Search the Community

Showing results for 'accutron' in topics.

-

I finally feel like I have the confidence, tools, and fine motor control to tackle these tuning fork movements. I've got my 700 test meter here (in beautiful shape with the original box, I might add!) and it seems to work as it's supposed to, at least with one of those 1.35v diode batteries in it. I'm planning to phase the watches for silver oxide cell voltage at 1.65v, so what I'd like to do is use my low voltage power supply to supply the test meter, and so I don't have to keep buying cells. I feel like I saw a thread where someone made a dummy 343/344 cell with power leads on it. Anyone have pictures or a link to that?

-

Accutron 700 meter

ArtK replied to ManSkirtBrew's topic in Watch Timing & Testing Equipment / Timegraphers

Hello all. I am new to this group. I own two Accutron 700 test meters and one spare d’arsonval movement in its housing. Does anyone know someone experienced in evaluating the caps, etc., and tuning up or restoring these devices for a fee? I am most interested in. I am in New York State. Thank you -

Hello all, Please let me introduce myself. My name is Karl, mid 50's professional in the New England area that has taken his first official steps I the watch repair world. However, not my first exposure. My father was an engineer for close to 50yrs in the defense system, power generation and various other manufacturing entities. He was one of those people that could fix anything. His passion however was clock and watch repair. I, being very much like my father. Always watched and learned. Be it auto repair, home repair, eectrical work and of course watch and clock repair. He used to say to me that I should have been an engineer, but I like to talk too much. It goes without saying that he taught me all I know. Well, he passed a few years ago, and I never thought I would end up being involved in watch repair, despite my interest. Always busy with work, family and other interests. After he passed, I helped my mother with an auction company in NH catalog all his horology treasures, not thinking I would ever do it. He had hundreds of clocks, watches, parts, tools, machinery, ect... He had 4 work benches each with a different purpose. Now, I'm obsessed with it, and I'm sure he is somewhere having a good laugh. I've had the pleasure of meeting one watchmaker in particular in the lakes region of NH that restored my father's 1964 Heuer Carrera that I found in a drawer as a disheveled mess. It was thru conversation with him and suggestion of downloading the Bulova watch repair course. Now, I haven't completed it yet, but I an a tinkerer at heart. I've restored a couple Oris and a number of vintage Tissot for mainly myself, but one of my son's and am currently working on a 1969 Tissot Visodate PR 516 for my wife. I do favor tge seiss watches. But do now have a 1970 Seiko Sea Lion nd a early 70s Accutron that I will attempt. I do have quite a collection of close to 50 watches including Omega, Tissot, Oris, Hamilton, Elgin, Seiko, Sinn, Swiss Westclox, Matthey-Doret with a Junghans electromechanical movement and a few pocket watches of mixed time periods. Sorry so long, butbi do like to talk. I look forward to being a part of this forum, as I've found it invaluable in my education and help in some unknown waters. Take care Karl

-

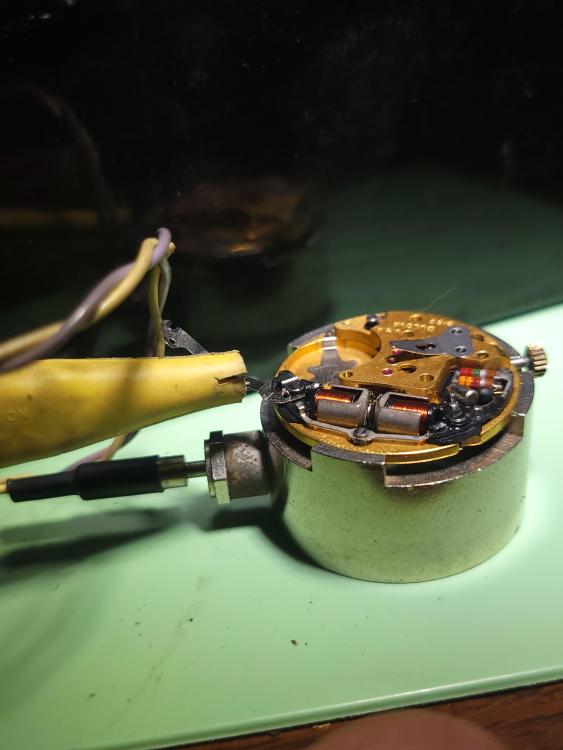

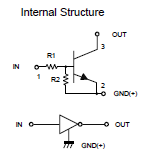

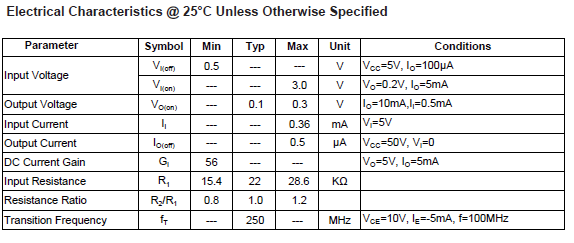

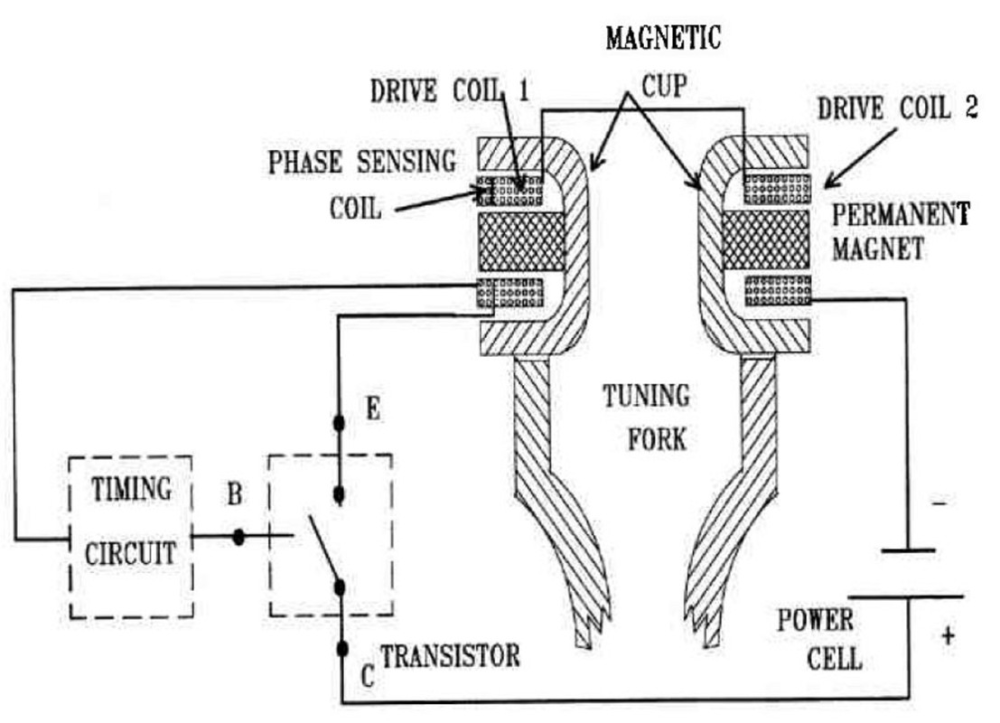

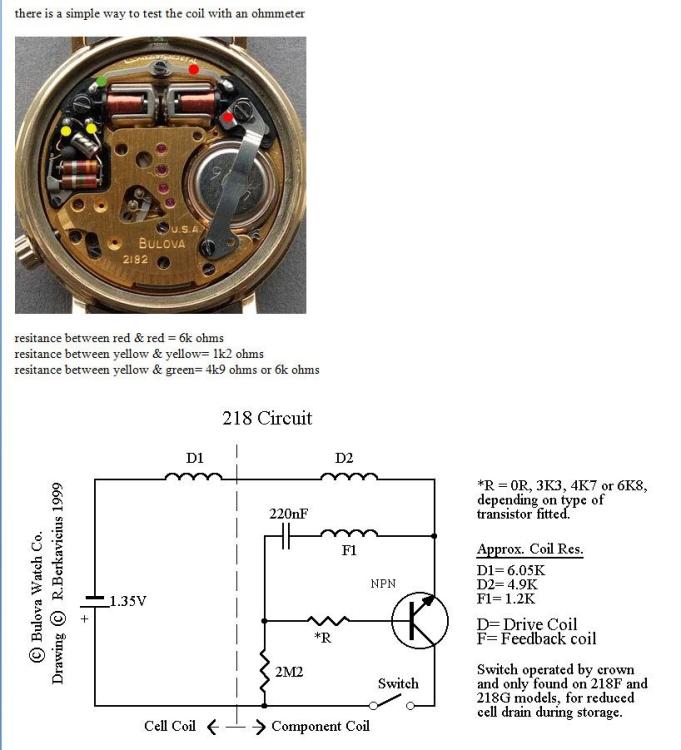

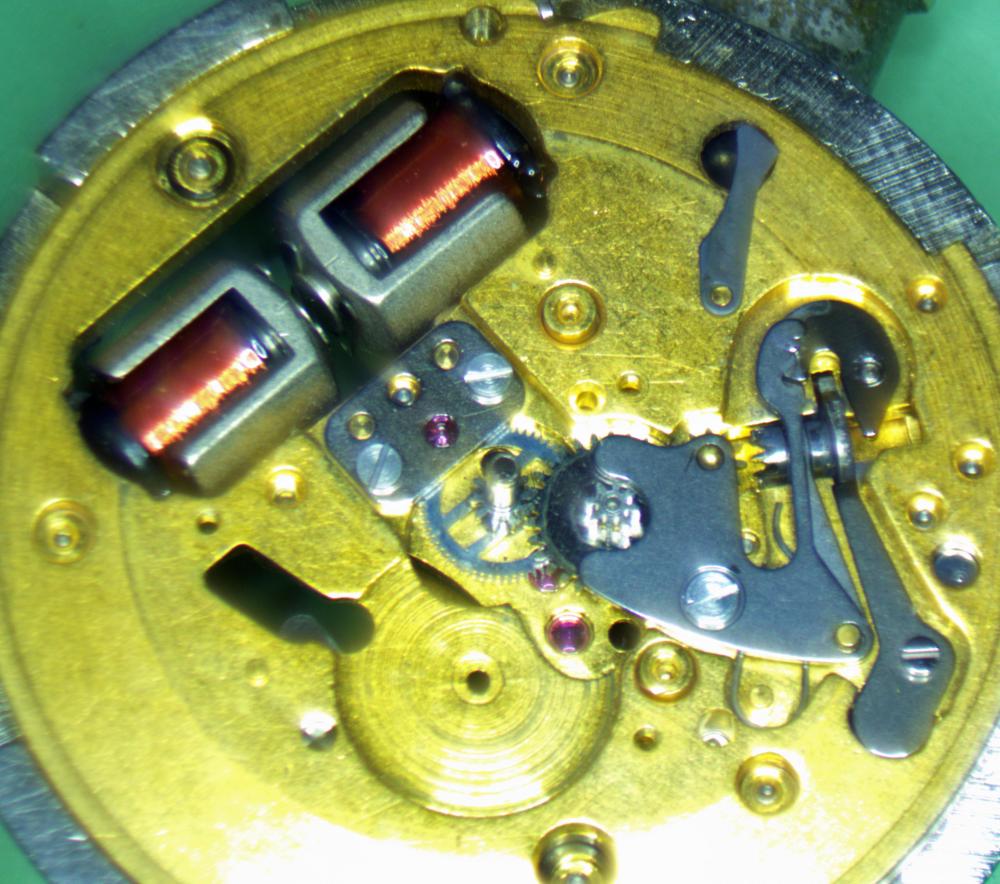

Having had success replacing the resistor and capacitor in a few 218 and 219 circuits, I've gone down the rabbit hole trying to find a modern replacement transistor. I've searched everywhere I know to look for specs on the original transistors and come up empty. My last digital design class was too many decades ago, so I was hoping one of y'all out there is a EEE (Electronics Engineer or Expert) and can offer some advice. For example, let's say I'm considering an NPN digital transistor. When I look up the part, it's available with a built in 47k, 22k, or 10k ohm input resistance. How does one decide? I assume that's what the starred *R resistor in the schematic below is for. And then how do we make the decision between a digital and bipolar transistor?

-

Which Watch Have You Got Coming In The Mail ? Show Us !!!

LittleWatchShop replied to SCOTTY's topic in Your Watch Collection

Last year or so, somebody found me and asked for help. May have been on this forum. They had an "accutron" that had been "modified." He wanted it returned to its former glory. Well, it was an accutron case, accutron dial, with an automatic wind movement inside!! Yes, it is true. The dial feet had been removed and glued on to the autowind movement with those dial dots. Anyway, I rebuilt it for him. So, you never know what is inside!! -

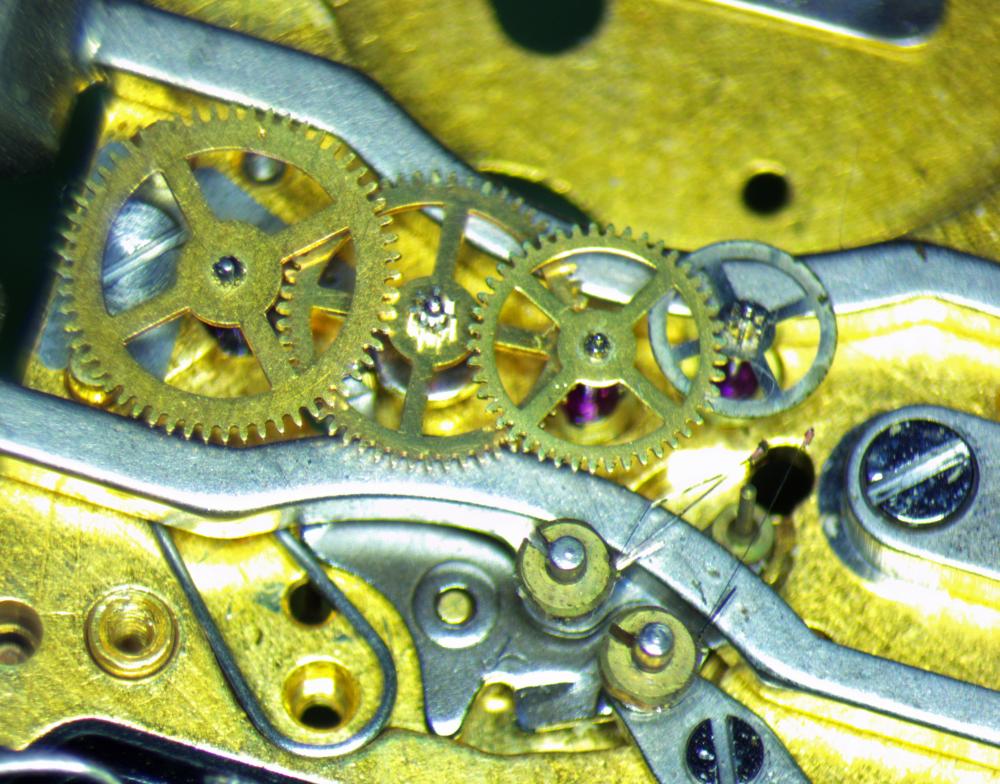

A nice watch with a long name . Automatic , 19 jewels , day / date with the day in Kanji at 6 o'clock , 38mm w/out crown , the standard Orient date change push button , and a scuba dude emblem on the caseback . A friend and acquaintance from the Seiko Citizen Watch Forum and regular seller of hard to get Seikos and Citizens on Ebay , that goes by the username of Seikocitizencollector , emailed me and asked If i could look at his NOS CitizenHi-Sonic for a few repairs . On a normal mechanical watch the repairs are minor , but the Hi-Sonic has the same movement as the Bulova Accutron tuning fork 218 model . The stem would not stay in the watch so he took it to a watchmaker for the repair and when he got it back the stem was still out and now the watch would still hum but not run . He sent the watch to me and I discovered that the setting lever screw was broken . To replace the screw you have to remove the train wheel bridge ,which on a regular mechanical watch isn't a big deal , but on an Accutron you start sweating bullets because you have to deal with the tiny index and pawl jewel fingers , and the VERY delicate 320 tooth index wheel . To make a long story short I asked for a watch in payment . He was awaiting a lot from Japan and he gave me several good choices , and I chose the Orient . When I got it I found the tightest case back in the history of the world . It was tight , had dirt and was rusted to the case . It took me a couple of weeks to finally loosen it . I found a very clean movement inside . It came with an expansion watch band which I changed out with one I had in my stash as well as install a new crystal ........... The Gentleman was also kind enough to include a bonus watch . A Seiko 5 , with a 5126 - 7040 movement and case . The 5126 movement is a little more complicated then the standard Seiko movements in it's autowind mechanism . Gears instead of the normal "Magic Fingers "

-

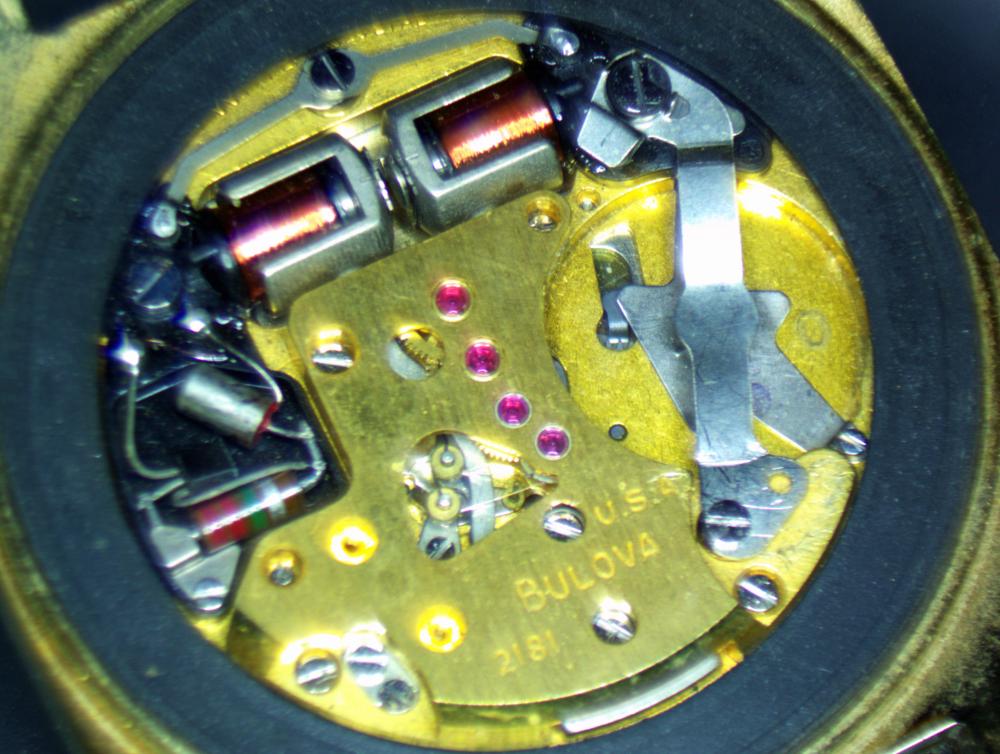

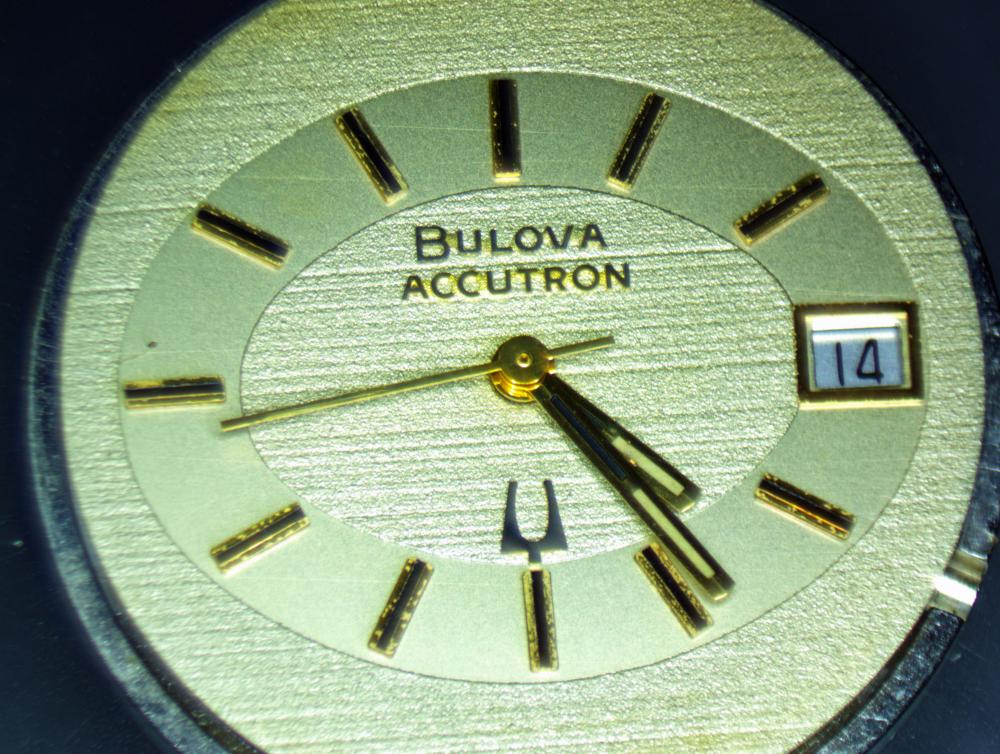

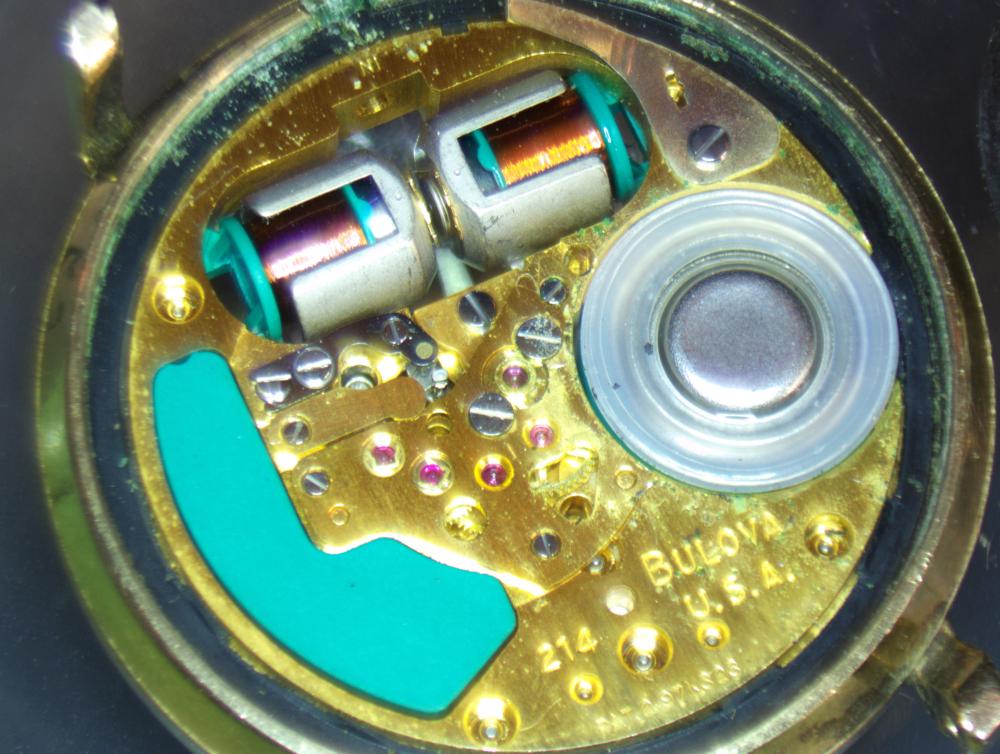

My grandfather died back in 2004, and my mom gave me his Accutron. I've wanted to restore it for years, and finally have the experience and confidence to do so. Of course the first thing I did was slip and bend the pawl finger, but at least it's not my first rodeo and I was able to fix that. Not running with an Accu-Cell, but the index wheel is pretty grungy so I took it apart and powered the circuit without the train installed. The fork kicks up, but instead of a hum I get a pulsing vibration. Never seen that before. I checked the electronics, and the resistor reads about 990 ohms instead of the 2,200 ohms we expect. The capacitor reads 197 pF, which is reasonably close to the 220 pF we're looking for. I'm going to give it a thorough cleaning and see if it'll run, but I have a feeling I'm going to be replacing the resistor and capacitor. A much harder task on the 218 than on the 219. Edit to add in some circuit diagrams, in case anyone is here for 218 diagnosis help:

-

I have a 2180 that hums and a 2181 that does not. I'm about to start these two projects. Besides lots of photos any advice?

-

Background: Somebody sent me an "Accutron" that was a gift many years ago. Somewhere along the way, the Accutron died and somebody replaced it with an NH35. It, of course was too thick, so they removed the auto wind oscillating weight. Ouch!!! Since the dial feet did not match, they cut them off the Accutron dial and used sticky tabs to attach the dial to the NH35. What a frigging abomination!!!! Anyway, this "somebody" sent me two accutron movements in hopes that I could return the watch to its former glory. OMG, these were hacked up as well. But!!! I was able to make one functioning movement. Cleaned, oiled, and soon to be adjusted. The BIG issue now is the dial. I am pretty sure I cannot solder feet on the dial. I did give it a try. No bueno. Here is my idea. Drill holes through the dial where the dial feet belong. Then insert and glue posts (feet). I checked the visibility of the dial through the crystal and the drill holes would not be visible. Thoughts??

-

Just got this guy from the eBay. Purchased as "for repair." First thing I notice is the contact spring in the battery hatch is missing. My dad recently asked me to repair his non-running Spaceview and it turned out that was the entire problem with his, so I put the world's tiniest ball of tin foil in there and what do you know. Looks like a good service is all it needs! One more quick note: according to the list from myBulova, this is a factory Spaceview. Nice!

-

OK, I have recently services four Accutron 218s and disassembled another (my first) which is now a parts watch...lol. Feeling really good about my results and my methodology. Accutron recommends OL-207 for all but jewel settings. OK, if these watches I have serviced were lubricated in this way...I am not a fan! It appears to dry and then flakes everywhere. When confined (e.g., center wheel) it seems to gum up and freeze. I determined not to use it--NO. I am using Molykote for those lube points instead. Shields up--prepared for incoming!

-

Which Watch Have You Got Coming In The Mail ? Show Us !!!

ManSkirtBrew replied to SCOTTY's topic in Your Watch Collection

True, I just meant what kind of shape it'd be in. Looks pretty nice. I was wondering if maybe the caseback was taken from a different watch, but it is a 1966 Accutron caseback. Interesting! Edit to note of course digging a little further, I see 218s being manufactured as early as 1965. -

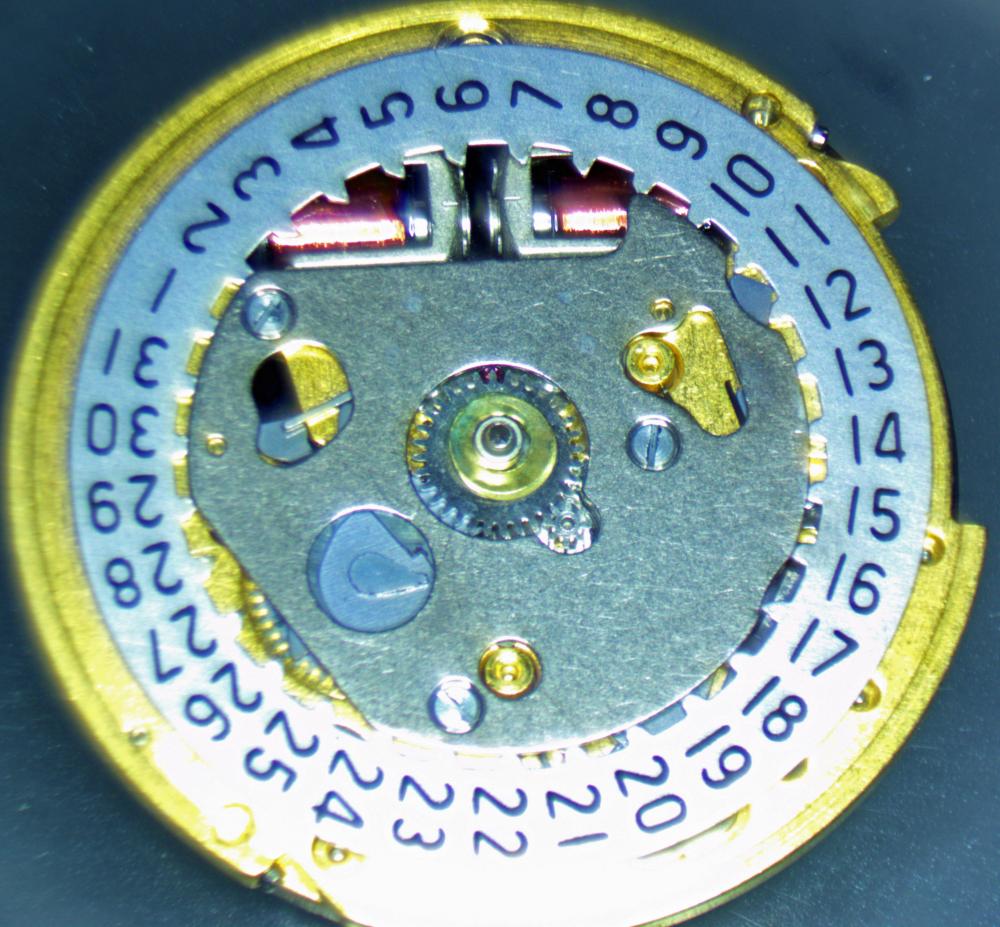

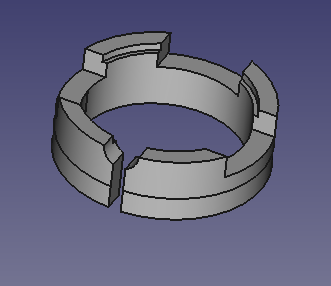

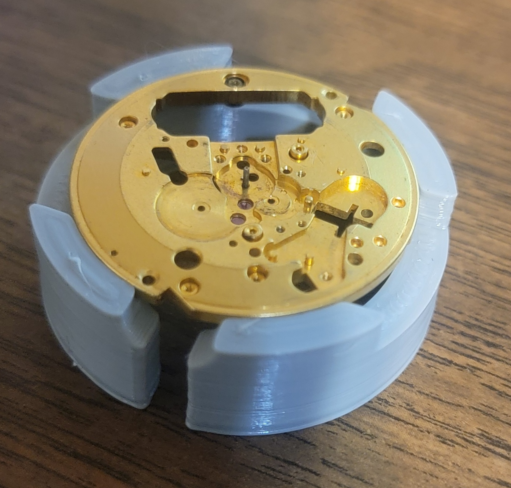

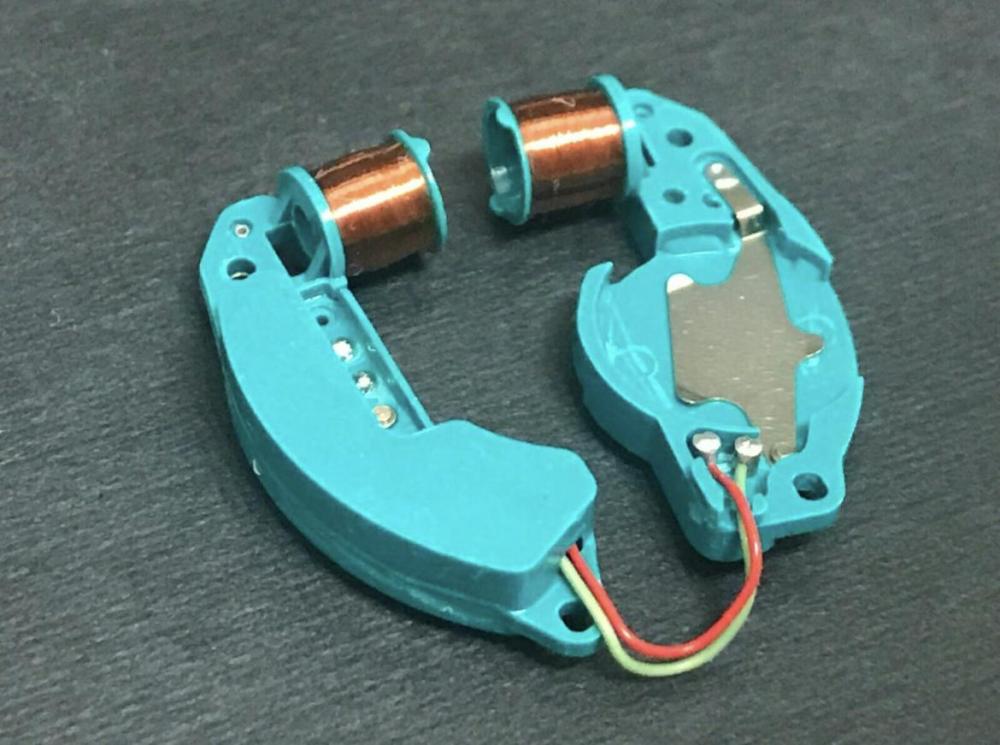

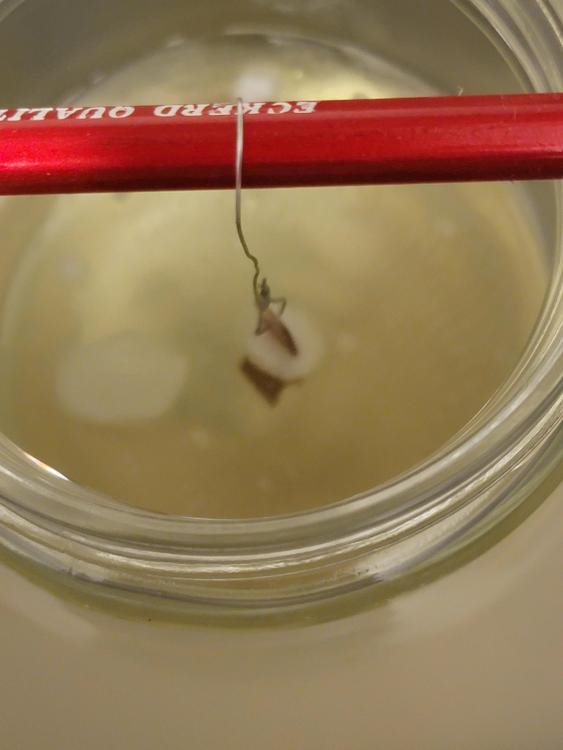

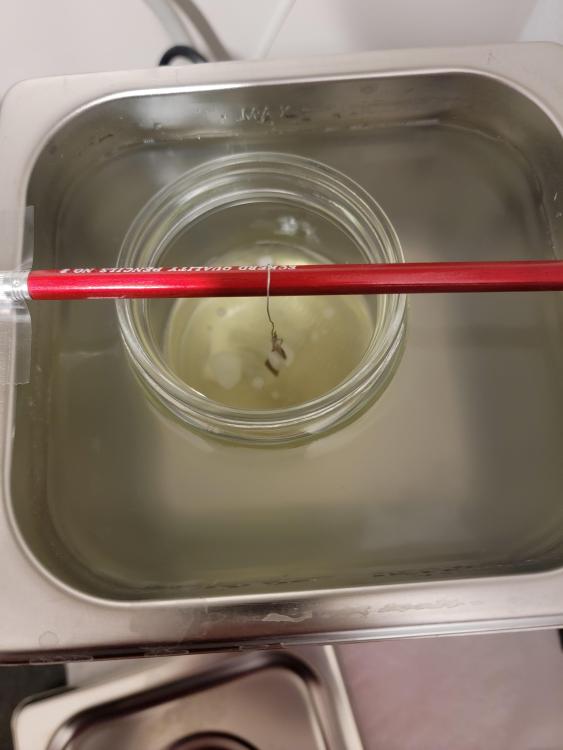

I have spoke about my remote Accutron repair center (my house in Bryan, TX). Here I will outline the cleaning methodology I will use. 1) the index wheel will be installed into the official Accutron holder (seen in the first picture). 2) the index wheel and holder will be placed in the bottom of an L&R basket and then covered (second and third pictures) 3) the two plates will be placed on top of the separator lid (not shown) 4) the compartmental holder will be where all of the wheels are placed, yoke, etc are placed (no parts shown in the pictures), and the top lid placed 5) the electronics, tuning fork, the pawl are separated out and placed into a petri dish. Using a syringe with needle, I will bath these parts with one-dip. 6) the basket will be immersed into a jar with L&R cleaner (what I show is ammoniated, but I am going to use non-ammoniated going forward (when it arrives). 7) the jar is placed into an ultrasonic machine for a short period (maybe 5 minutes) remove the basket and spin dry using an L&R spinning machine (not shown) 9) place the basket into a jar of L&R rinsing solution (not shown) and run in the ultrasonic for a short period 10) remove the basket and spin dry as before 11) place the basket into a second jar of rinsing solution and run in the ultrasonic for a short period 12) remove the basket and spin dry as before 13) the final step is to move the basket to the drying station of the L&R cleaning machine I would appreciate thoughts on this.

-

HI. Does anyone know how to remove the coil coating on an accutron? I tried leaving it in pure acertone for a whole day: the coating softens but does not melt. Thank you

-

After servicing about six with minimal issues, I have run across a couple that stump me. I think I mentioned one before that seemed electrically sound but did not hum. I have another. All components check to the extent that I have measured them (cannot measure transistor Beta). When measured on the test set, I get a little over 25uA. This is about right if the unit is not oscillating. 1.5V and a 2.2M bias resistor with a beta of 50 would get in the ball park of 20uA. A little more beta and you are north of 25uA. This further confirms that the circuitry is functioning. The cap measures about right. I do not believe its value is too critical anyway. It mostly serves as dc blocking and not establishing resonance. I tried another tuning fork and...no luck. I am going to drive this one to the end so that I can understand root cause.

-

Before I lose my mind, I could use some help with another o-ring issue. According to the case #, I have the correct o-ring (Bulova G852 for case #3423), which sits in a groove in the case. The crystal is supposed to press fit into it. The problem I'm having is the crystal drags the o-ring out of the groove when I press it in, no matter what I do. I have generously lubricated the o-ring. It does seem like the o-ring is a slightly loose fit in the groove, so maybe I need to go a size up from the factory one?

-

For the time when these were introduced, the technology was truly leading edge. The 218 movement seems solid...not difficult to service. But...and this is a BIG but, Accutron (really Bulova) fails at the non-tech stuff. While I like the two-piece back, the case quality is generally poor. The dials seem fine enough, but the hands are low quality compared to a nice swiss watch. I have one case where the crown interface appears to have been milled incorrectly. Not sure...still investigating.

-

- 3

-

-

-

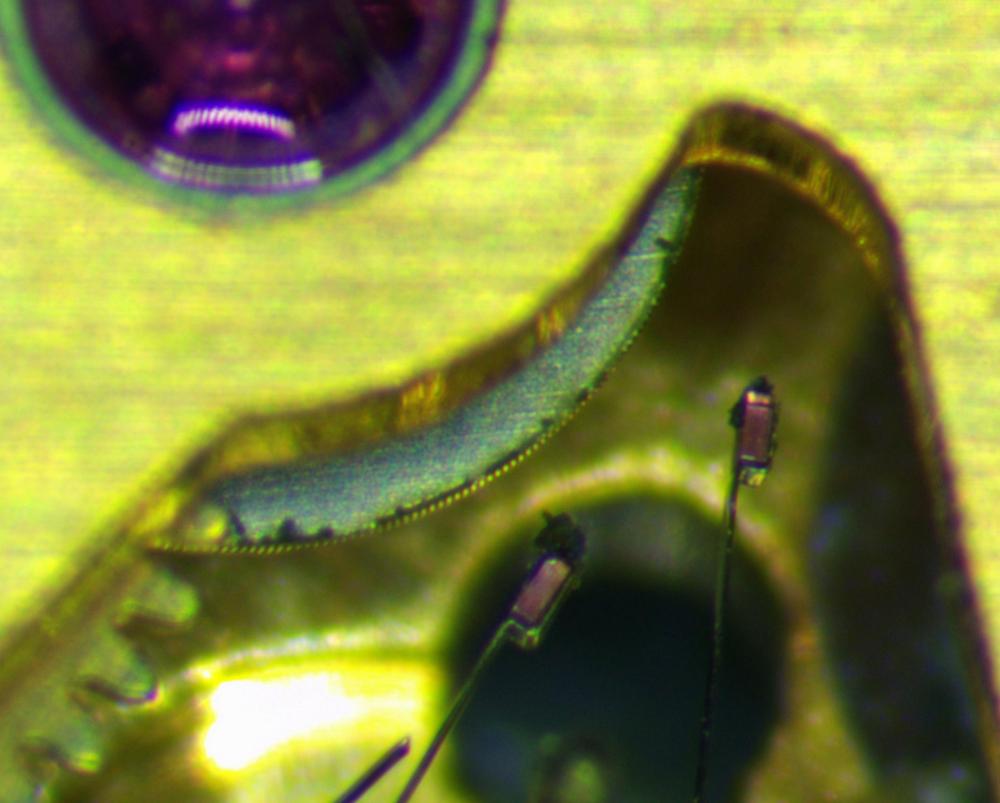

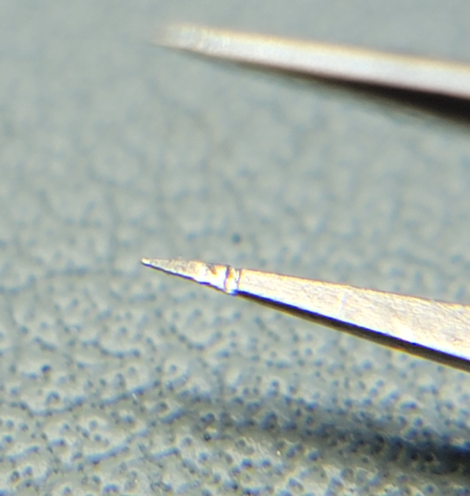

When I clean the index wheel I put it in the Accutron index wheel holder. What have found is that while holding the arbor, the wheel flops around because the tweezer will not hold it in a fixed orientation. Well, I fixed that!!! I modified a set of 3C tweezers by adding a notch so that the index wheel arbor is held orthogonal to the length of the tweezer and will not wobble. The notch is on both legs of the tweezer but only one is shown.

-

- 3

-

-

OK, I am on my fifth or sixth 218 service with great success. Once you establish a methodology, these are relatively easy. I am servicing a 218 D now and it will not hum I have verified the following -drive coils -phasing coil -resistors -capacitor -EB junction, CB junction (have not verified beta) Kind of at a loss. All connections seem to be fine. Wondering if the watch was accidentally demagnetized??? Using a compass, I verified that the tuning fork does have some magnetic attraction. Scratching my head.

-

This 218 Accutron center wheel (which functions like a cannon pinion) is loose resulting losing time due to slipping. Not sure if there is a way to tighten it. Funny thing, I had a donor so I stole the center wheel only to find that it was shorter! Yes, the donor had no date, but the fixing watch is day-date.