Search the Community

Showing results for tags 'roller jewel'.

-

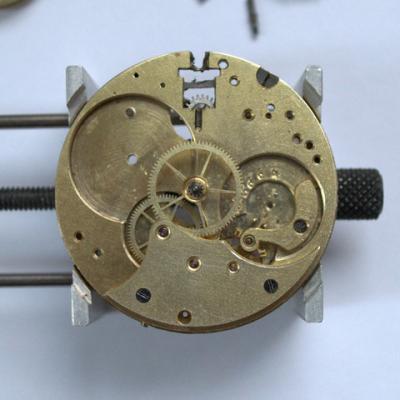

I am working on an Elgin pocket watch grade 312. It was an estate sale purchase and was not running when purchased. I assumed that it was not running because it was very dirty and thought cleaning would solve all the problems. I completely disassembled it and ran it through an ultrasound cleaner and rinse. It came out bright and shiny and when I started to reassemble for the first time I saw that there was NO roller jewel! So, what now? Can the roller jewel be replaced by a person with very modest ability? I am including two pictures of the balance and roller plate. I do not see any sign of where it was attached. Thanks in advance for any guidance. Bill H.

-

I have an old Waltham pocket watch movement which is missing the impulse pin (roller jewel). I have a limited number of actual jewels and since this is just a practice movement I thought I'd try to make one out of brass. I've seen this several times in old pieces--usually a very sloppy job. So I got some brass stock of the same diameter as the "D" in the roller table, filed it and burnished it to a high gloss. Then I took a small, very fine diamond file and filed it half flat to form the "D" I then polished the face using progressively finer sandpaper on a steel block. This works fine--so far! Problem is separation of the piece from the stock. Again I used a small cutting file to do this but it doesn't leave the end very pretty. So what I've done so far is to fit the good end into the roller table. I then plan to shellac it in place and see if I can very carefully adjust the length and clean up the end. Has anyone done this before? Any suggestions as to how best to do it?

- 5 replies

-

- roller jewel

- impulse jewel

-

(and 2 more)

Tagged with:

-

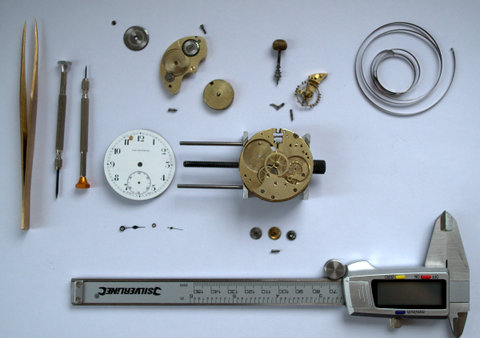

Dear readers, This is my first post. I hope we will get know one another and with your co-operation we will trade the pleasure of learning for the satisfaction of sharing one's knowledge. To illustrate my story I have added some pictures below. You can see some basic tools, a partly disassembled antique 19 lignes (42.8 diameter) lever movement and the removed parts. I had never disassembled a movement before and this one seemed like the perfect candidate to experiment, but now that I have learnt to assemble/disassemble this movement, I want to fix it. After all, we are talking of a fully jewelled movement from a century ago. On close inspection several issues are revealed: broken mainspring, broken balance staff... ...and missing roller jewel. I have not been able to identify the maker, but the dial and the case (935 silver) confirm it is Swiss. The balance cock bears a factory symbol consisting of a five-pointed star connected to three lightning bolts that come out the star each in a different direction. I am aware that getting spare parts is going to be hard work, but I want to learn to solve these issues. I have measured the broken mainspring with a Vernier caliper but I cannot find a replacement in Cousinuk.com. Perhaps someone could check for me in the Générale Ressorts catalogue? These are its specifications: Height: 2.2 mm. Thickness: 0.22 mm. Length: 24 inch (61 cm). Barrel: 16.5 mm. End hole type. Any advice, guidance, comments, support, contributions, collaboration will be greatly appreciated. I will be watching this space!

- 11 replies

-

- WatchmakingRepairs

- Beginners

- (and 6 more)