Search the Community

Showing results for tags 'dial feet'.

-

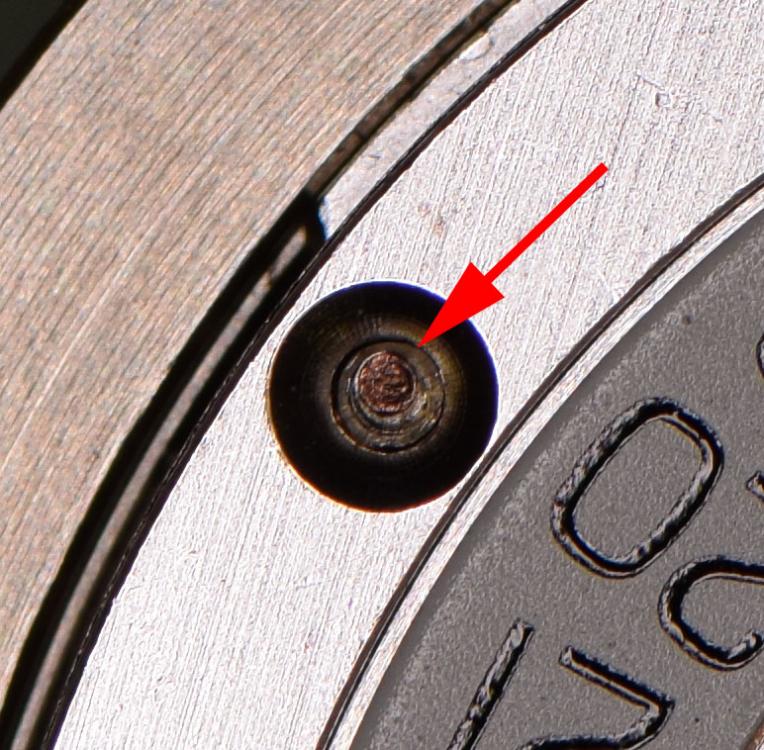

Morning everyone, I have the following Seiko 7009A watch with a huge amount of rust damage: I took this on as a personal challenge, I have a question regarding the dial feet retaining screws, these are the eccentric screw type: One of these feet has rusted and crumbled away to nothing, leaving a hole where it should be. Anyone have any experience on how to replace these? I have a donor movement so I can find the part, but need help/advice on how to install it. Or is there another method I can use to secure the dial? Dial dots etc will not work as they will fowl the day/date discs.

-

Does anyone have any experience using a dial foot welder/solder machine? I know Mark has a video on this subject, but I was wondering if anyone uses one regularly and can provide some advice and hints/tips based on their experience. For someone at my level and not Marks. Currently I have been using a hand milling tool (see picture below) to cut a small round recess in the back of a dial and then glue on replacement feet. However I have the following issues: - The dial foot mill has a small point to center the cutting blade in the right position on the back of the dial, but this can cause dimples on the dial face. I have tried removing the point, but this causes the blade to wander and is useless. - I have tried 2 part epoxy, and superglue to affix the dial feet, but the feet pop off with minimal force. I have also tried scoring the surfaces to increase the bond surface area with each type of adhesive, with little/no improvement. This is the reason I am looking at a welding machine, my main concerns are: - Can the heat scorch/damage the paint or finish on the dial face? - how difficult is it to prepare the new feet prior and during the soldering process? - any recommendations on soldering compounds/flux/???? - what are good settings for the machine Any links to machines etc and any hints/tips/cautions greatly appreciated. My current tool:

-

A friend of mine handed me a watch last night that he is going to gift to his wife for Christmas , but it is running very slow, losing >>5 mins every hour. I took it home last night and after applying a full wind I placed it on my timegrapher in multiple orientations expecting to see a mess, but it was running very sweet, 0.1 ms beat error and rate was only a second or two out per day. I can't recall the figure for the amplitude, but I remember thinking it was respectable at the time. Unfortunately, I had a family drama so couldn't investigate further at the time, so I placed it on my auto winder and tried to deal with the family...! A quick glance this morning at it spinning away on the winder before heading out to work revealed that it was several hours out, thinking about it on my half hour drive to work with the other very courteous and considerate drivers I had a flash of inspiration, perhaps the dial is off center and causing friction on the hands? If my theory is correct about the dial, I think I need to bend the feet slightly to re-position the dial to align better with the center of the watch - from what I remember, I should bend the feet in the opposite direction of the tight spot? Can anyone think of any other reasons or things I should look for, or let me know if they think my explanation for the problem is on the right track and if so my proposed fix is the correct approach/method.

-

A work colleague asked me to have a look at his Ebel 1911 Discovery (ETA 7750). The hour counting hand was floating around in the case. Loupe inspection showed that the post was broken off in the hand - so before starting I ordered a replacement hour counting wheel. When I opened the case I found the dial was not attached - it was sliding around under the hands. Removal showed that both dial feet were broken off. Time to break out my dial foot soldering machine. Here's a video showing the technique. Enjoy!

-

I've scoured the usual sources, including the ETA Customer Service site, but I can't seem to find a cross reference for the dial feet locations on an ETA 2783 compared with the 2824 or 2836 movements. Many aftermarket dials are advertised as fitting these latter movements and if I can determine whether the location and diameter of their dial holes match my 2783, then I'm sure to succeed with an aftermarket dial. The dial feet holes on the 2783 are at (eye-balling) 11 minutes and 41 minutes, and center-to-center diameter of 24.0mm. Any suggestions for a data source? Anyone have a 2824 or 2836 sitting on their bench and their calipers close at hand and bounce me a reply with a measurement as above? Thanks as always.