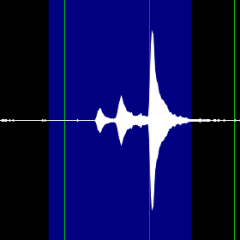

The Worst Timegrapher Reading?

-

Similar Content

-

Recently Browsing

- No registered users viewing this page.

-

Topics

-

Posts

-

By RichardHarris123 · Posted

Better eyes than me, where does it say "push "? -

To be honest I had not read the fine print. But I went back and read the fine print and let me snipped out an image. So it appears to be I should have read the fine print. But there's also my confusing email I sent the image of the watch the somebody who I figured would know any did. So this is the answer I got back Now we have a problem or I have a problem of not paying attention to users names in the discussion group. You'll notice in my quoted email to persons name is Jeff who happens to be the exact same Jeff in the discussion. So it's not my fault if the exact same Jeff gives us two separate answers for the exact same watch. So apparently one of the Pierce chronographs has rubber and the other one does not.

-

Here you are a video by our good friend J D Richard. https://www.youtube.com/watch?v=LMxoZjRaH50

-

By nevenbekriev · Posted

You have to push where it says 'push' with something that can enter the hole I guess -

By nevenbekriev · Posted

Nothing is lost at this stage. But You first have to take out the clutch part from the pinion. Then next is to fix the wheel table to the pinion. If it can not be riveted, then must be soldered. Then trueing, and clutch part reattaching. It is possible to make a bush that will stay press fitted between the table and the clutch and will hold tight the table in place instead soldering.

-

Recommended Posts