Search the Community

Showing results for tags 'bergeon'.

-

Bergeon Platax No. 2677 How to Guide.pdf Bergeon Platax No. 2677.pdf Background In the old days, before shock protection, I’m sure replacing balance staffs was one of the most common tasks for a watch repairer. They probably replaced several staffs every day. There are many ways to remove a balance staff. One very convenient and quick method is to use a Platax tool. However, this method is considered a destructive method by some repairers, meaning you can only replace the balance staff so many times before the hole in the centre of the balance wheel will become too wide. You can read a more about it here. I guess I would think twice or trice before using use a Platax tool on a Philippe Dufour balance. Anyway, for my standard ETA, Sellita, Unitas, Vostok, etc. balances I have no reservations about using a Platax tool. One dilemma with the Platax tool is that it has been discontinued by Bergeon (No. 2677). The offerings on eBay are few and far between, and as with everything else Bergeon, they are silly expensive. I would feel a bit embarrassed to let you know what I paid for my used copy which probably has seen hundreds if not thousands balance staffs in its life. Anyway, as with most everything else Bergeon, the quality of the tool is second to none, so I’m pretty sure I’d get my money back (if not more) should I decide to sell it in the future. That’s a major benefit with quality tools which makes it a lot easier to pull the trigger. So, how often do I expect to use this tool? Well, as all my watches so far have been equipped with shock protection and as I expect most future watches that I’ll be working on will be as well, the answer is, not very often. As a matter of fact, I expect it to be so rare that I might forget how to use my Platax tool when I need it the next time. For this reason, I decided to document my findings and that is what you’ll find in the attached PDF document. Do note that the document isn’t a tutorial, it is my personal notes, gathered from watching two YouTube videos (see below) and my own thinking and experimenting. For this reason, it is possible I got something backwards. If so, please let me know!

-

- 5

-

-

-

- 2677

- balance staff

-

(and 3 more)

Tagged with:

-

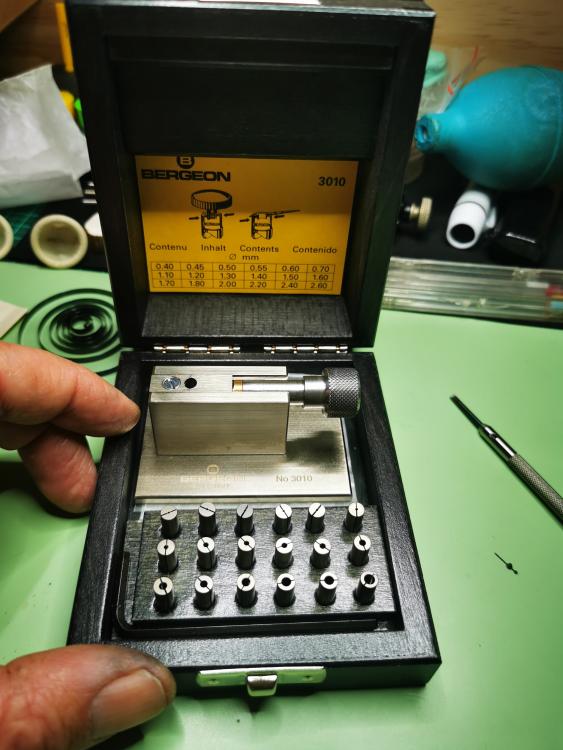

This is a great tool for tightening pipe hands on vintage watches and especially the centre seconds hands on 7750 chrono and reshape centre seconds hands on seiko 6138 and 6319 movements so you can repush hands on back at zero. Even short pipe. Just pick a collet, place it into the tightener and turn screw slowly, rotate hand and repeat. And presto you can now push tight hands back on. From .4mm to 2.6mm

-

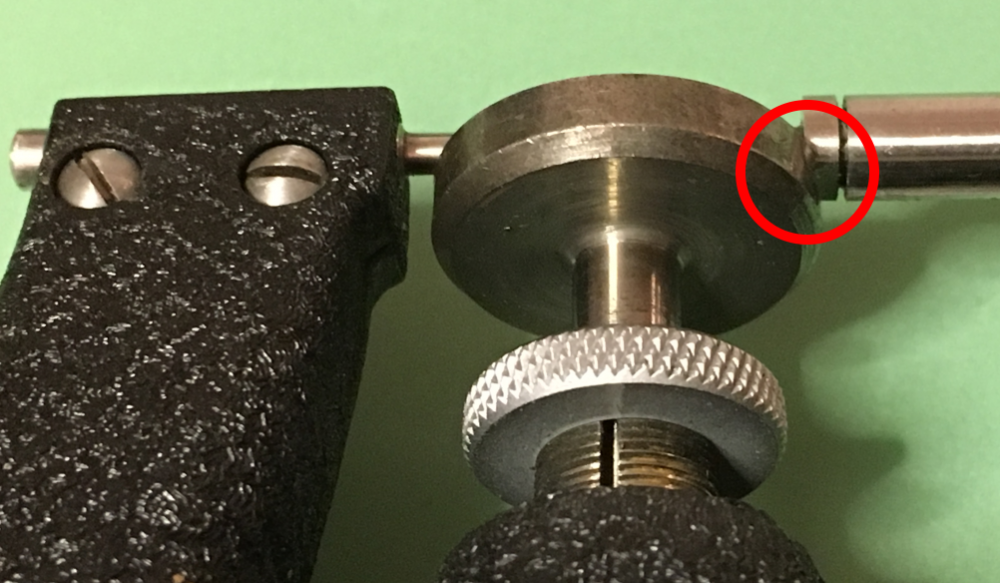

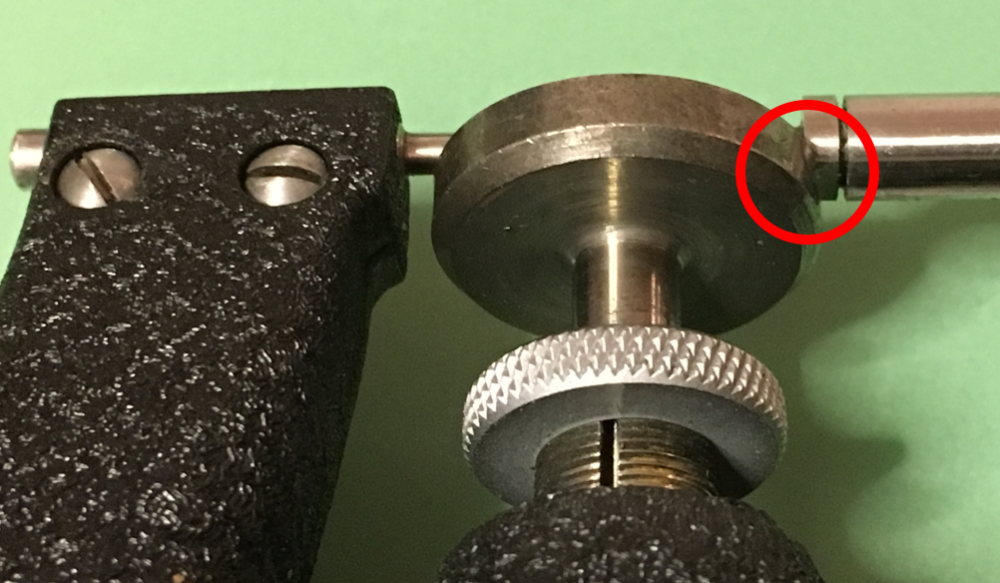

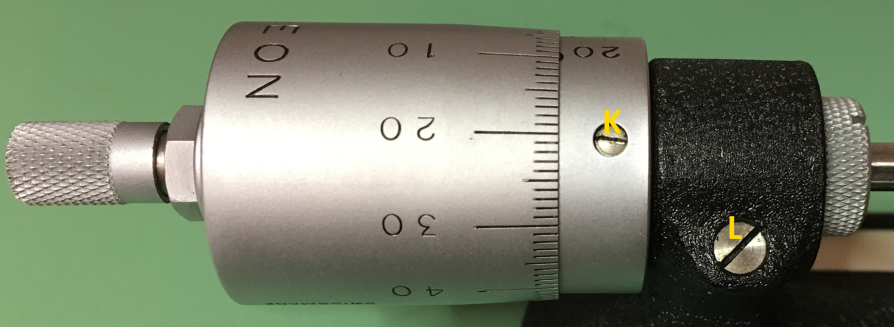

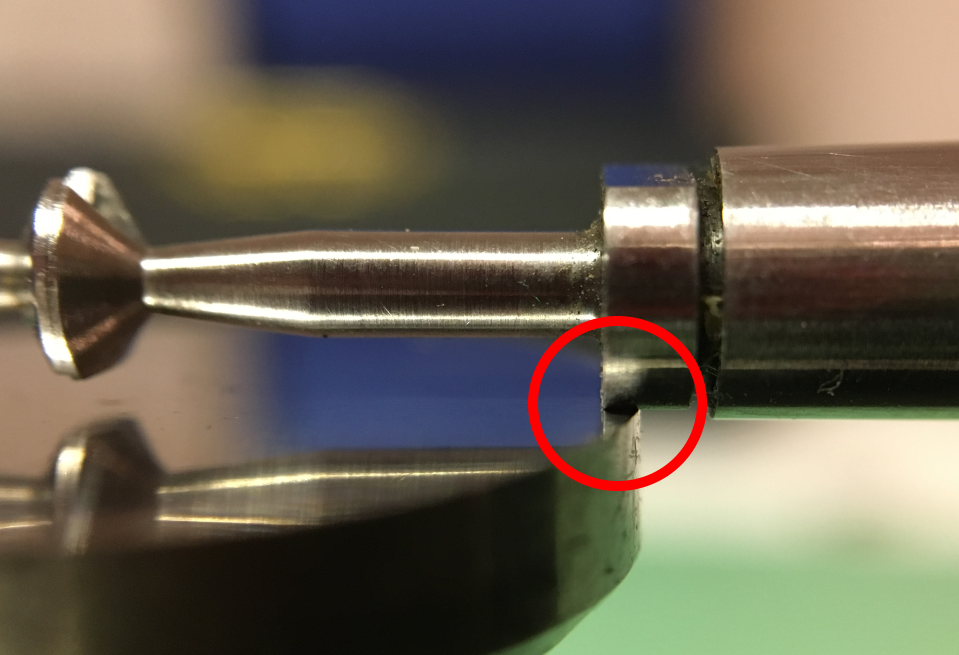

Some time ago I bought a Bergeon micrometre (and a Seitz jewelling tool) to be able to replace damaged jewels. The micrometre works perfectly down to the exact hundredth of a millimetre but trying to measure my first jewel I bumped into a very unexpected problem; the height adjustable round table fouls the spindle (circled in red). I don’t think, or rather I hope, that the micrometre isn’t out of order and can be adjusted so that the spindle does not bump into the table. But searching high and low I just can’t find any documentation or user manual for this type of micrometre. Being a hobbyist having spent a small fortune on these tools, this situation is very frustrating. So, the question is, what can I do to adjust my micrometre? As I have no clue what the various parts of the micrometre are named, I have given the various parts in the pictures a letter (in yellow) so that if anyone who knows how do this (and takes pity on me ) more easily can guide me. Keeping my fingers crossed. Hard!

-

I probably thought about it for a year, before pulling the trigger on a Bergeon 4854 Cannon Pinion Remover, thinking expensive but that it would be the ultimate tool for the job. Especially so having seen Mark Lovick use this tool in his videos, for example this video. Well, it certainly didn’t work out the way I was expecting. It simply won’t pull the cannon pinion. I’ve recorded a video of it here. I don’t think I’m doing anything wrong, and I don’t think the remover has any parts missing as I took it apart in an attempt to figure out how it works. It seems to be a simple enough design to understand. Anyway, I guess I could be wrong about that, and if so please let me know! When looking at Mark Lovick’s video the design of the tool (the grabbing part) looks different from my copy of the tool. I guess Bergeon changed the design and unfortunately into something that just doesn’t work, but I agree, that doesn’t sound very plausible. Well, I’m more than puzzled! What should I do?

-

Hi All, Thought id share this weeks tool purchase. My case cushion i've been using for a while now has become a bit worn and the cushion itself seems to have shrunk a little, leaving a gap between it and the base - so the odd screw or part disappears! So i thought id try one of these new Gel cushions from Bergeon, but as usual with anything Bergeon it wasn't cheap. Retails for about £26 including VAT (this is the larger one, there is a smaller for a few pounds less) but i have to say i'm really happy with it, so would recommend one.

-

So I picked up this bad boy on eBay from someone in Spain. It's pretty messed up cosmetically, and missing a heeled bush and a removing punch. Considering all that, I definitely overpaid, but oh well. I don't know how rare these are to find on eBay, so I just decided to grab it. I scraped off all the old flaking paint and found a very similar color paint at Michaels. Not a very professional job and you can see some brush strokes, but all in all it's much better. I know the colors look off in the pictures, but that's a camera white balance issue. In real life the colors are very similar... a completely unattractive greenish gray oatmeal. Why Bergeon used this color I'll never know. Carefully removed the rust from the metal plate with steel wool and very very fine sandpaper. Did the same with the punches and bushes which had a nice coat of oxidation on them, then put them through the ultrasonic like they were watch parts. The original chrome plating had worn away on the top knurled nut, but not to fear! I busted out my little Caswell "Plug N Plate" kit and used "copy chrome" (real chrome plating is dangerous and pretty toxic apparently, but I can't see much of a difference between old chrome plate and Caswell's 'copy chrome' - looks about the same). The biggest unknown was if I could find replacement punches / bushes and yep! I just ordered them from perrinwatchparts.com... they were super expensive. I definitely overpaid for these, but again, oh well. I just wanted the tool to be complete. So ta da! I now have a Platax tool. I'm going to break out one of my many Bulova movements with a broken staff and experiment with using this tool on the poor thing. I don't know the I really needed this tool, per se. I have a nutcracker - type roller remover which works pretty well (I might have broken a few staffs by squeezing a little too much, but those staffs were broken anyway), and I have the little K & D balance remover tools for my staking set. I don't see how the Platax tool would be so so much better than the K & D tool, and I'd imagine any objections or concerns about the K & D tool widening the hole in the balance by using force instead of cutting out the old staff would also apply to the Platax tool, no? It also uses force to drive out the old staff while keeping the balance arms pinned. So maybe I didn't strictly need this, but when it popped up on eBay I couldn't resist, because I want to be able to follow along with what Mark does as closely as possible... and I'm still so new at doing this. So, now I have a Platax tool, a complete 'inverto' K & D staking set (got for under $100, go eBay!), and just picked up a Seitz Jeweling tool (ouch, that was too expensive). I am now wondering what other real watchmaker specific tools you need to have to be able to deal with most, if certainly not all, the issues you find on vintage watch movements ??? I mean, I'm not going to buy an old mechanical watch washer and put it in my one bedroom apartment in manhattan, not going to happen (at least, not if I don't want my husband to divorce me ). So I make do with a tiny, cheap Chinese made ultrasonic machine. And obviously, I'm not going to buy a lathe either, for similar reasons (space constraints, expense, plus wouldn't know how to even begin to use it)... but I'm wondering if I've covered almost everything else? In terms of being able to make watch parts, yeah, that's the holy grail. Living in manhattan comes with many advantages and disadvantages. The disadvantages are obviously space constraints and expense of living. But the advantages are there are lots and lots of resources. In fact, there are a few "Maker Spaces" in the city, which are co-ops you can join and you can use their tools, like CNC mills, CNC lathes, 3D printers, 3D scanners etc etc... you can join these co ops for not much money, and they teach you how to use the tools.... I know that the consensus so far is that 3D printing watch parts won't work, because the machines are not accurate enough on such a small scale. But the CNC lathes? The CNC mills? Could they do micro-machining, in theory? It's something to think about. I think I'll create another thread about that sometime. Maybe I can pick up some good tips. Anyway, hooray for overpriced watch tools! They are so much fun!

-

Just recently i have been rather busy with a large intake of repairs & servicing, i figured since ive worked so hard ( and yet still have more to do ) id treat myself to another tool. I know i don't really need it but i do like Bergeon tools and this one i picked up is in mint condition with original box. I normally use my Bergeon staking set but this will make a nice addition to my growing collection. Sad that a new tool makes me excited, or are you guys like me ? Next on my list is the Bergeon hairspring collet tightening tool :) Hopefully i should have some nice watch photos to upload over the coming weeks as i have had an Omega repair frenzy including a rather battered Omega RAF 1953 Cal 283 and also a return of a personal favourite 1956/58 Seamaster, and not forgetting a complete restoration of a Tudor Oyster Princess :D

- 41 replies

-

- 5

-

-

- canon pinion

- bergeon

-

(and 1 more)

Tagged with:

-

Hi Guys, Found this article on the new premium screwdrivers being offered by Bergeon ... nice piece of kit. Can't find them to buy online yet, so I have no idea of the price; but I expect it will be shocking :P Here's the link: http://www.jewelrytraderesources.com/2014/07/02/bergeon-7965-watchmakers-screwdriver-special-knurled-profile/