Search the Community

Showing results for tags 'project'.

-

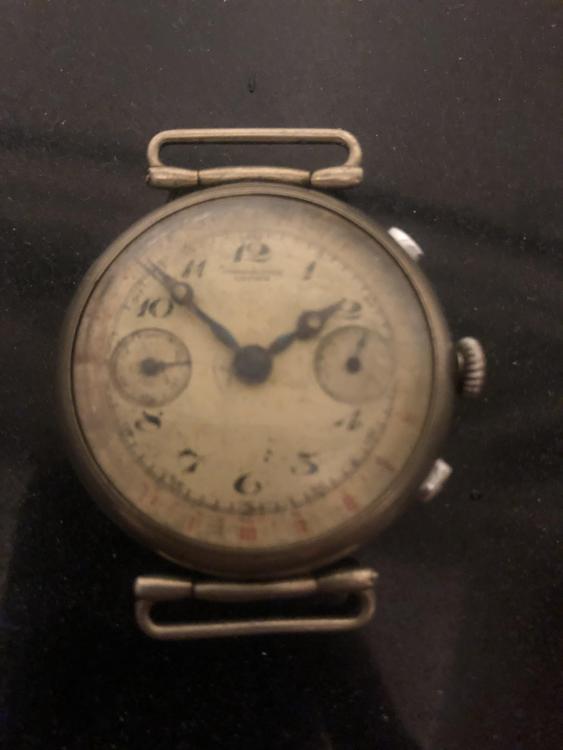

Sourced this watch, want to know your thoughts about it. Like the looks of early Landeron Hahn 15 1/2 dials. Looks like this is Landeron Hahn 2 (judging by 45 minutes register)? I am new to watches, so any insight/thoughts/help are welcome. Here are some questions I already have: 1) What do you think about restoring this one? 2) How hard would be to source the bezel for it? Where to look for it? Looks like case is quite large - 40mm in diameter. I assume sourcing mineral crystal later shouldn't be a problem? 3) How to fix that broken fixed lug? Or it's better to transform to non-fixed lugs? 4) Movement looks complete to me, seller says balance swings nicely (i hope so), hopefully just needs cleaning/oiling. Or you can already spot something off? 5) Missing seconds hand shouldn't be an issue? Probably regular Landeron should fit with 0,25 or 0,27 hole size? 6) What to do with hands (assuming seconds hand will be new, unless I will source by some miracle something with matching condition). Looks like someone restored similar watch: https://www.watchpatrol.net/listing/611413/

-

Hi there, my son is doing his International international Baccalaureate in computer science (equivalent to UK A levels) and needs a project to do, he would like to create some watchmaking related software rather than a clone of mine-craft which seems to be what the rest of the people on the course are doing. The duration of the project is about one year, so will be a fairly substantial project. I'm racking my brain to come up with something, so wondered if anyone out there had any ideas?

-

Hi, Looking for suggestions to shop for new project watches (ie non-working, old, not too expensive) while visiting Amsterdam this weekend? Thinking either shops known for carrying used/vintage horological stuff or flea markets? Admin: If this is too off topic for this thread, apologies in advance and please move to an appropriate sub-thread if one exists. levine98

-

Hello, everybody. I wanted to share my restoration stories that I have done for a long time and thrown into my archive. First I discussed the Atomic Mars 71 Brand using Valjoux 7734. As it was seen, scratch and dial is broken. To begin with, I tried to brush the Case as Brushed and make it the first day. If it is decorated, I polished and re-painted the indexes (with acrylic paint). I usually do this in three layers so that the paint is not deleted in a short time. I replaced the case buttons and tubes with aftermarket buttons. Since the condition of the dial was in very poor condition, I had it re-painted. The quality is not so good. In Turkey, unfortunately, not doing the job well. Caliber 7734 (Valjoux) is a special and robust mechanism for me. With good maintenance and lubrication, you can reduce deflection values up to 3-4 seconds per day. I added a short timelapse video about it :) As a result, such a result came before us. Thank you Taskin https://www.youtube.com/watch?v=XKH6yTKUfpM

-

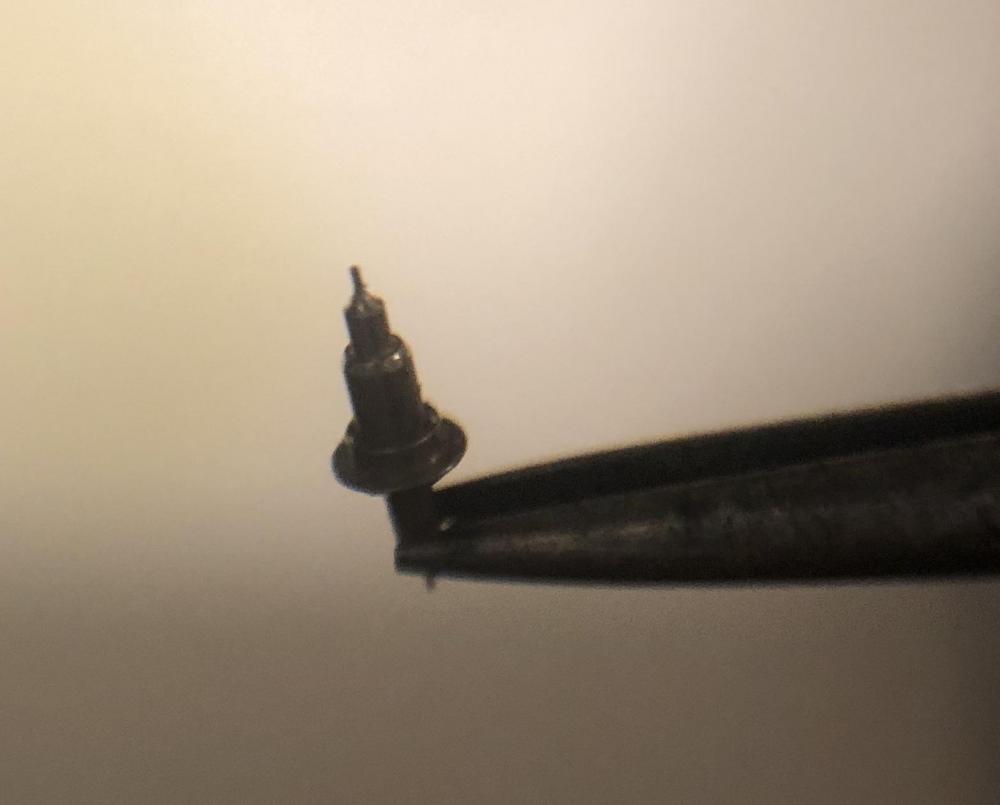

I have a watch movement that I have hunting for a case for a long time now. I bought the movement rather cheaply as I absolutely love the patina on the dial. The movement is an Wittnauer 11arg (as 1361). When the rotor turns the automatic assembly slips (or maybe the mainspring). The pictured gear slips when the rotor turns. I can still wind the movement by hand however the automatic assembly slipping I believe causes the mainspring to unwind. Does anyone know what is wrong/ what I can do to remedy it? Thanks for your help, Amateurwatchbreaker

-

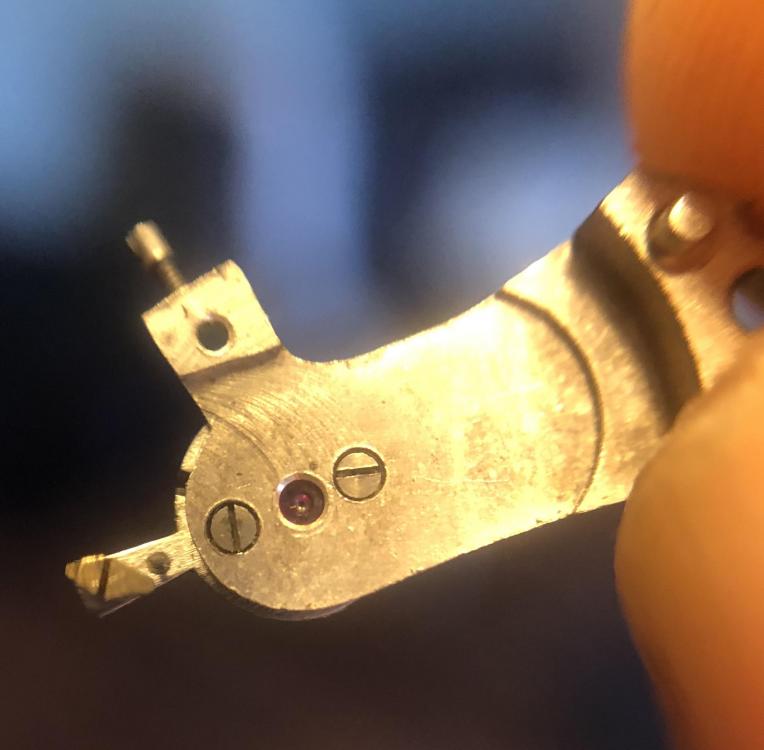

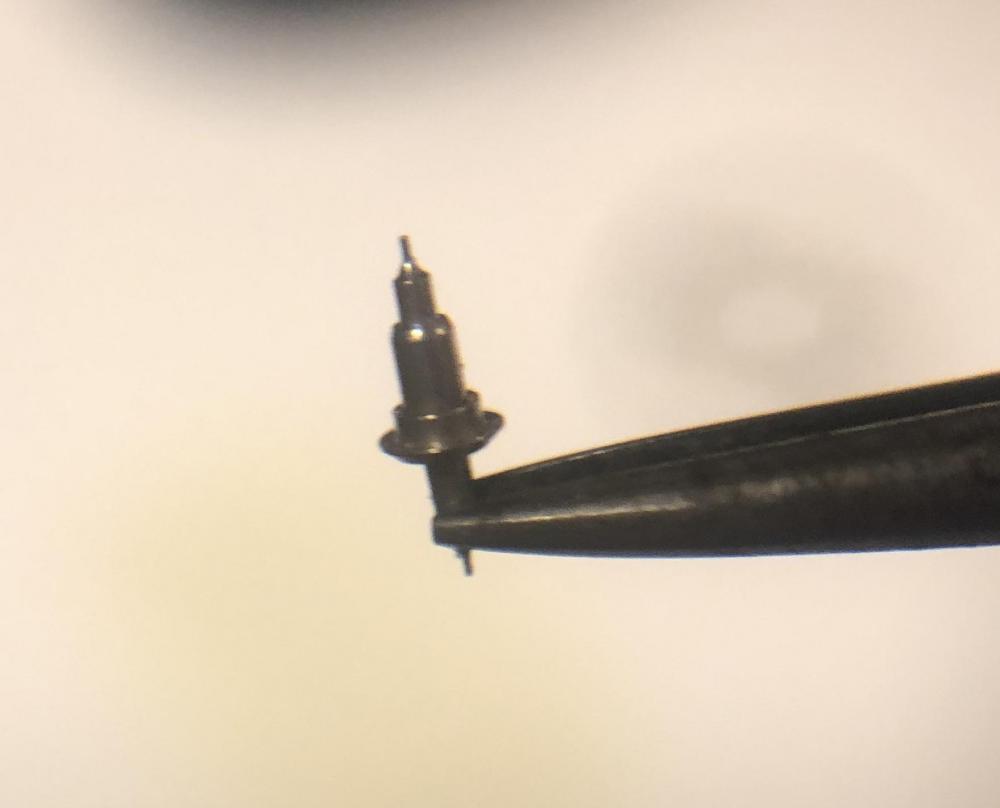

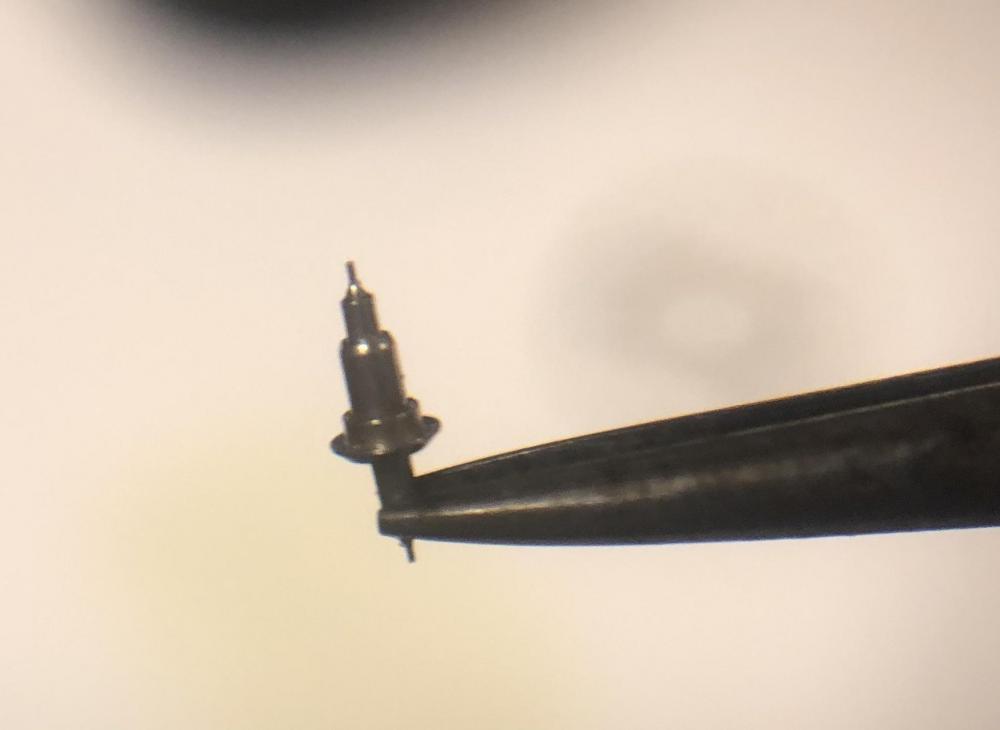

Sourced on ebay some relatively inexpensive Landeron 3 watch. Looks like 30ties, all original. 40mm diameter without crown. Watch was sold for parts or repairs. This is all info what I got from seller: Watch looks very dirty (I will not wonder if that dirt is still from war)... Balance completely disassembled, but all parts present (in the same box as watch, at least hairspring was in container). One of the pusher levers is broken (but broken piece is there). Other pusher was not properly installed (fixed that already). Foil disc from under dial is also there inside the box. Dial was not tightened enough, so small register seconds hand was hanging around under scratched glass. Mainspring was fully wounded. I don't know what to think about that... I mean, I am a beginner, but at least I wouldn't left wounded mainspring, and probably disassembled balance parts I wouldn't just throw in a box with the watch. When I look at the balance staff, it doesn't look so bad to me (see the pics and comment please, I might be wrong), so I wonder, why it's disassembled. Could it be, that watch stopped working because of dirt/old oil, and someone unexperienced decided that balance needs to be disassembled? Any ideas where to start? I was thinking about bringing it to watchmaker to check/assemble the balance, and see if it swings more or less fine, and after that start with cleaning/oiling. P.S. Does anyone has spare pusher levers for this movement? Or could some laser welding work to fix broken one, or that will not be strong enough? And any suggestions about hands - should I restore them (blue layer is coming off at some parts) or keep them "patinated" as they are?

-

Well its been a while since i shared a post and i thought id share a mini project with you splendid folks as i know you all like looking at new and shiny things Ive spent several months working away almost non stop on various repairs and services, so when i finally had a chance to clear my table i figured id get stuck into a small project idea i had. When i set out with a specific idea/design in mind i usually write down every dimension and draw up diagrams and spec sheets etc, but i figured for this project id just play it by ear, or eye in this case. I was working on a pocket watch movement when it occurred to me how boring ( although reasonably functional ) my movement holder was, and i thought to my self why not make my own. With some metal stock lying under one of my cabinets i got to work and just lost myself in my machines........... Top corner is my trusty albeit ragged holder, with parts machined by eye underneath..apologies for lack of focus After a clean up and light polish ( lets not go too crazy it is a tool after all ) i got round to assembling the holder and setting the bar shims and threads with some Loctite > As you can see i didn't go too crazy with the finishing of every piece as it is going to be put to work but i think its an improvement over the standard el cheapo i use for large movements. As i used thicker parts overall , the holder is much more rigid Im sure i will likely be making some more in the near future but im going to design them next time rather than play it by eye I do like Bergeon Holders but nothing quite beats something you made for yourself . Next project is a new tweezer/forcep stand for my trusty Dumonts ( For those interested in boring details > M4 Threaded centre stainless steel > 12mm Free Machining Brass Knurled knob & retainer screw > 6mm Brass shims > 4mm Brass sliders with M4 threads 3mm long >2 x Aluminum flat bars machined in mill and hand finished angle ZZZzzzZZzz )

- 16 replies

-

- 6

-

-

- tools

- movement holder

-

(and 2 more)

Tagged with: