Search the Community

Showing results for tags 'manual'.

-

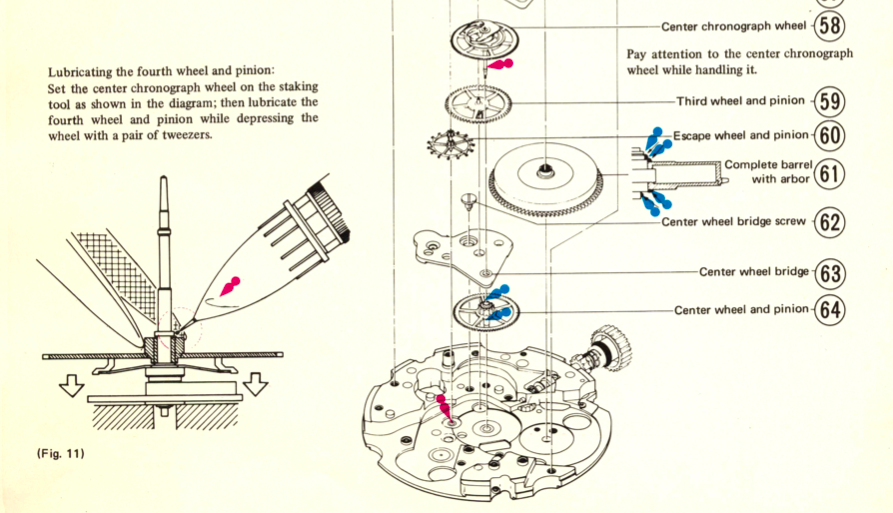

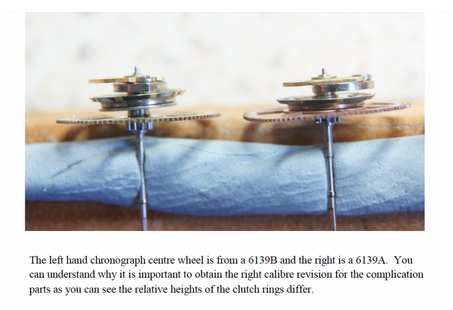

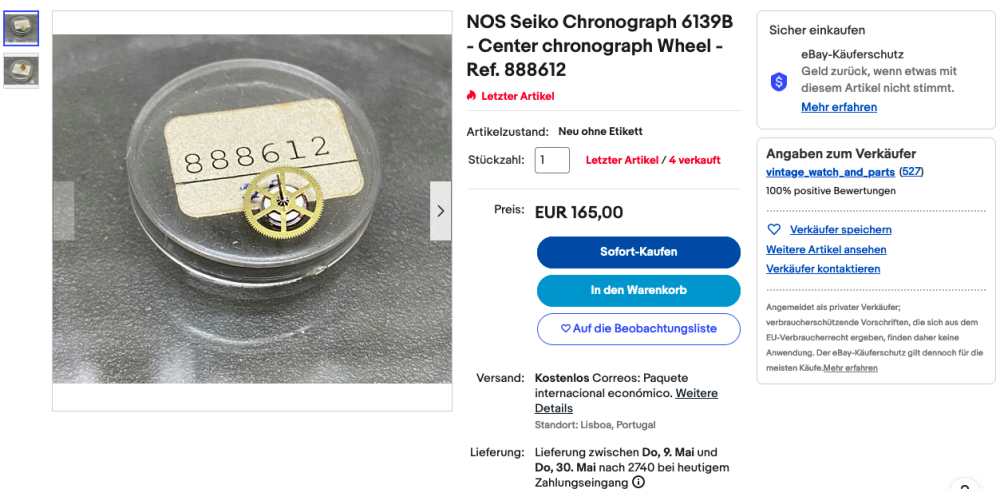

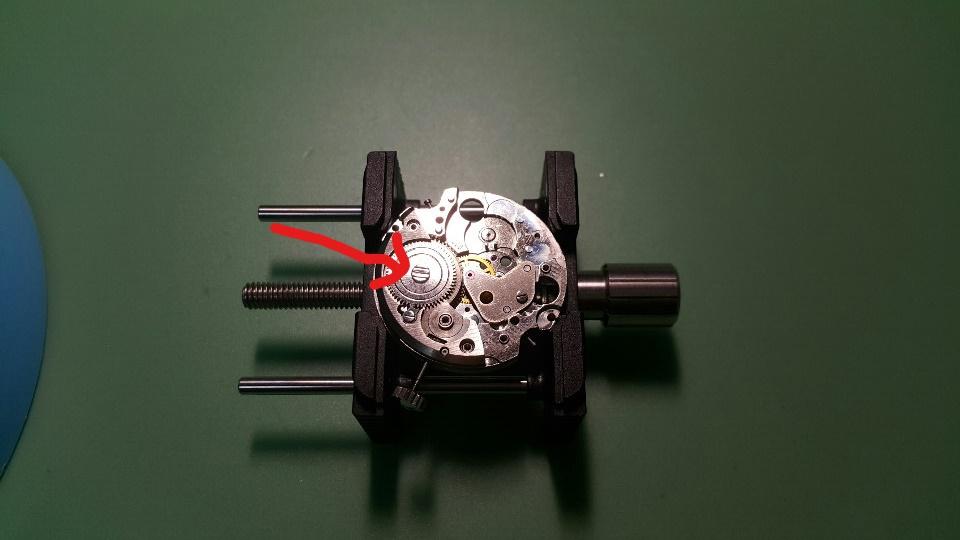

I am certainly not the first one who happen to ruin the chronograph center-wheel of a Seiko 6139B. The internet, when you search for it, is littered with stories, even here on WRT there are some. One of the problems is that the service manual of the 6139A is readily available on the net, not so with the service manual of the 6139B. On top, reading other forums & stories, there are people who claim that there is hardly any difference between the 6139A and the 6139B movement, so the 6139A service manual will suffice. However, one of the crucial differences is the design of the chronograph center-wheel. Also the Seiko reference numbers are different. For the 6139A, the reference number for the chronograph center-wheel is 888610 and for the 6139B: 888612. To lubricated the 6139A chronograph center-wheel, the following graphic picture in the 6139A service manual is given; One has to press down the sprocket and oil it. Unaware of the difference in chrono center-wheel design, I pressed down on the sprocket, but there was no movement. Perhaps not understanding or interpreting the drawing correctly, I pressed with the tweezers on the 4th wheel. This caused the 4th wheel, which turned out to be a press fit to the sprocket by the 6139B, to strip off the sprocket. Thereby me joining the line of all the others, who tried this before and are now searching for "how to fix" this misfortune. In an older thread on WRT, member @ricardopalamino place a picture in which he shows the difference in center-wheel design between the 6139A and the 6139B. To the left the 6139B and to the right the 6139A. As can be seen on the left center-wheel, the 4th wheel is pressed onto a sprocket. Pressing down on it, as shown in the 6139A service manual, gives a ruinous result. People did several attempts to repair the damage, but so far, I haven't found a success story. Here is one of the attempts; Reading what already has been tried, I tried a different approach ..... but sadly failed too. Nevertheless, I'll show what I've done; perhaps somebody may fine-tune or expand on the idea and has success? In my staking set was an anvil with a 4.5mm hole, exact the size needed to fit the chrono center-wheel "up-side-down". The distance between the clutch parts and the 4th wheel was 0.25mm. To support the 4th wheel as close as possible up to its center, I used feeler gauge blades, on one side a 0.25mm blade, and on the other side a combination of 0.15mm + 0.10mm blades. This allowed me to tap the sprocket back onto the 4th wheel ...... The thickness of 0.25 blades doesn't prevent some "spring" action, and so my 4th wheel was slightly deformed. The re-attachment seemed successful, but when trying to true the wheel, the connection failed again Currently there is a NOS 6139B chronograph center-wheel on eBay. Last Sunday the price was €150, on Monday the seller increased the price to €165 !! Prevention is better than the cure and I do hope that anyone in the future, searching for a 6139 manual, with read my "Warning". As for my Seiko, I'm not going to invest €165 for one part and since the rest is pretty good, I will sell the watch for "parts or repair"

-

Hi All, I just recently had my Cartier tank fully serviced as the main spring broke ( was running perfectly before the main spring broke and i dint know when the last service was done so I went ahead and did the full service anyways ). Main spring was replaced. Got the watch back from my watch maker and about 5 hours later it stopped working as it seemed like the main spring broke again. Took it back again, main spring replaced, watch ran for about an hour and stopped again, so I then went back and dropped it to my watch maker, fixed it and advised a screw or what not was not tightened and the spring was not released?. So I got the watch back and it ran for about 6 hours and stopped again. Main spring is still good. The watch was able to wind fully but still does not run. I opened it up myself and I can see the balance wheel does move freely. My question is, what seems to be the issue here? Why does it keep stopping? Ill be taking it back to my watch maker for the 4th time now.... Thank you in advance! 1980s Cartier Tank 925 Argent Manual Wind.

-

Hi everyone, I have some problems with a manual winding watch. It needs some work but I would try to do it myself. The watch appears fully wound but it doesn't work. Which is the problem? Thank you in advance Alessandro

- 8 replies

-

- manual

- hairspring

-

(and 2 more)

Tagged with:

-

Greetings Guys from Puerto Rico: I'm new to the forum and also to the watch community, I love watches since childhood but now I am introducing to this all new repair aspect of it. I am on need for help since I have been reserching about 2 months ago from this particular caliber (7606A/42 799 RO) and with not sucess of find anything about it. The 7606A its in the balance cock printed and on the dial its marked as a 42 799 RO. If any one out there on the community has any information or the repair manual of it would be very helpful to me since a have a complete watch but in pieces. Just looking down as my first project ot get it back running if its possible. Thanks, Gustavo A.

-

Hello dear watch repairers. I am disassembling a vintage citizen caliber 0200. It is a manual wind caliber with 21 jewels. I usually do not have much problem disassembling simple movement like this. However, the rachet wheel screw is very stiff and won't move at all. I tried to unscrew it anti-clockwise with nicely fitting screwdriver but it is stuck. Actually I have an bad experience with a citizen movement like this before. It was cal.1801, very similar to 0200 and only difference was the date function. I had same issue with the rachet wheel screw and I ended up breaking the screw. The head part of the screw came apart. Is this a typical issue with citizen calibers?? or am I doing it wrong?? Please help me out! caliber 0200.

-

I just got my grandfathers Gucci 9300 Chronograph and I installed 2 new batteries. However, I cant seem to get the chronograph function to work properly and I cannot find any manual to help me get the watch back in working order. Any advice would be much appreciated

- 3 replies

-

- gucci

- chronograph

-

(and 1 more)

Tagged with:

-

I have a dear little vintage wrist watch. The movement runs well and the 2nd hand turns (it is on its own small dial) but the hour and minute hands don't turn unless the watch is face down.. You can set the time easily, but then they don't move when face up. Any help would be most welcome.