasket thickness should change. Which unfortunately will occur today as you may not really get original 214 gaskets and they have replacements and of the thickness is different it can be an issue. Oh and then if you are installing this for the first time you'd need the thing on the stems because you would have to change those to get one of the right length. I very distinctly remember when I installed one of these I was a student in school which was quite a while ago and I do not remember being a pleasant experience. Because as you can see with the instructions you have to set everything up and put it all together and if not right then you have to yes they can be a fun experience. I don't think I've ever done a 214 after that that had a hack though Accutron 214 hack.PDF Accutron 214 stems.PDF

-

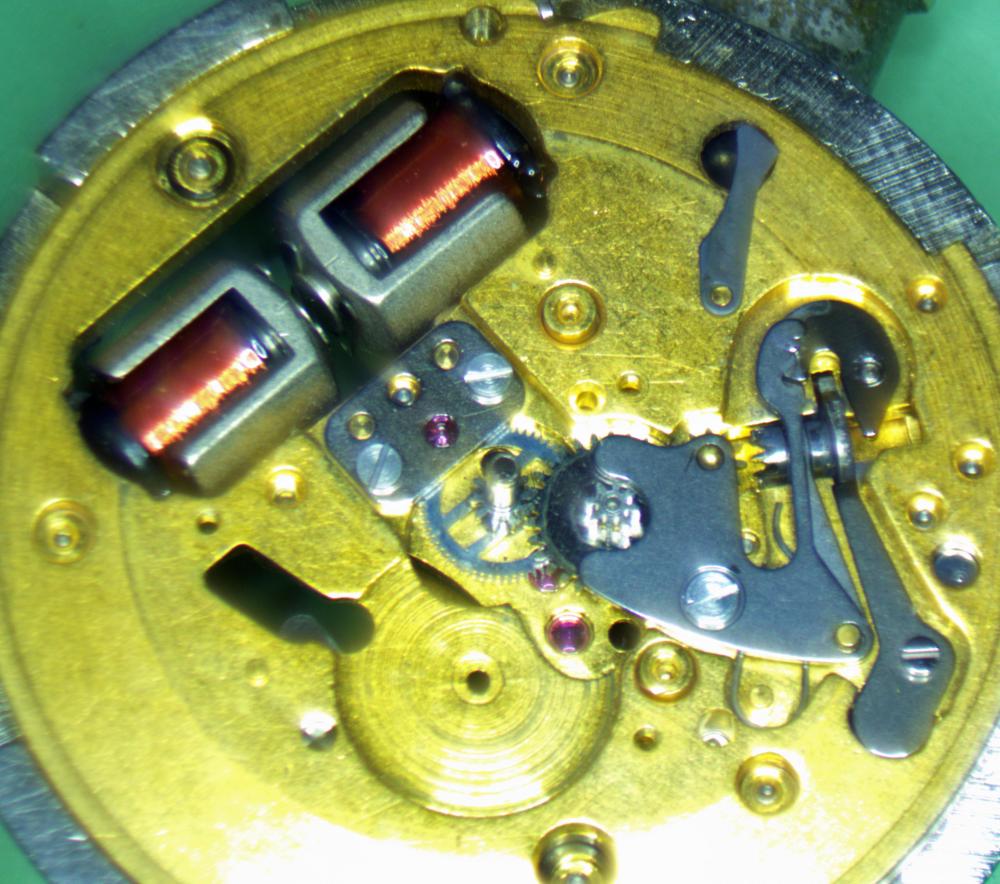

I use M56-b (AKA LGN) for pivots (surprise surprise!). It has a lower viscosity than 9020. Of course there is this craziness from the Accutron service manual. I am taking a shine to servicing these things. Each one gets easier. Still a little tricky getting the index and pawl fingers just right. My cleaning methodology is pretty refined now, using the ultrasonic for the clean and an L&R Master to spin dry between each step as well as dry in the last step. Found the right jars for the job and printed a lifter to lift the basket out of the jars.

-

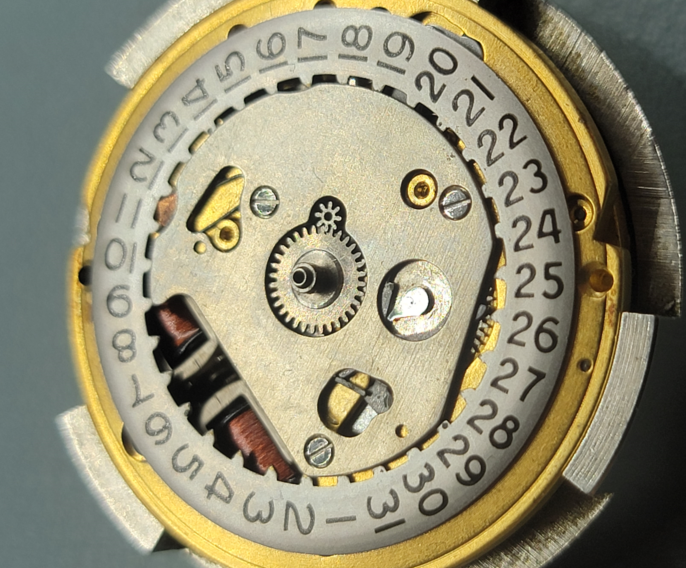

OK, I have recently services four Accutron 218s and disassembled another (my first) which is now a parts watch...lol. Feeling really good about my results and my methodology. Accutron recommends OL-207 for all but jewel settings. OK, if these watches I have serviced were lubricated in this way...I am not a fan! It appears to dry and then flakes everywhere. When confined (e.g., center wheel) it seems to gum up and freeze. I determined not to use it--NO. I am using Molykote for those lube points instead. Shields up--prepared for incoming!

-

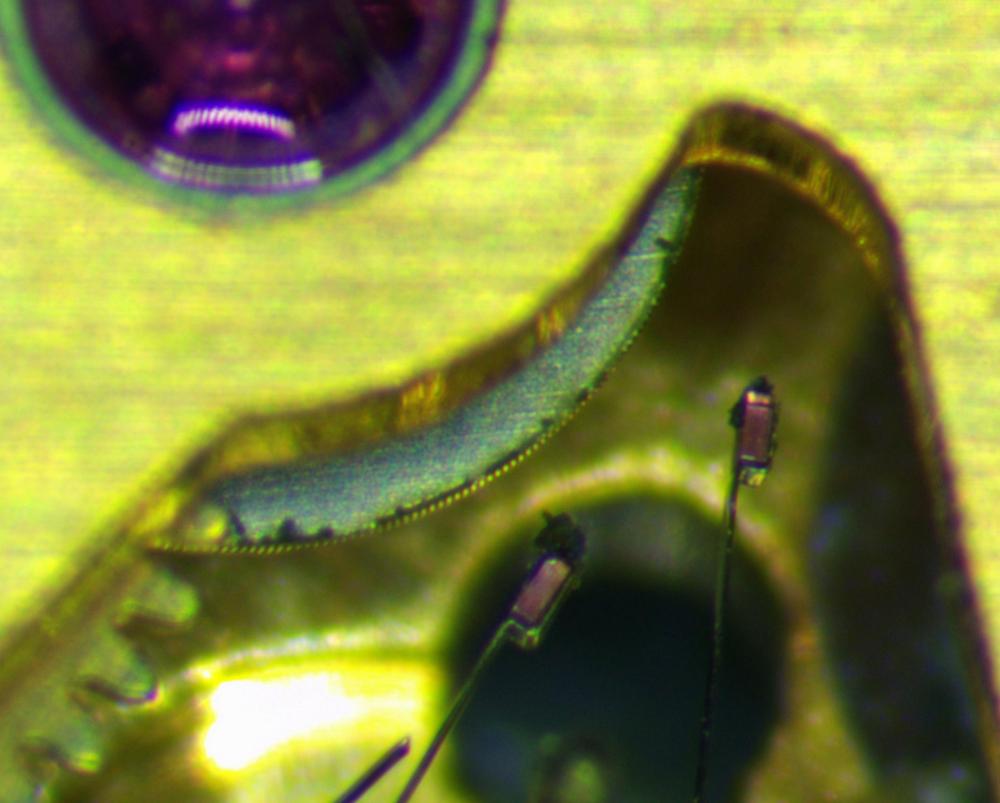

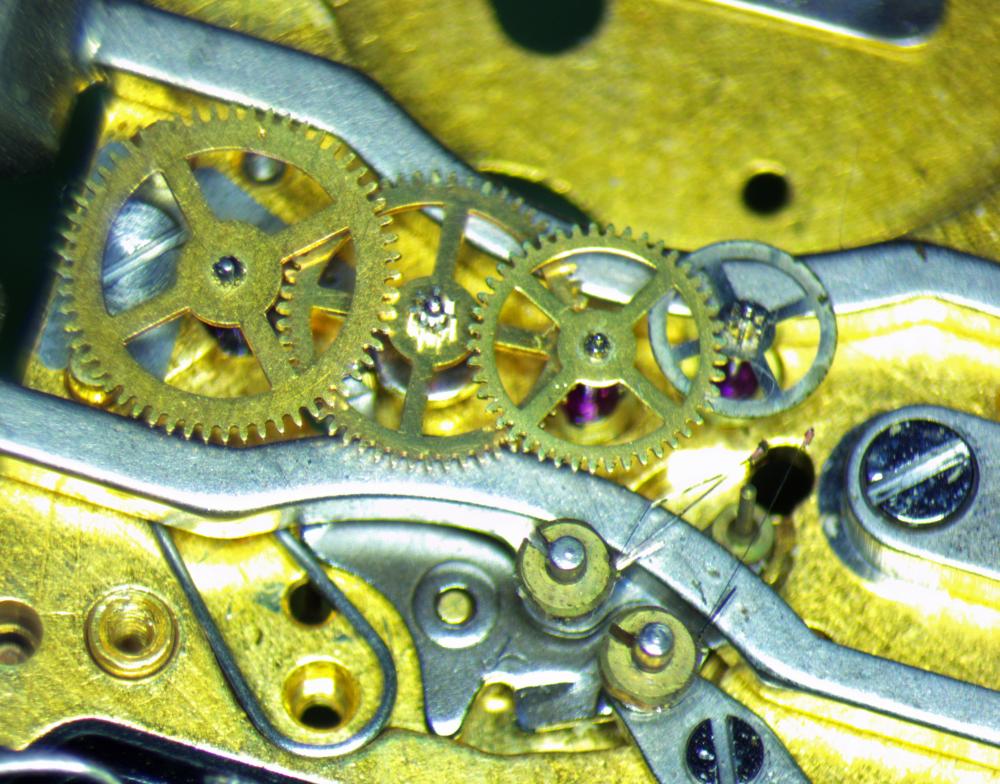

Yes, on an Accutron the power for the train is actually generated at the escapement, so counter-intuitively that tiny delicate index wheel generates a lot of torque by the time you get to the hands. This is why you see Accutrons still running after decades of no oil, but when you get them apart, you see pivots almost completely worn away and such.

-

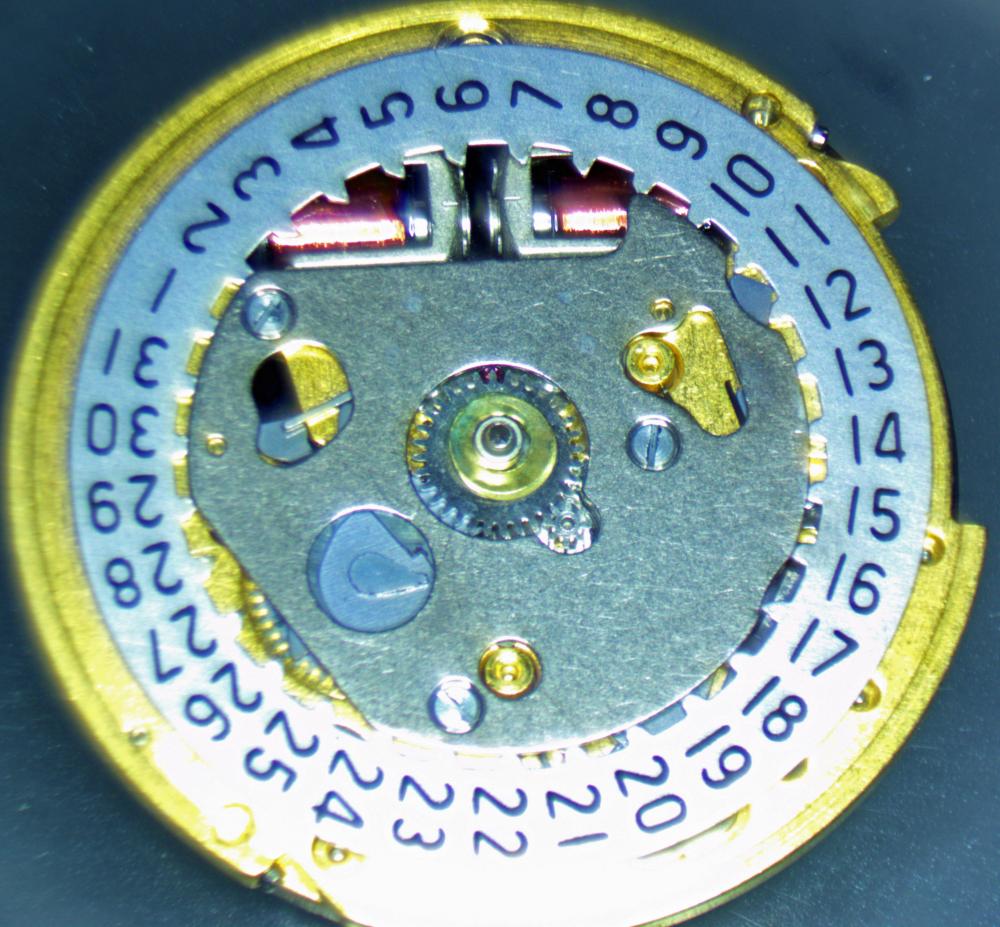

This 218 Accutron center wheel (which functions like a cannon pinion) is loose resulting losing time due to slipping. Not sure if there is a way to tighten it. Funny thing, I had a donor so I stole the center wheel only to find that it was shorter! Yes, the donor had no date, but the fixing watch is day-date.

-

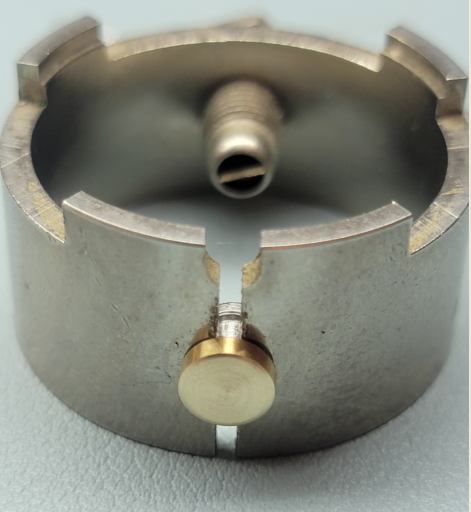

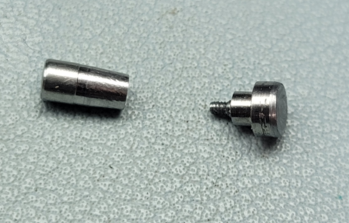

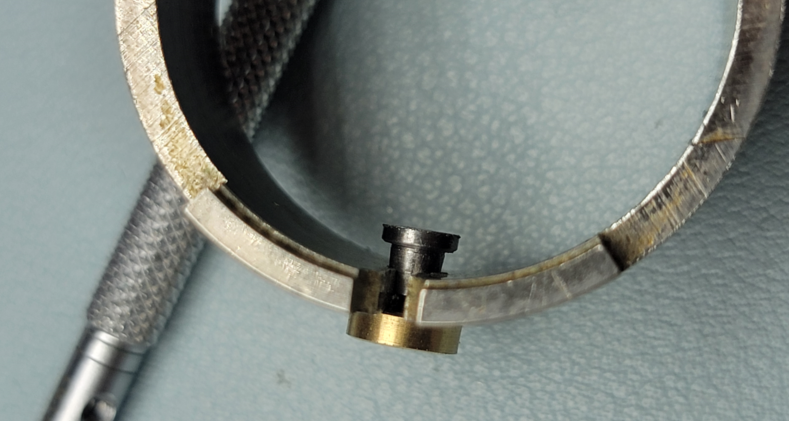

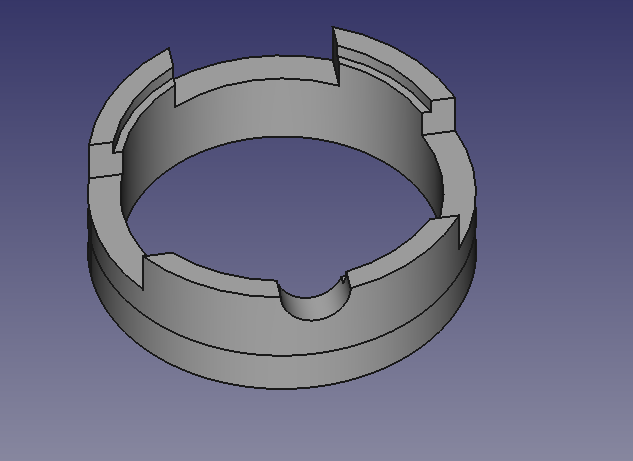

I have a couple of these movement holders for 218 Accutrons. In order to mount the movement, the holder must be splayed ever so slightly and then released when the movement is in place. I have been splaying with a screwdriver, but this morning, I made an add-on tool that does the work for me. I turned a slight conical profile with the initial diameter equal to the hole in the holder in rest position. I turned to a larger diameter enough to open the holder enough for the movement to drop in. Then I tapped the small end and made a threaded button. The tool is mounted in the holder in a semi-permanent way. When you want to insert the movement, press the pin from the inside of the holder and it splays out. Once the movement is inserted, the outside butt is pressed so that the holder collapses on the movement. I made two of these. One is mounted on the holder with a brass button. The other I show sitting alone so that the structure is obvious. The second one uses the brass button--easier to turn and thread.

- 1 reply

-

- 4

-

-

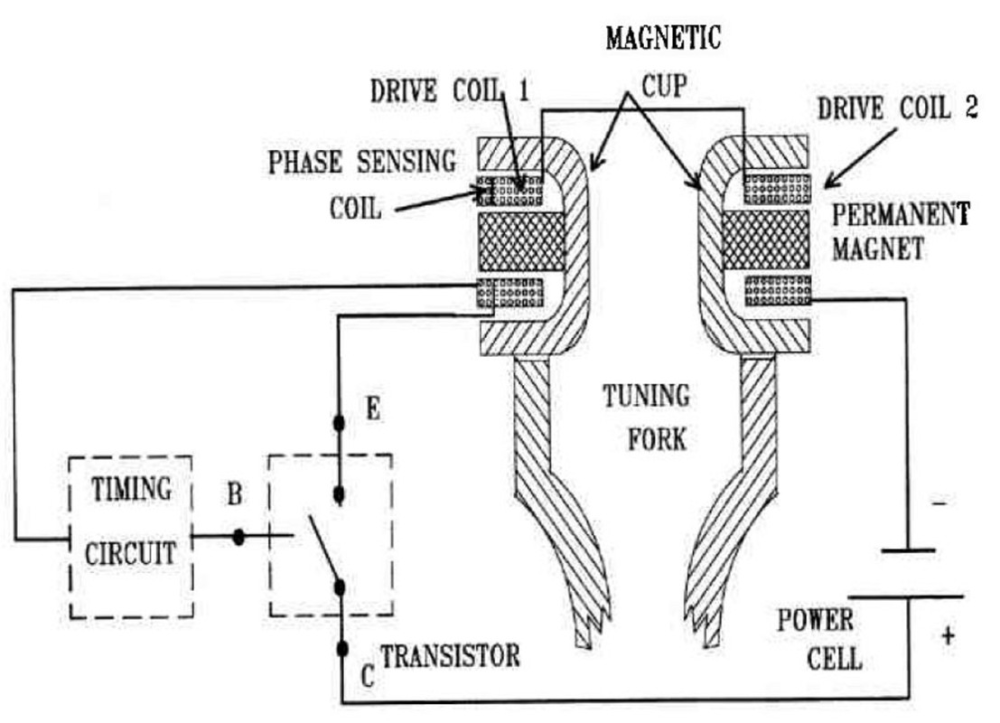

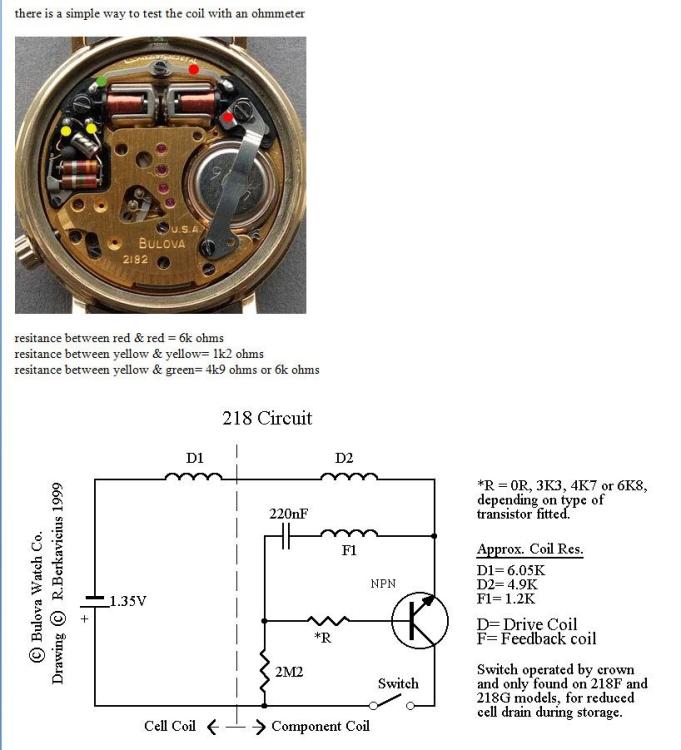

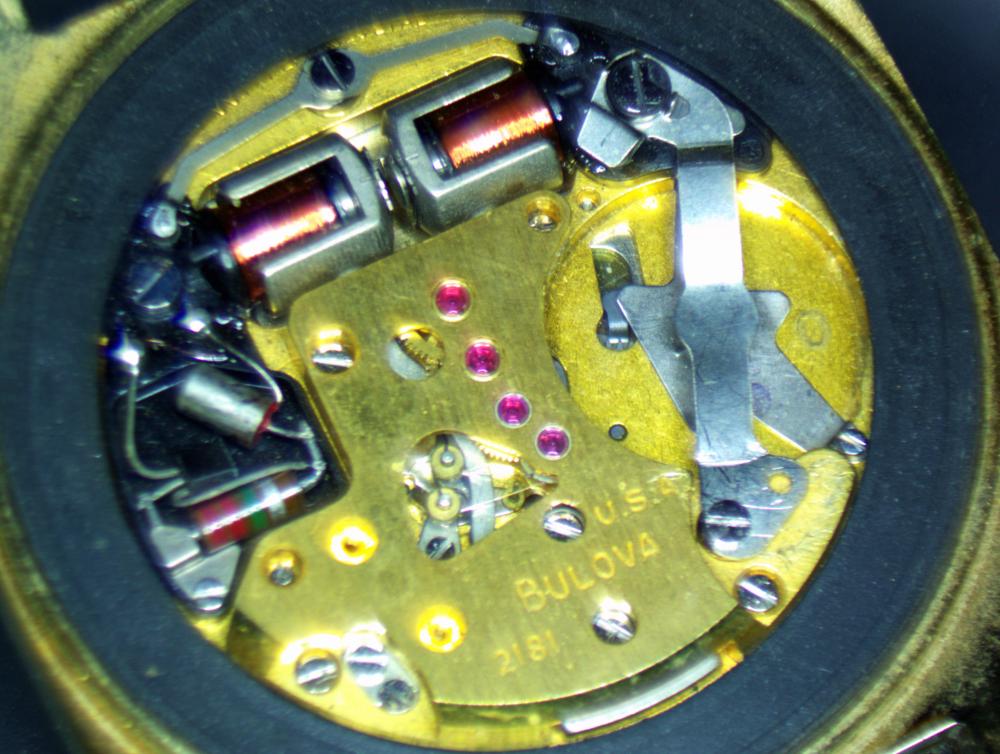

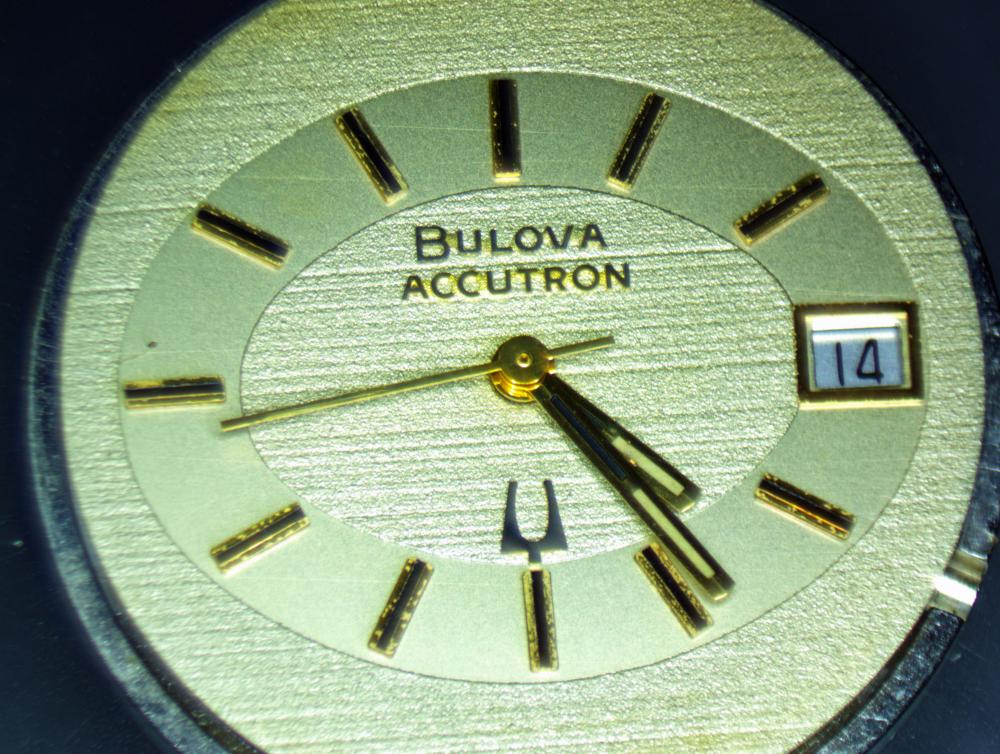

My grandfather died back in 2004, and my mom gave me his Accutron. I've wanted to restore it for years, and finally have the experience and confidence to do so. Of course the first thing I did was slip and bend the pawl finger, but at least it's not my first rodeo and I was able to fix that. Not running with an Accu-Cell, but the index wheel is pretty grungy so I took it apart and powered the circuit without the train installed. The fork kicks up, but instead of a hum I get a pulsing vibration. Never seen that before. I checked the electronics, and the resistor reads about 990 ohms instead of the 2,200 ohms we expect. The capacitor reads 197 pF, which is reasonably close to the 220 pF we're looking for. I'm going to give it a thorough cleaning and see if it'll run, but I have a feeling I'm going to be replacing the resistor and capacitor. A much harder task on the 218 than on the 219. Edit to add in some circuit diagrams, in case anyone is here for 218 diagnosis help:

-

I have spoke about my remote Accutron repair center (my house in Bryan, TX). Here I will outline the cleaning methodology I will use. 1) the index wheel will be installed into the official Accutron holder (seen in the first picture). 2) the index wheel and holder will be placed in the bottom of an L&R basket and then covered (second and third pictures) 3) the two plates will be placed on top of the separator lid (not shown) 4) the compartmental holder will be where all of the wheels are placed, yoke, etc are placed (no parts shown in the pictures), and the top lid placed 5) the electronics, tuning fork, the pawl are separated out and placed into a petri dish. Using a syringe with needle, I will bath these parts with one-dip. 6) the basket will be immersed into a jar with L&R cleaner (what I show is ammoniated, but I am going to use non-ammoniated going forward (when it arrives). 7) the jar is placed into an ultrasonic machine for a short period (maybe 5 minutes) remove the basket and spin dry using an L&R spinning machine (not shown) 9) place the basket into a jar of L&R rinsing solution (not shown) and run in the ultrasonic for a short period 10) remove the basket and spin dry as before 11) place the basket into a second jar of rinsing solution and run in the ultrasonic for a short period 12) remove the basket and spin dry as before 13) the final step is to move the basket to the drying station of the L&R cleaning machine I would appreciate thoughts on this.

-

Bench Testing Seiko 3823 Movement

JohnR725 replied to RickTock's topic in Quartz and Tuning Fork Battery Operated Watches

Yes you're going to have to make a New Year's resolution to get a life and not spend so much time here oh wait, I suppose that means I'd have to make the same silly New Year's resolution of having a life and spending too much time here so just forget about that silly thing everyone has to have a hobby. It's a secret code word you need the secret decoder ring to grasp its meaning. It's a reference to something forbidden at least by a horological Association Which is explained in the paragraphs on the webpage. http://www.pocketwatchrepair.com/catt/pwr-supply.php Here's another example of something similar. Then if you didn't have the Bulova holder for electronics they do make nice small clips that will clip on to the watch itself without a problem. Because that's typically what I do with my power supply just don't have a picture of the clips that I'm using but I see if I find something https://electric-watches.co.uk/accutron-test-meter-mark-3/ Here's what I'm using what I work on electric watches their very nice and tiny and providing you have really lightweight wire that don't pull on anything but basically any of the really tiny microbe grabbing for electronics would work Here's a link to all kinds of places you can buy them from then you do want to buy them into separate colors C keep track your plus and minus so typically that The red and black https://www.pomonaelectronics.com/products/test-clips/micrograbber-test-clip-do-it-yourself-available-ten-colors -

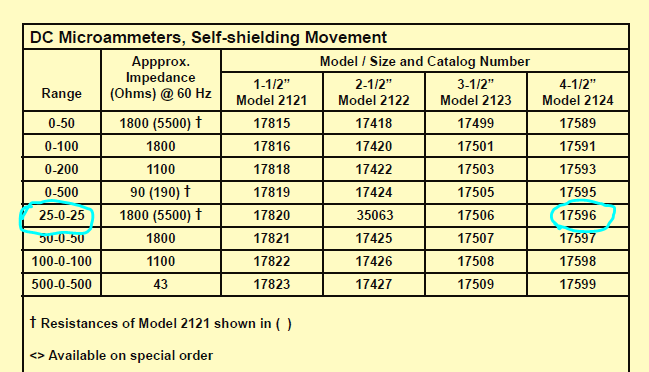

Did you notice the specifications for your 25 µA meter? It's a plus or minus meter it's not a 0 to 25 kind of. EBay is still a nice place to get meters if you're patient anticipating someday I might build a new power supply I managed to get a 0 to 20 µA meter who knows where though it is lurking in the house they purchased a while back. The other source of service manuals for Accutron Is it just download the PDF's as the book is basically a copy of the service manual anyway. The link below has all sorts of interesting Bulova stuff with all of the tuning fork service males etc. found basically at the bottom of the page https://www.mybulova.com/vintage-bulova-catalogs

-

OK...more like a "place" than a "center." I will be spending half my time here, so I needed some way to do horology. Since Accutrons need a subset of my tools, and I have about 50 to work on, I decided that I could setup to do just Accutrons here. I still need a cleaning setup...working on that! I have the microscope, test set, and the hand tools. Today, I took an Accutron that was not working, opened it up, adjusted the index and got it running. It needs a cleaning, but I was proving the tool set to see if anything was missing. Hopefully I will solve the cleaning methodology over the next couple of weeks.

- 16 replies

-

- 11

-

-

-

This is an interesting thread. I am trying to setup a methodology solely for Accutrons. Since the manual says to use ultrasonic, I have to deviate from my L&R Master cleaning system that I use for mechanical watches. And I just rebuilt another one for my remote location where I will be doing this work...oh well. The last few days I have been working on two "learner" accutrons. My method is to use the L&R Fine (which is all that I have) in a mason jar and then in my ultrasonic (small jewelry type). I run two short cycles, then do a pre rinse in L&R rinse and then a final rinse in same. Then I take the parts out and set them under an incandescent lamp (60 watt) to dry. I also puff off the parts to accelerate evaporation. I treat the pawl and index fingers separately by dunking them in one-dip. My glass cup is too small for the tuning fork, so I just squirt one-dip with a syringe. A kludge for now. I also dip the index wheel in one-dip. This seems to work. I have ordered some petri dishes that are larger and will allow the tuning fork to immerse fully. I know that some suggest putting all of this in the ultrasonic, but I am not ready for that yet. In a perfect world, I would have jars that accommodated my L&R basket. That way, I could put the parts in that and on the last step, I could use my L&R Master to do the drying. I am looking for the appropriate jar. Am I overthinking all of this. Perhaps. But, I have about 50 of these to repair, so it is worth the effort to design a really nice process. On a side note, the two watches I have worked on had crappy black residue and one had the seep second stuck with the black crap. I think it is the molybdenum disulfide that Accutron recommends...dries up resulting in bad things. I will not use the recommended oil, but will instead use MolyKote for those places. I see no reason why not. I am gonna order some L&R 566 and associated rinse for the long haul, but I used what I had this first round.

-

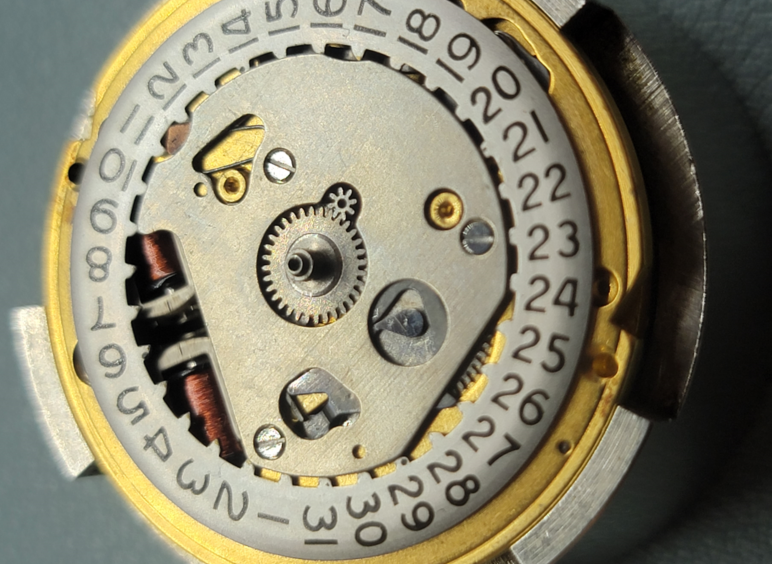

This is the same watch I have posted about under different topics. After assembly, the date does not advance. In the pictures I show the Date Trip Arm and the Date Trip Wheel in different positions. What is happening is that the hook on the Date Trip Wheel is releasing the Date Trip Arm BEFORE it moves far enough to grab the Date Indicator. Everything moves freely and I have lubricated according to the manual instructions. I wonder if the Arm or the Wheel have worn to cause this problem. BTW, before I opened this watch up for service, I noticed that the date was not working. Thoughts?

-

I bought these to work on Accutrons because the are non magnetic. I have many tweezers which I inherited and most are Dumont. I have two #3s I use daily--a sharp pair and a dull pair. Sharp ones for delicate work and the dull pair to muscle things around (bending, shoving, etc.). I love them both...very delicate feel that suits me. I bought a new pair of Dumont 3C last year and was disappointed with the feel. Harder to squeeze...I was too accustomed to my old Dumonts. I bought a cheap pair of Ti tweezers earlier this year. They are not sharp, have hard feel and just not all that useful. So, I was skeptical when I purchased the Dumont 5Ti. Figured they would disappoint. Well, they did not. After one full day of use working on an Accutron, I am very happy with them. Delicate touch, sharp, and light. I would be happier if they were heavier, but they are Titanium, duh. So I highly recommend the Dumont 5Ti tweezers.

-

----------- Further observations: The Accutron 218 movement holder (I inherited) is far better than a conventional movement holder. It clamps on to the movement very secure. Second, I do not know how anyone could work on one of these without a microscope. I have the Bulova microscope but I am using my stereo for this work. Using a battery installed on the test set. Yes, I read this but forgot it. I will revisit this issue today. The couple that I have looked at also corroborate this.

-

I am about to start the journey into Accutron service and came across this thread after reading the Accutron service manual. I will bite the bullet on 9020, but it seems to me that a molybdenum disulfide grease is a reasonable substitute for OL 207 (8201) because when you read the marketing data on 8201, it is recommended as a breaking grease (MDS): "This special purpose Moebius grease contains Molybdenum disulphide to enhance it lubricity and resistance to pressure. It is designed for use on automatic mainsprings, to ensure proper functioning of the bridle. It is also recommended for use on the Bulova Accutron watch movements. Moebius 8201 natural watch grease lubricant Contains Molybdenum disulphide Black color Drop point: 32°C Viscosity: solid at 40°C Viscosity: 22 cST at 60°C Viscosity: 13 cST at 80°C"

-

I'm sure that this has been covered before but, I have one of the Accutron watches, I seam to remember that there was a movement that could replace the 218 movement. I have one the movement is no good it's just too far gone. I'm hoping that someone will be able to help me, I'm sure it's been done before. Thanks in advance.

-

I will do jobs for friends, neighbours, colleagues etc. on the understanding that "I'll have a look at it, but if I decide against it, I'll hand it back in a day or two, no charge. If anything needs replacing, then even if I can get the parts, they could be very expensive. If I encounter anything I don't feel ready to tackle, I'll put things back as they were, no harm done." That broaches the subject of cost, and you can start to have a conversation about the amount of time and effort actually involved. Most people don't have the faintest idea. Regarding liability, I don't tackle anything I'm not confident about (e.g. recently rejected the chance to work on an Accutron), and I try to be extra careful with other people's property, so no problem so far. If I know I couldn't afford to replace it if I broke it, then I won't touch it. For reimbursement, I usually work for upmarket alcohol; whisky, Belgian beer, wine, not cash. Something personal, with a bit of prestige, a treat I might not get for myself. Decent people will do the decent thing, if they understand the value of what you are doing for them. A neighbour gave me one of his pocket watches after I'd serviced part of his collection, which was a lovely surprise. If you don't feel sufficiently valued, just reject the next approach. In the end you have to weigh up what it is worth to you in terms of practice, experience, goodwill etc. A newish Rolex might be worth less to you than a Poljot chronograph and carry considerably more risk. If you don't feel comfortable reject it, explain why, and don't be shy about telling them what a professional job is likely cost and how long it will take. We are hobbyists in the end, amateurs, and we don't pay taxes, have liability insurance or guarantee our work. In my opinion, you can't charge, not even "mates rates". If you're anything like me, you have far more jobs lined up than time available, so why take on anything you wouldn't want to do for your own pleasure and satisfaction?

.thumb.png.e3ea96bbff95e4995053f85304262add.png)