Search the Community

Showing results for tags 'watch repair'.

-

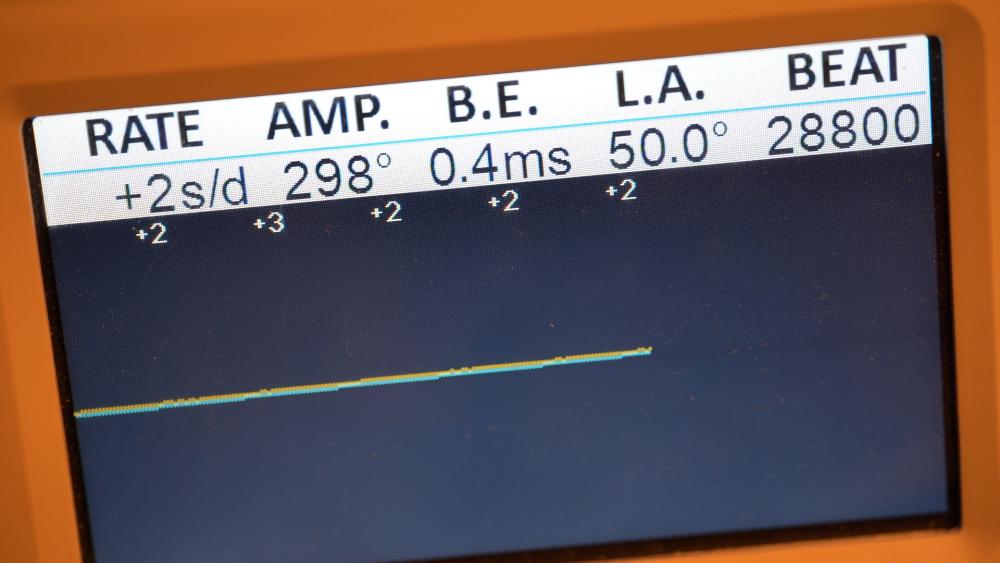

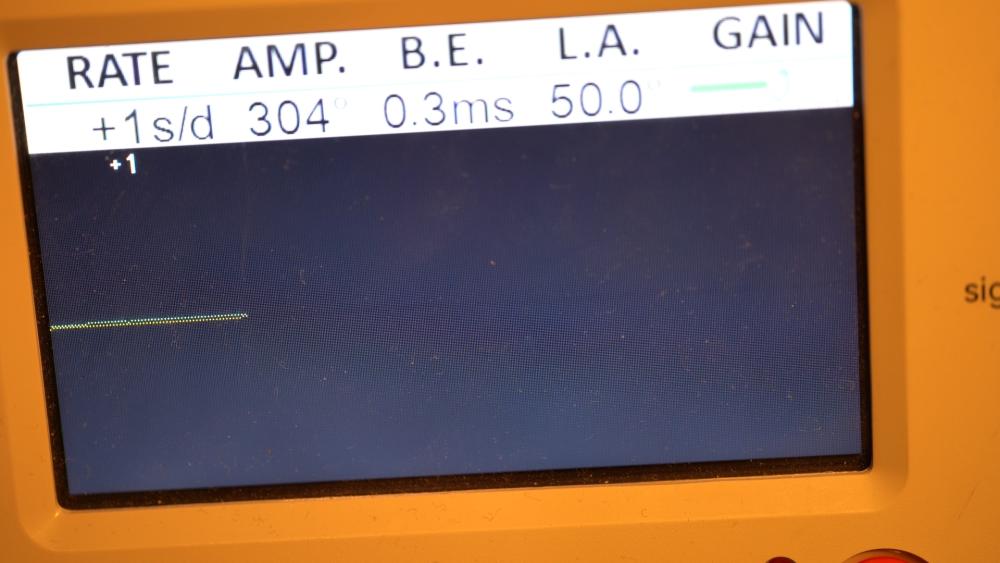

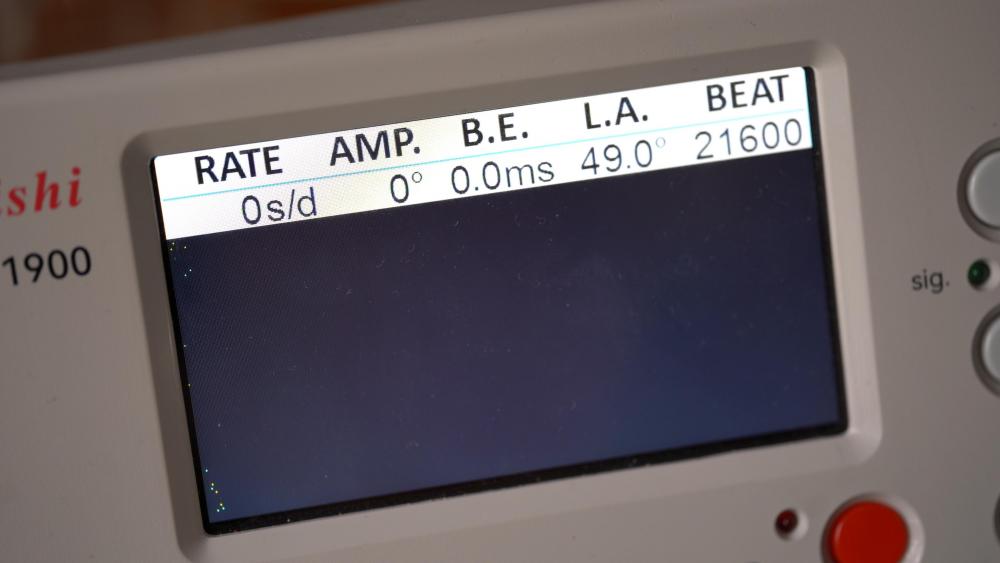

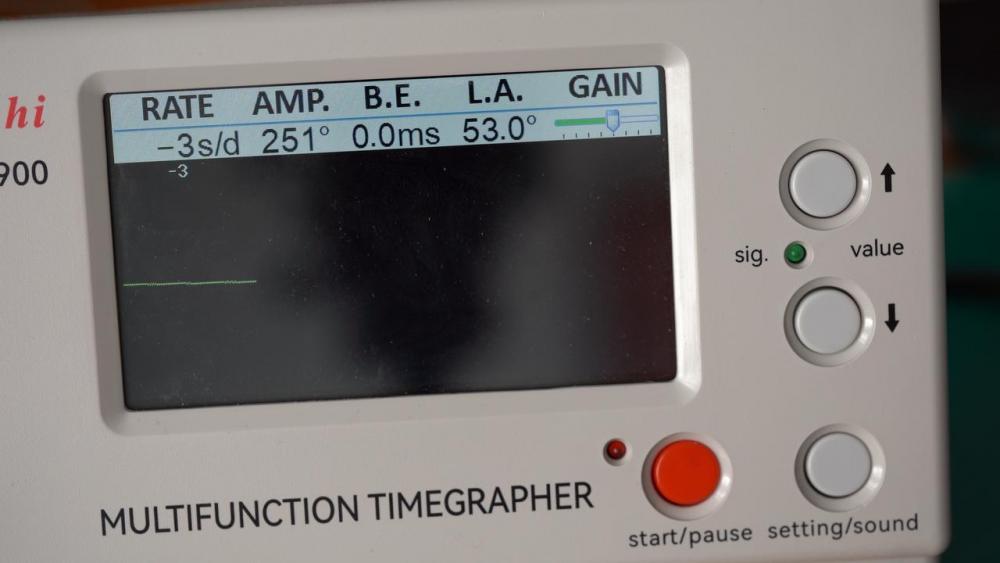

Hello Watchbangers! Welcome back to my usual watch repair report! It feels like an eternity since I’ve also had a bunch of other side projects and the upload schedule has changed but its good being able to present another solid watch! Now todays watch was, as always, bought over the local German eBay. It caught my eye because it was a swatch watch, but not any crappy swatch! It was a swatch with a mechanical movement! Till then I always thought that swatch only produced those small junky mechanical watches but low and behold! A swatch with a solid movement! And for the solid price of 50 Euros, with included box, papers (definitely super important ) and shipping I just had to snag it. Now before we jump into the whole process, here is a link to the full 4k commented video version on YouTube for the lazy readers out there: Now let’s go! After receiving the watch, this was the starting state of the watch: As you can see the outer appearance was still very good! The acrylic case has some scratches that would be easy to polish out and through the back, a clean looking movement was to be seen. The only thing which stood out was that the watch did not run after being wound. The seconds hand ticked a bit but stopped after a quarter of a minute. I was not sure what the issue was there, but I assumed that a good old service would do the trick! Disassembly: We start by prying off the see through case back. We unlock the watch spacer ring and movement in a counterclockwise direction from the case and lift them both out. We remove the hands. As you can see their condition is pretty good and the lume is pristine! After that we can just lift the minimalistic “chapter” dial from the watch face as well! Now we can carefully unlick the movement spacer ring and separate the two. Careful not to use too much force and snap the poor piece of plastic in half. After we have achieved in isolating the movement, we can strap it into our trusty holder. Unscrew the nicely blued rotor screw and lift of the smoothly signed rotor. I must say that the font reminds me of Comic Sans haha. Then unscrew the two screws for the automatic module. Flip it over to disassemble the whole automatic gear train. Once that is done, we can come back to the pretty movement body. A closer look reveals the stamped ETA 2842 marking. The numbers next to the caliber are probably the quality grade I assume. Unscrew the balance bridge and lift out the whole balance wheel carefully. I was super surprised at how tight the balance wheel and spring was sticking the bridge when lifting out. Usually, the wheel just droops into infinity xD The movement was already empty on mechanical power so I took out the pallet fork system here. Don’t forget the unwind the watch when doing this! Moving on we can take out the winding wheel above the mainspring and the click spring for the winding. You can see that these is a good amount of lubrication residue under the click wheel! Probably some Molycote DX I would say. Then we can unscrew the barrel bridge and take that away. Disassembling the train wheel bridge, we can see the whole power transmission journey laid out in front of us. I take out the whole gear train including the complete mainspring barrel to finish taking apart the whole back side of the movement. We can now flip the movement around. On the front side we can take of the minute wheel and hour wheel which is the canon pinion and the transmission wheel to the setting system. Now we can take away the small transmission wheel which engages and disengages when the setting system is used. Moving on to unscrewing and removing the smooth golden system cover. I was super careful here not to slip and scratch the cover since everything would be seen when looking down at the dial-less watch. Lastly, we can just simply take away the three parts of the setting system. Oh and the two part-clutch fell out while turning the movement so keep an eye on those too! With this last step, the disassembly of this Swatch ETA 2842 has been completed. Cleaning Process So this cleaning process has also been done the manual way. However! I did buy a cleaning machine now which I’m setting up and testing slowly. It should be in use in a few more weeks and then I can introduce it to you all! And clean my watches with it of course. Now the usual way of cleaning the watch parts is using lighter fluid and isopropanol alcohol for the rinse. And that’s exactly what I did! Now usually I also obviously service the mainspring and lubricate the balance jewels but this time I used the practical development of globalization and bought myself replacements for the complete barrel and balance of AliExpress to save some time and build into the Watch. Lubrication Here is a list of the used lubrication for the watch and their used areas. Moebius 9010 – Oil for jewel bearings with high rotation parts Moebius HP 1300 – Oil for slower moving parts and bearing. Molycote DX – Grease for high friction points on lever, wheels and contact points. Moebius 9415 – Grease for pallet jewels and escapement Crystal Polishing As mentioned at the beginning, the see through plastic case and case back had a number of tiny scratches from the years of use so I just polished them out with a rotary tool and some Polywatch. You can see a video of the method on my channel I think, but here was the result: Reassembly For the reassembly, we can just reverse the disassembly steps which I wrote down. I must however share a super smooth picture of the reassembled aftermarket balance. It just looks so good! Timegrapher Test And after everything was recased again I slapped the watch on to the timegrapher to see how well my work was done. Here are the the results without regulation: Looks like the aftermarket balance and mainspring barrel really do work out nicely! I did however regulate the watch a little to this: Just lowered the rate and beat error a little and bumped the amplitude up a few degrees aswell Final Results: I am very happy with the final results! The service went super smooth and I am glad that i tried out aftermarket parts for the first time. Now we just have to see how long these will actually last. Otherwise it was exciting working on my first swiss calibre! They definetly have a different style of design and function. A sort of different personality of a watch I would say Anyways I hope you all enjoyed going through the walkthrough and hope that this will help anyone looking for some sort of guide! If there are questions or comments, please comment! And critism is also always welcome! Till next time !

- 3 replies

-

- 4

-

-

-

- watch repair

- swatch

-

(and 2 more)

Tagged with:

-

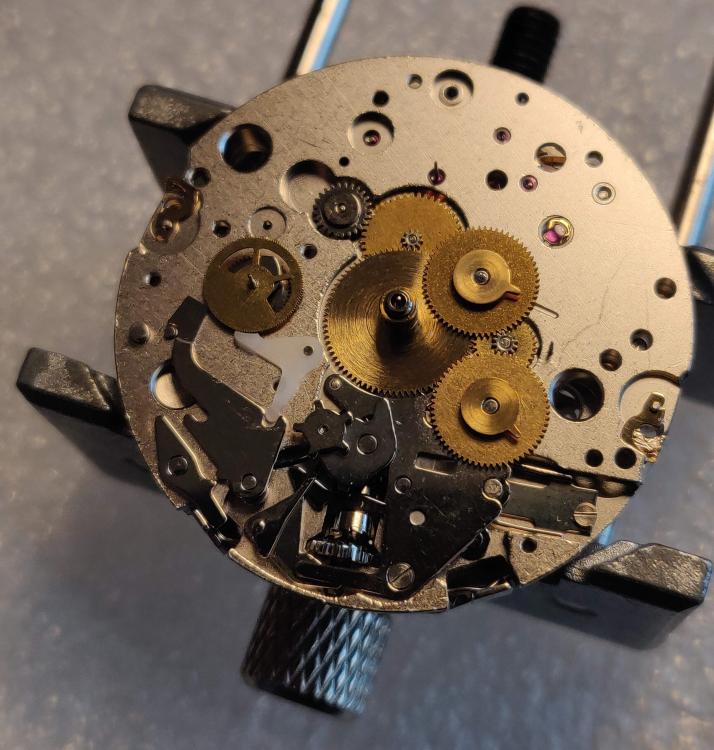

Hello watch bangers! Its been a while because I have decided to change my project schedule a bit but nevertheless, I bring you my most recent watch! This Report will be focusing on my work on an old Citizen watch with a Miyota 8200 movement! Next to the usual service features such as crystal replacement, lubrication and cleaning, I will also be talking a little about dial feet repairs since this watch needed one! Nevertheless, for you lazy people out there, here is the 4k fully commented video on Youtube: Overwise enjoy the read! Arrival status: Here is the watch when it first arrived on my work table Here is a list of what is wrong with this poor old watch: - Missing front crystal and dirty case back crystal - Detached hands - Misaligned dial - Non-Running movement So as you can see this is quite alot of work, but we will be covering all of this and the result definitely are worth it! Disassembly: 1.Removed the detached hands to protect them and screwed open the case back. 2.Removed the case, the dial spacer and the dial ( which had no dial feet attached anymore) and strapped the movement into the holder. 3.Took off the golden day wheel clip and the day wheel. 4.Unscrewed and removed the date cover to reveal all the setting subsystems. 5.Removed the date wheel by releasing tension on its little spring. 6.Took off the date spring and the two quick date and day levers. 7.Off with the canon pinion and the minute and whole wheel. 8.Removed the stem setting system ( Yoke and setting lever) as well as the translation to the canon pinion ( the two translation wheel and their cover). 9.Finally removed the clutch to complete the front side disassembly, well except for the balance jewel! 10.Flip the movement and remove the Rotor. I was really lucky and had a green gilden rotor on this miyota 8200! Loved the look of it! 11.Removed the complete balance. Loved the cool contrast of the round balance shape to the square jewel cap! 12. Undid the pallet fork bridge and lifted both of them away. Pallet fork jewels looked good under x20 magnification. 13. Unscrewed the brutalistically designed main bridge and took it off to be able to dig into the inner gear works. Took off all the gear leading from the escapement to the mainspring and moved on the to the ratchet system. 14.Removed the ratchet system and moved on to the Mainspring barrel and winding wheel which where both removed. 15.Here,I came to the final sub bridge where I removed the sweeping second pinion . 16. Lastly, I removed the final bridge and the underlying wheel which went through the mainplate. With this 99% of the disassembly was done! You can see all the parts (Around 75 I think) assorted in my sorting box! Mainspring As always, I did not have a spare mainspring at hand not did I plan on getting a new one so we once again go to servicing the mainspring! Unwound it out of the barrel and it came out pretty decent, maybe a few small nicks and unevenness but nothing major! After a manual rub down in lighter fluid and alcohol and the following lubrication of its whole length and the barrel insides, carefully wound it back inside to get this result: Cleaning Since I have decided to just keep going with the manual cleaning method, It is the usual process! A good soak in lighter fluid followed by a rinse in isopropanol alcohol. I of course did not include the balance or the pallet fork into this methodology since the alcohol could dissolve the shellac used in the jewel adhesion. I just gave them a good lighter fluid bath! Lubrication All the lubrication I used: Moebius 9010 - Basically All jewel bearing Moebius 8200 - Mainspring lubrication and barrel bottom and under the barrel lid. Moebius 8217 - Mainspring barrel grease Moebius 9415 - A miniscule amount on the palletfork jewel tips Moebius HP 1300 - Slower moving contact points such as: Metal barrel bearing, canon pinion and hour pinion sides Molycote DX - Heavy contact points mainly in the gearless setting system. Reassembly: Just follow the disassembly steps and you should be good! Dont forget to clean and lubricate the balance shock jewels. I haven't really taken any pictures of that process but they will be coming in the following reports! Here is one right after I did the whole process: Dial feet Repair: Now dial feet repair was quite a big issue for me since I always buy used watches and their parts online. And very often I would be super enthusiastic about a lovely looking dial that I snagged just to get it and realize that the dial feet are snapped off. And since I dont like glueing dial and not even mentioning the fact that glueing dials on watches withd ay/date complication being basically impossible anyways, I had to find another way. After some research, I decided to go into the field of resoldering the dial feet onto the dials. Now this has alot of variables which decide if it works out without ruining the dial ( dial material, print, cover, thickness etc..). I went onto my balcony and used a little tools holder, solder, copper wire, safety goggles, soldering paste to solder the copper wire used as a replacement to the dials again. Here are a few pictures of the balcony: And here of the “fixed” dial, even though the back does look absolutely demolished. You dont see that side though hehe. I wont write down the whole process here but I probably will do a more in depth one on a separate post in the proper forum. Timegrapher Test: After everything came back together, it was time to test my work on the good old timegrapher! Here is the result right after reassembly without any regulation: And here it the watch post-regulation: The low Amplitude is probably a mixture of the mainspring not being replaced and not being wound fully! Im also not very satisfied with the slight background noise with is visible on the graph ( just because I like my lines neat and straight haha). Oh and I regulate the watches to their best performance in two position. So once dial up and once dial down. Everything else really is outside of my skill, ressource and patience level xD Final Results So here are the final results of the restored watch! I did end up buying a fitting original citizen stainless steel bracelet but I did not have the chance to use my works camera to capture pictures. Anyhow, the pictures of the watch still look great to enjoy the view! Conclusion So in conclusion, working on this watch was a nice experience! It was cool to show you guys the movement since this was the last movement of a 6 watch lot which I finished off! I loved the brutalistic but kind of aesthetic design on the parts so shout out to the people at Miyota. Im writing this up last minute since im going on holidays tomorrow and I havent done anything in terms of packing or cleaning so i'm sorry for the shallow and short finish! Hope you guys enjoyed the write up and hopefully the video! Criticism, comments, tipps and anything else really can be put into the comments below! Enjoy the next weeks and see you watchbangers for the next watch!

- 1 reply

-

- 3

-

-

- citizen

- automatic watch

- (and 5 more)

-

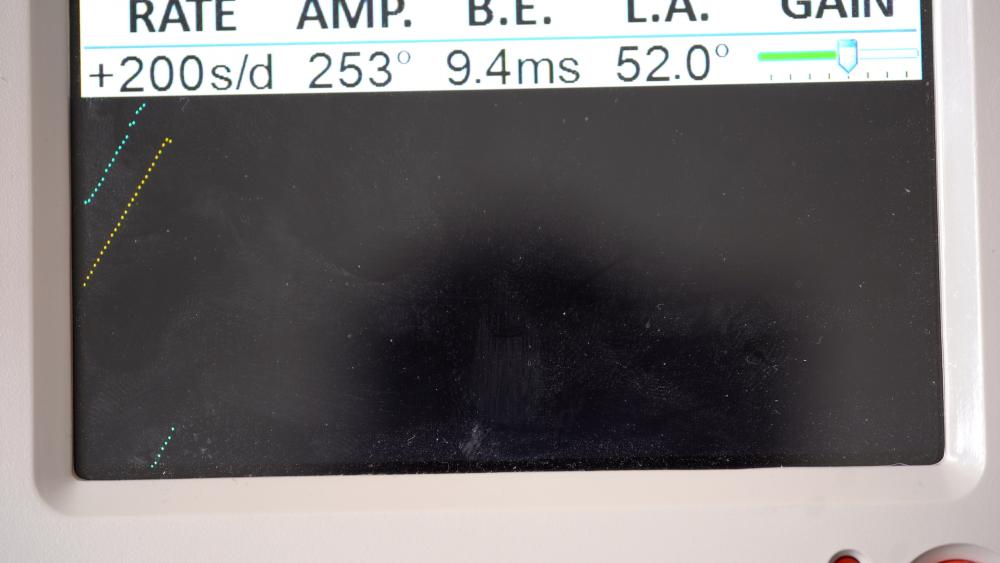

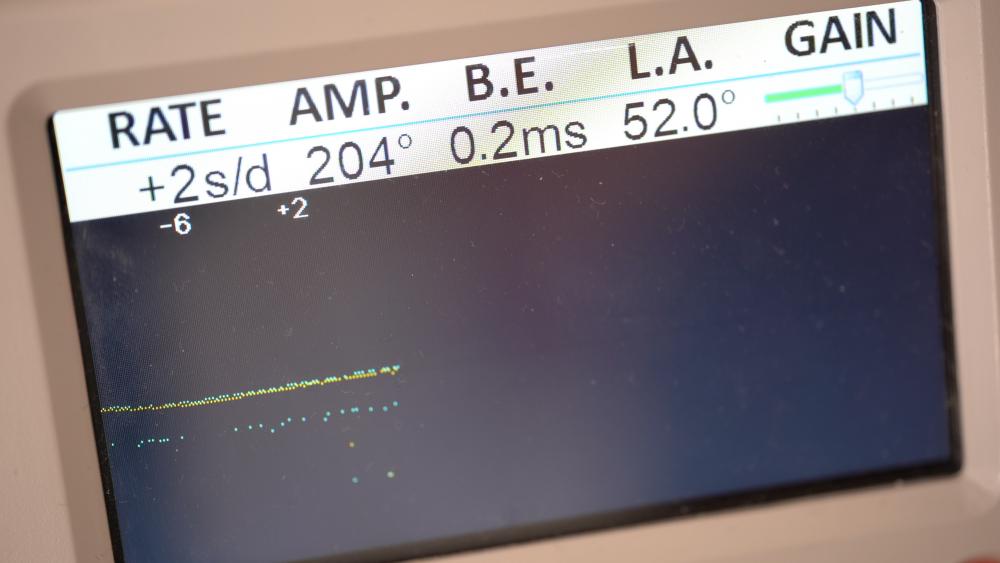

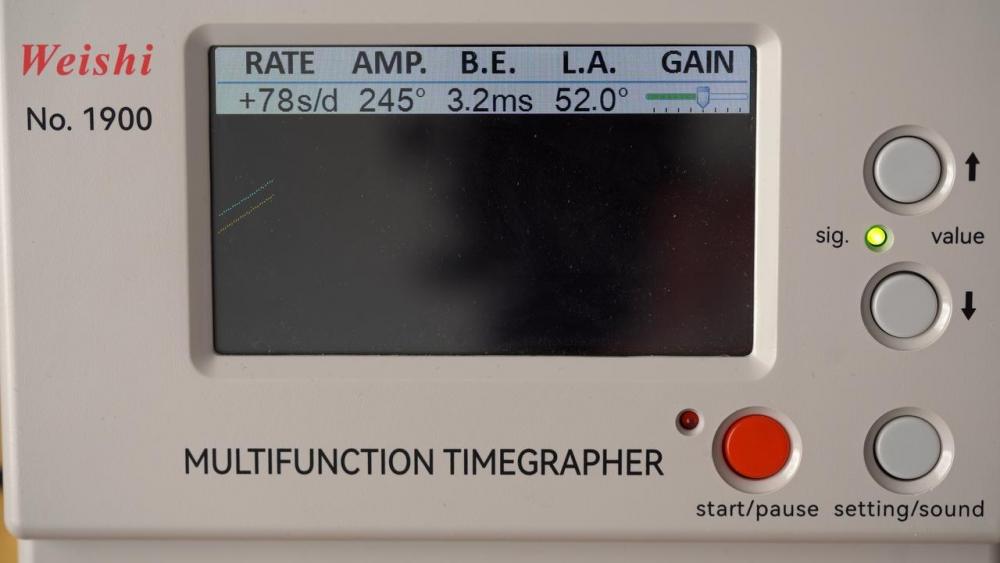

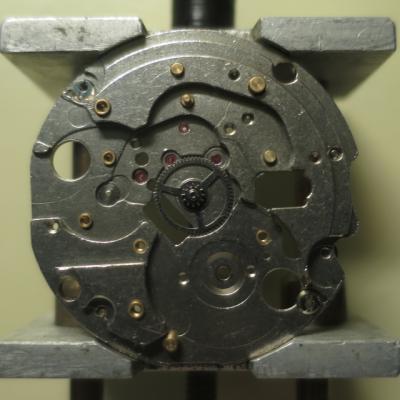

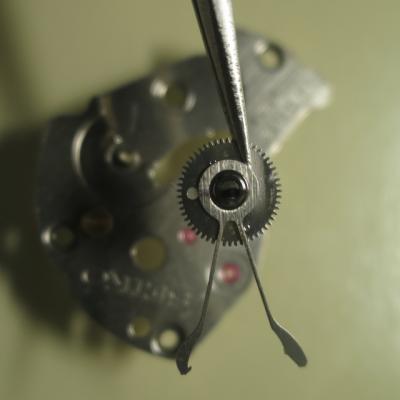

Hi Watch bangers! I did actually make it a personal goal of mine to present a watch every week but real-life caught up and ive been busy helping people move around haha. Bit nevertheless I am a week late but have another beautifull watch and project report for you guys! This watch was one of a few which I presented my Mother for her birthday to let her decide which one I should fix for her. She chose this vintage Seiko 4206A which I got from Ebay and so I sat down and got to work. Now I bought this watch online because I was really surprised at the remaining quality of the original dials and how there where still so many of them. After purchasing one and reading up a bit online it turned out that this movement line was particularly prone to behave irrationally or to repair so I kind of messe dup but nevertheless, I faced my challenge! The watch on arrival: Disassembly 1. Remove the watch case by unscrewing the back and removing the stem 2. Remove the Watch hands 3. Release the Dial feet from the back with the small levelr at the 10 and the 4 Position I think and remove the dial. As you can see it is in pretty good condition and has a very pretty sunbust effect. There is a slight stain though around the “ Automatic” text which left me kind of clueless since it is a metal surface and I wouldn’t really know what would stain it in such a way. I decided to leave it be to minimize the risk of further damage. Heres a close up picture: 4. Remove the Day clip and the Day wheel underneath it. This revealed a very interesting sping-like swan neck system for the day-wheel quick set system. Never seen that before! 5. Then remove the Day wheel spring and the 24 Hour day turning wheel. 6. Now you can unscrew and remove the main setting cover plate and the attached date wheel. 7. Take away the ( im not sure what this part really is called) but it is part of the quick set system which hooks into the second clutch wheel. 8. Now remove the Date Spring and lever, the bottom day wheel and the hour wheel to remove some more from the front side. 9. Remove the one translation wheel and the setting system sub cover which also separated the two clutches. 10. And finally take out the clitches and the yoke, setting system to completely disassembly the front side. Now you can turn the movement so we can work further on the back side. 11. Remove the Rotor 12. Take off the Automatic module 13. Remove the Winding wheel Y ratchet. I did try to remove the winding wheel in the first run but for some reason the screw did not watch to budge so I left it in for the picture. Off camera however I eventually did make. 14. Remove the elegant arching balance wheel. I was really surprised to see this in this kind of movement since I thought that this kind of design was only present in really high end watches. Interestingly enough the 4206 B however has the classical one winged balance. 15. Remove the Pallet fork system ( sorry for the blurry focus) 16. Take off the main bridge and and the small spring attached to one of the screws. 17. Pick out the Barrel, its ratchet and the 4th and 5th wheel. Interestingly enough the gears wheels have as many holes in them as the number which is kind of cool! 18. Now focus on the little winding module on the bottom right. Remove the translation wheel, the spring and the small bridge to take it out completely. 19. Almost done! Take of the final bridge which holds down the 6th wheel and the escapement. 20. And finally remove the 6th wheel and the escapement wheel. With that, we have completed the disassembly of the Seiko 4206A. Cleaning For cleaning im still sticking to the good old hand cleaning method. So this means that I let the individual parts marinade in lighter fuel for a while before giving them a scrub and rinsing them of in Isopropanal alcohol. I was thinking about dipping my toes into the ultrasonic cleaning branch but im unsure what fluids to buy and what parts I cannot drop into the cleaner so I think ill stay with what works at the moment. Additionally im broke haha. Mainspring service Now as always I did not have a spare Mainspring at hand so I removed the spring by hand and checked it out: As you can see it is / was absolutely disgusting haha so I gave It a good rub down in lighter fluid and isopropanol and the paper used for that was absolutely nasty in the end, see for yourself: However, I did clean it nicely I think and lubricated the spring with Moebius 8200 and the barrel wit Moebius 8217 before winding the spring back in carefully. After closing the barrel I did a mainspring wind test with the winding wheel and it had tension on it so it seems like I did a decent enough job. Lubrication Moebius 9010 – All jewels aside from the pallet fork jewel pivots Moebius HP 1300 – For parts which turn a bit slower. Between the arbour and the watches wheel, the barrel pivot in the main bridge or the metal pivots for translation wheels for example. But that’s just my personal tase Moebius 8200 – Used to lubricate the mainspring Moebius 8217 – Braking grease for automatic barrel wall Moebius 9415 – For the tip of the pallet fork jewels. Molycote DX Paste – Any strong friction contact points. So the setting and winding system basically Reassembly For the reassembly of course you just follow the above given steps and pictures from the disassembly backwards. Ive been thinking about making reassembly pictures as well, it would make the report way more comprehensive and would show more difficult nifty parts for example shock and balance jewel lubrication. However it would be way more annoying to take the pictures and it would cost me a lot more time. What do you all think? Timegrapher Test Okey, so once I’ve cleaned everything it was time to put my work to the test and I strapped the watch into the timegrapher. And this is the catastrophic result: This was the start of the snowstorm like reading which followed. It couldn’t really pick anything up and I was just devastated. Because I did not have any replacement balance on hand, I was desperate and opted to measuring the Rate my eye and stop watch. As you can think, this did not end up well so I ordered a lot of a few spare movement to butcher them for the balance. After placing in the 4th replacement balance however, I managed to get a decent reading. The Amplitide could be better, but this is the way I left it in the end haha. Final Results: After the timegrapher drama I closed the back up and attached a basic rubber strap for testing purposes. And from here on its basically B-Roll pictures! Here is a comparison of the movements size to my pinkie finger! And here the final satisfying shot: So yeah all in all a stressful but also fun little project which I could conclude by gifting the watch to my mother. I was very surprised to see the winged balance as well as challenged by working on a movement of this size but in the end I managed! I hope you all enjoyed reading this and that the guide may help other hobbysts or even professionals ( haha who am I kidding) in the future. Any comments, questions or criticism is of course welcome! If you guys would like the full commentated 4K Macro video of the whole process, ive uploaded it to my Youtube channel here and it would bring me great joy if you would watch it! And so as always watch bangers... Stay safe and healthy and till next time!

- 3 replies

-

- 2

-

-

- watch repair

- walkthrough

-

(and 2 more)

Tagged with:

-

Hello there. I am just starting in this hobby of watch repair and after changing some batteries and fixed hands, have bought two books: Beginner Watch Making by Tim Swike which was very helpful to me and Watch Repairing as a Hobby by D.W. Fletcher which I just can't connect too, I guess in terms of writing style and the way he refers to illustrations which are unclear at a time. My question is ther any book that you will recommend for a real beginner about quartz and manual watch repairing. Many thanks for your advice.

- 14 replies

-

- watch repair books

- books

-

(and 2 more)

Tagged with:

-

Seiko 7009 Report Hi dear Watchbangers, and welcome back to another little report from me! This week I am keeping in my set deadline and delivering my next project on time haha (not like last week).I know there probably have been a million reports, reviews and video on this but hey, it’s a classic; so this weeks watch is: A Seiko 7009 with a fully lumed up dial! I was super lucky to have found this, since at the time of purchase, I only found the pattern and colour scheme interesting and suddenly, this dial is just glowing up during night! So yeah, as always here’s a link to the commented 4K YouTube video for the lazy readers out there: Lets get into the written report then: Arrival status So this is how the watch arrived after I ordered it on Speedtimerkollektion and it seemed in pretty decent shape. The case was still in a nice condition, the original signed Seiko strap as well and the glass only had a minor little chuff so no need for replacement there. Interestingly enough the watch did not move a second for the first few weeks of me having it but started working again once I was filming for the above-mentioned video. Disassembly 1. Remove the caseback. 2. Remove the Stem by pulling into second position and pressing on the revealed lever to release it. Then remove the case. 3. . Remove the watch hands. They seemed In very good condition with me so no repolishing or reluming. Yay! 4. . Remove the Dial by turning the lever knobs at the dial feet, on the back side, releasing them in the process. The dial texture looks super organic and it makes sense since it is fully lumed! I used a little new makeshift dial container here for the first time to store the dial! 5. Take of the Dial spacer ring. 6. Remove the Front clip folding down the Day wheel by user something thin and sharp ( a cutter knife for example) and follow up by removing the day wheel. This day wheel was in English/ Arabic, which I found really awesome, and it also looks great so Ill be keeping that! 7. Unscrew the day wheel spring. 8. Unscrew the front cover plate and take that off. 9. Remove the top part of the 24 hour wheel by unscrewing the screw holding it all together. 10. Take away the rest of the 24 Hour wheel, the hour wheel, the cannon pinion underneath and the date spring. 11. Then remove the day quick set lever and its spring and the translation wheel from the setting system. 12. Move on to the setting system cover, the yoke and the clutch lever. 13. Remove the cluth and optionally the stem (if its inserted). 14. Lastly unscrew and remove the large metal arch which goes around the movement and hooks against small metal pole. With that, you have completed the disassembly of the front! Turn the movement in the holder so we can work on the back. 15. Remove the rotor and the balance wheel so that no further harm could possibly happen to it. 17. Remove the Pallet fork bridge and the pallet fork (this is ideally in an unwinded state, if there is power, please unwind the mainspring first). 18. Now you can unscrew the winding wheel and the ratchet wheel for the mainspring. 19. Unscrew the main bridge and remove it to reveal the gear train! 20. Remove the small clips holding in the automatic winding mechanism to completely disassemble the main bridge. 21. Remove the Mainspring and its ratchet spring and the complete gear train. 22. Unscrew the secondary small bridge. 23. Remove the final wheel underneath it to fully disassemble the complete watch! Congratulation!! Cleaning Cleaning as always is the hand cleaning method. Let the parts marinate in some naphta and then brush them if necessary. After this treatment I rince the parts of with Isopropanol alcohol to get rid of the previous cleaning fluids and left-over residue. I did however do some searching for vintage cleaners and what not but they really are expensive, around 200 Euros. And while that is a worth while investment, im not really sure if I want to and even can spent that money on something that ill only be using a few times a month at most. Well it’s a dilemma haha. But im also thinking about putting jars with cleaning fluids into ultra-sonic cleaners but I’m not sure if the jar walls are too thick for the ultrasonic waves to be effective. Mainspring Service As usual, I did not have a replacement Mainspring so it came down to servicing the mainspring. Upon opening the barrel, the spring seemed in decent condition, maybe a bit dirty but no visible physical defects. The barrel lid however did show signs of wear, so that place would get some well needed lubrication. Here is is unwinded and the back in its serviced barrel before closing it up. Lubrication Moebius 9010 : All jewels except for the pallet fork jewels Moebius 8200 : Mainspring lubrication Moebius 8217 : Breaking grease for mainspring barrel wall lubrication Moebius HP-1300 : Lubrication for slower turning/moving parts. On the barrel arbour for example. Moebius 9415 : Lubrication for pallet fork jewel teeth Molykote DX: Grease for heavy contact points. Mostly for the front in the setting and winding system for example. Reassembly Just reverse the disassembly Process above. Don’t forget to lubricate the balance and shock jewels and reassemble the main bridge correctly. Timegrapher Test So after cleaning and lubrication, I slapped the watch onto the timegreapher to see if the whole process did anything at all. Here it is preregulated: And post regulation within acceptable parameters. Im very happy about the Amplitude since this amplitude was the highest I have ever gotten in all of my projects! Final Results Concluding Fotoshoot strapped and lumed up again: Conclusion: All in all, restoring this old Seiko 7009 was really fun! Despite me not having the spare and clean replacement parts to replace all parts with visible damages and wear, I still managed to get the watch running in good condition again. Also the very unique and rare dial adds to that and Im happy that the light brushing with th Q-Tip did not damage the Lume on the Dial. Sadly, since the dial is a bit older (70s I would say), the fully charged lume on the dial does not hold its glow for very long and I have no possibility to relume the dial. Either way, Im happy if it even shines a little and yeah! Was a cool little project to work on! So if you guys have any comments, questions, criticism or suggestions/tipps, please write me or put them in the comments! I hope you guys enjoyed reading or the video and stay healthy! Till next time Watch bangers!

-

We are **LINK REMOVED - PLEASE READ THE RULES**, In Vietnam, we are the first to follow the direction of professional watch repair. However, in our country there are still many restrictions on new technologies. Even so, we still try to fix the downside factors. And here are some pictures of us in Vietnam. What do you think about us, please give us the most sincere comments. Thank for all.

-

Good day, guys! This is my little way of giving back to this wonderful community. We usually receive for repair a watch handed down by a father to his son. In this case, its a watch given by the son to his father - a Seiko 5 from the early 1990s. The watch has seen better days, with its hardilex crystal beaten and the watch not moving at all regardless of the amount of shaking you give it. The hands are corroded and the dial mounted on the movement using contact cement. I'll skip the disassembly and show you how the Seiko 7009 movement works. The Seiko 7009 technical guide is easy to find on the net though. First to be mounted is the center wheel that drives the cannon pinion. After which I install the escape wheel and the center wheel bridge. The third wheel and fourth wheel is installed next. Note that the fourth wheel drives the second hand directly. Then the click comes next. Prior to installing the unified barrel and train-wheel bridge, you have to install the pawl lever and first reduction wheel assembly. The assembly is held in place by the first reduction wheel holder. Take note of the orientation of the pawl lever. I find it difficult to install the barrel and train wheel bridge while ensuring that the click spring doesn't get in the way. <end of part 1>

- 15 replies

-

- walkthrough

- watch repair

-

(and 1 more)

Tagged with:

-

-

If two wrong things don't make it right try three

-

Hi I have recently gotten interested to learn and acquire knowledge about watches and there movements. I have a question for the initiated,if there is rust in the parts of the watch must the patts be replaced or can they be cleaned with a rust removal process or is that not advisable due to the parts being very fragile in nature. Thanks again for youre time.

-

Hi, I am new to watch repair and have mainly been servicing simple eta movements for my own I have always wanted a chronograph watch and have found a watch based on a valjoux 7750 with a broken case. I want to put the movement into a new case but the dial is a day date and the movement is date only. I have sourced all the parts and have fitted them to the movement to add the day function. The donor watch didn't use a dial washer / foil, do I need to use one now I have added the day indicator? If I do need a foil, what size and where from? Thanks very much Stuart

- 15 replies

-

- valjoux 7750

- watch repair

-

(and 1 more)

Tagged with:

-

First part of the disassembly, fixing and reassembly of my new Seiko 7T32-7C20 Flightmaster Chronograph that recently bought as defect. The damage was caused by trying to manually setting the date at around 11:30PM, when the watch usually starts to change the date automatically. Enjoy the first part of the video.

-

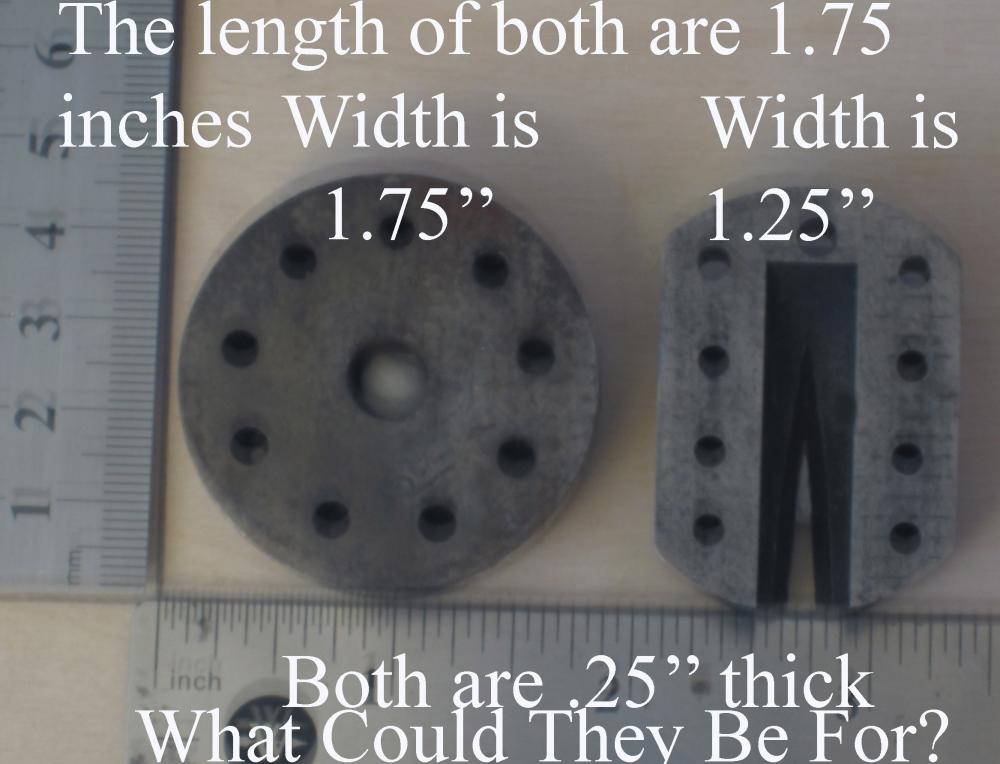

Hello and greetings to all!, I have 2 "tools" perhaps. I don't see a spot for it on my staking tool. Let me back up as well. I have introduced myself on Watch Repair Talk. I said I am a fledgling watch repairer.However, I am more like still in the egg. I have fixed quite a few watches and destroyed even more. Its ok though, I get a box of watches and practice. One time I even got a great deal on a box of watches price wise and it contained 2 working Suunto watches and even a couple of watches that were solid gold. You have to admire and love young adults that sell granddads watches on eBay for pocket money without a clue what they are selling. If people spend a few bucks to have it appraised it would knock their socks off at what the watch is really worth. Sorry I am babbling . If anyone kind enough that knows what these "Tools?" are I would be grateful and possible name my next child after you. The one thing you can not see from the picture is some or most of the hole are tapered. Thank-You Matt H. Clearwater, Florida

- 2 replies

-

- 1

-

-

- tool

- watch repair

- (and 3 more)

-

I got this Seiko 6139-6002 for pennies on the dollar albeit it was not working, in poor physical condition and with missing and damaged parts. I used after-market parts to “restore” this watch to a portion of its lost glory. This will go down as one of my favorite repair and restoration projects.

-

I have a Rotary watch GB42826/08 but having trouble removing the back. It seems to be a snap on but won't budge? Do I have to remove the crown first if so how. Thanking you in advance.

-

This survey is about the use of your staking tools and should take you no more than 5 minutes, the link is posted below. This interview is being conducted for my university engineering design course so any input you supply would be greatly appreciated. https://goo.gl/forms/zFa3XYt19rYp8wX63 If you wish to provide more info, especially related to what you like about your staking tool and what you would like to change about it, please comment below. Thank you for your time and participation in our survey.

- 7 replies

-

- watchmaking

- watch repair

-

(and 2 more)

Tagged with:

-

I'm a beginner when it comes to watches, but I'm just about ready to try to service my first watch. I've been gathering tools and just got a Little Giant C. E. Marshall cleaning machine. Can you all recommend resources for watch parts and supplies in the US? Specifically watch parts. I was also wondering about jewel settings. Do you remove all jewel setting when cleaning a watch with setting? How do you keep them organized so they don't get mixed up while cleaning? Maybe there are some threads that already have this info...if so, I missed them. Thanks for your help!

- 6 replies

-

- beginner

- watch repair

-

(and 2 more)

Tagged with:

-

(sunny it is, even in February, though its a bit chilly this AM, just under 0 centigrade...) Hi, I am Tom, and I live in South Carolina, USA, and after years of dabbling about with watches, the bug has finally bit in earnest. By background, I have been many things...I worked in the printing industry to start with, then went back and got degrees in business education, then I taught US History at the high school level for a few years, and have worked mostly as an IT person since then. Now, I run my own little IT consulting business and do work mostly for private non-profit organizations here in the state capitol, Columbia. Interspersed with all of that, I also worked as a licensed gunsmith specializing in centerfire long range target rifles and was a competitive shooter, and became a pretty fair machinist, doing a lot of custom barrel and chambering work. I will probably be cranking that operation back up fairly soon... The watch thing started with two watches I inherited from my uncle via my father...the first was his Bulova A-11 that was issued to him back in World War 2, when he flew B-17s out of England. I got this one perhaps 25 years ago and had it professionally serviced at the time. I will probably go into it for another service sometimes soon when I get better at this stuff. Then, just this year, from my fathers estate I received my uncles 1940s vintage Longens, a simply beautiful old watch. I also have my father's Bulova Accutron Railroad Approved (he was a railroad man for 36 years) that is due for a major overhaul...alas, his Hamilton 992B was stolen by a disreputable coworker on the job, which lead to his buying the Accutron in the early '70s... So, now I want to learn to work on these things, and being fairly methodical about this sort of operation, decided to standardise on just a few movements at first, ones that I can get plenty of cheap parts and donors to go with. Owning and liking several of the Vostok Amphibias and Kommanderskes, and spying that I can get a seemingly limitless supply of parts and scrap movements out of Russia and the Ukraine on eBay, I bought up a basic set of tools, some fifty 2409, 2416, 2209 and 2214 movements out of Kiev for about $1.50 each, and started buying up Vostok watches in various states of disrepair to match. I am not much of a watchmaker at this point, but I am having fun! Thanks; -Tom

- 12 replies

-

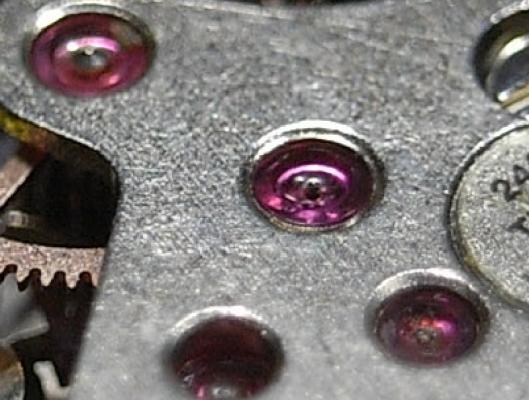

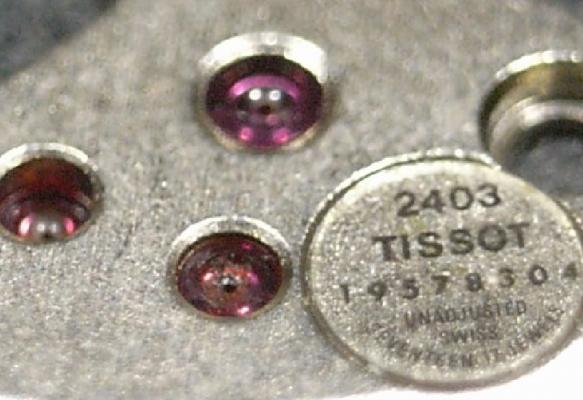

Tissot 2403 Service Walkthrough What is it with me and small movements?! I seem to attract them in absurd numbers. Oh well, here's another one to push my Zeiss optics to the limit, a Tissot 2403. My brother's father-in-law found this at the local rubbish tip, thrown away and unloved :( Upon initial inspection the condition looked dirty but not marked up, Canon Pinion felt good when setting the hands, and it seemed to wind smoothly. But alas it wasn't running at all. So to the bench I go, and de-case this little gem of a find. It removes like many ladies fashion watches, with the movement cradled in the Caseback. I removed it from the Caseback, and it looked remarkably clean. So I gave it a close inspection to see if there was something obvious that was stopping the movement. First thing that stood out, and is common on these types of movements, is the lack of a Crown Seal. As you can see there is a lot of contamination along the Stem, including nylon fibres ... perhaps from the sleeve of a sweater. I continued to look and found more of these fibres near the Balance. Continuing my inspection it was obvious that this watch was in desperate need of a complete service. Note the condition of the jewels. But besides a strip and clean, I couldn't see anything else wrong with it. No rust, nothing bent or broken; just some contamination stopping it from running. It's sad to see we live in such a throw away society today, 50 or 60 years ago this would have never been discarded on a tip. Ok, time to bring this watch back to life. First step as always, release the tension from the Mainspring, and remove the Balance and Pallets. Now the Balance and Pallet Fork safe, we can remove the Keyless Work. Start by removing the Hour Wheel, then the Setting Lever Spring. Then remove the Yoke and Setting Lever. Be sure to secure the Yoke Spring with Pegwood and note is orientation. Then remove the Minute Wheel and Setting Wheel. Then pull the Stem, and remove the Sliding Pinion and Winding Pinion. Flip it over and remove the Ratchet Wheel and Crown Wheel. Then you can remove the Mainspring and Train Bridges. As you can see, even if this watch was running, it would have not been giving accurate time. All the jewel holes are filthy! Here is a reference shot of the train on the 2403. Now, if you had good eyes you might have seen it. The object that stopped this watch from running. You guessed it ... a nylon fibre has found it's way into the wheels of the train, and gotten jammed between the Intermediate and Third Wheel. So know the mystery is solved, it's just a simple matter of cleaning and re-assembly. To Be Continued ......

-

Just a quick video to show my method of re-aligning the hairspring on the balance staff correctly after prior removal, just in case you have not marked or noted where the stud is before removal. Hope it's helpful to someone :) Watch here...

- 19 replies

-

- 5

-

-

- video

- watch repair

-

(and 1 more)

Tagged with:

-

Hi Everyone... I sent my Automatic watch off for repair (crown and stem replacement + pendant replacement) and when it was returned it was gaining 3 to 4 minutes per day. I have sent it back to get it sorted and now am being told that I will have to pay again as the original repair did not go anywhere near the movement. 1, I asume a stem would connect directly to the movewent. Would it?? 2, As the watch was NOT gaining before the original repair could anything they did cause the watch to gain time?? Basically, am I being ripped off?? Cheers

-

New here, looks like a nice site. Been in the trade for the last 47 years, hope to help other and learn new things. Thanks

-

1. Could this be the worst reading possible on a timegrapher? 2. Where do you start in fixing this watch that has just came in for a repair? Thanks