Search the Community

Showing results for 'lighter fluid' in topics.

-

Hello, everyone. I can’t seem to find Naphtha here in the Philippines. I’ve been using locally-produced lighter fluid for my pre-cleaning and though the results are ok, I’m not really sure of its content. I found a video of someone doing a movement service using Gamblin Gamsol, a solvent used by artists in oil painting. I checked the MSDS and it indicates it is 100% naphtha hydrotreated heavy. But I find it a bit oily/waxy compared to lighter fluid. I’m not sure if this how Naphtha is supposed to be. Anyone has used Gamblin Gamsol for cleaning Watch movements?

-

Hello everybody, sorry for the late reply. Thank you all so much for your help and your tips. I got lucky and found a replacement wheel bridge for cheap which actually ended up being in decent condition. I decided not to do anything about the mainspring barrel pivot since I didn't have the right tools and the barrel didn't have much endshake anyhow. I am happy to report that the watch now runs great, I have regulated it to about +-10/s day which is fine by my standards. The timegrapher result looks decent as well, although beat error is around 0.6ms which could be better I suppose. Amplitude reaches over 230 quite consistently which I'm happy with also. My lighter fluid has also been replaced by balance spring cleaning solution and now the springs don't stick to themselves anymore - who would have thought. I'm super happy with this watch, it might not be worth a whole lot but it's awesome that I could restore it and it makes me wear it with pride. To me it's a genuinely good lucking watch, it'll be my daily driver for a while. Thanks again to everybody for their input! I couldn't have done the repair without your help. Here are some images for those interested, the bracelet isn't original but I don't really mind:

-

The effect that You describe (no friction when turning train backwards and noise + friction when turning forward) is due the oval wear of the 4th wheel bush. The oval lets the 4th wheel tilt and get closer to the escape wheel in normal direction rotation, and thus the mesh with 'scape pinion is wrong. There is a simple way to confirm this - mark the bush, remove it and press it back but rotated to 180 degr. This will restore the correct wheel position and mesh when rotating the train in normal direction. The mowement will start working normally. Well, this is not perfect soluion of the problem as the oil retention will be not as good as with new bush, but if You lubricate with 8200 grease, it will stay in place and work good. Of course, placing a stone there is good, if You can find one with correct sizes. The hole for the arbour in the main plate looks rather punched than weared. So if You have not punched it, then someone before You did. It means that You have to check if the arbour stays upright, as closing the hole by punching it may lead to shifting the hole. What You actually need to check is wether the barrel stays tilted when the movement is wound and let to unwind by train rotation, does it rubb on the bridge or the mainplate or gets dangerously close to the 4th wheel table, and if the mesh with the 2nd wheel pinion is correct. Wear of the barrel bearing holes may lead to similar problems too. Lighter fluid is good for lighters, it is not ment for hairspring cleaning. Well it doesn't mean that it is not possible to use it for hairsprings. But if they stay sticky, then it means that the fluid is not fully evaporating or it has some oil in it solved. You can try to use hairdryer to dry the balance complete. If the spring is OK after drying, then You have the solution. If not, then source some pure hexane, acetone or another fast drying and clean oil solvent. Clean - put some drop on clean glass, wait untill evaporates and see if the glass is still clean.

-

Naptha appears to be a general name and its content can be varied depending upon what it's specific use is. Lighter fluid as an example can be light or heavier also with other ingredients to help it burn. Try sesrching for benzine ( as opposed to benzene which is linked to causing health issues ) . There are other fluids such as ethanol that you could try and also methylated sprirts, mostly ethanol with a small percentage of methanol added. Experiment with any new chemical to see how quickly schellac dissolves in its presence. I have tried a few things but hexane is not one of them, i understand it does evaporate very quickly. Be sure sure to check out any safety data on chemicals you try. Toxicity of fumes and flash point information, ultrasonic machines can heat up fluids even without a heater function. And of course always ask here for personal opinions when trying a new substance.

-

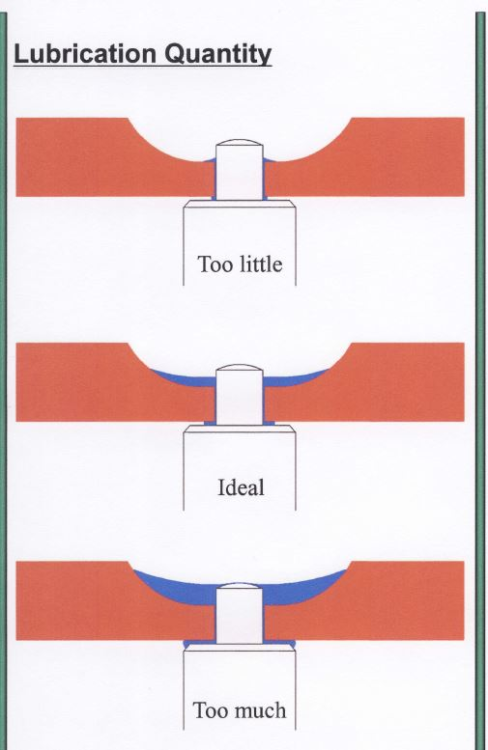

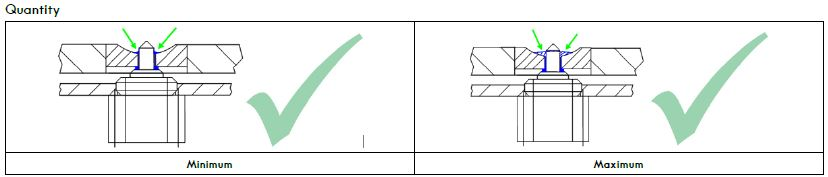

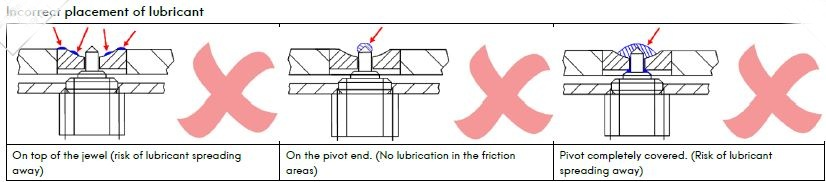

story that I'm not quite grasping all of this so it appears to be that you using three separate jars of the lighter fluid of two minutes each followed by three jars of the alcohol for two minutes each and this isn't right at all then despite the cautions and I don't use lighter fluid I know others do on the group. But as I said before I run everything through the ultrasonic and I don't have issues with the jewels falling out. So let's pretend lighter fluid is a watch cleaning product which it's not really. But it's your cleaning product I would run it for at least four minutes. then you would rule over the first jar into the second jar then into the third jar all of lighter fluid. The purpose of this is that the first jar of lighter fluid your poor cleaner would clean off aggressively and become very dirty and as you go from jar jar your reducing the bad stuff on the plates. Then the isopropyl rinse is just a rinse off the lighter fluid and I probably wouldn't you run that in the ultrasonic I would just swirl it around for a little bit the rinse off the lighter fluid and go right to the dryer. If you're using a commercial product you would do a cleaning cycle first. then typically two separate rinses and the only reason why we normally use alcohol is issues with the rinse drying. They change the properties so basically it doesn't draw I-had it in my hairdryer blowing across it and the plates for nice and hot too hot to even hold and the rinse was still there because it's environmentally safe now. That's why use the isopropyl as just a final rinse so I wouldn't even run an ultrasonic I'd concentrate on just the lighter fluid and then if you can figure out how to buy some commercial fluids They would be so much better for you to be using. But it is what you have I see have been influenced by old-school watchmaking. When I was in school I was told if you could see the oil you had too much that's old school. What they discovered is old-school isn't enough lubrication. your oil choices are interesting you have a super light oil and the super heavy oil. Then I assume you're oiling the escapement with the 9010? I would like to know exactly how you do that and yes it's extremely critical at this be done right it's amazing how much amplitude can be lost by not lubricating the escapement correctly. now how much oil should you use in your jewels? Old school would be the top picture which is now considered unacceptable now let's find another picture of the confusion of lubrication as the minimum here almost could pass as the unacceptable in the picture up above then what is considered unacceptable basically putting the oil any place except where it's supposed to be and you still have to be able to see the top of the pivots

-

The hole in the main plate looks kind of oval from here, but it could be perspective. You'll probably want to put the arbor and bridge back in and wiggle it around to check for side shake. I'm not sure about the 6309, but for the 6139 you can get a jeweling kit to replace the barrel bushings, if you're looking to make extra work for yourself I found the same thing, and is one of the reasons I bit the bullet and switched from lighter fluid to L&R 566 in my ultrasonic. It's a night-and-day difference in cleaning quality. That said, I still clean my balances, hairsprings, pallet fork, and cap jewels separately in hairspring dip. It dries fast and leaves no residue. I get mine from Esslinger here. Edit to note the fact that it dries fast also means it evaporates quickly from whatever vessel it's in. I used to use the guy on the right, which everyone sells. Then I found the one on the left and it's once again a game changer. The ground glass seals very well and minimizes evaporation. Link to previous thread on the topic.

-

I don't know how I could miss it, but your suspicions were right: it looks to me like one of the pivot holes is elliptical, and quite clearly so. There also seems to be some scoring from the ratchet wheel on the bridge, which is odd, as well as the other pivot for the barrell bridge on the main plate. I suppose I need to find a replacement wheel bridge at least, what do you think about the other damage on the mainspring barrel pivot? Also perhaps a little unrelated: using lighter fluid to clean balances seems to make the balance springs stick to themselves, what other cleaning agent should I use? There are some wear marks on the other pivot for the mainspring barrel as well

-

A little update on this if anyone is interested: I have found some time to open it up and really have a proper look at the movement. The markings indicate that it hasn't been serviced since August 1992. This seems consistent with the state of the movement, as there were small pieces of gunk built up between teeth, under the mainspring barrel etc. . While I couldn't identify a specific piece of dirt that was impeding the movement, it seems highly likely that this was the cause for the stoppages. It's proving somewhat difficult to clean the teeth on the escape wheel and the center wheel, but a few more rinsings in lighter fluid/99,9% IPA should do the trick (I would really love to have a cleaning machine). Overall the movement is in good shape, all of the jewels look great and it honestly just appears to me like the issue was a lack of service. Obviously at this point in time the movement is not back together, so I will refrain from celebrating until the thing is actually ticking away and keeping good time! I will update once more once I've put it back together.

-

I currently use an Amazon chinese ultrasonic cleaner with containers of different chemicals. I use Zenith "radiant" which I really like for clock movements and then I've been using Zenith "Drizbrite" rinse. I think it may just be that my radiant cleaner is contaminated from cleaning filthy clock movements (I strain it through a coffee filter. But I've been finding this results in my movements being dirtier than when it went into the cleaner. I also don't love the rinse product as it takes ages to dry and results in hair and dust being stuck to the parts as they sit. I use lighter fluid to clean balances and pallet forks. I find myself scrubbing plates with a toothbrush in the lighter fluid to get sediment off that has accumulated like snow during the cleaning process. I'm going to start with buying a new jug of the radiant cleaner and only using it for watches. I'm not really sure what else to do to make this better other than buying an expensive machine. I feel that I have a lot of issues that are the result of ineffective cleaning methods.

-

So, I'm to the point in my watch repair learning process where I'm able to take apart and put together all the movements that I've ordered so I've begun buying old pocket watches. Instead of getting an ultrasonic cleaner I am going to try using lighter fluid and soaking those dirty parts in small glass jars. My question is this: How long to I soak the parts for? And when they are done soaking do I just air dry them or set them on some paper and blow some air with my air blower on them? I also got some oils and some oil applying tools that I'm going to attempt to use as well. But the soaking question is what I really need some input on. Thank you so much!

-

Hello to all. I live in the UK and the cost of purchasing cleaning fluid from abroad is prohibitive. I would like to change my cleaning system so that I do not need to remove the balance and pallet forks from my baskets when rinsing. I have a 3 stage cleaning system using an ultrasonic machine. 1. Peg wood, fibre brush (if needed)and lighter fluid. 2 and 3. Isoprol. Unfortunately for me on a few occasions I have forgotten to remove the balance and pallet fork from the basket. Shallec knackered. To alleviated this I would like to purchase a fluid for 2 and 3 in the UK that rinses but does not damage the shellac. I've priced #3 and it's £50 + postage from America Can I use this? https://www.ebay.co.uk/itm/121858985665?hash=item1c5f5c8ec1:g:fJYAAOSwAC1aBgqS&amdata=enc%3AAQAIAAABALN0bgGOHmritWwGUejc4MHif0%2BQKZf%2Fsl2BNbySZrj8t3MycTtPCzkpgrNhjl79VhNi4e3z08RslsS1kZLB8vUijFyQ2gEvDX1ZWVLOIvEulbhHFvevCMIcxYGQ7sBpOfVuAZ%2B0YvZPKTvqdQEgrayykIvlb%2F4x3Jj78ohdzxezhdYcuXJPVmC%2BC40gmRg2MU1WQcOAEWGKKYh1ot8udJqtzrp8flJdtY95DgPjnDnAgFJPQ8ARpvC7uDGKl8EqK2j5AgE7ZtuhqbbQ0sCh1VYb0rJ%2FWvFWaFb7uIT83j9L%2Fi5sIzpPG%2BHtJLha5YmhHb2%2BV6h8XnA4tclC2PP8k2c%3D|tkp%3ABFBM_qrfjtFi Any advice would be greatly appreciated. Thank you Ross

-

For years, since I didn't know how much further I would take "watch-repair", I've been "scrubbing" my watch parts in Zippo lighter fluid........ Recently I decided to "up" my cleaning game. Bought a 2nd hand Elma S15H ultra-sonic and the "official" chemicals (in my case Elma WF pro (cleaning), Elma Suprol (rinse) and Isopropyl alcohol (IPA). That made a world of difference ! So, if you are serious in continuing this hobby, fed up scrubbing with lighter fluid and want to "up" your cleaning game to near professional levels; get the decent stuff

-

Thank you John. baskets into jar of lighter fluid. Jar 1. Jar 1 into Ultrasonic machine containing water. Level above lighter fluid. Ultrasonic Switched on for 2 minute cycle. This is the only setting. When stopped, leave jar 1 in situ. Press start again. 2 minute cycle. When stopped. repeat for cycle 3. End of lighter fluid cycle. All items and baskets removed from Jar 1. Placed on Kitchen paper and blow dried. Isopropyl cycle all items and baskets, except shellac items, into Jar 2. Ultrasonic machine containing water. Level above Isopropyl fluid. Ultrasonic Switched on for 2 minute cycle. This is the only setting. When stopped, leave jar 2 in situ. Press start again. 2 minute cycle. When stopped. repeat for cycle 3. End of Isopropyl cycle. All items remove and placed into warm air blower area for 10 minutes. Remove from basket and placed on kitchen paper. Each item check before placing into holding box. Oiling My oiling for posts is as the 'ideal'. I am very careful to observe your diagrams. Saw them early and have used that as my system. My oiling for jewels is as per the green tick. Honest. Escape wheel jewels 9010. All jewel 9010. Posts, rotation areas D5 Contact rubbing areas. DX Every area is always dabbed with Rodico. No Rodico is accidentally left. Final rinse. Your are saying no ultrasonic for Isopropyl. However the balance is not receiving anything of Isopropyl ultrasonic. I still get the problem Thank you. That I do. Hand clean both. Check for shellac problems under the microscope I watch both as I dry them in the little container.

-

I'm presently using a cheap supermarket ultrasonic cleaner, with L&R #111 cleaner and #3 rinse solutions. I cut a bit off the bottom of an appropriate size plastic sports drink bottle, which is a perfect fit around the mesh basket I use (~65mm diameter). That allows me to use mostly water in the machine tub and cleaner or rinse only in the small plastic container. I keep the solutions that are still fit for use in small glass jam jars. I use the cleaner then two rinses, then the mesh basket balances on my bathroom radiator (once it stops dripping) to dry the parts with moderate warmth. Prior to that I tried just lighter fluid (eg. generic zippo fluid) and just soaking / swirling parts in the glass jars, but the movements did not run at all well afterwards, they were still acting gummed up. The proper solutions make a world of difference & the watches now work as they should!

-

You risk loosing shellac in ultrasonic regardless of chemistry of cleaning solution. Shellac doesn't get a chance to dissolve with a quick dip into lighter fluid , dip a tooth pic ( sharp end) in lighter fluid to peg pallet face with, ( rotate the toothpick ) repeat pegging 5 to 10 times, stick fork pivots into the tooth pic, rotate the toothpic, rinse for few seconds, put the fork in a bottle with lid to retard lighter fluid evaporation cuz air moisture condences to water if evaporation is quick. Close inspection of the clean under high magnification is a good pracrice. Balance complete shouldn't go in ultrasonic, ought to get cleand by hand. rgds

-

Have you removed the hole-jewel-chaton assembly ? you can push it out and give it more bath in ultrasonic, can't think of better way to remove crud out of chaton. Soaking chaton assembly in lighter fluid four a day wont hurt it, not even in ultrasonic. Do you peg holes of the jewels. To peg the pivots, stick pivots in a wooden toothpic, turn the tooth pic, dip the tooth pic in lighter fluid, and stick pivots in wetted tooth pic & turn . With a mild puff of air by puffer, oscilator should oscilate freely at least for thirty seconds, ideally up to sixty seconds. Looks like you can't overclean these chaton-jewel assembly, no worry clean in ultrasonic as much as you like. No expert so far as temperature, have seen folks trying forty to sixty celcius degrees. Good luck Pal.

-

Rone 1057 movement service

Nucejoe replied to rog63's topic in Your Current Projects and Achievements

How could you have damaged the hairspring if balance complete was detached from the cock? Balance detached first, little screws next. Are we learning the proper / safe aproach to tasks , or looking for cheap watches to break. Whenever you suspect such lubrication issue, drop a bit of lighter fluid on capstone, it finds its way to the hole jewel , next a puff of air to get the balance turn, then balance usually thanks you and oscilates. -

Sorry. I learned this early on and have always applied it. I still do that test before a build starts. I have always noticed that the oscillation, no matter which watch I am working on, is low. 10 to 15 seconds, not much oscillation. Usually less than 150 degrees. This is why I began this question. Do you think it may be the fact that I have left the balance on the plate and left it too long in the Lighter fluid whilst under Ultrasonic? 3 x 2 minutes. Before I obtained the ultrasonic I used place all items into the lighter fluid jar and spend 10 minutes rotating it gently back and forth by hand. However the above observation was still carried out. Result was the same as I have always noticed that my Amplitude was low. After oiling, I do notice and improvement, but never to the level of what others or I would find acceptable. Maybe 180 degrees. I though as I get more experienced I will make it better. I can now do all other aspects of a service, not with ease, but application. I have few more 'balance' options to try. Gently immersion in cleaning fluid. No balance Ultrasonic. Gentle immersion in Isopropyl for under 30 seconds and dry as normal. Result? Cry. Don't cry.

-

Lighter , isopropinol and most other petrochemical product are no longer shelac friendly in ultrasonic. I bet you a whole dime , you have been loosing shelac in ultrasonic, rendering pallets loose to misalign or move, which has been causing amplitude loss. Check you pallets to find little or no shelac on them, impulse pins were shelaced back in the days, so check the shelac on them as well. Hairspring is flex so it easily vibrates in response to mild waves of ultrasonic thus wont get damaged. Check all shelaced points Ross. Clean and peg pallets and impulse pins by hand, use lighter fluid but keep shelac away from lighter fluid as best as you can. Good luck pal.

-

Tbh ross the cost of the cleaning fluid is probably close to the cost of your lighter fluid. If i remember lighter fluid works out around £12 / litre when bought in numerous small tins, the cleaner is maybe a little more expensive. The rinse I'm not sure about, i like isopropyl, i think i paid £18 for 5 litres. For balance and pallet i went with the b dip equivalent which has been suggested is tetrachloroethylene or perc drycleaning fluid.

-

Update. And I know it is nice to read about an update and not wonder at the outcome. Before I commence to tell. I would like to send special thanks to members, both in the post and those who contacted me via private messages. Many sensed that I was becoming stressed and being concerned for me, contacted with help and messages of well intention. As you may have realised, I was very close. Despondent. I took the advice of many and set myself down and read the messages a number of times. Do you know how good you are? Friendship is not a big enough word. Where am I now? Back is where. Thank you. And possible end of my woes. I put into practice what many said. Look at what you do. As you have all said, in some form. I needed to look at all aspects of my system of installation. Well, this I have done. I looked at:- Disassembly. Did I pull, twist , damage any item in removal, especially the balance and pallet. I checked a number of watches that I had serviced and it looked ok. Checked all items on the microscope. Showed how careful I was. No damage seen. Cleaning. As before. Pegwood. All items in lighter fluid (Naptha) then Ultrasonic. Pallet fork and balance cleaning in fluid but not Ultrasonic. All items in Isopropyl and Ultrasonic. Pallet fork and balance cleaning dipped in fluid and then blow dried (no ultrasonic for these). Everything checked again with microscope. No damage to pallet or balance. I now needed to reassemble, so plenty of more practice now. Each item installed, following many members videos. Took my time. always check train of wheels ease of free movement. Barrel and spring always cleaned and lubricated. End shake checked. Dial side, motion works and keyless works always check and lubricated. Pallet installed. Exit stone oiled and rotated. Jewels removed and installed, correct way up folks. Oiled as per directions. And now. The balance. And the problem amplitude. After a number of tests it would appear the culprit it is me. I am careful with screw installation of all parts. I never overtighten. I close down, check item and then tighten gently. Using Alex Hamilton's guidance of down, check and then tighten only the width of the screw head gap, if that. Never had a problem. It would appear that as the balance is always on a heavy bridge I always secured it tight. I inadvertently closed the end shake, increasing resistance and decreasing the Amplitude. This is the only screw on which I ever put a 'full' pressure turn. It would appear that little amount of extra pressure always gave enough to close down the end shake. Less is more it would seem. I have tested this with a few watches now. Removed the balance. Cleaned, jewels also, and replaced. Installed to the bind, but this time watching the groove, tighten to possibly half the distance. Amplitude is increasing to a tolerable rate. Certainly in the 200 degree area, an increase of 30% all round. Whilst it is not the bee all and end all to my problems, at least it has given me a way forward. Have I overcome my problem? Could it have been so simple? In reality, I don't think so, still some way to go. But sitting back, going over system and totally applying what members say is the way. The outcome? Watchmaking, ongoing. I feel able to begin to partake in discussions again. So, thank you. Ross

-

Cleaning procedure Since I began I have learned how important it is to clean the watch parts. I can't afford a cleaning machine. I have made my own variation. My system on disassembly. Pegwood and fibre brush if needed. Large items into base of lighter fluid holder (No. 1 jar). Place all items into baskets then add them into the lighter fluid jar. Ultrasonic for 6 minutes. Remove shellac items and dip into Isopropyl alcohol for 30 seconds and blow dry. Place all other items into isopropyl alcohol fluid jar (No. 2 jar) Ultrasonic for 6 minutes Remove all baskets and items and blow dry in warm air from nail drier for up to 10 minutes Place all item back into parts holder and check items individually. Reassemble

-

Ah, yes, I was intending to buy replacement and keep it away from dirty old clocks but I thought I would try and rescue it. then a minor confusion on my part are we discussing clock cleaning or watch cleaning here? Watches, I just was saying it worked well for clocks, and I have no issue with my clock cleaning methods. that said, I have worked on many clocks that have a Swiss lever style escapement. I'd like to buy a used old cleaning machine like an L&R with the heater, I feel like at least then I would be using an actual cleaning machine and I wouldn't have to mess around with jars in and out of the ultrasonic. Although since trying and failing to post this reply last week, I have purchased improved cleaning baskets and a wire mesh insert. I will be using fresh cleaner in the ultrasonic and two rinses in the zenith rinse. I have also purchased 99% IPA as a third rinse and I finally found a local supplier for onedip hairspring cleaner, so I can stop with the naphtha. use the two different solutions I have in the ultrasonic. I fill the machine with water and heat the water up to like 30-50 and then i put the jars in the machine and clean for 10 minutes usually. This was working okish with when the chemical was new. Oh also I peg the jewels and pith etc. I had tried to find onedip to clean the more delicate parts but I couldn't find anyone selling it anymore. So that is why I went to the lighter fluid. I read that apparently that leaves an oily residue so I guess I should switch to something else. I also only use the one rinse so I suppose I should get an extra jar and switch it all to something else. The issue is that this is very time consuming as I cannot put the parts in all at the same time so adding a step adds like 5 seperate cleanings. Oh for gods sake of course now my reply from last week suddenly works having written out the whole thing again. whatever.