Search the Community

Showing results for tags 'tools'.

-

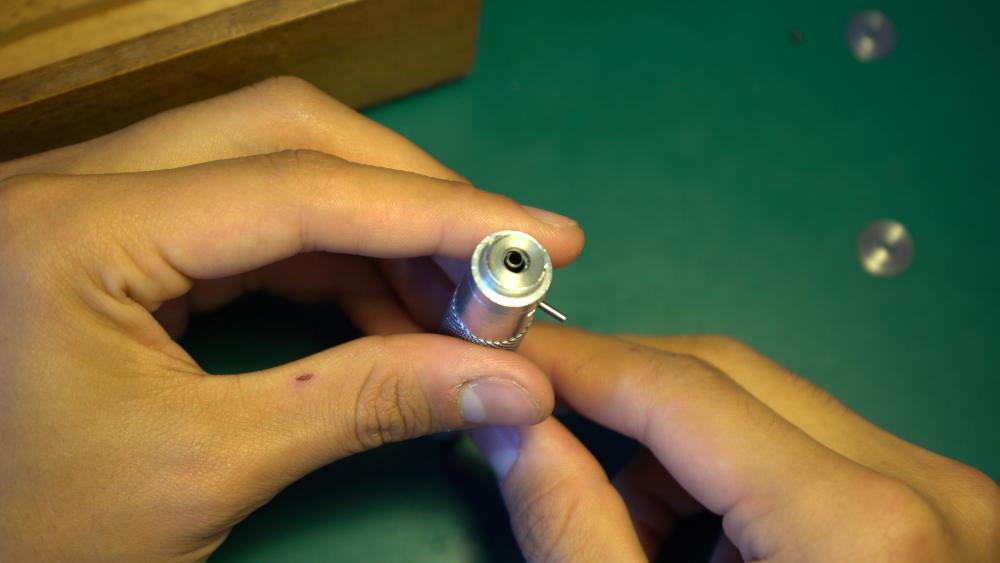

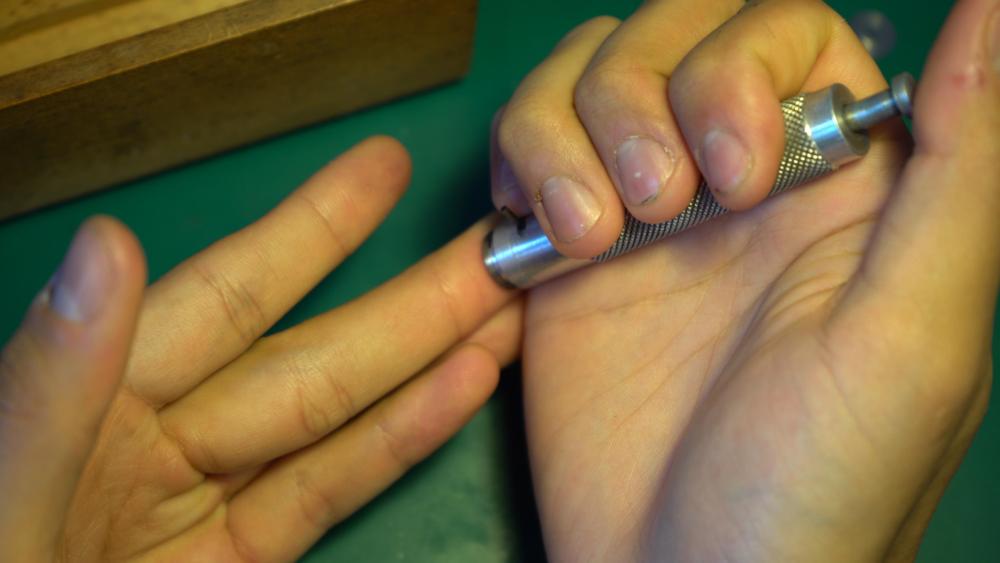

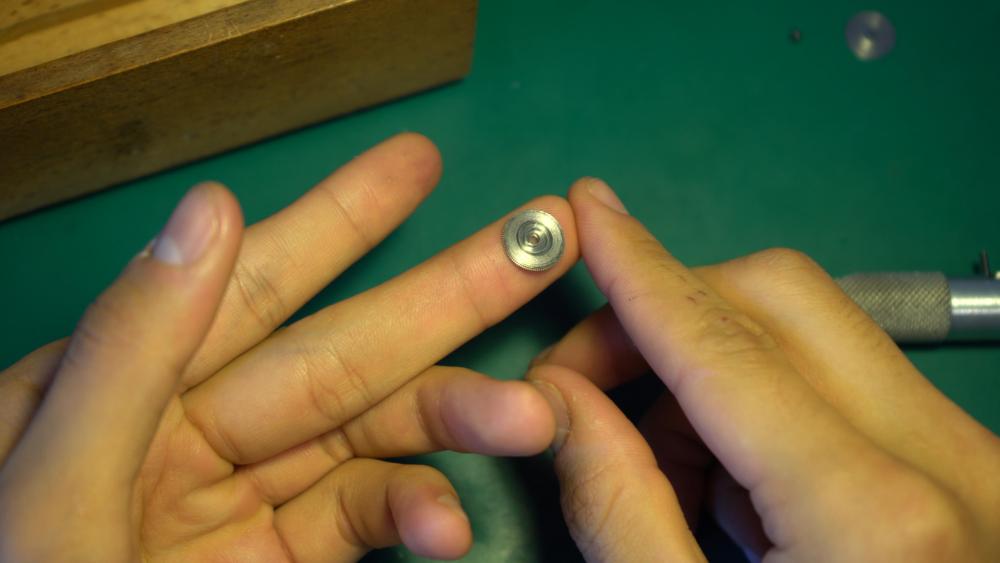

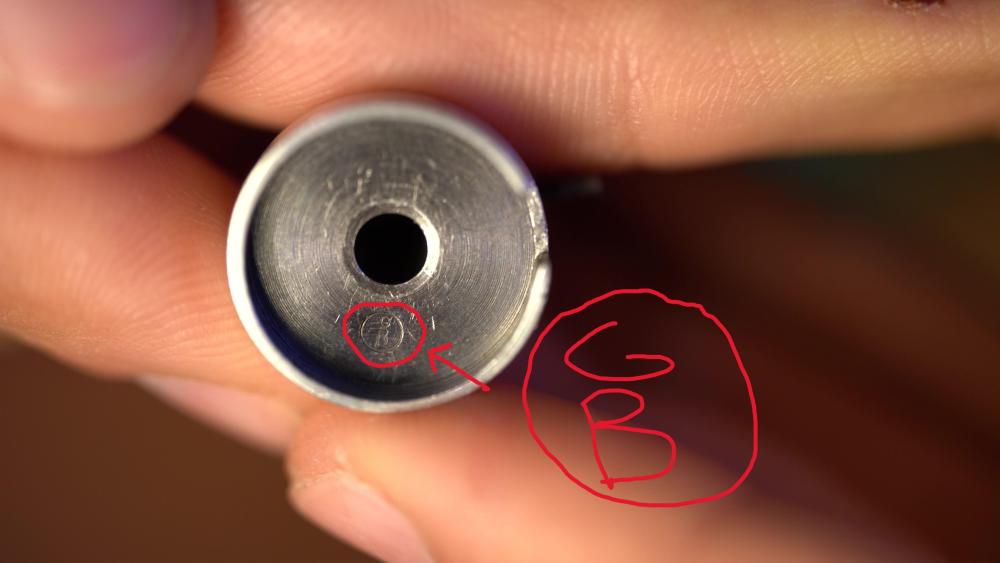

Hello Watchbangers! Today I return with another small post introducing my vintage mainspring winders! For those who prefer watching something rather than reading through the whole post, here is all the contents in form of a video: https://youtu.be/-63Do2Dkikk Now to the written part! While I first started winding mainsprings by hand ( and recommend this method for hobbyists who don't want to break their wallets) it was clear that I couldn't continue this practise due to the wear and damage it left on the mainspring and barrel! Thus I set out on the search for a pair of vintage Winders as the modern alternatives are not financially possible for a student. I was first eying american K&D winders or Watchcraft sets but coincidentally found a unbranded box of winders on Ebay for around 100 Euros: After inspecting and cleaning the set I was delighted to find that they were produced by Boley as they were stamped gB ( Gebrüder Boley) meaning Brothers Boley: The set came with 8 sized drums, their cranks and a holder! While I'm pretty sure that the hooks only point in one direction, I have tried winding left and right turning mainsprings with success, not sure what is going on there haha. Now the process of using these mainspring winders is the same as any other really! 1. You start by pressing the innermost coil of the spring down onto the arbor, making sure that the hook catches the mainspring latch. Be sure that you are attaching the mainspring the right direction/ way otherwise you will wind it wrong! 2. Then you slide the arbor into the drum and start turning the crank to wind the spring! Be careful on manual-wind springs when approaching the part of the spring which hooks into the barrel! If you go too fast these can catch the edge of the drum opening and break off! Just go slow and optionally help out with a tweezer for example! 3. Then carefully lift off the arbor, making sure that the innermost coil of the spring unlatches itself from the arbor hook again. This will make sure that the spring won't be pulled out as you remove the crank. I like using a pair of tweezers here! 4. Finally you just press down on the pusher, pressing the spring out of the winder into the cleaned and lubricated barrel drum underneath. While I am fully satisfied with the performance of my older set, I must say that it is a bit fidgety to use! The spring power often turns the barrel out of the holder slot leaving me no option other than to press against it firmly. Secondly, the lids of the cranks are also a bit bent. Occasionally, when the spring is almost fully wound in, the strong power allows the left over spring to slip between lid and barrel lip, scratching it around for one turn before I can press down firmly on the lid so the spring is wound into where it should be! I hope you guys are also as lucky in finding an affordable set of mainspring winders and if you have any other questions or comments, please put them down below!

-

- 1

-

-

- mainspring winders

- review

-

(and 2 more)

Tagged with:

-

Hi everyone, after searching I realised that there is no group on Printables to share watchmaker 3D printing related stuff, so I decided to start one. Not trying to compete with this site, I think they both serve very different purposes. Below is the link to the group in case you would like to join and contribute: https://www.printables.com/group/watchmakers-1569rjQ Thanks

-

Hi, Has anyone got one of these lathes?? if so are they any good for repairing pivots etc..I know they would not be any use for heavy work, but thought I would ask first.. Have a good weekend all.. Thanks Len

-

Got this from a buyout. Anyone know what this tool is used for? Shown are both sides and the box it came in.

- 5 replies

-

- watch tool

- tools

-

(and 1 more)

Tagged with:

-

Hey guys, Been a while, real life got in the way of this hobby for a bit. Been watching the brilliant Alex Hamilton's Its about time Channel https://www.youtube.com/@Its_About_Time. One of the tips he mentioned in his videos is to make these pegging tools for jewel holes. I finally got around to it and now I am so ready to do some proper pegging. Wishing you all health, happiness and love this holiday, Happy new year! Stephen

- 5 replies

-

- tools starting out

- tools

-

(and 2 more)

Tagged with:

-

Hello everyone! My name is Benjamin Marn, I am a 20 year old college student who has been interested in horology for about 4 years now. I have since aspired to be an independent watchmaker, most likely as a hobby or a side gig but possibly as a full time career, assuming people appreciate the watches I would design and build. More immediately, I have been planning to make my own bespoke, finely finished watchmakers tools, everything from tweezers to mainspring winders, to jeweling and staking tools, as I am fortunate enough to have access to a 1934 South Bend lathe, a 40's LeBlond lathe, a surface grinder, and a Bridgeport mill. Eventually I would like to build my own watchmakers lathe in the style of a Bergeon 50, from my own iron castings (I also have access to a furnace that is hot enough to melt iron), and after that, perhaps even a rose engine.Hopefully, I will build up a collection of tools that exceeds the quality of brands like Horotec and Bergeon at a price of only the raw materials and the time taken in the machine shop, which I enjoy anyway. In the meantime, I have slowly begun to build up my library of books, starting of course with the great George Daniels' Watchmaking, but I am always looking for more books, especially on the theory behind horology and movement design, as right now one of my biggest struggles is grasping the concepts behind gear trains, tooth counts, mathematical ideas, etc etc. I am also a bit of a visual learner, and another thing I struggle with is visualizing the complex diagrams and explanations of the complications in Daniels' book. Perhaps that's why I like Mark's channel so much, I can see things like keyless works in action.

-

Pt III of III nothing special. I probably missed a ton of info and description. All errors belong to me.

-

Hello All, I'm wondering what tool is commonly used to manipulate the regulator arm? I've used everything from tweezers to a plastic stick used to help open up computers. My main issue is that all of the things I've used are risky for slippage and I find it incredibly hard to just nudge a little when you're really trying to dial in the timing. I would think there would be a special tool for this (there's a special tool for EVERYTHING), but I haven't managed to find such a tool if it exists. Today I made my own tool using an old broken spring bar tool that I reshaped that should make life a little easier, but I'm very curious to see what everyone else is using. thank you

-

Hi all Does anyone know of a video showing the adjustment of a Rolex using the latest micro stella tool?

- 1 reply

-

- tools

- micro stella

-

(and 1 more)

Tagged with:

-

Hi all, I'm thinking about investing in the set of automatic oilers available from cousins. They cost about 200 quid with the VAT, that's obviously a lot of money so just wondered if any of you use them and are they worth the money?

-

Would it be interesting for this forum to set up a list where we could exchange things like parts and tools? I happen to have duplicate tools from my lot purchases, and feel that those could be better used. No money involved. Would that be feasible?

- 19 replies

-

- watchparts

- tools

-

(and 1 more)

Tagged with:

-

Hi All, Thought id share this weeks tool purchase. My case cushion i've been using for a while now has become a bit worn and the cushion itself seems to have shrunk a little, leaving a gap between it and the base - so the odd screw or part disappears! So i thought id try one of these new Gel cushions from Bergeon, but as usual with anything Bergeon it wasn't cheap. Retails for about £26 including VAT (this is the larger one, there is a smaller for a few pounds less) but i have to say i'm really happy with it, so would recommend one.

-

I got a nice surprise gift in the post from my aunt which she found at an auction, labelled "watchmaker's tool". Certainly looks attractive but I'm not sure what it is! My instinct is a staking set but as I've never seen or used one, I could be wrong, and my image searches don't throw up anything similar. Suggestions on another forum included a hole punch for watch straps or a sizing tool for jewels or caps. Can anyone help with the answer?

-

Continued Creations Art's, Craft's, furniture and construction... I always considered adding watchmaker and jeweler but I lost sight in one eye. But I do have a few tool's that I don't know what they are or how to use them? So, thought I'd share and hopefully gain some knowledge. **** MODERATORS NOTE -> No buying or selling on the forum please **** Or if someone is interested in them?

-

Who here uses a microscope for most of their repair work? I step over to the diamond scope from time to time to check out a part that my double loop eyeglass setup won't magnify enough for my need. I would just like some feedback on how other people enlarge these small parts. I think it would be fabulous to be able to assemble most all of the small parts with some form of a scope where you have great light and magnification. Thanks

-

So I picked up this bad boy on eBay from someone in Spain. It's pretty messed up cosmetically, and missing a heeled bush and a removing punch. Considering all that, I definitely overpaid, but oh well. I don't know how rare these are to find on eBay, so I just decided to grab it. I scraped off all the old flaking paint and found a very similar color paint at Michaels. Not a very professional job and you can see some brush strokes, but all in all it's much better. I know the colors look off in the pictures, but that's a camera white balance issue. In real life the colors are very similar... a completely unattractive greenish gray oatmeal. Why Bergeon used this color I'll never know. Carefully removed the rust from the metal plate with steel wool and very very fine sandpaper. Did the same with the punches and bushes which had a nice coat of oxidation on them, then put them through the ultrasonic like they were watch parts. The original chrome plating had worn away on the top knurled nut, but not to fear! I busted out my little Caswell "Plug N Plate" kit and used "copy chrome" (real chrome plating is dangerous and pretty toxic apparently, but I can't see much of a difference between old chrome plate and Caswell's 'copy chrome' - looks about the same). The biggest unknown was if I could find replacement punches / bushes and yep! I just ordered them from perrinwatchparts.com... they were super expensive. I definitely overpaid for these, but again, oh well. I just wanted the tool to be complete. So ta da! I now have a Platax tool. I'm going to break out one of my many Bulova movements with a broken staff and experiment with using this tool on the poor thing. I don't know the I really needed this tool, per se. I have a nutcracker - type roller remover which works pretty well (I might have broken a few staffs by squeezing a little too much, but those staffs were broken anyway), and I have the little K & D balance remover tools for my staking set. I don't see how the Platax tool would be so so much better than the K & D tool, and I'd imagine any objections or concerns about the K & D tool widening the hole in the balance by using force instead of cutting out the old staff would also apply to the Platax tool, no? It also uses force to drive out the old staff while keeping the balance arms pinned. So maybe I didn't strictly need this, but when it popped up on eBay I couldn't resist, because I want to be able to follow along with what Mark does as closely as possible... and I'm still so new at doing this. So, now I have a Platax tool, a complete 'inverto' K & D staking set (got for under $100, go eBay!), and just picked up a Seitz Jeweling tool (ouch, that was too expensive). I am now wondering what other real watchmaker specific tools you need to have to be able to deal with most, if certainly not all, the issues you find on vintage watch movements ??? I mean, I'm not going to buy an old mechanical watch washer and put it in my one bedroom apartment in manhattan, not going to happen (at least, not if I don't want my husband to divorce me ). So I make do with a tiny, cheap Chinese made ultrasonic machine. And obviously, I'm not going to buy a lathe either, for similar reasons (space constraints, expense, plus wouldn't know how to even begin to use it)... but I'm wondering if I've covered almost everything else? In terms of being able to make watch parts, yeah, that's the holy grail. Living in manhattan comes with many advantages and disadvantages. The disadvantages are obviously space constraints and expense of living. But the advantages are there are lots and lots of resources. In fact, there are a few "Maker Spaces" in the city, which are co-ops you can join and you can use their tools, like CNC mills, CNC lathes, 3D printers, 3D scanners etc etc... you can join these co ops for not much money, and they teach you how to use the tools.... I know that the consensus so far is that 3D printing watch parts won't work, because the machines are not accurate enough on such a small scale. But the CNC lathes? The CNC mills? Could they do micro-machining, in theory? It's something to think about. I think I'll create another thread about that sometime. Maybe I can pick up some good tips. Anyway, hooray for overpriced watch tools! They are so much fun!

-

Hi, I'm hoping to buy a set of essential watch making tools for servicing mechanical movements. What tools are should I Purchase? I already have a few basics such as spring bar tools, case back knives and an Ultrasonic cleaning bath. I have been repolshing watches for a few years now and have an array of buffing wheels and polishing pastes etc, so I'm just looking at tools that are specific to movement maintenance. I have been looking at a selection or tools on Cousinsuk.com, I am looking to spend around £200 on tools. I have a few specific questions aslo; Is it worth buying a set of 9 bergeon ergonomic screwdrivers, or is it possible to make do with a smaller selection of screwdrivers? And are Bergeon screwdrivers significantly better than A*F Swiss etc. What lubricants and applicators are needed for servicing basic movements (such as ETA, vintage timex etc)? Is it worth investing in Bergeon eyeglasses, over cousins eyeglasses? And would buying a x2.5 and a x10 glass be sufficient? Lastly are there any books that are highly recommended for watch repair? I would really appreciate any advice that you can give.

- 2 replies

-

- watchmaking

- tools

-

(and 1 more)

Tagged with:

-

I've been working on my little collection of watches (Seiko 5106, ETA 536.121 in a Birk's branded diver, ETA 2783 in a Benrus, ETA 2789 running a really nice Mirexal dial/case, 1950's Wittnauer Automatic in the queue for an overhaul)) for about a year now and I've decided that Rodico, good tweezers, excellent screwdrivers, eye-glass mount loupe lens, and decent cleaning fluids and u-sonic machine - plus the all-important "large" turkey roasting bag - are my favorite tools. I will get a real watch cleaning machine at some point, and a timer. And probably progress to jewel and balance work in the not too distant future. I've also discovered that the mechanics of precision work, mostly thanks to Mark's great videos and Martin's unbelievably good writing and photos in "adventuresinamatuerwatchfettling", are pretty accessible and moderately straightforward to learn. So far, I've stuck to stripping, cleaning, lube and re-assembly, plus replacing worn or damaged parts, including crystals. What I haven't been able to quickly understand is the sourcing of parts, cross referencing, sources of information (technical manuals), and how much experience and knowledge counts for knowing how to identify and source replacement parts. Even mundane things like a cross reference between my Seiko 5106-8010 to the OEM replacement crystal number takes me an hour of checking on the internet, or deciding what the correct gasket/o-ring size for a watch case back is still a matter of fear and trepidation. i hope that comes with experience and practice - but from my perspective, that is the hardest part of watch maintenance (I'm not going to claim I'm repairing) - identifying replacement parts for my old watches. luckily, this site, forum and friendly community exists to help. Thanks to everyone who asks and answers questions - your curiousity and skills feed my own and I appreciate the thoughtful, supportive, generous nature of forum users. Attached is the 5106 - a 33 jewel marvel from Seiko. A ton of parts, but they all serve a purpose - hacking seconds, instant/simultaneous day/date change, manual date change, automatic and manual wind, and every jewel supports a rotating shaft. Happy New Year! Bill

-

Just recently i have been rather busy with a large intake of repairs & servicing, i figured since ive worked so hard ( and yet still have more to do ) id treat myself to another tool. I know i don't really need it but i do like Bergeon tools and this one i picked up is in mint condition with original box. I normally use my Bergeon staking set but this will make a nice addition to my growing collection. Sad that a new tool makes me excited, or are you guys like me ? Next on my list is the Bergeon hairspring collet tightening tool :) Hopefully i should have some nice watch photos to upload over the coming weeks as i have had an Omega repair frenzy including a rather battered Omega RAF 1953 Cal 283 and also a return of a personal favourite 1956/58 Seamaster, and not forgetting a complete restoration of a Tudor Oyster Princess :D

- 41 replies

-

- 5

-

-

- canon pinion

- bergeon

-

(and 1 more)

Tagged with:

-

Hi all. I am trying to identify this allegedly watchmaker tool. Found it in a garage sale but seller doesn't know much about it. If someone can help identify this tool and assess its use that would be awesome. Thanks in advance.

-

Well its been a while since i shared a post and i thought id share a mini project with you splendid folks as i know you all like looking at new and shiny things Ive spent several months working away almost non stop on various repairs and services, so when i finally had a chance to clear my table i figured id get stuck into a small project idea i had. When i set out with a specific idea/design in mind i usually write down every dimension and draw up diagrams and spec sheets etc, but i figured for this project id just play it by ear, or eye in this case. I was working on a pocket watch movement when it occurred to me how boring ( although reasonably functional ) my movement holder was, and i thought to my self why not make my own. With some metal stock lying under one of my cabinets i got to work and just lost myself in my machines........... Top corner is my trusty albeit ragged holder, with parts machined by eye underneath..apologies for lack of focus After a clean up and light polish ( lets not go too crazy it is a tool after all ) i got round to assembling the holder and setting the bar shims and threads with some Loctite > As you can see i didn't go too crazy with the finishing of every piece as it is going to be put to work but i think its an improvement over the standard el cheapo i use for large movements. As i used thicker parts overall , the holder is much more rigid Im sure i will likely be making some more in the near future but im going to design them next time rather than play it by eye I do like Bergeon Holders but nothing quite beats something you made for yourself . Next project is a new tweezer/forcep stand for my trusty Dumonts ( For those interested in boring details > M4 Threaded centre stainless steel > 12mm Free Machining Brass Knurled knob & retainer screw > 6mm Brass shims > 4mm Brass sliders with M4 threads 3mm long >2 x Aluminum flat bars machined in mill and hand finished angle ZZZzzzZZzz )

- 16 replies

-

- 6

-

-

- tools

- movement holder

-

(and 2 more)

Tagged with:

-

Hi All, Just a general question, and hopefully not too obvious, but how many of us here make our own tools like oilers or specialty screwdrivers or "pointy sticks"? I'm anxiously awaiting delivery today of my Bergeon screwdriver set and my #5 Dumont tweezers and I've been (voraciously) reading my copy of Practical Watch Repair where he touches on making oilers out of sewing needles. I dabble in woodworking and I love restoring an old brace and bit or hand planes and have made some specialty planes just for fun. Would love to know what can be done in watchmaking if anyone is willing to share? Thanks, Rossco

-

Hi, I am new to horology and I am hoping to fix a couple of watches that I have won on ebay, cheap so if I screw up it's no loss, so with this in mind I watched the tutorial by Mark on cleaning a Rotary mechanical watch, really nice easy to follow tutorial, which brings me to a couple of questions. I have most of the tweezers, screw drivers and basic tools, but in Part 2 of the tutorial he uses: 1. A Steaking Block, 2. A Steaking Set. 3. A Rolo Remover, my question is this, are these tools nessasary? are there alternatives to these tools, I know at some point I will need a main spring winder but that will have to wait as money is an issue at the moment. Can anyone help with the above, and while I'm on the subject of money (lack of) are there any alternetives to the exspensive Mobeous Oils & Greases. All lot of questions I know, but I really am looking forward to striping and rebuilding some watches, so I can have a go at my Grandfathers Ingersol pocket watch when I am confident enough. Thanks. Den.

-

I need your help to identify a set I recently purchased. Does anyone know this model? Also I would like to hear about the things you guys do with your own staking tools. I have never used one of these and I only know that they are useful to replace balance staffs. Thanks.