Leaderboard

Popular Content

Showing content with the highest reputation on 01/21/23 in Posts

-

Detach the hairspring from the balance, pin the collet on white sheet of paper/ cardborad, to have much more control over the peice. Shaping a perfect terminal curve is challanging, call it good as long as the coil is centered and oscilator runs alright. Rgds Your oscilator would inevitably be out of beat when you sort out the coil anyway, another task to adjust it in beat.3 points

-

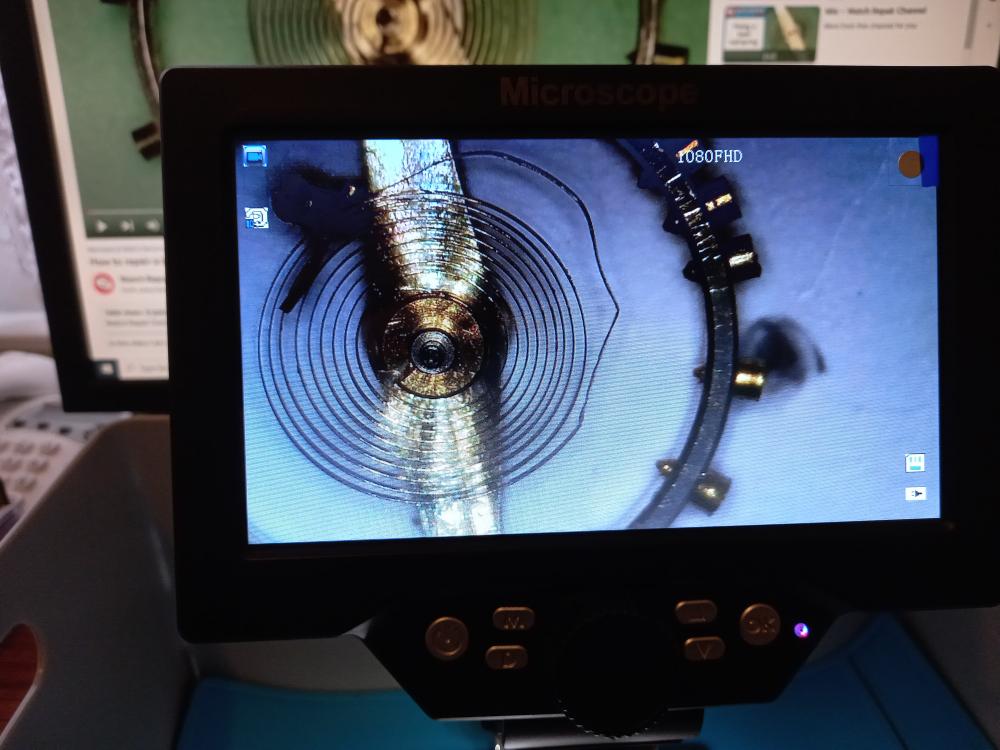

Update on balance hairspring straightening. Tried to do the straightening using magnifying glasses. Too awkward. Duh! Use the digital microscope your bride got you for Christmas. Placed spring on paper and then on staking block. Better for vision. Metal block makes it awkward to differentiate hairspring and metal background. Using two tweezers. Probably incorrectly, but watching and learning from Marks video I set about the repair. Gentle hold, gentle stoke. After 1/2 an hour, it's a little better, but i''m getting heavy tweezered. Almost went to bend it. Take a break. As can be seen it is a little better, but long way to go.3 points

-

You are right. Balance complete is the ONLY timekeeping element in mechanical movements. Rgds3 points

-

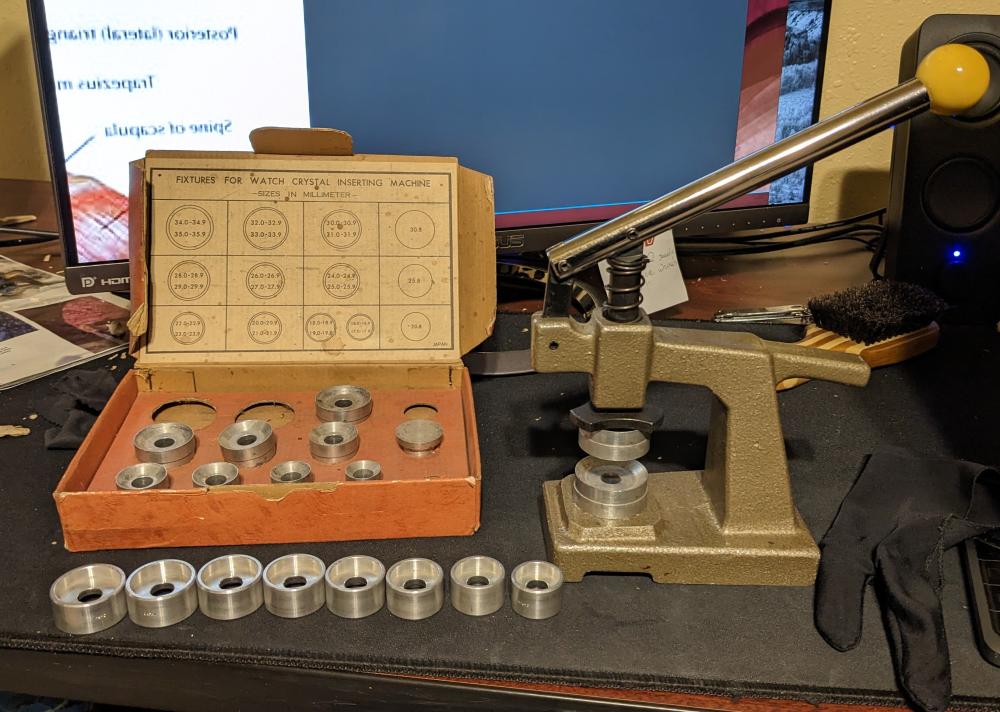

Seller was a scammer and I had to file a case with ebay, but ebay is such a broken site it wouldn't even let me file a case for awhile. Teh day my replacement BB press from another seller came in which seems amazing ebay came through and ruled in my favor and i'm getting my money back thank god. I've been scammed on ebay a couple times and they usually rule in the scammers favor.2 points

-

1 point

-

Success! It was very easy to bend it back in place, thanks all for the guidance.1 point

-

Hello thank you for your reply. My theory was to demagnetise the magnet temporarily to shift the debris. Whether thats a flawed theory or not i do not know but it worked. The 5 ticks i was getting after was actually due to the battery being drained, i accidentally put in the original right sized battery after demagnetizing instead of the brand new slightly wrong sized that i had started with. Its been running flawless for the past 24 hours. Heres a gif of the operating stepper motor for your interest.1 point

-

The 388 battery was a mercury cell and as such has been out of manufacture now for decades. It appears that 329, 392, or 384 cell may be suitable alternatives although they are slightly smaller than the 388. At least one company supplies a 329 to 388 converter here.1 point

-

Yes. Mark is right when he intimates 'practice, practice and more practice'. Some good videos on YouTube. Can recommend this cheap digital microscope. £42.50 inc VAT and free postage. 7" display1 point

-

A good start on that terminal curve. I’m struggling with this myself. Destroyed three practice springs. Have managed to get one in a decent condition. This really requires patience.1 point

-

Whelp, i now have two presses and two sets of dies of different styles but all say japan on them so i assume they're from whatever company made the thing. This second press actually works and i gotta say i'm beyond impressed with the stability and precision of it. It is PERFECTLY square, zero play in the posts. I can see why these things keep coming up on ebay. It seems like a really really high quality tool. How does it compare to the bergeon?1 point

-

Thanks Simon, that's not a bad idea to get an idea of how long it runs for. I'm pretty sure I've narrowed the issue down to the oscillating weight bearing now. The rotor is getting stuck ocasionally and only loosens up with a hard shake, then it spins fine. The bearing has a lot of play in it which isn't great, so I suspect there's a certain angle/position combination where it manages to bind against the case back and movement. I have a few spare rotors here but they are not in great condition either. I'll try one or two of those anyway to see if it still binds up. The last option is a new aftermarket rotor. I could replace the bearing but don't have the correct tools, and it's about the same price to get a whole rotor...1 point

-

Hello all, recently found this same model in my attic. After hours of searching, I found this forum. Other than that the trail is bone dry. What else have you learned about the machine, if anything? What is the going rate for something like this? I don’t want to test it due to the wiring being old and brittle. I have no interest in keeping it personally. I just can’t find any other info on this.1 point

-

1 point

-

Evening, On wet and wild Saturday last week I found this lurking in a dark corner of the hospice charity shop. It's definitely french, name on the face is a bit of a give away, which made me look a little closer. Then I thought I was in luck as the bell tinkled away as I picked it up, it was loose inside, on opening the front it had the pendulum (detached) and even a key that fitted. I couldn't leave it behind. By the time I got it home the poor thing was going like the clappers so I think it'll work again with a bit of TLC. After I got it home and much better look at it I pretty sure this is a marriage. The movement I've seen similar on much more elaborate clocks. All gold with figures and sculptures. Though I do like the case as it's solid wood. Now comes to the questions, am I right in guessing the movement is late 19th century with possibly early 20th century, or later case? Not sure on the name of the style. Was Potonie a clock maker or known as a Paris jeweler? I've seen similar movements with different markings. Would I be right in saying '465' is the model number as its on both the movement and pendulum, and '13029' the serial number perhaps? As you can see it's been the victim of rough handling as couple of things are bent up and if you look closely you can see what's left of the suspension spring. Would anyone know length/dimensions of the suspension spring? Thanks in advance for any insights.1 point

-

Thanks everyone for the warm welcome. I had a go at servicing my first mechanical watch over the weekend. It's a Citizen 21 jewel Cal 0201 from an old Homer watch that I picked up on eBay for a few £. I figured I wouldn't try with something too precious for the first go. The movement was running but would stop regularly. It appears to have been a fairly successful attempt. I disassembled all the parts (including removing the extra cap jewels for the 21J movement), pegged the jewel holes and washed everything (in one of those gem washing jars with the sieve). I managed to get every gear and jewel and screw back into the right place. I carefully wound the mainspring back in by hand (with gloves on and can now see why it's better to use a winder). I oiled the components based on the normal ETA recommendations as I couldn't find a chart for this specific movement. The good news it that it still ticks, no longer stops and keeps good time over a day. There was a little bit of rust on where some water had got in past the crown. I cleaned it up as best as I could with some tea and a fibreglass brush. The winding pinion and clutch really need replacing. It seems run fast when fully wound but slows down again as the mainspring unwinds and over the 24 hour period is only a few seconds out. Is this normal behaviour? I used a timing app for my phone and it looks pretty good. Just slightly out of beat. Something I may have a go at rectifying. The last thing I did was replace the acrylic crystal as the original was cracked. It's now all back together and just needs a new strap. I tried out the microscope at during re-assembly and it seems to be pretty useful in this application. The auto-focus can hunt when viewing highly reflective or transparent surfaces but I've managed to work out how to engage manual focus for this situation. I think I'll build a proper control box to send these command and perhaps use some pedals instead of my laptop. So now just to purchase a mainspring winder and a timing machine. Oh and a decent cleaning machine. This is not a cheap hobby is it. Marks videos (particularly the ones covering the service of the AS 1900 movement) proved to be inspiring, helpful and a good guide as to what to expect more or less when tearing down a movement. Next time (although that could be a few months away. I'm about to undertake an international move) I'll make sure I get some pictures and video of the process. - Cheers, Tex1 point

.thumb.jpg.ef094527aa7e090c9c4d6ecf981704de.jpg)