Search the Community

Showing results for tags 'Assembly'.

-

Hi. I have this Geneva clock which wasn't working for a long time. I decided to open it change it's battery and put back second arrow which fell of. I opened clock and tipped insides and gears fell of. I don't know how they were placed and know nothing about watches. I hope you can help me. These are parts that fell of. Thanks

-

Good day to you all. I'm deciding to ask for help because I really can't manage it by myself. For the life of me I cannot understand how to set the balance assembly back into position after having replaced a broken escape wheel. I'm working on a Lanco/Tissot 782-1 movement, I had already removed/replaced the balance before and I haven't had any issue. Now I just can't seem to get the balance oscillation working. The wheel seems to stick or isn't turning freely. I have spare parts and checked 2 or 3 different balances, I checked the staff & its pivot which are not broken, the roller jewel isn't broken either, the balance pivot hole is not clogged nor does it seem widened, and the pallet is in working order (I checked the escapement by arming the mainspring a couple of clicks then manually oscillating the pallet with a wood pick, everything runs perfectly). So it seems the rest of the movement is okay, the issue lies with how to place the balance back into position. I checked lots of tutorials & videos, Mark's included and I'm always quite astonished when I see how watchmakers and repairmen handle the balance, even if the hairspring is fragile even professionals seem to handle that part somewhat roughly. I take the greatest care when manipulating that part (and others) but no matter how I set the wheel&pivot back, the movement doesn't seem to run. Is there something I'm missing? Should the pallet be positioned specifically when replacing the balance? Should the roller jewel be placed in a specific setting versus the pallet fork as well? Everytime I tried before those things didn't seem to make a difference, so I'm really wondering what's wrong here, considering I tried several balances with different plates and different pallets, I can't understand where the issue is. I guess my question is: as tutorials don't usually give out many details about how to lay a balance back down into the plate, what should I take into account and what are the exact right steps to perform to ensure the balance will run smoothly ? Thanks for your help, I'm getting desperate here :-/ Laurent AKA HardTop

-

I recently bought an old stopwatch from the USSR, I bought it on eBay and it said it was missing parts. I can't figure out what they are. I figured out how to reassemble, but it doesn't tick. There doesn't seem to be a mainspring and I don't know where one would be. Does anyone know how stopwatches work and how they tick without mainspring? There is this pendulum which makes everything move when I ticks. How does it swing, what force is pushing? Thanks for any help. Photo:

-

I've already broken two escape wheels when assembling a watch (i broke the tiny little top on top of the stem). It happens when i try to place back the train wheel bridge. Placing the bridge back is for me the hardest part when assembling a watch. Am i doing something wrong ( or am i just clumsy) or is there just a nice trick to do it? Any help appreciated! Grtz, Gert

-

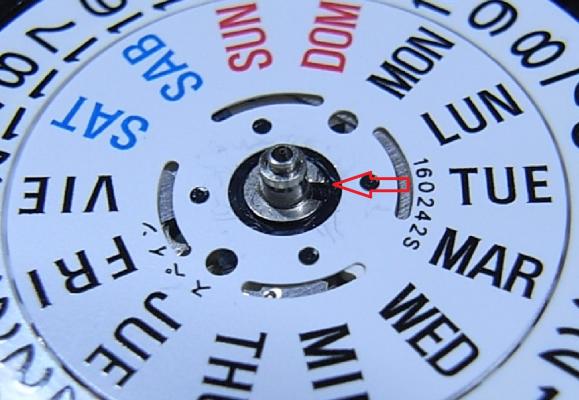

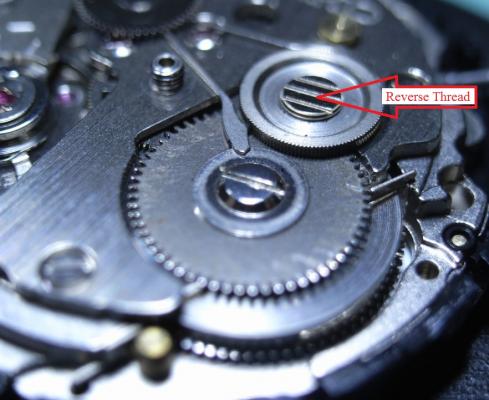

Seiko 7S26A Complete Service Background I have a good friend, a brother in Christ Jesus, who I've known for many years. He knows I've embarked on retraining myself for a new career in Watchmaking, and seen my first two restored watches. He told me that his old faithful Seiko 5, which he's worn everyday for 12 years, has recently had issues. Occasionally it will advance rapidly in time (up to an hour in a few seconds) and then just keep ticking away normally. I told him I'd be happy to take a look at it, and put it on my ACEtimer Timegrapher. The pattern on the screen looked like a B-52 drop in Nam (stupid me forgot to take a photo), and I told him that his watch definitely needed an inspection and service. So started my research on what the problem might be. After reading a "Practical Watchmaking", and the many forums that I've read, I was pretty sure it was the Pallet Fork ... either very dirty or damaged stones, or a broken/damaged fork pivot. So onward to the service... Disassembly One unusual aspect of this watch is the crown ... or lack there of, more to the point. I suppose since this is an automatic watch, they thought it didn't need to be wound. This watch also has a display back, so extra special care not to mark any of the plates, or damage screw heads! The first issue you'll face when working on a 7S26A Movement, is how to get the stem out! It isn't obvious at all, and there is a little trick. The crown needs to be pushed all the way in to expose the push plate (it is hidden in the other crown positions). I took this photo once the movement was out to best illustrate where to push. Remove the Hands, Dial and Oscillating Weight (2.0mm Screwdriver). Gently lever up one end of the circlip and carefully work your way around. You then should be able to raise the circlip up the length of the shaft without it pinging off. Remove the Day Wheel and the four screws holding the Date Dial Guard. (Use a 1.40mm Screwdriver, and this driver is good of all the screws from now on; bar one.) NOTE ORANGE ARROW: Seiko Special Tool needed for the 0.98mm Philipshead Screw (Part Number: S-921) I had to journey down to my nearest Seiko Distributor and grab one ... cost was AU$24.00 Here's a closer look at the troublesome screw. Remove Date Jumper, and note that the Date Drivewheel lips over the top of the plate. Remove all the motion work, and pull the Cannon Pinion Remove the tension from the Mainspring. Remove the Ratchet Wheel and the Second Reduction Wheel and Pinion. (remember the Reduction Wheel has a reverse thread) Unscrew the Balance Cock and remove the Balance. Also unscrew the Pellet Cock and remove the Pellet Fork. BINGO! Found the problem with my friends watch. The top pivot on the fork is broken. Easy fix with a replacement fork :) Remove the Barrel/Train Wheel Bridge Remove the Click, then the Barrel. Remove the Fourth Wheel, Third Wheel and Escapement. Unscrew the Centre Wheel Bridge and remove the Centre Wheel Now to the Keyless Work. Remove the Setting Lever Spring Remove the Yoke and the Setting Lever Pull the Stem out, and the Clutch and Intermediate Wheel will fall away. Lastly, pull the black plastic location ring off. ... and now it's bath time!!! I hope this has been of help to you guys. I'll post the Assembly steps in this thread tomorrow morning.

- 94 replies

-

- 12

-

-

Hello, Hi Newbie here with my first attempt at watch repair. I just cleaned and disassembled my speedmaster (model 3513.53) 7750 movement having watched the breitling 7750 youtube videos, studied some walkthroughs and also the ETA assembly sheets but am having some problems re-assembling and getting it functioning. I installed all the (new; complete assembly) mainspring, train gear, the bridge, the ratchet wheel and then check by rotating the ratchet wheel whereupon a little a satisfying whirring noise occurs as all the wheels freely spin indicating that they are correctly installed. I install the (new) pallet fork and the bridge for that and it freely moves. Then I install the balance wheel, carefully and several times now but it doesn't enthusiastically oscillate like I see in all the youtube videos the momen it's installed. If I give it a nudge it moves seemingly freely and the pallet fork/escapement wheel moves back and forth but only for half a second then it stops. So I think there's not enough power from the (new; complete assembly) mainspring (same thing happened with the old mainspring)and give it some winds then inevitably the click spring pings out of the ratchet wheel teeth and unwinds the crown/mainspring rapidly (I have now damaged 2 escapement wheels in the process, snapping off their location pins) One time I physically held the click spring against the ratchet wheel so that it couldn't ping out, wound the watch a few times (maybe 10 turns) and got a few seconds of oscillation from the balance wheel but knew that the moment I stopped holding the click spring it would just ping out again! I notice now on ebay someone is actually selling a 7750 movement but with the click spring actually soldered (!) in place presumably to stop it pinging out like mine! I am trying to persevere and repair this watch myself despite this so joined this forum!!! I've tried assembly about 5 times with this now but can't get past it. Any ideas? Thanks.

- 8 replies

-

- 7750

- click spring

-

(and 3 more)

Tagged with: