Search the Community

Showing results for tags 'hairspring'.

-

Where would one even start with this mess? Trying to put the balance in after cleaning everything, one small slip, and in less than a second: disaster. Comes from not having 100% focus at the end of a day I guess. "No Excuse Sir!"

- 9 replies

-

- 1

-

-

- tangle

- hairspring

-

(and 3 more)

Tagged with:

-

Hi All, I'm relatively new to watchmaking. Having serviced a few watches already, but I so far dodged more involved repairs. I was working on a nice Vostok watch. I have disassembled, cleaned, reassembled and lubricated the movement. One of the last steps were to reseat the balance complete. The balance didn't want to move freely so I had to take out and put it back a few times. I could have been too hard with the part or maybe the hairspring wasn't connected well enough. All in all, the hairspring got disconnected from the balance cock. My main problem now is that I don't recognize the substance/adhesive that the hairspring was connected with originally. It's a relatively tidy job so I think it was done in the factory but it's not shellac. I don't know if this can be warmed up so I can offer back the hairspring or should it be removed and replaced with an equivalent adhesive substance. The hairspring is OK as far as I can tell. Please kindly help me formulate a repair plan for this part. I would like to repair this part myself. I can easily source a replacement balance complete but I would like to learn how to deal with this. And now the pictures.

- 3 replies

-

- vostok 2409

- balance

-

(and 3 more)

Tagged with:

-

Hello everyone, I bought an omega with an 711 movement and managed to find the problem : the hairspring was twisted. So I bought another balance and while trying to fit it in the movement I pushed a bit too hard on the tweezers and it made a 180 Flip (upside down). This tiny little accident made a “knot” in the hairspring, does anyone know if there is a way to fix it ? Thank you very much and sorry for my frenglish Louis

- 20 replies

-

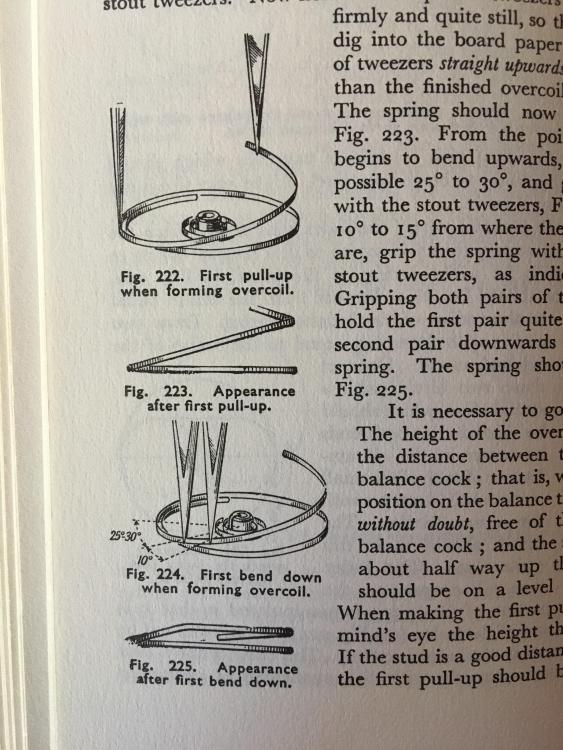

I am correcting a deformed hairspring and need to set the curve for the regulator pins. De Carle mentions using curve-forming tweezers, which I cannot yet find. What are the alternate practices for forming this curved portion of the over curve? Thanks, RMD

- 43 replies

-

- breguet

- hairspring

-

(and 2 more)

Tagged with:

-

I have purchased a GUB09207211 hairspring from Cousins watch parts and I am not sure how to attached it to the anchor on the balance cock. Is there a tool I should use or is there a method that I can employ. Any help is appreciated Thanks.

-

Hi everyone, I have some problems with a manual winding watch. It needs some work but I would try to do it myself. The watch appears fully wound but it doesn't work. Which is the problem? Thank you in advance Alessandro

- 8 replies

-

- manual

- hairspring

-

(and 2 more)

Tagged with:

-

Hi all, I’m a new member and new to this ‘hobby’. This site seems to be where it’s happening. my very first attempt is with a BFG 866 which I have stripped cleaned and rebuilt. Not applied any oils or greases yet as I plan to do this a few times. However... I have noticed that the hairspring has come detached from the ‘cock’ plate? I cannot see nor find how this is reattached... is this broken? Any guidance is much appreciated. Thanks, Marc

-

I work a lot on small caliber (ladies watch size) movements but still have mishaps with the balance hairspring. These hairsprings are very fragile and easily bent and removing/replacing the balance assembly seems to be my problem. I would like any comments on the risks of deforming the hairspring by allowing the wheel to dangle during handling. I would also like to know if the position of the regulator arm/pins has any effect re risk of deforming the spring, should it be close to the stud or as far a possible from the stud, I normally leave it where I find it so the timing is close to what it was before dis-assembly. Any advice on techniques etc will be much appreciated.

-

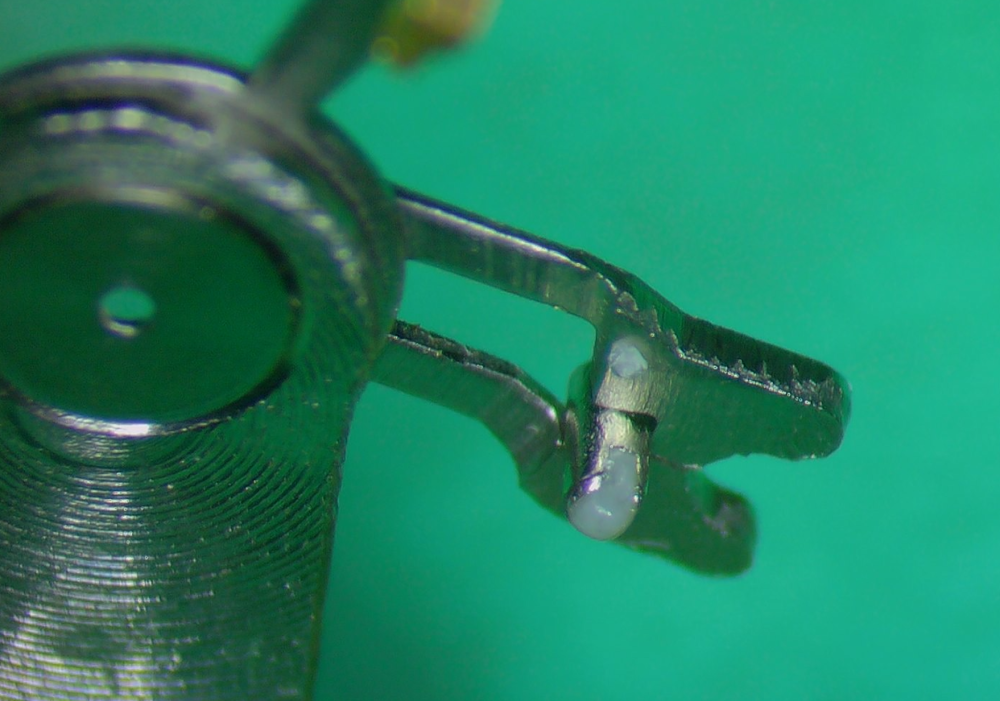

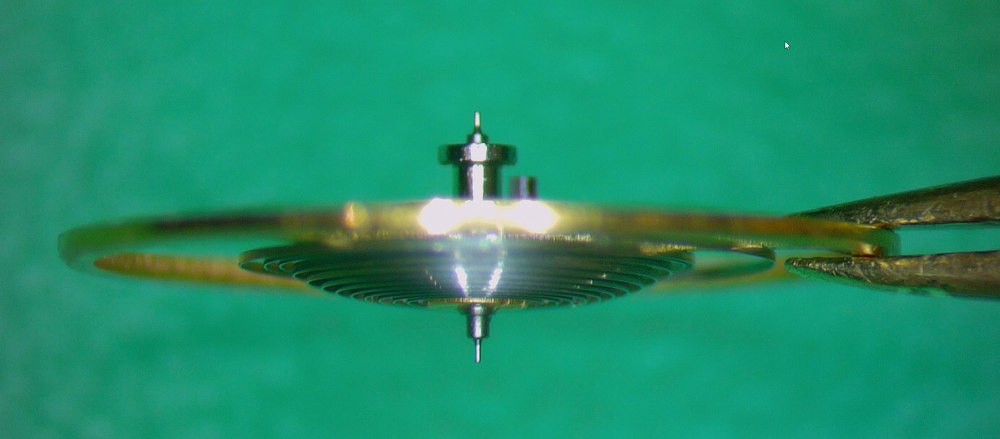

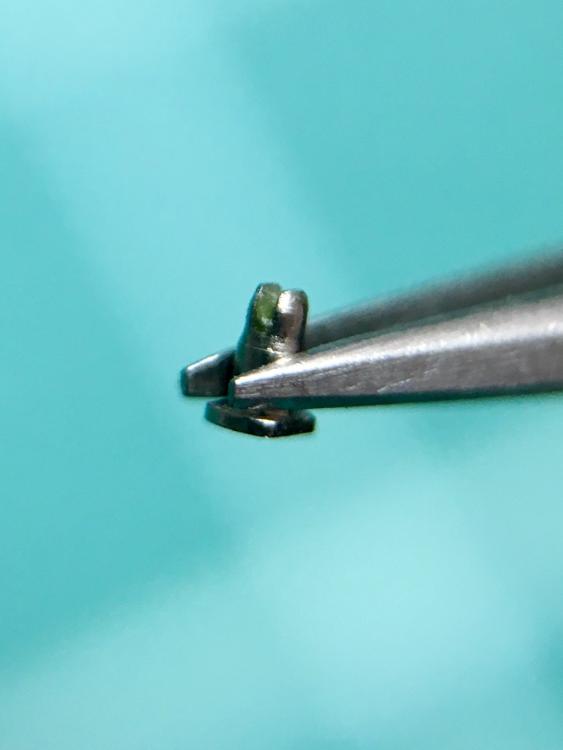

While disassembling a Unitas 6497 (or during subsequent reassembly) I slightly deformed the hairspring, and to fix it I removed the wheel from the balance cock and then the hairspring from the wheel. The balance cock is of the Etachron type, so the index pin is simply clipped into the stud support. The spring sits inside a notch on the underside of the pin, and is secured in place with some sort of gummy, flexible adhesive (instead of a tiny pin, as I've seen elsewhere). Anyway, I had a lot of trouble getting the spring stud back into the stud support, and after about an hour of man-handling the glue finally gave out and the spring came loose. Now I have a spring (in perfect condition, thank you very much!) and stud I need to reattach to each other. What kind of adhesive is this? What are some accepted ways of reattaching the spring? I saw someone on the internet use shellac, but 1) I don't think that was the correct thing to do (this stuff was flexible, and probably for a reason) and 2) I don't have shellac or know how to use it regardless. Thanks for reading, and thanks for any help you can offer! Here are some pictures to help visualize what I'm talking about:

-

Question for those who work on Vintage Timex watches: I've restored several Timex pieces from the late '60s to the late '70s. The technique I learned (from Internet posts and tutorials) say to simply loosen the dial-side balance pivot by unscrewing it 1/2 turn prior to cleaning the entire movement in an ultrasonic cleaner. This method contradicts the official Timex service manuals, which state that the balance should be removed, cleaned separately and reinstalled. Thus preventing the hairspring form being damaged in the ultrasonic cleaner. My experience is this: Leaving the balance in place (slightly loosened) is much easier and will work on the standard movements used in the '70s (M24/25, M32/33, M104, etc.) Attempting the same method on movements from the '50s and '60s (M22, M29, etc) will result in a kinked hairspring that is damn near impossible to un-kink. So my question is this: What do you experienced Timex restoration experts recommend? Leave the balance/hairspring in the movement for cleaning, or take it out to soak in a separate jar? Is the potential for hairspring damage greater when removing/reinstalling the balance - in comparison to leaving it in place? I've messed up a couple of vintage movements that I really wish I hadn't. I don't want to make those mistakes again. Thanks for any insights! -Todd

-

Hi again all, since there are some really knowledgeable people here I hope you can impart some wisdom regarding repairing a bent hair spring. after getting this old movement working again with the help of this group (new mainspring), I need a little more advice. after hooking this beaut up to watch-a-scope it shows low amplitude and very erratic trace. I can see the hairspring is bent and need to start here in addressing the issue. What tools are needed (not willing to spend £50 on hairspring levers at the moment)? I have basic tools (enough to service a movement), but what are the essentials for working on a hairspring? i.e for removing from a balance safely what tweezers types/sizes are recommended for correction etc. Also, is there an easy way to identify and obtain replacement hairsprings? I assume they are very interchangeable as it would not have been easy to make new hairsprings for every watch model.

- 26 replies

-

- felsa 690

- hairspring

-

(and 1 more)

Tagged with:

-

Is there a 'golden rule' relating to relocating a hairspring onto a balance staff with regards to getting zero beat error after it has been removed for attention. I usually take pics or use marker pen but sometime forget!

-

Hi all. I have a question about the fragility of hairsprings. I’m completely new to watch repair, and have started by regulating my mechanical watches (Seiko 7S26 and Orient F6922 movements). While adjusting the rate with a wooden dowel oriented parallel to the balance wheel, I have accidentally lightly grazed the hairspring. It was enough pressure to stop the balance wheel, but there appear to be no negative consequences. Both watches keep great time and have good positional accuracy. And according to my timegrapher the beat error and amplitude were not affected. So should I just chalk this up to good luck? Or could there be lurking damage I’m not seeing?

-

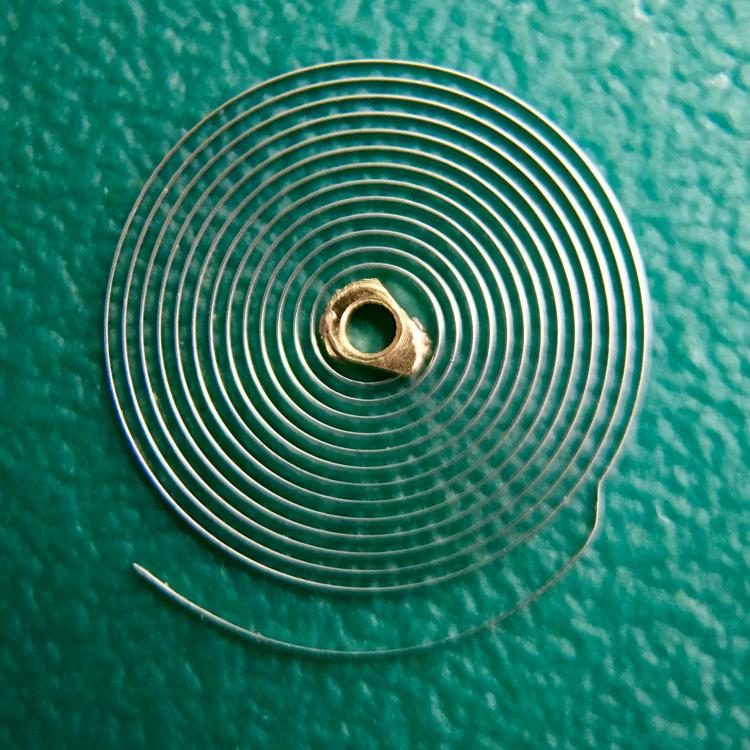

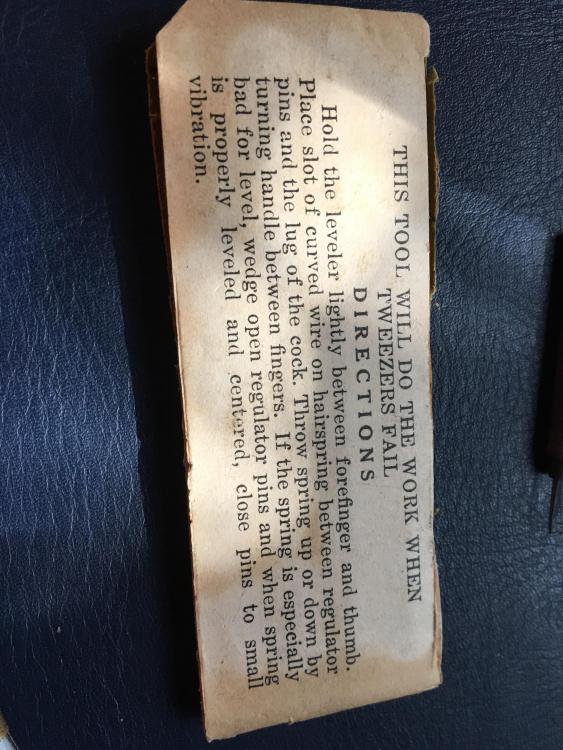

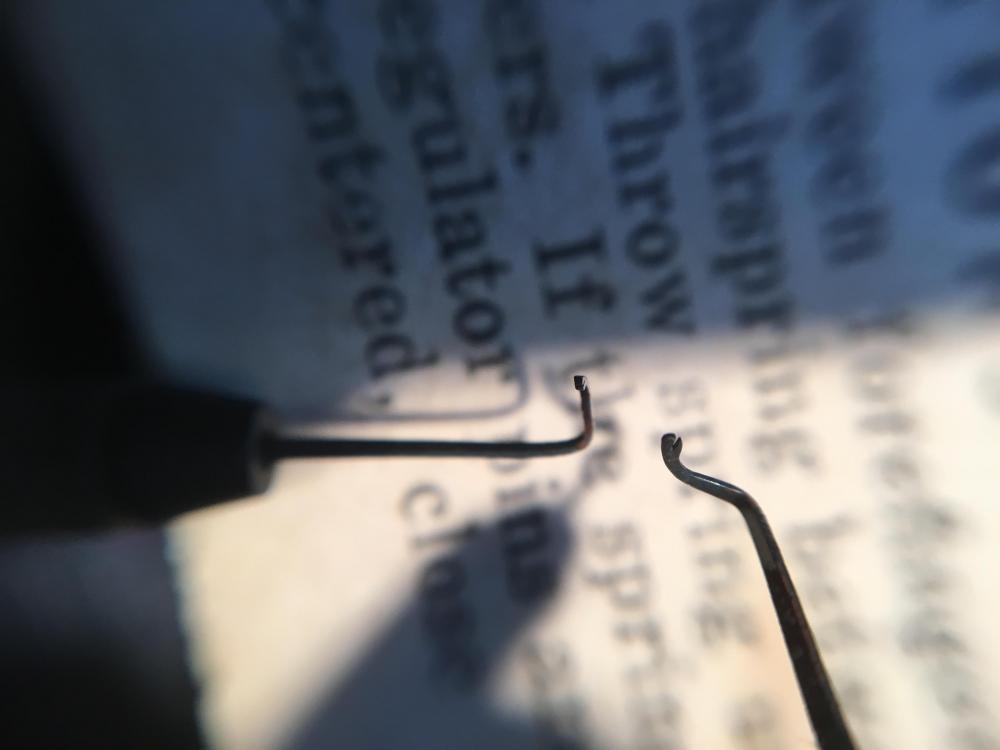

Dear all, I recently had the pleasure of finding a damaged hairspring needing care. My first! It’s an inexpensive orient watch, gaining 20 minutes a day. I am taking Mark’s fault finding course, and have other inexpensive hairsprings to practise with. I also got some vintage tools I’d love to use. Until now for me levellers were only the Oliver Cromwell people, but ebay never ceases to surprise... I could pass the first stages of correcting the coil, with two tweezers. But could not find a use for the vintage tools. Could you help me to figure it out? Picture 1 is the bent hairspring picture 2 and 3 the box of tas levellers picture 4 is the hairspring suffering under my tweezers now picture 5 shows the tip of the tools picture 6: from De Carle. Would this be the purpose of the levellers? The overcoil?

-

Hey, I'm on the lookout for a Hairpsring for a Hamilton cal 770. I've managed to find out that it's a Breguet made from Elinvar but that's about it. Does anybody know the parts number? If you also know where to get hold of one it would be very appreciated. Thanks! /A

-

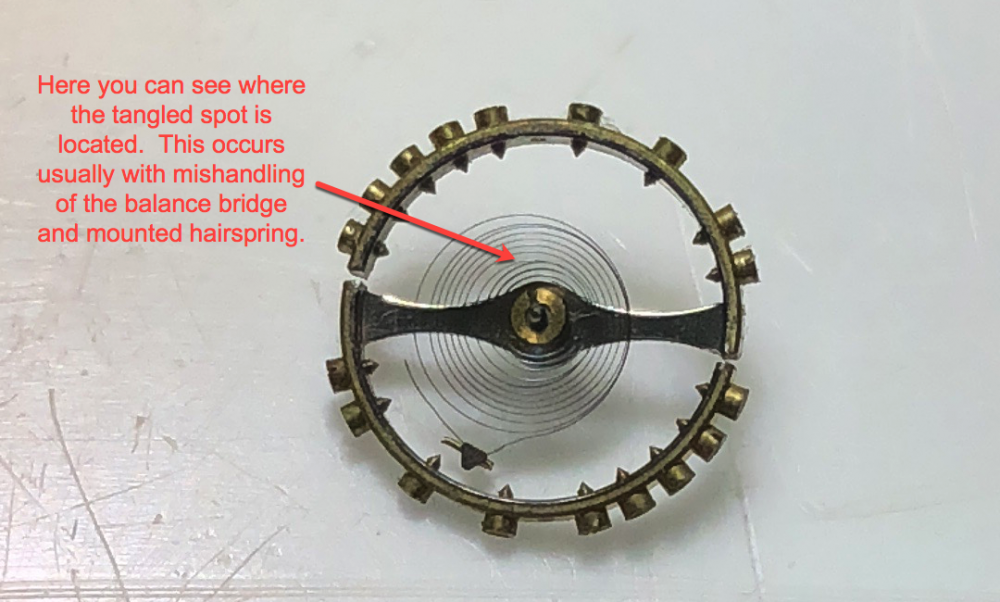

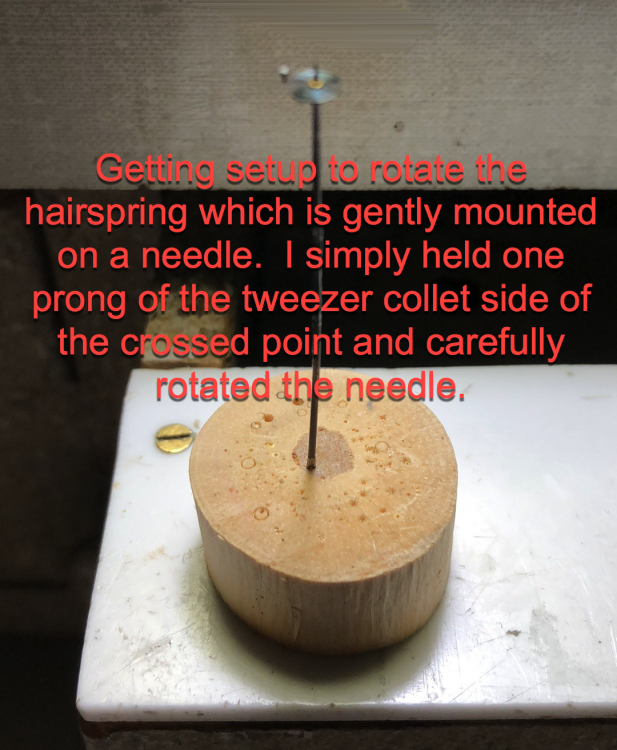

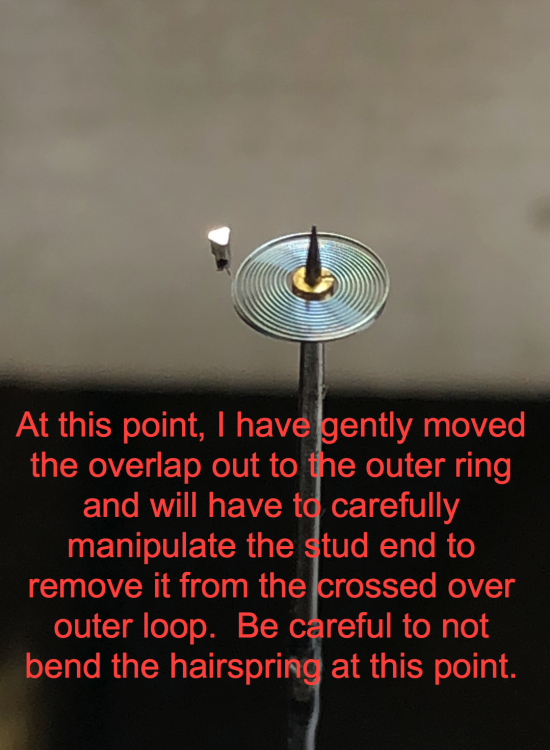

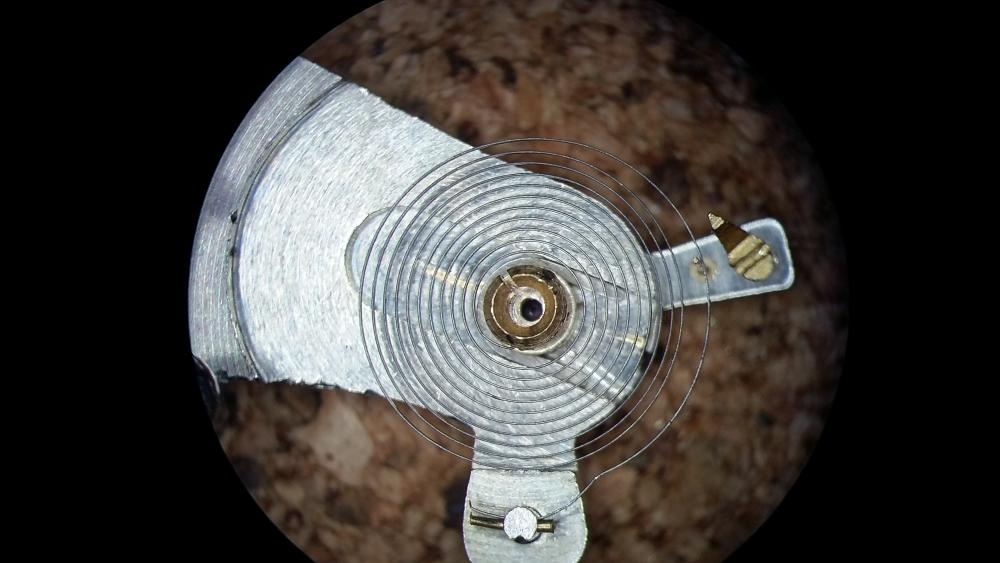

I received a lys Longines 5L for cleaning. Upon opening the case, I saw some surprises under the balance bridge. I have outlined my steps on how I uncoil a tangled hairspring in hopes that others can benefit by this method. George Corder IMG_0505.m4v

-

I need help with removing and then putting back in a hairspring that has a friction fit stud. I know there is a special tool one can use for this purpose. Does anyone have any pictures and know who might have made it? Can anyone "walk me through" how to remove and replace a hairspring without using the tool? Thanks!

-

I have a few old Vostok 24xx movements which seem perfectly fine except the the hairsprings are ruined. Most of these movements have come from eBay sold as “for parts or service”. So, my plan is to buy a few new balance wheels complete with hairsprings (like these) and replace them. (I just haven't got the tools or skills to just replace the hairspring). I have a pretty good idea about how to remove the hairspring stud (like this, or is there a better/easier way?), but how do I remove and re-fit the hairspring from the regulator arm? Can it just be lifted off and re-fitted with a tweezers, or do I need some special tool or procedure for this operation? I haven’t seen any instructions or videos about this, perhaps because it’s so easy or obvious? Well, at least that’s what I’m hoping!

-

Hello! So I was trying to work on the HS, like so I took a coaster from Ikea: and spare 1mm screwdriver blade and 2 pins: and I got:

-

Help please anyone. Having trouble getting a hairspring for the Rolex calibre 59. FHF30/ 30-1 is the base model but I cant find any listings. Is there another movement spring that is the same? Peter

-

Hello, I got this vintage medana pocket watch with MST 12 movement. When I opened them I saw broken hairspring. What should I do ? I´m very new to these watches, I need some help/advice.

- 9 replies

-

- watch

- pocket watch

-

(and 2 more)

Tagged with:

-

I think I have the kit to do this but how do I go about finding the right size staff to replace the broken one?

-

First, thank you all for your help. I’ve been reading several posts that have helped me since I first joined several weeks ago. I’ve been very fortunately the last year or so learning watch repair as a hobby. It’s been very rewarding and fun (as all of you know :P) A few months ago, I drunk bid, and won, this Zodiac Seawolf on eBay. It was supposedly running and then stopping after a short while (which was true). However, during disassembly I found it was missing the case tabs, hacking/stop lever, and most of the date mechanism parts. I was able to get it appart, cleaned, and luckily with a donor Aerospace GMT for the date parts, was able to get it back together and running. I put the balance in and the hairspring adjusted, I put the automatic winding mechanism on and the watch went completely out of adjustment. After removing the auto winding mechanism, I noticed that the hairspring was touching itself. So I removed the balance, made sure the hairspring was back in position, reinstalled it adjusted it, and after putting the auto parts back on it was running ok. Then I cased it, and again it went completely out of adjustment. I’ve been through this exercise several times now, and even tried with the balance from the Aerospace GMT donor I have with the same results. The last time, I tried to check that the rotor wasn’t hitting the balance, and it doesn’t appear that it is (at least I can’t see where it would be). I’ve demagnitized the movement and case several times too. I’m still missing the stop lever and one of the case tabs, but I wouldn’t think either of those would cause this kind of havoic on the balance. Does anyone have any guidance on what to look for which might be causing my balance(s) to go wonky? Below are pics. Original balance in: Everything looks ok and adjusted (not great but ok): Auto on: Everything still looks ok: Just about to case it and then decided to check one more time and hairspring look ok from what I can see. WOW Look at that shotgun scatter pattern: And it’s wonky again :pulling-hair-out:

- 15 replies

-

- balance

- hairspring

-

(and 2 more)

Tagged with:

-

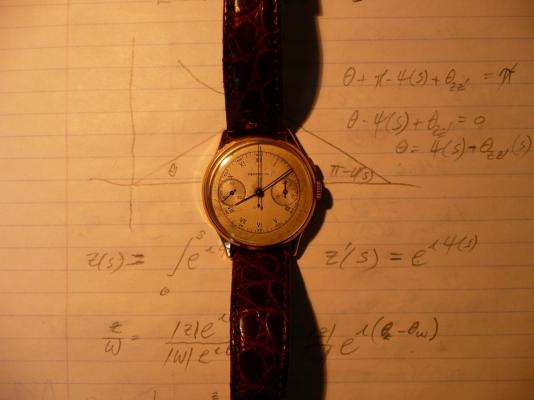

Here's picture of a WWII vintage chronograph I obtained c.1975. I think I paid $35 for it then--certainly less than $50. I actually wore it as a daily watch for many years. Then it started to run erratically so I put it in a drawer and let it "sleep" for about 10 years. In the late 90's I took it to a watchmaker in Chicago who said it could be restored, but it would cost! Even then something inside me--akin to a doctor's impulse to heal--wanted this watch to live. Besides, it has a nice rose gold case with the inscription "To Sid from Hank 1945 - 1946" on the back. So I let him do the work. It keeps great time. I'm not familiar with the Perfecta brand and I don't know who made the movement (anyone know about them?). The dial and hands are original. Please forgive the background! But part of the appeal of watchmaking is the theory behind horology. I've been working on the hairspring starting from a paper by S. Goudsmit and Ming-Chen Wan, Introduction to the Problem of the Isochronous Hairspring in the Journal of Applied Physics (December 1940). I tried working out the physics myself but without much success. The physics of the Archimedes Spiral is--one might say--non-trivial. There is at least one recent book out there which purports to work out the theory but it's really expensive. I also have Charles Edgar Fritts book, The Balance Spring. It's very complete and has a lot of practical information but its kind of densely written--requiring a lot of close study--but no mathematics. Moreover it requires an understanding of some of its figures and I've never been good at (actually patient with) drawings, especially 19th century drawings. (Can anyone explain to me Fig. 4?) I'm fascinated with the idea of building a computer program that would locate graphically the point where a hairspring could be vibrated. My impression is that experienced watchmakers can often get very close by visual inspection, but for beginners like myself it would be very helpful if we could see such points for a lot of different hairsprings. So, I've been using Mathematica along with its graphical processing functions to work from pictures of hairsprings. Once I know the spring constant it should be possible, using the physics of the spiral, to work out such points mathematically--numerically, at least. It goes like this: first, take a picture of your hairspring against a background of some standard hue. Then use graphical processing to pull out the pixels of the hairspring, assign them coordinates, fitting them to a mathematical spiral and use the theory to locate the vibration point, which can then be plotted on the same picture. That's the plan anyway but it may not be possible for reasons I haven't yet understood.

- 6 replies

-

- Perfecta

- hairspring

-

(and 1 more)

Tagged with:

-

Another excellent video produced by the Litiz Watch Technicum on adjusting a hairspring correctly. Very video on their YT Channel is worth watching, and this latest one is no exception. https://www.youtube.com/watch?v=4EYk787sjAM