Search the Community

Showing results for tags 'walkthrough'.

-

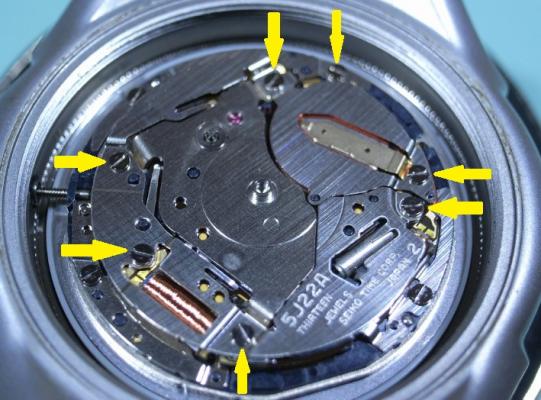

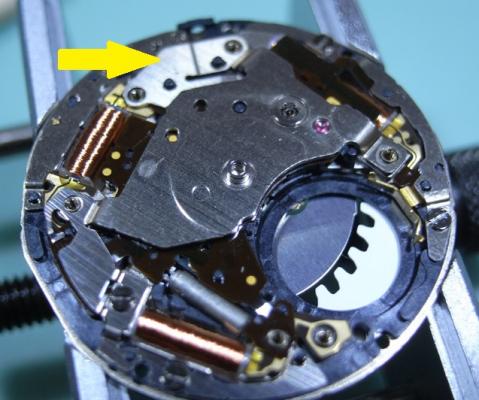

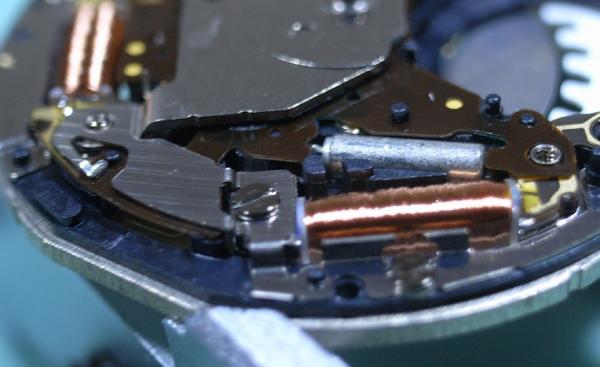

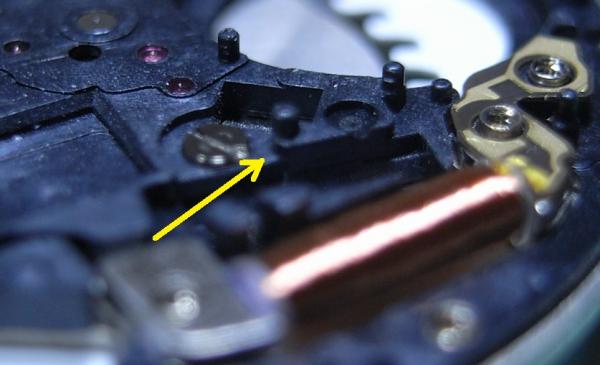

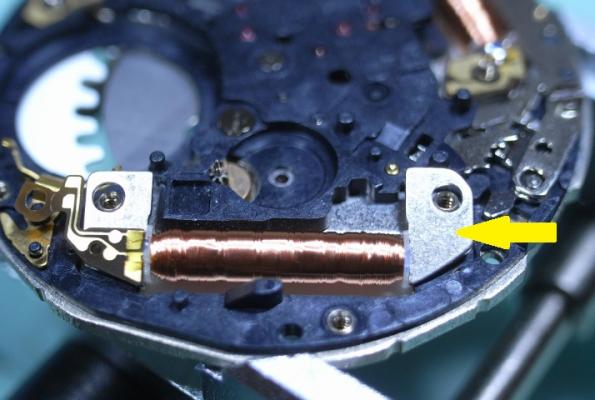

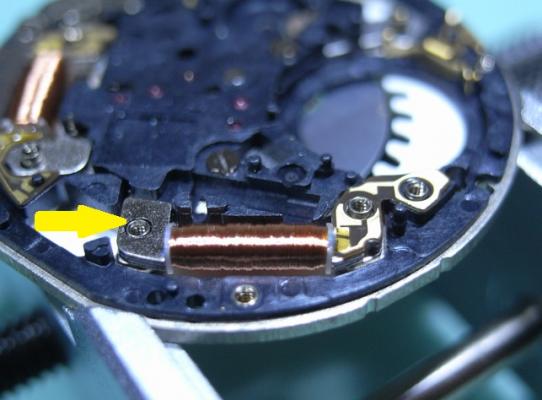

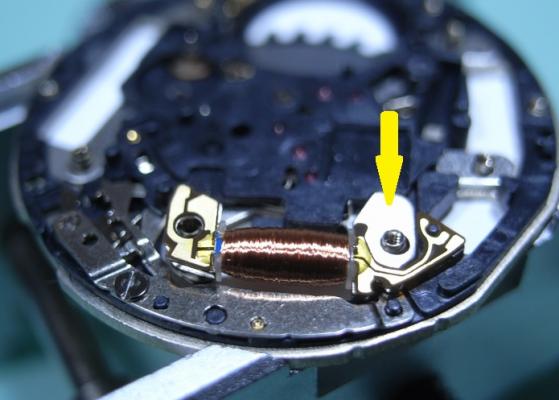

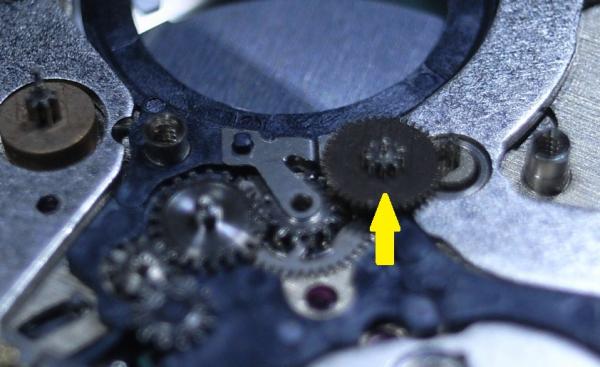

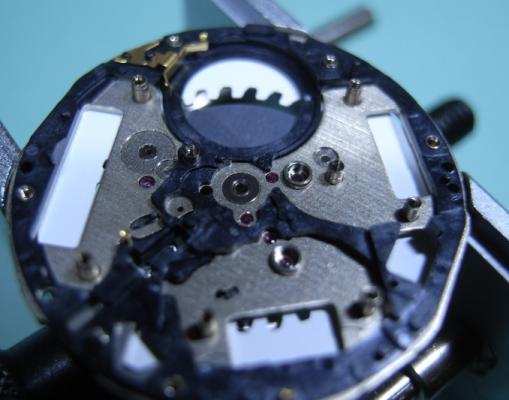

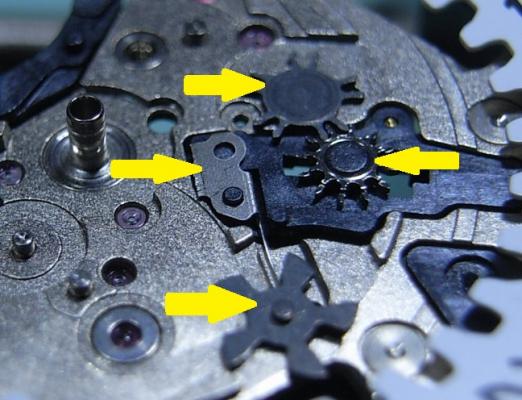

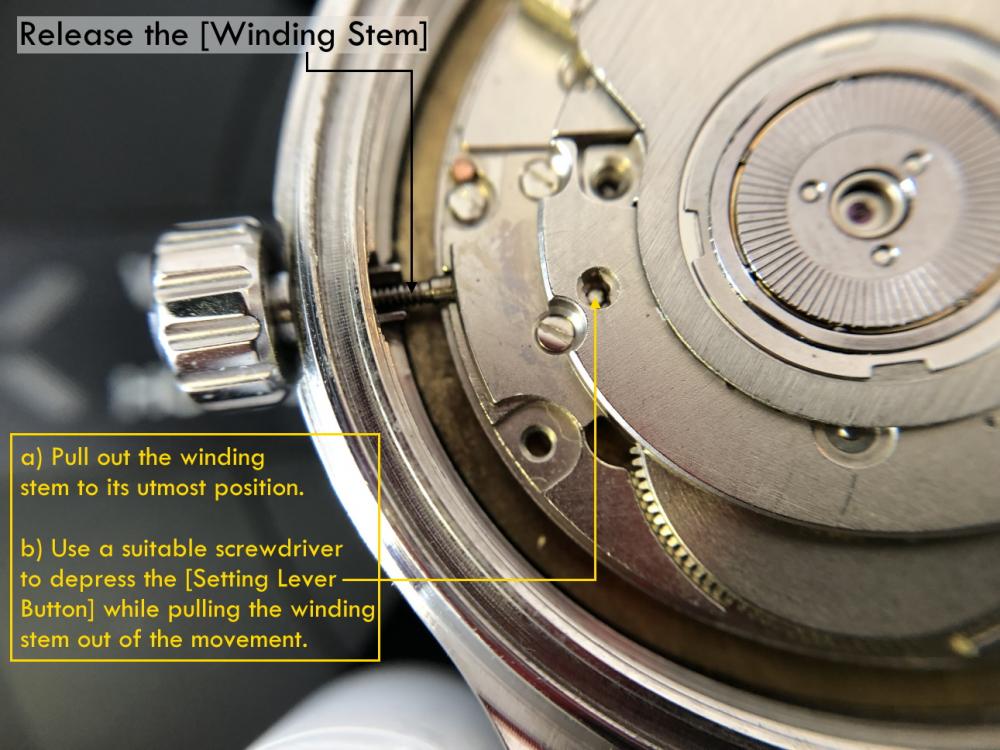

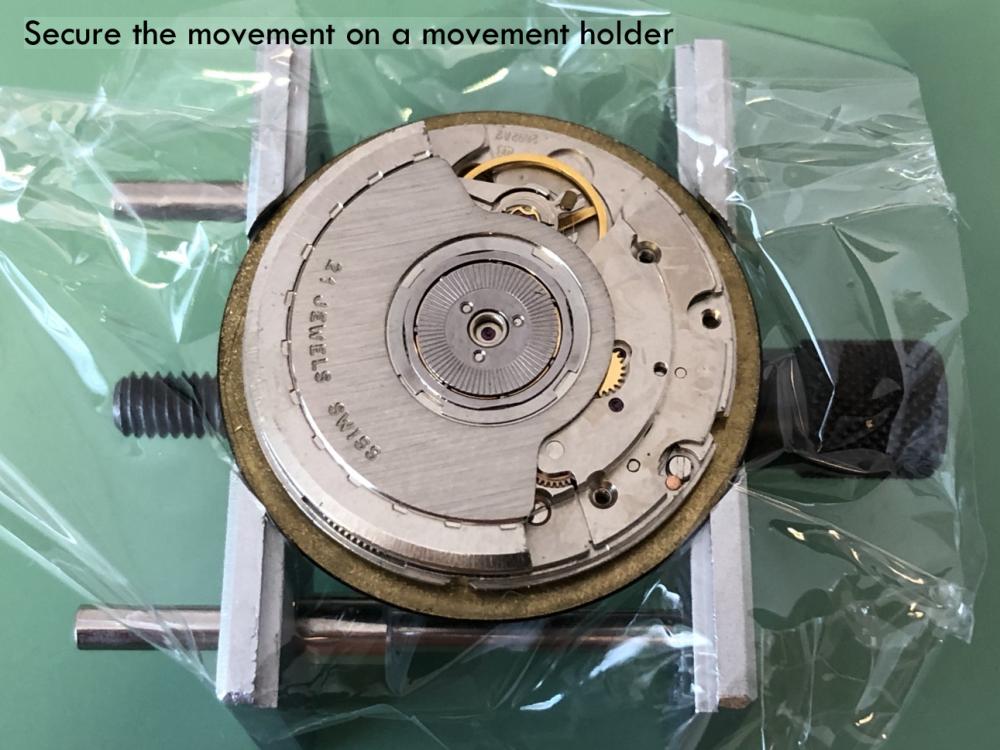

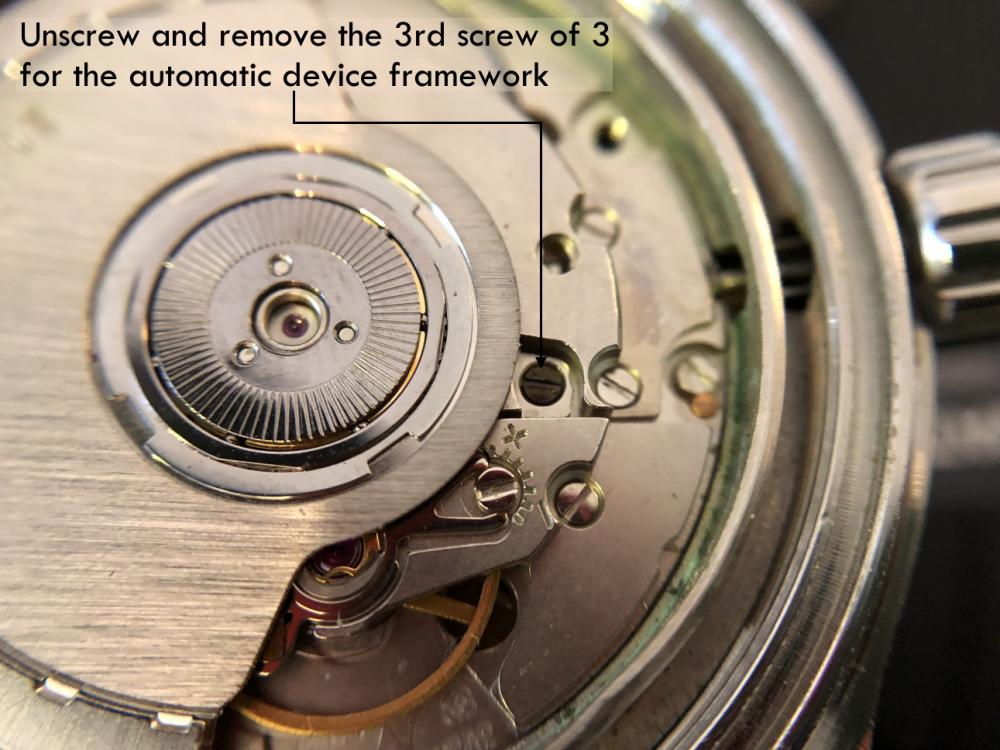

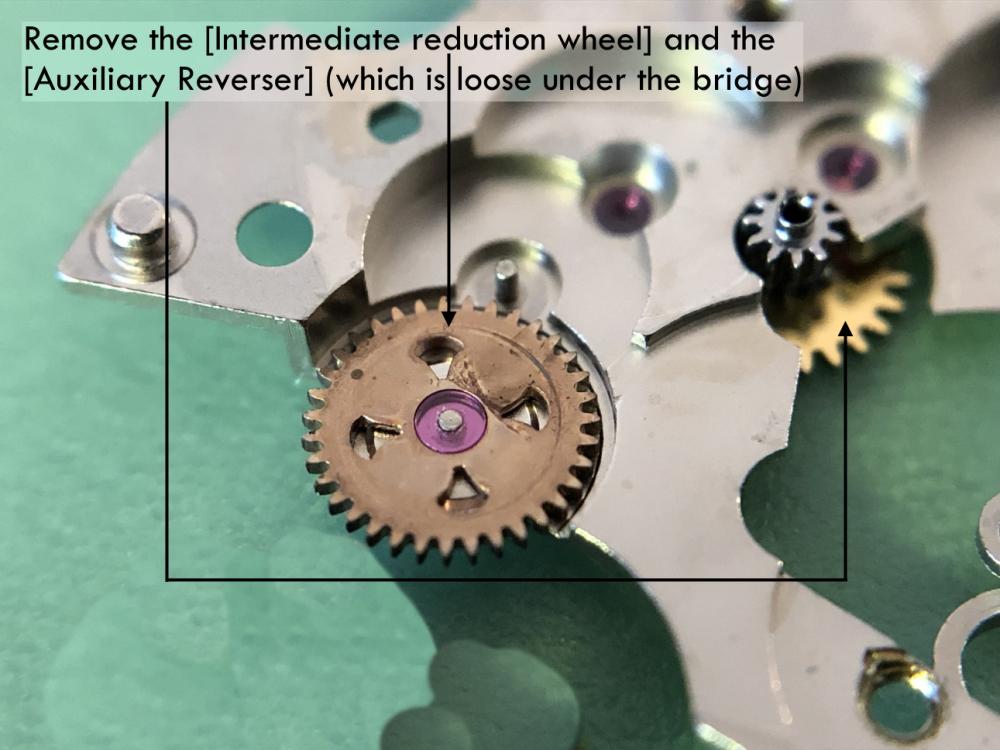

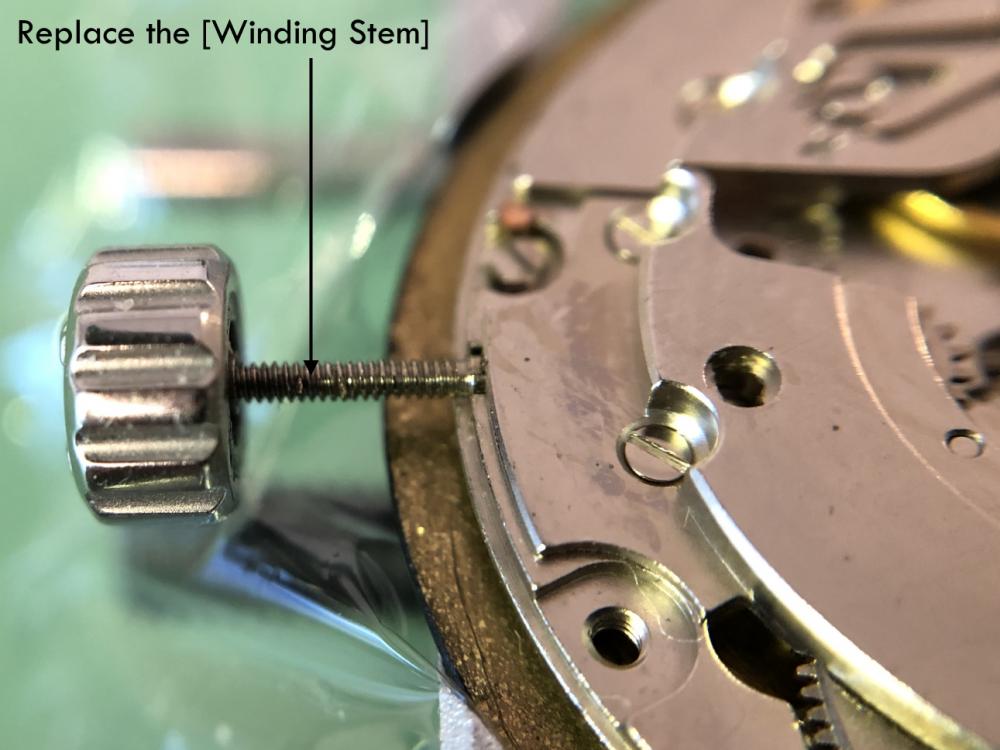

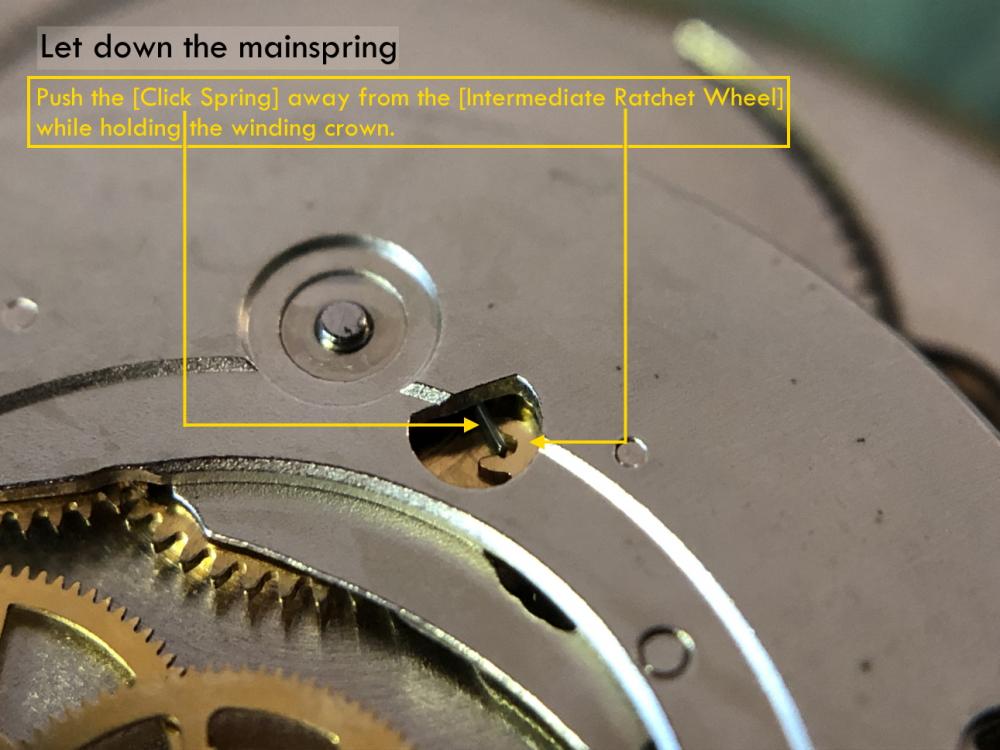

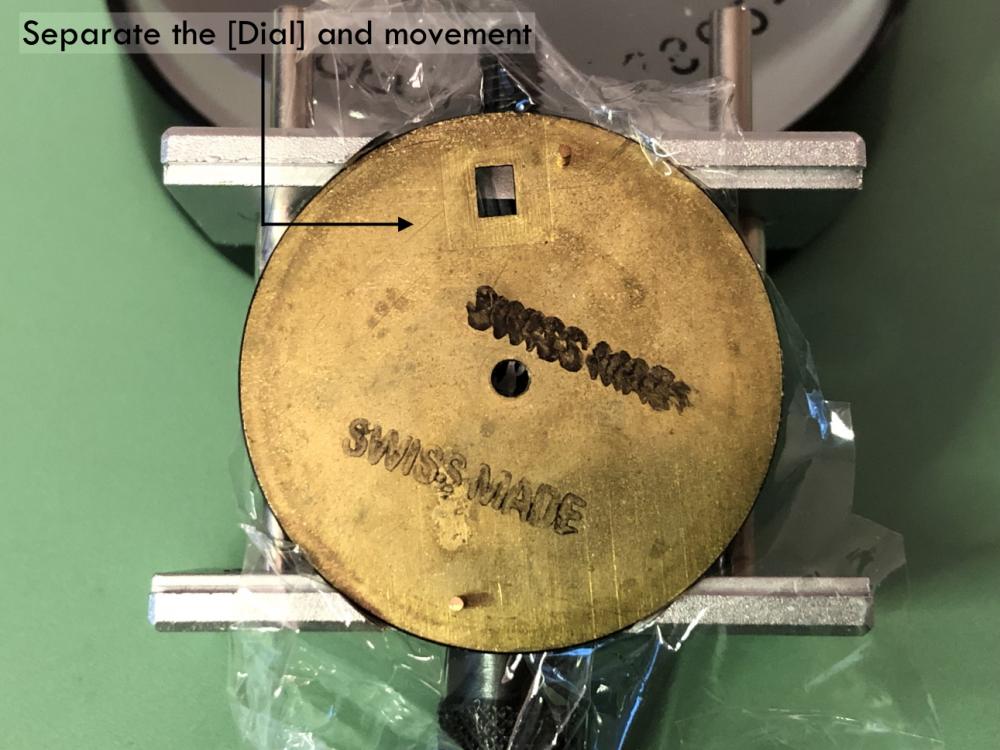

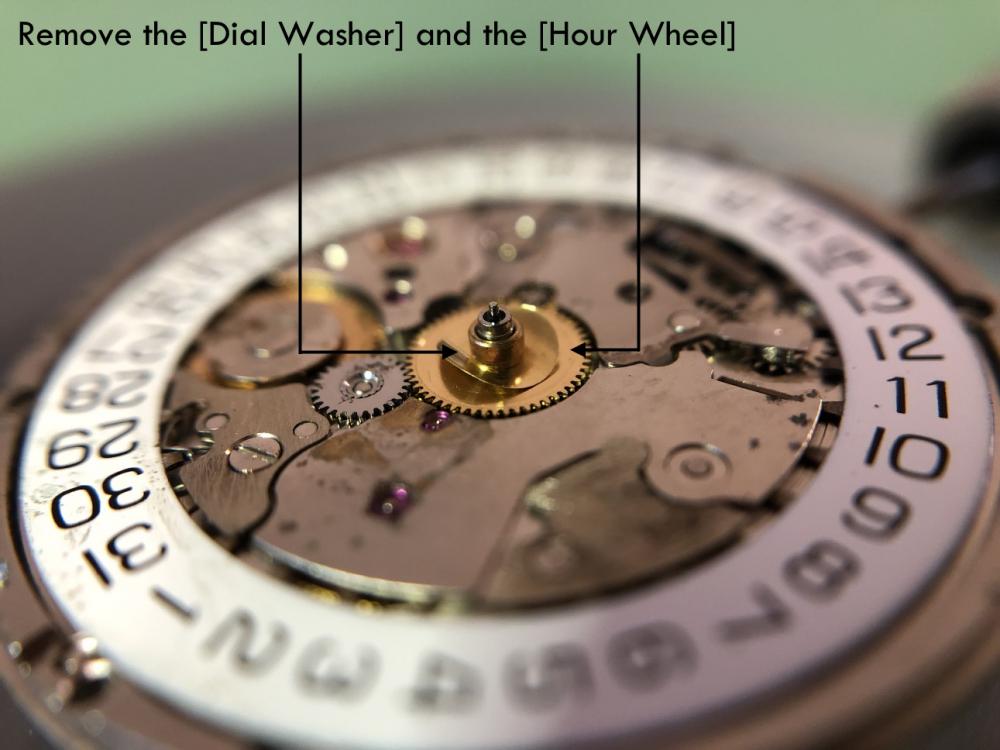

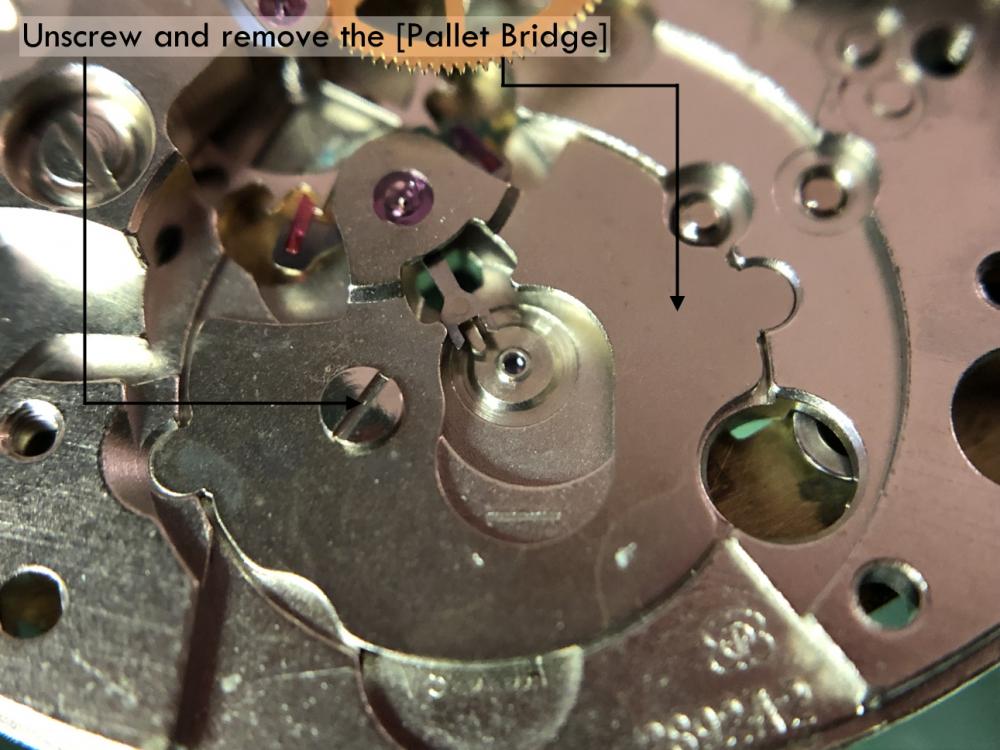

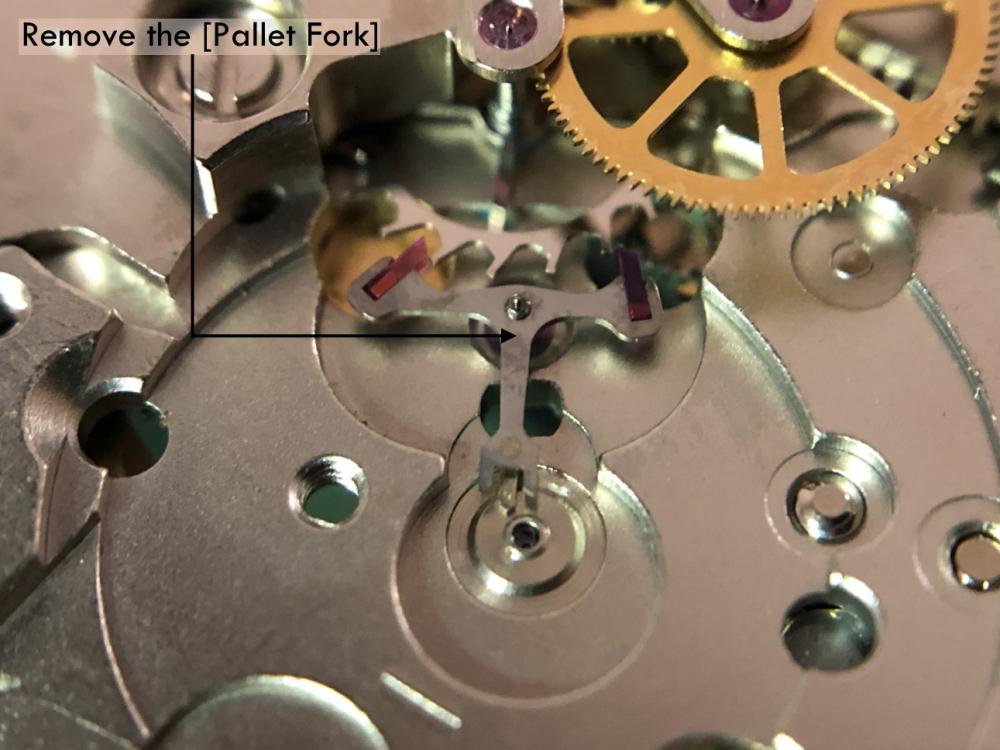

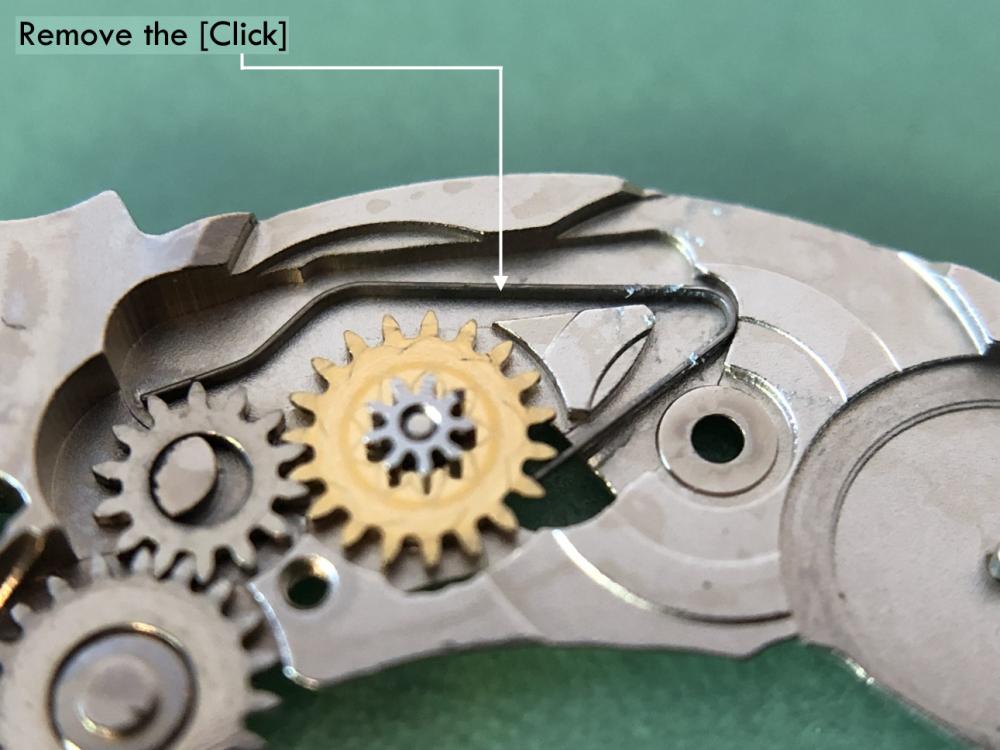

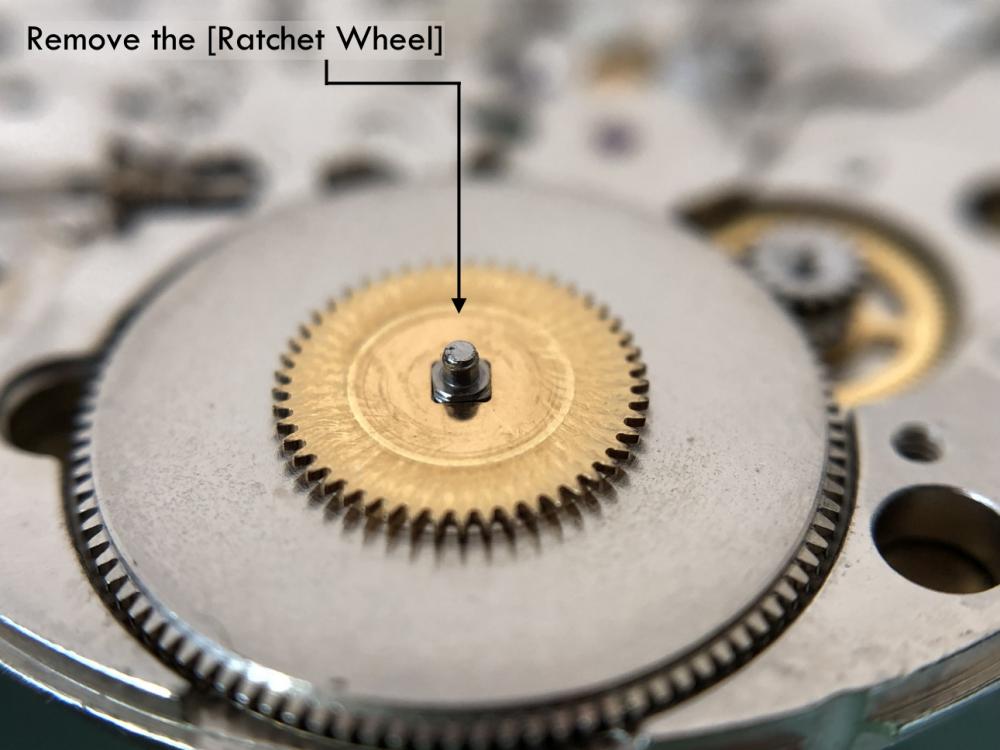

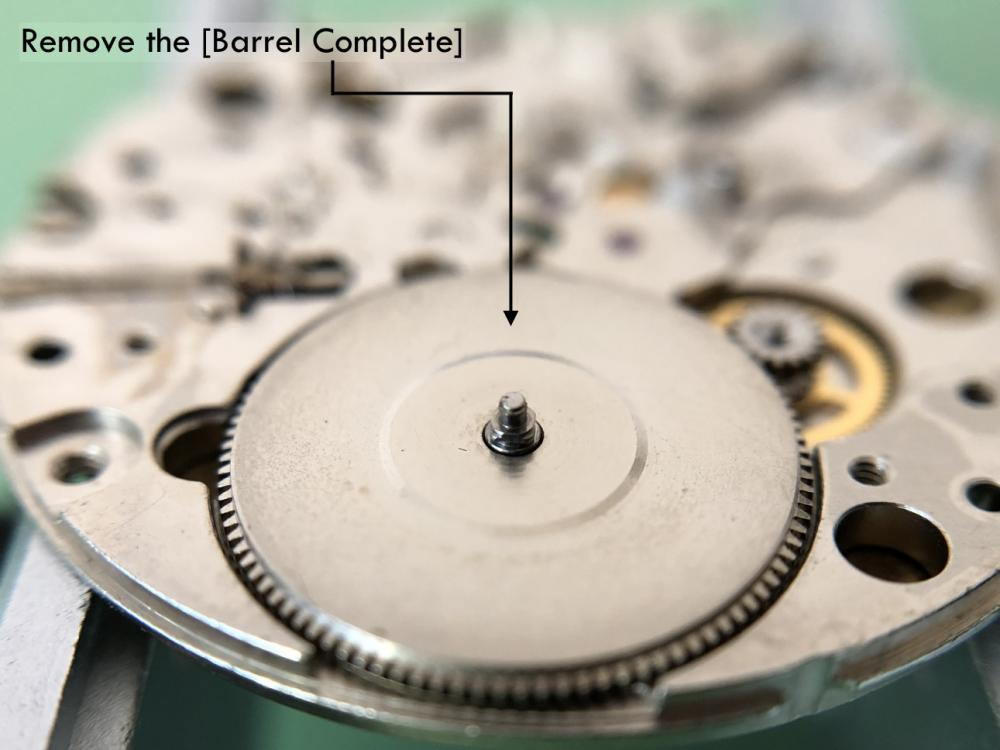

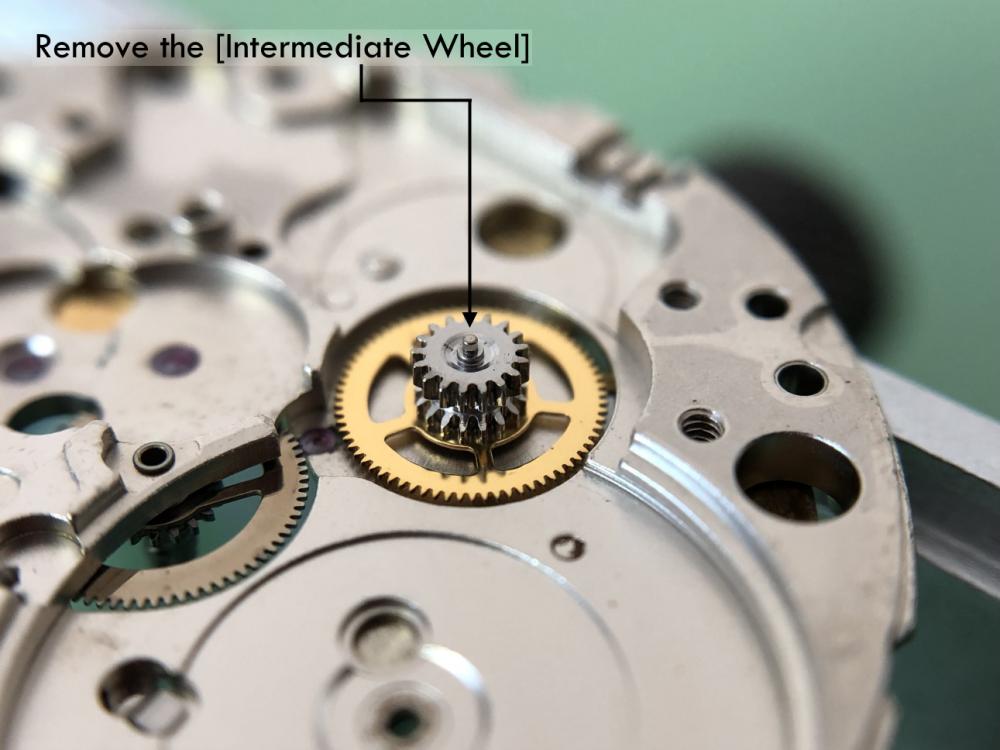

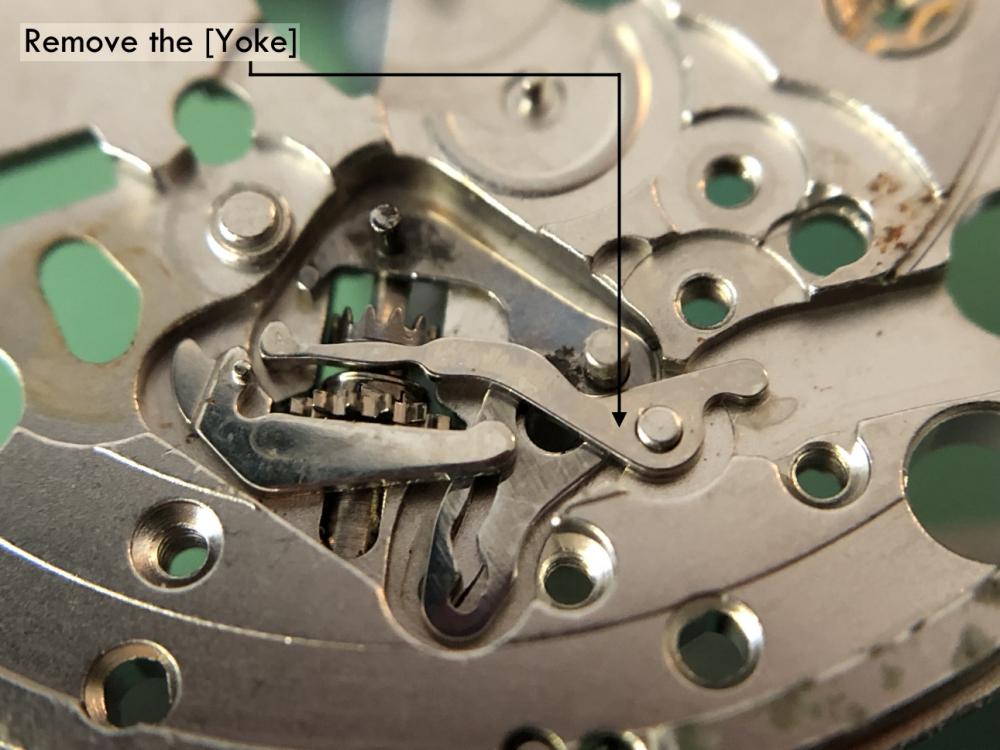

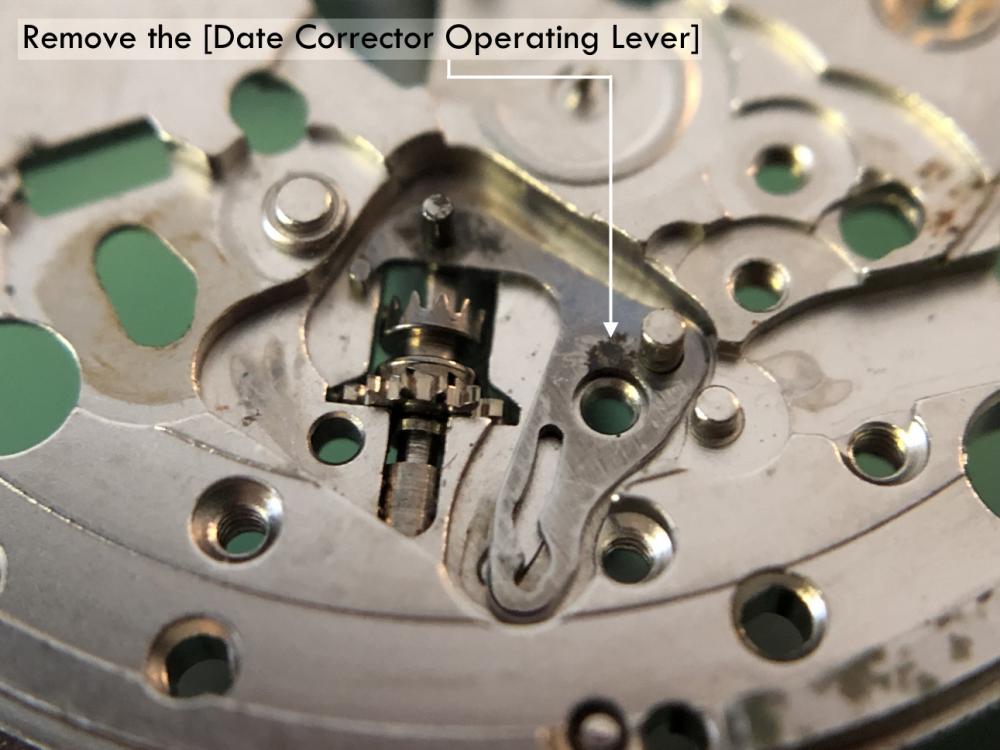

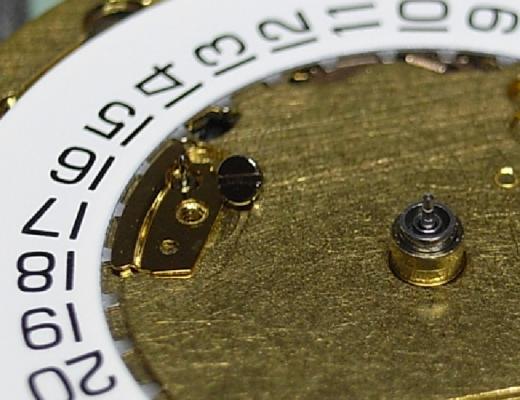

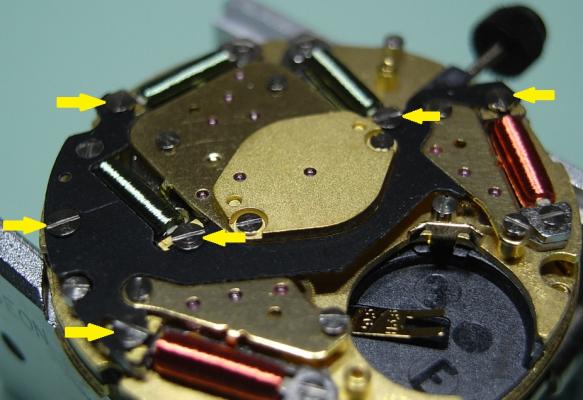

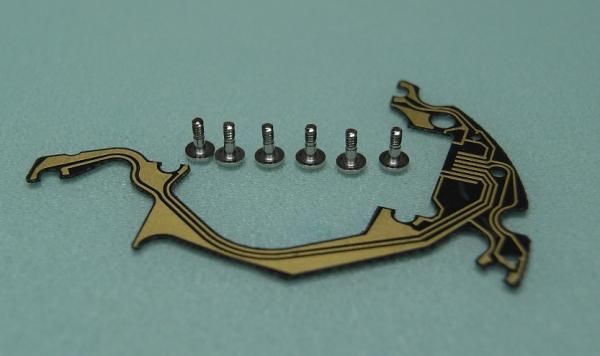

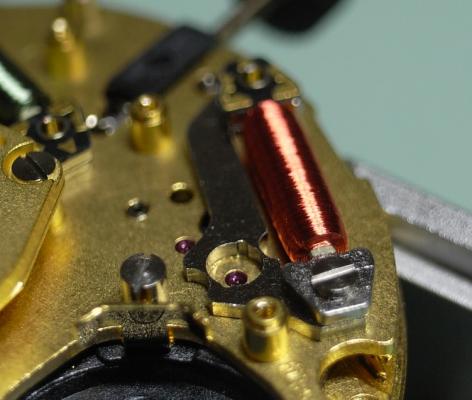

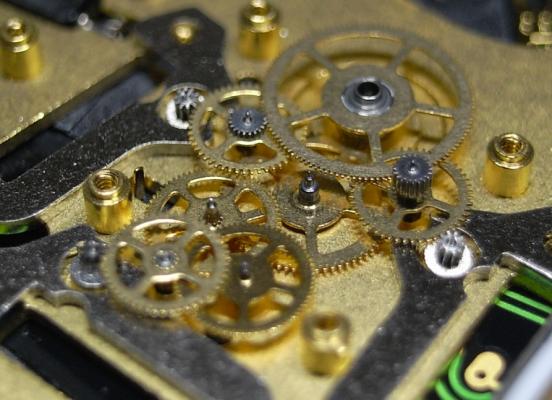

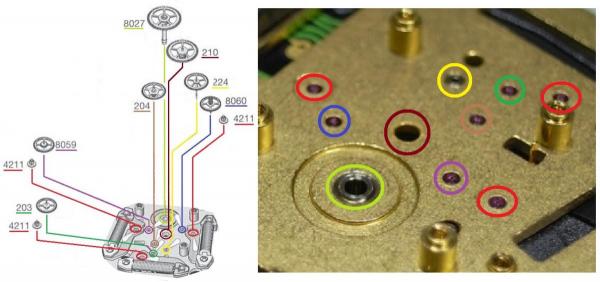

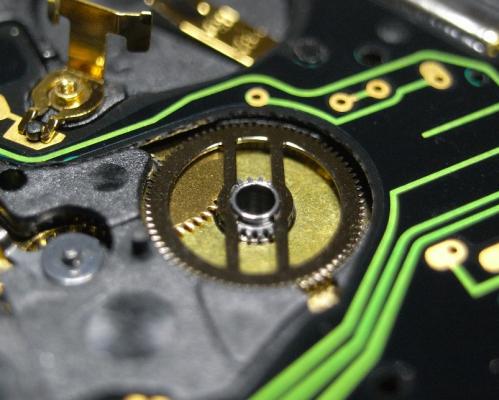

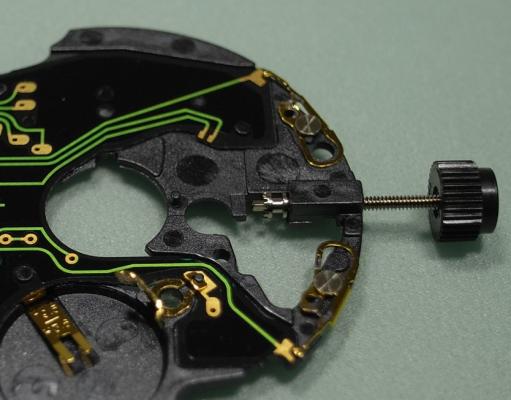

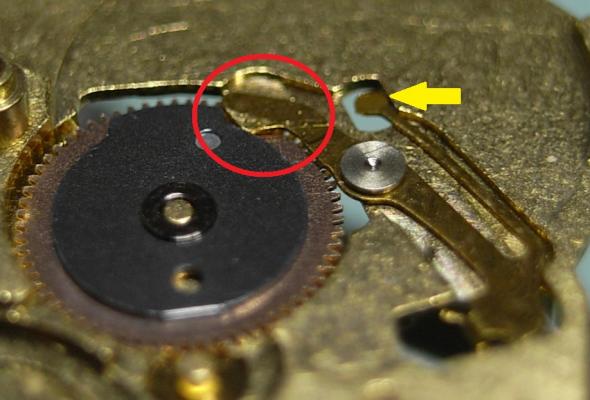

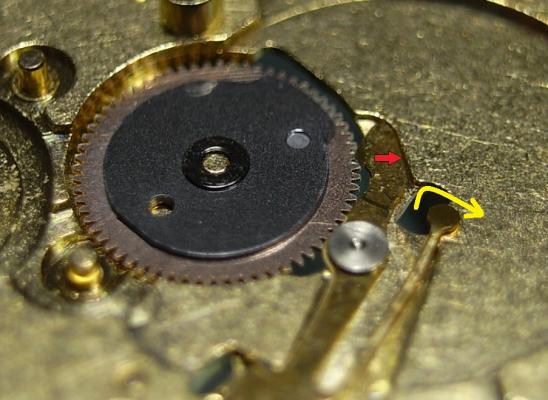

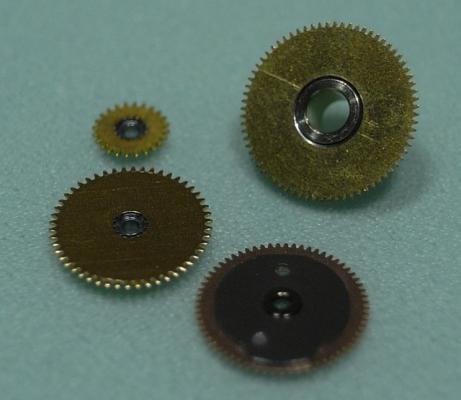

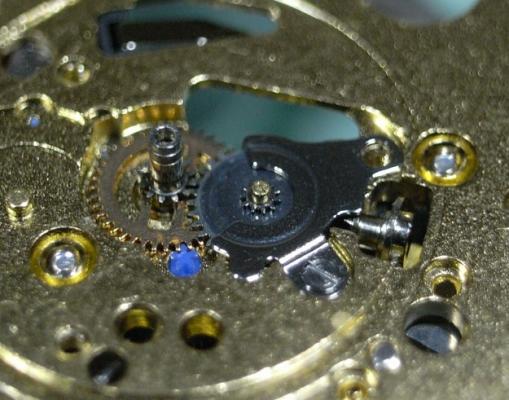

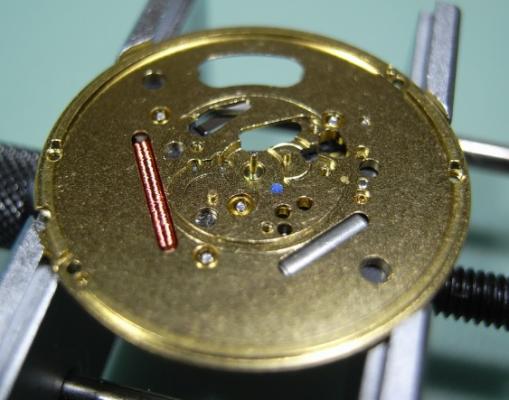

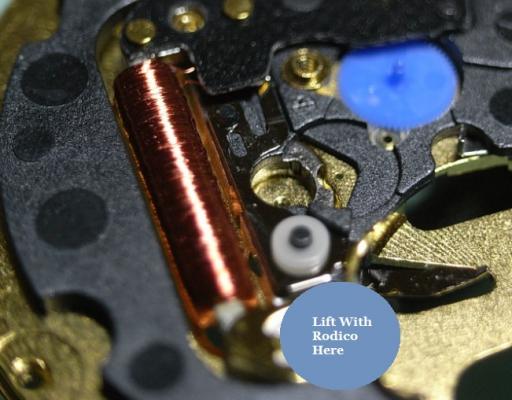

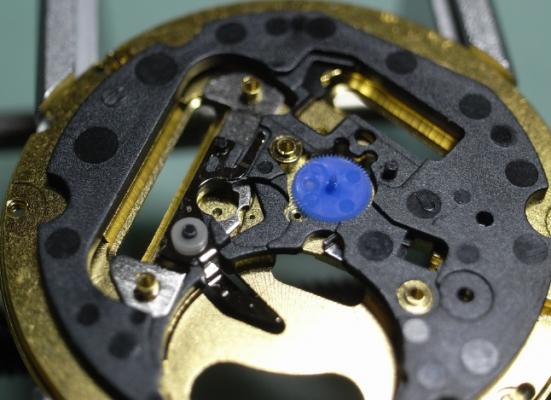

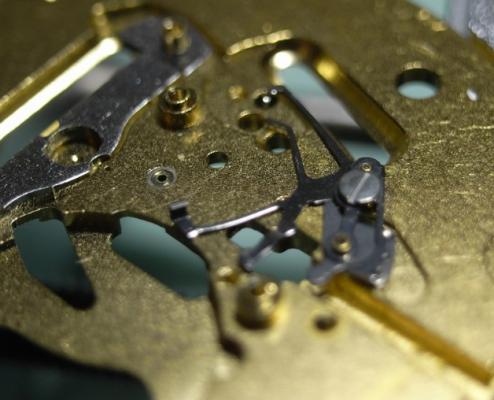

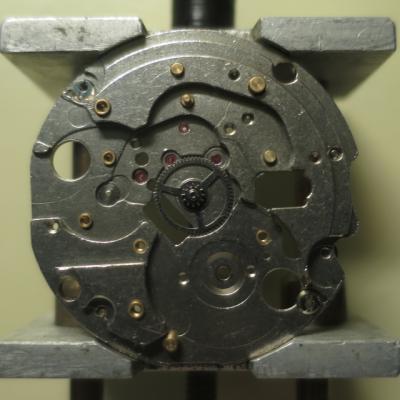

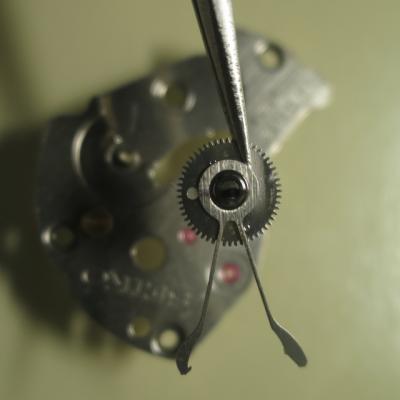

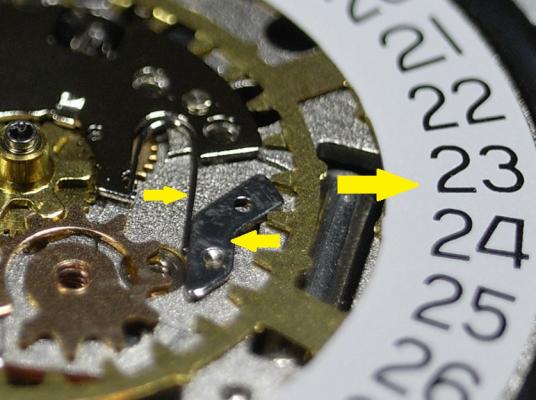

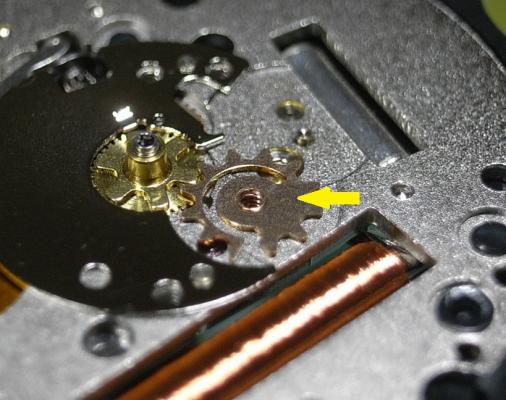

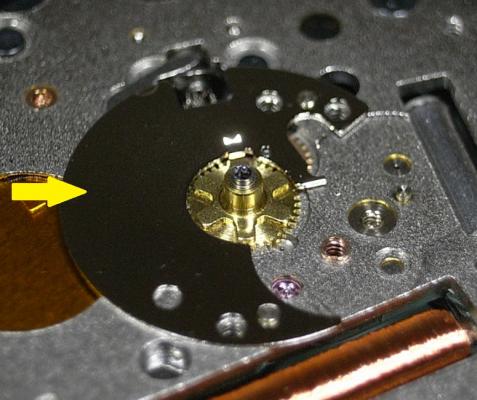

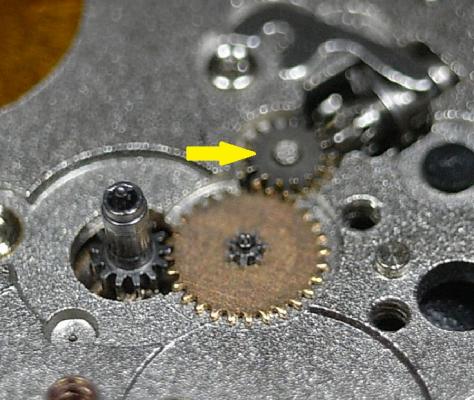

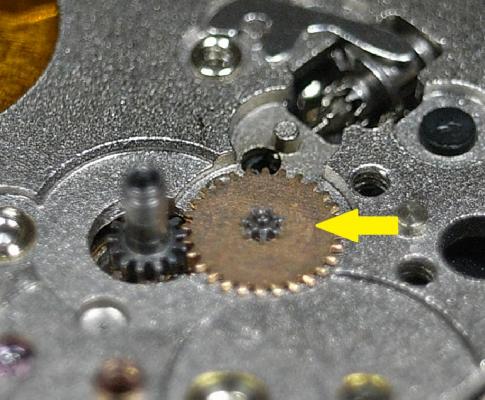

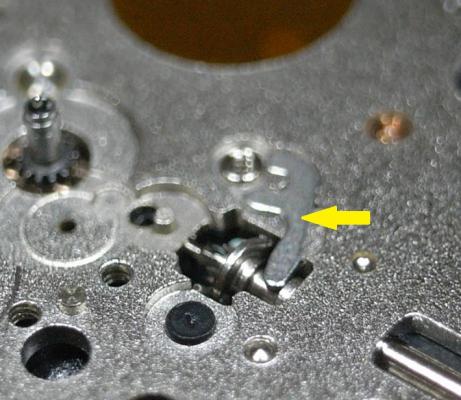

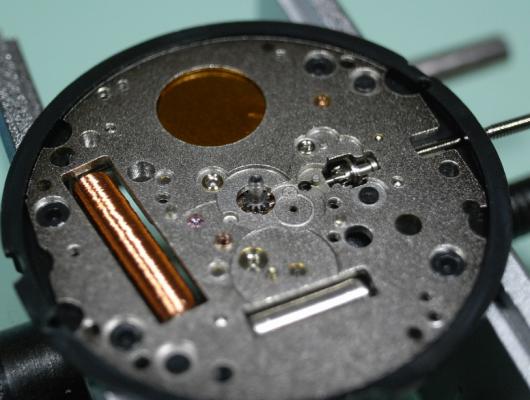

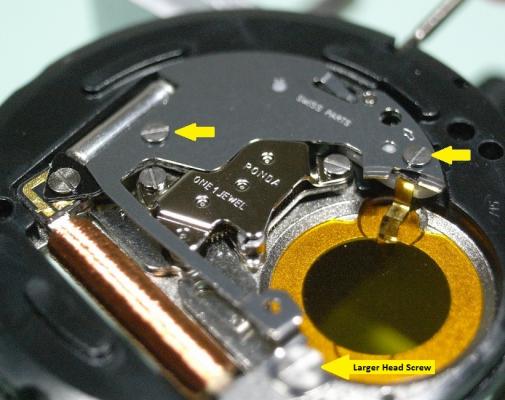

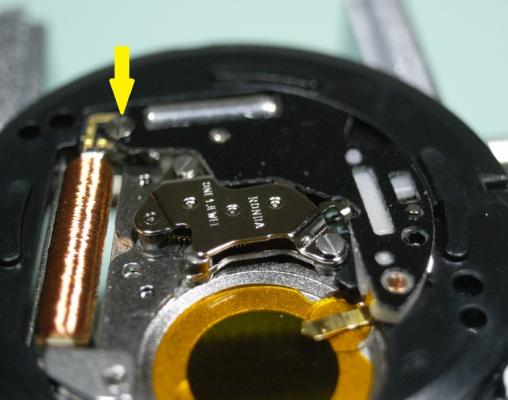

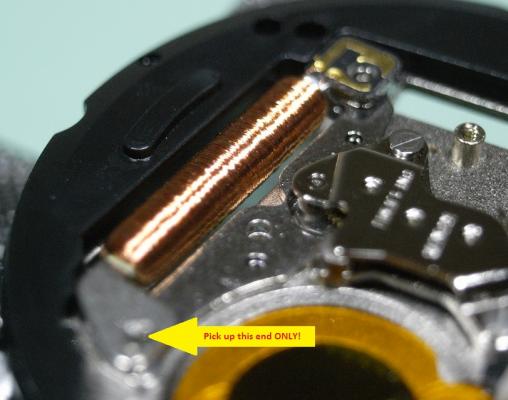

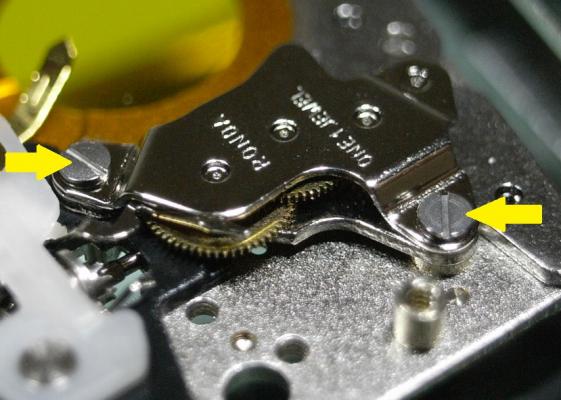

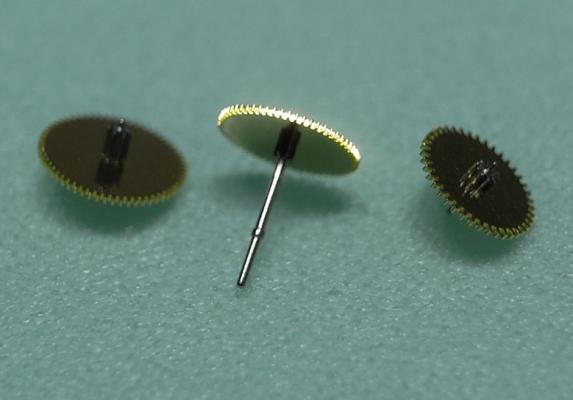

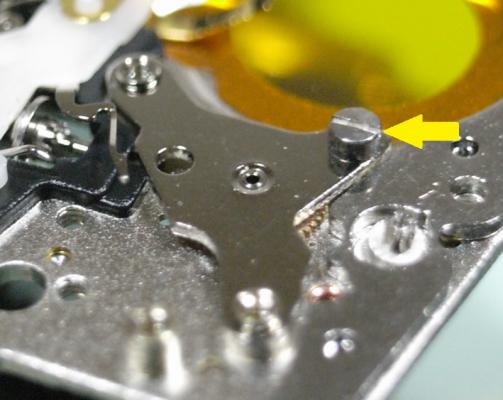

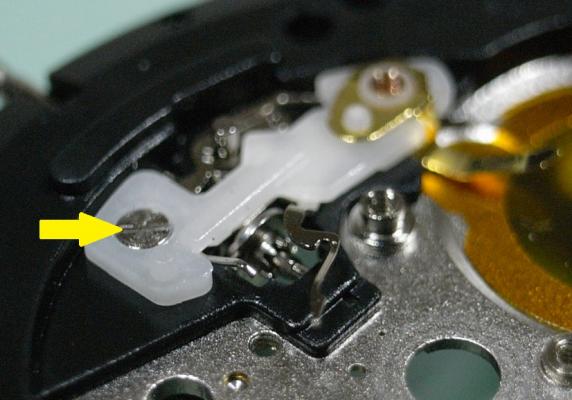

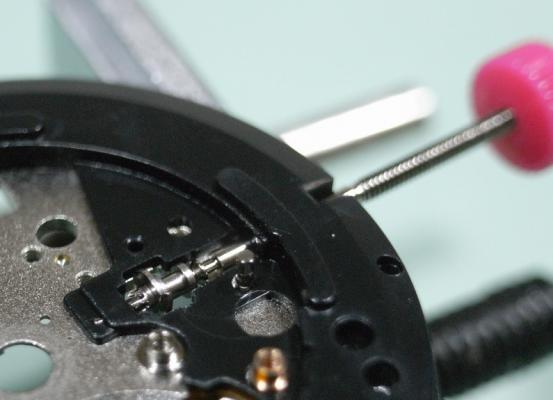

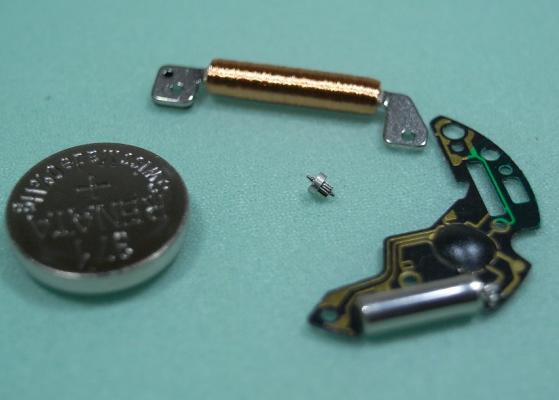

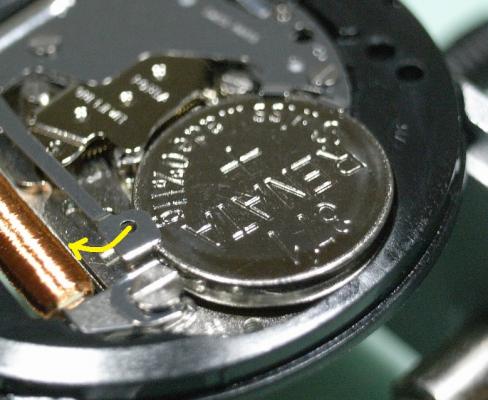

Seiko 5J22A Complete Service Hunting through my cupboards I found my old Seiko Kentic "Auto Relay" that I purchased sometime in the 90s, when this was the latest cutting edge Quartz Watch on the market offered by Seiko. It's been sitting for over a decade without use, and I decided to really push myself and, with the Lord's assistance, completely strip and service this watch. So I tracked down the Tech Specs, and if you are thinking of embarking on servicing the 5J22 YOU WILL NEED THEM!! :) So here they are: 5J22A.pdf I will be using the part names from this document for this walkthrough, so download and print it out for you own sanity. The parts in this movement are incredibly small, so much so that my camera had trouble focusing on them ... so part names will help you as much as the visuals aids for this service. Once again, I've had no one to guide me on this, so this is the way "I" stripped the movement down, the correct factory procedure may, and probably does, differ from my way ... so I give a warning here: CONTINUE AT YOUR OWN RISK. Disassembly Unscrew the back cover and store the rubber gasket away safely. With a 2.0mm Screwdriver, pry the Location Ring out with the slots provided in the plastic ring. Remove the Oscillating Weight with a 1.20mm Screwdriver ... and this will be the driver you use on all further screws. To remove the Stem, you need to have the Stem push all the way home, to move the Yoke into the correct position so you can depress the lever (Location shown in picture after I removed the movement to make it easier to see the spot where you push) The movement should now come out of the case along with the internal Bezel Ring. Remove the Hands Remove the 7 screws for the Circuit Block Cover A, and the Rechargeable Battery Clamp (Sorry referred to an older pic to so you the location of screws) Remove the Insulator for Rechargeable Battery, and then the Battery itself. Remove Circuit Block Cover A Remove Circuit Block Cover D Reference picture of Circuit Block Cover D Remove Circuit Block Cover B Reference picture of Circuit Block Cover B Remove Oscillating Weight Bridge Reference picture of Oscillating Weight Bridge Remove Circuit Block Cover C Reference picture of Circuit Block Cover C Remove Circuit Block NOTE: The pin with the yellow arrow pointing to it holds onto the Circuit Block very firmly. Be CAREFULLY and GENTLE, as the Circuit Block can be easily damaged. This is the angle of attack that I recommend. Coming in on an angle just in front of the Crystal Unit, and gently push upwards ... and I mean GENTLY. Patience wins the day! Remove the Intermediate Wheel for the Generating Rotor Remove the Generating Coil Block (grasp with tweezers where indicated with yellow arrow) Remove the Second Coil Block (grasp with tweezers where indicated with yellow arrow) Remove the Hour and Minute Coil Block (grasp with tweezers where indicated with yellow arrow) Remove the Train Wheel Bridge Remove the Second Wheel and Pinion, the Third and Fourth Wheel Remove the Intermediate Second Wheel TIP: Next is this first of three sets of Stators and Rotors that make up this Quartz Movement. Be sure to place all the Stators and Rotors into a piece of Rodico for safe keeping. As shown below: THESE PARTS ARE MAGNETIC AND WILL ATTRACT PARTICLES, SO DO NOT PUT INTO THE BASKET FOR CLEANING Remove the Second Stator and Second Rotor Remove the Minute Wheel and Pinion, Intermediate Minute Wheel, and Setting Wheel Remove the Center Wheel and Pinion Remove the Generating Stator and Generating Rotor Remove the Setting Lever Spring Remove the Yoke and Setting Lever Note: Release tension on the Yoke Spring FIRST Remove the Clutch Wheel and the First Intermediate Wheel for Calendar Corrector Remove the Hour and Minute Stator and Hour and Minute Rotor This side of the Main Plate is now finished ... time to flip it over and start on the Calendar Works Remove the two screws indicated and remove the Hour Wheel Guard Spring, and the Date Dial Guard Remove the Intermediate Date Driving Wheel Remove the Intermediate Hour Wheel, and Hour Wheel Remove the Date Dial Remove the Day-Date Corrector Wheel, Second Intermediate Wheel for Calendar Corrector, Date Driving Wheel and Spring Note the position of tension of the Date Driving Wheel Spring (bottom of page 9 in the Tech Specs) Remove the Circuit Block Spacer ... and the disassembly is complete! I started work on this rather late at night and took my time and studied each part before removing, making sure to document everything carefully. So I'll clean the parts and begin reassembly fresh tomorrow. I can see this one is really going to push my abilities, and I'm looking forward to tackling it and uploading the reassembly steps.

- 19 replies

-

- 5

-

-

-

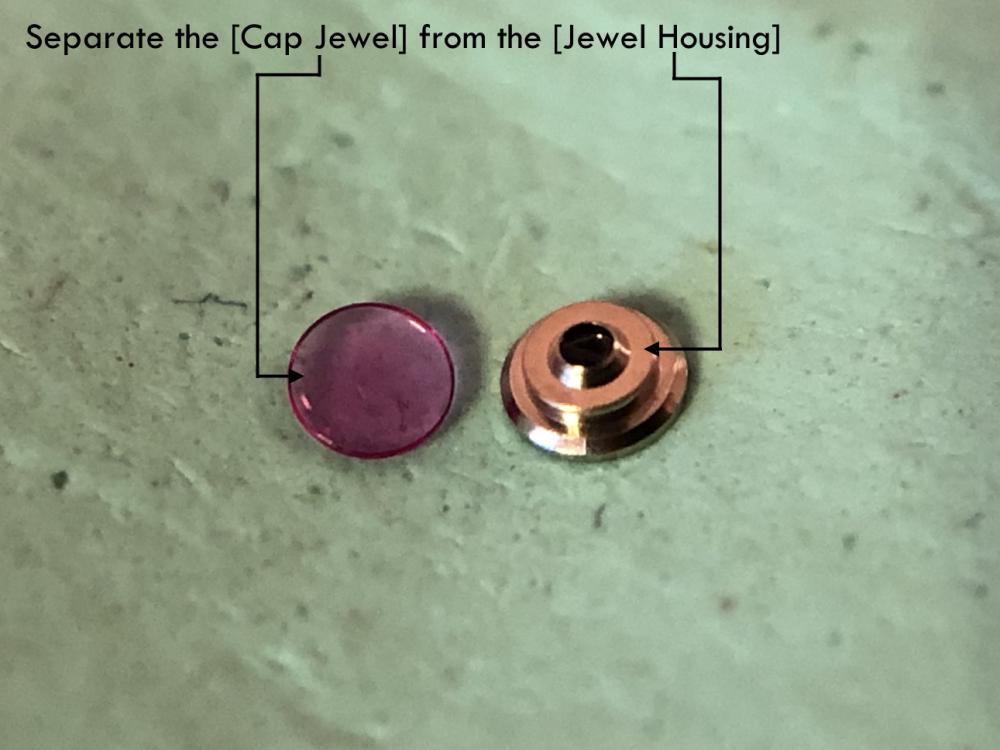

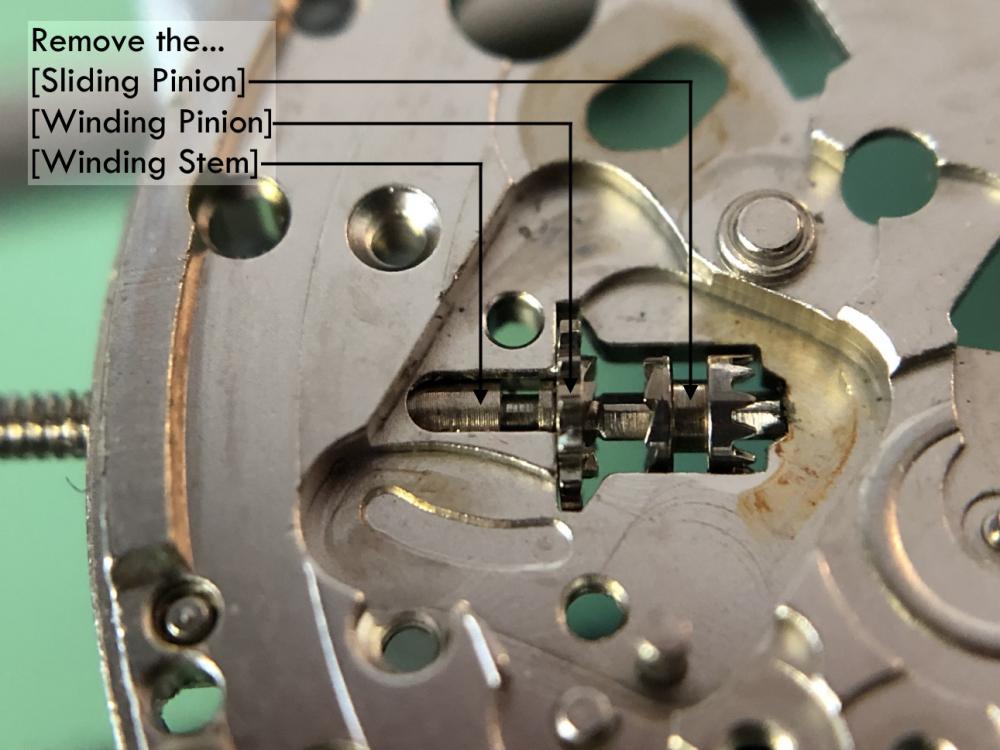

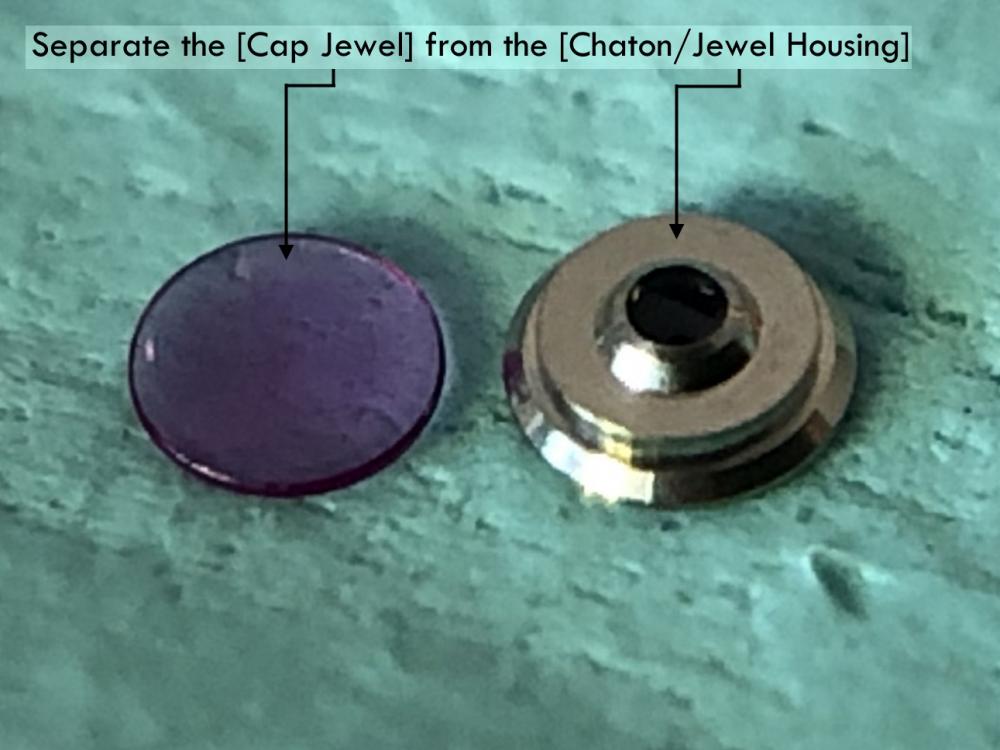

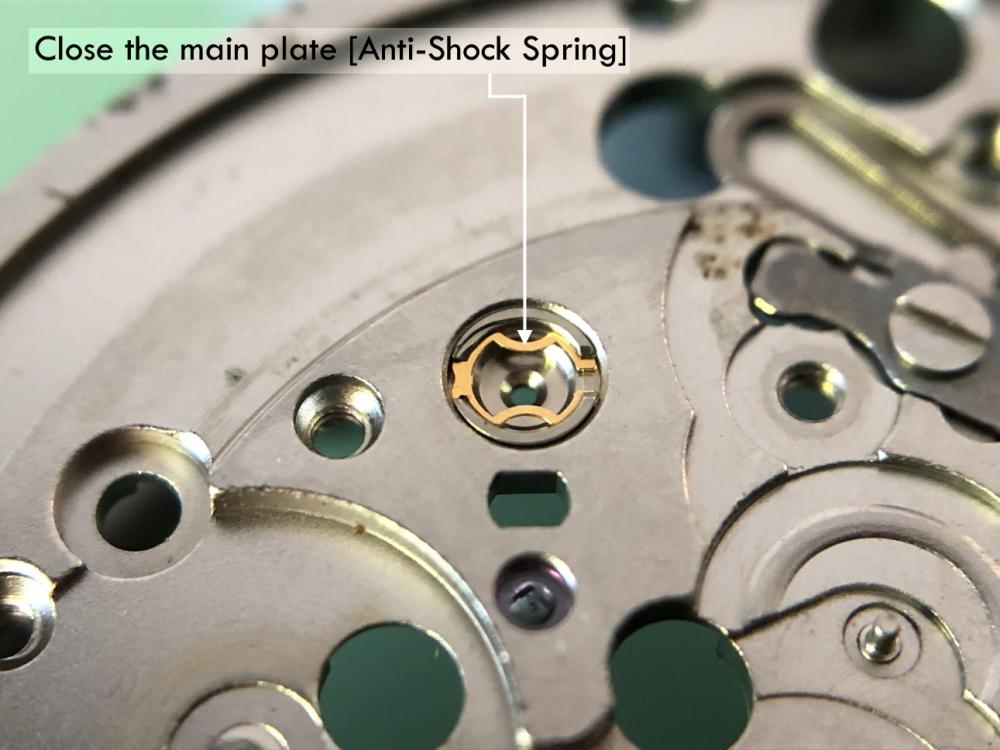

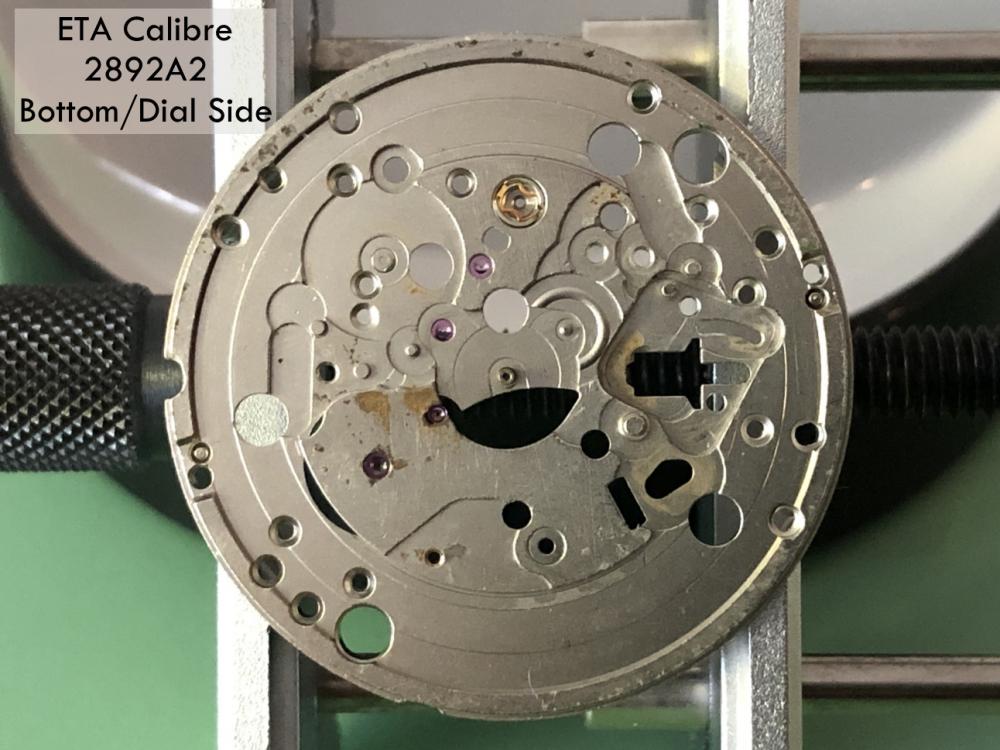

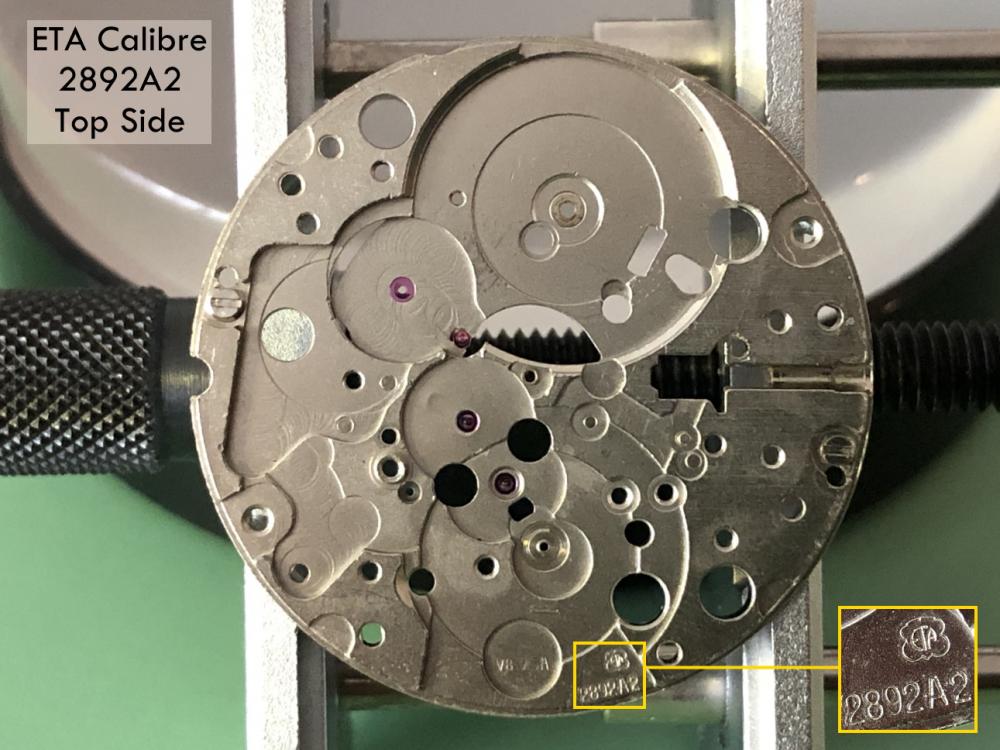

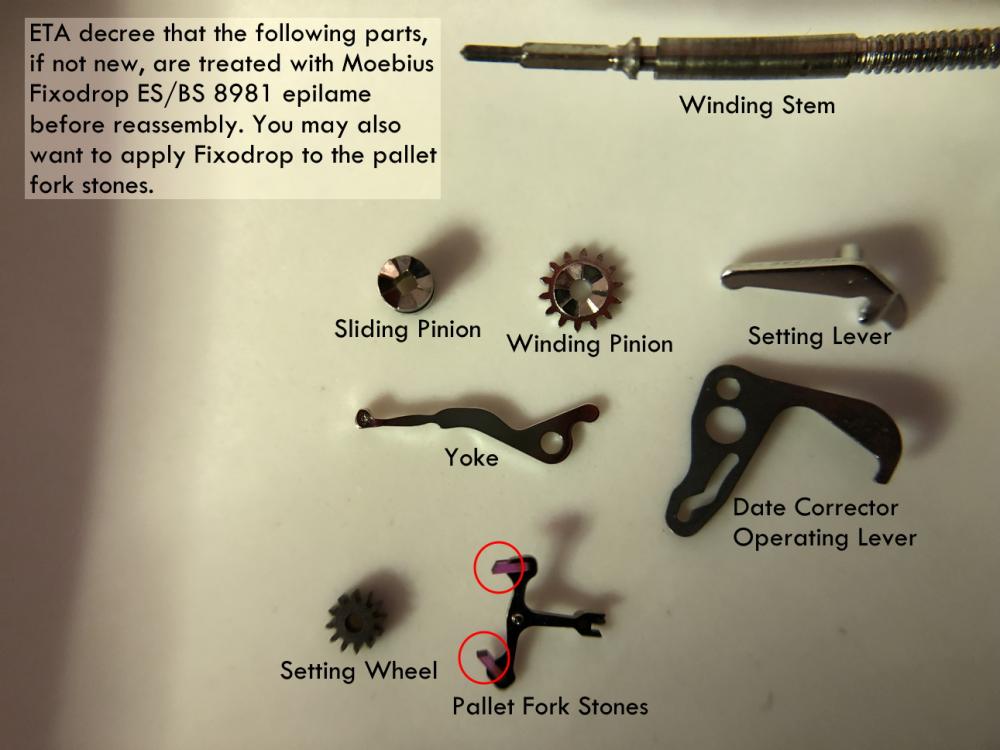

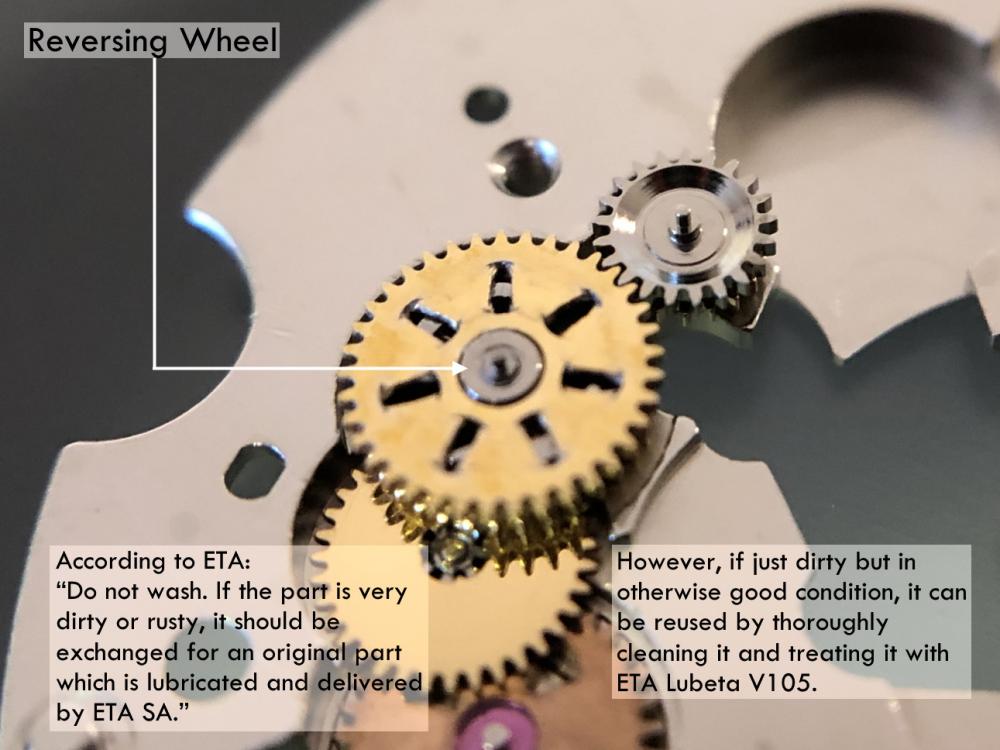

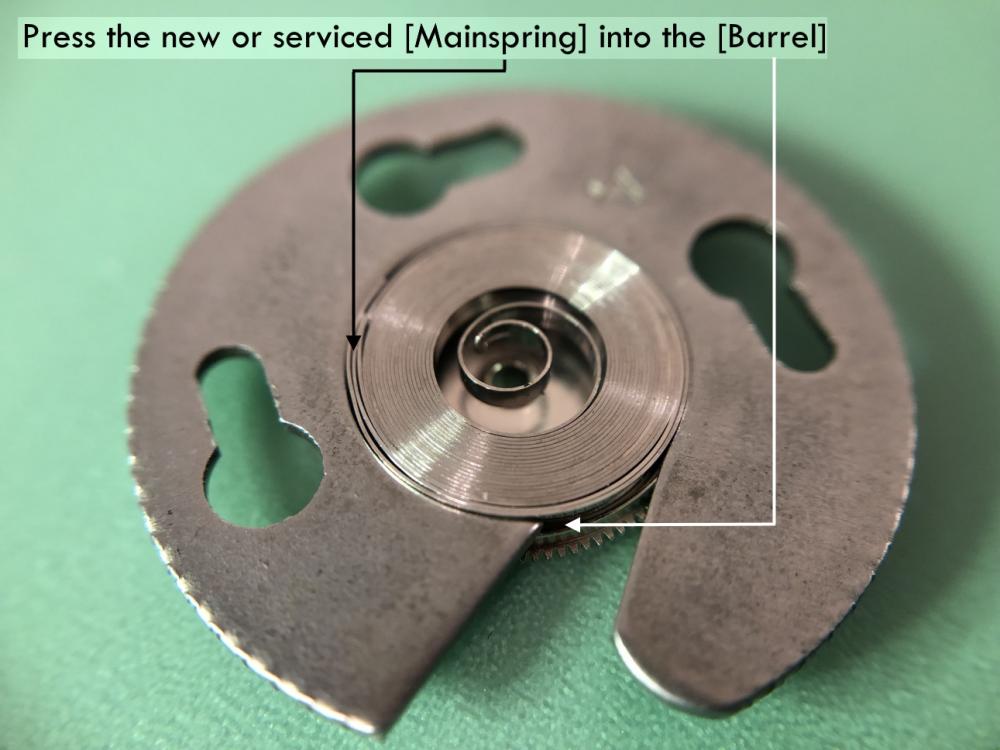

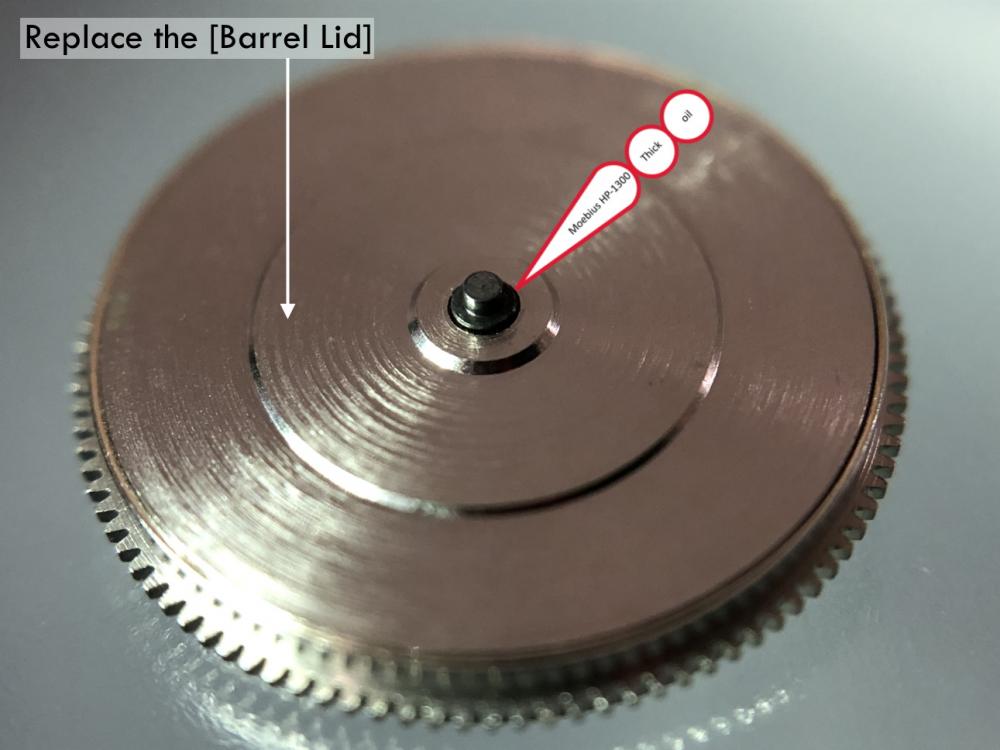

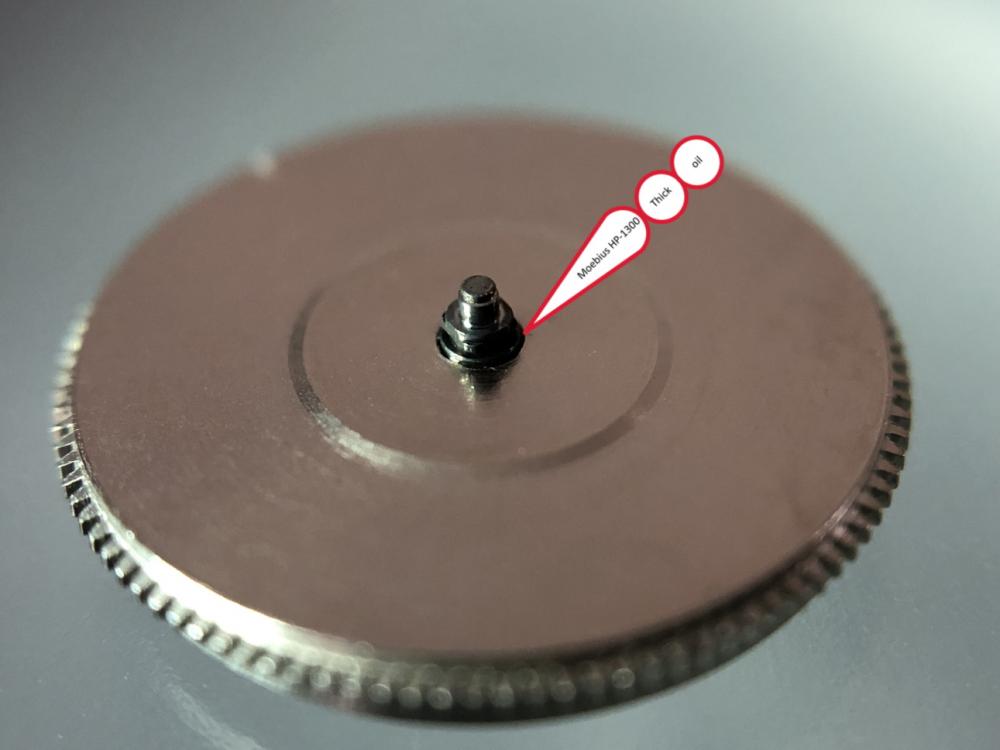

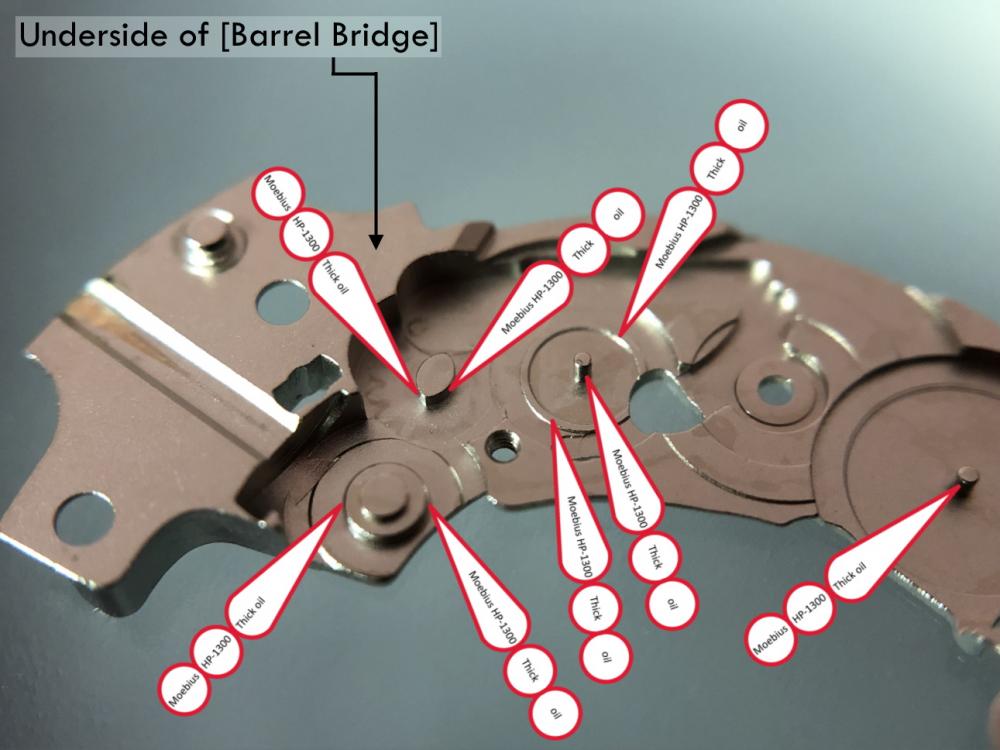

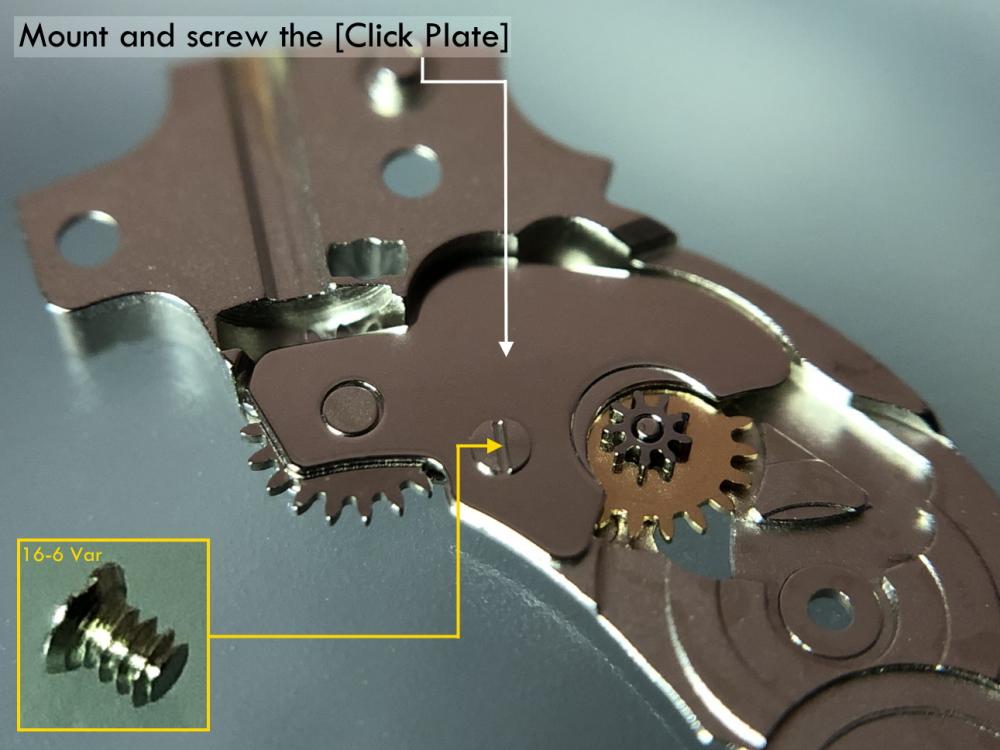

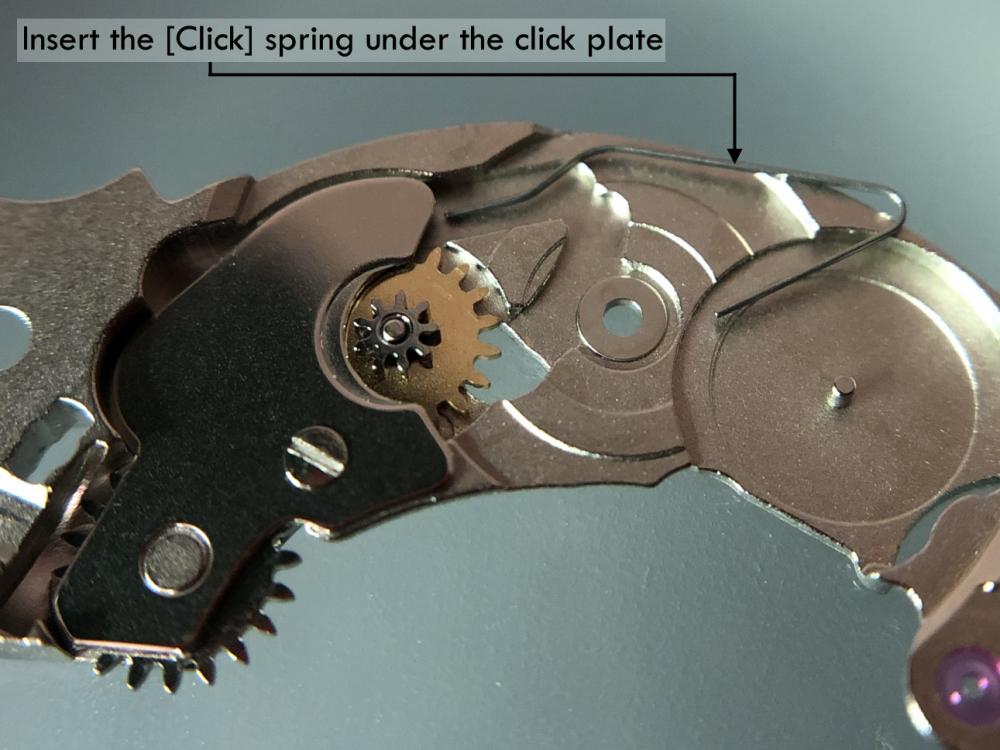

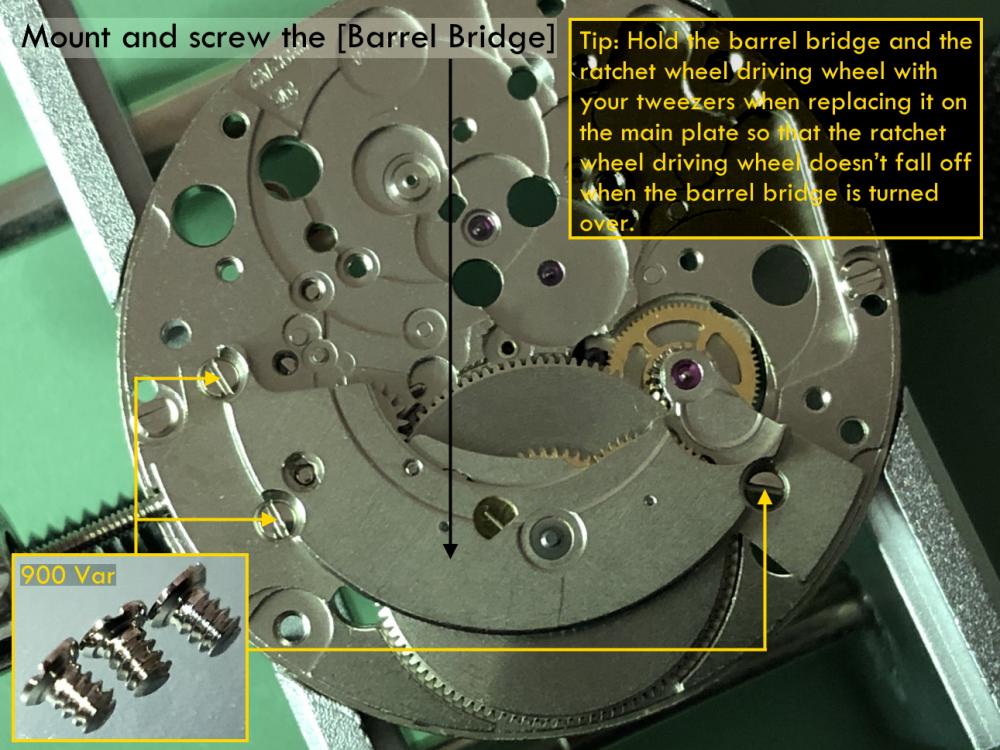

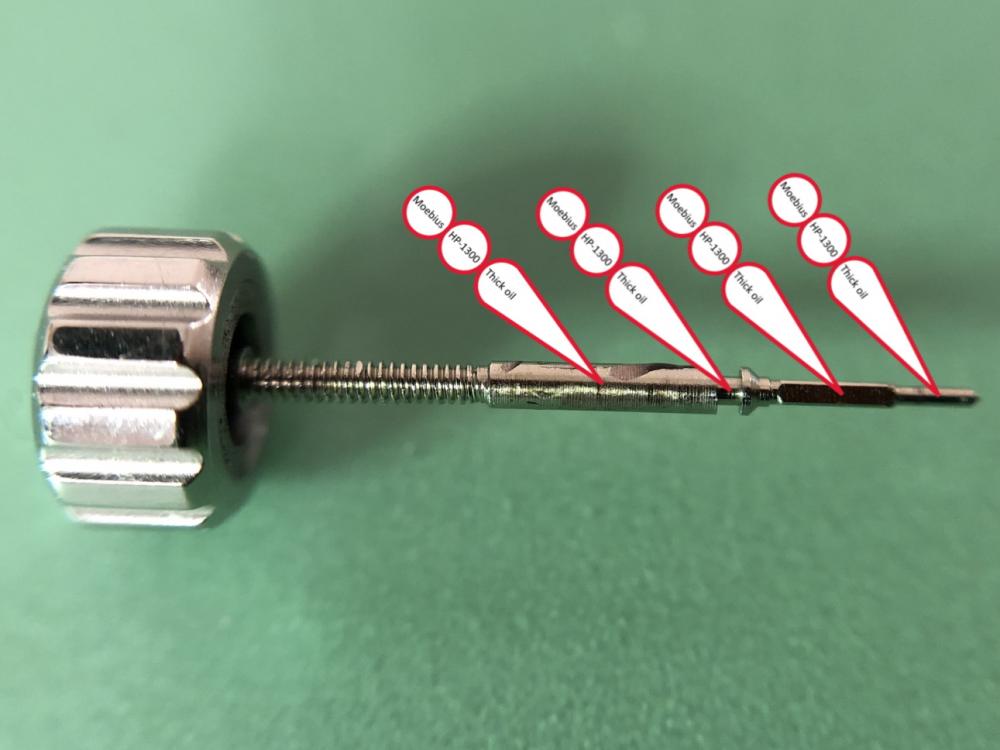

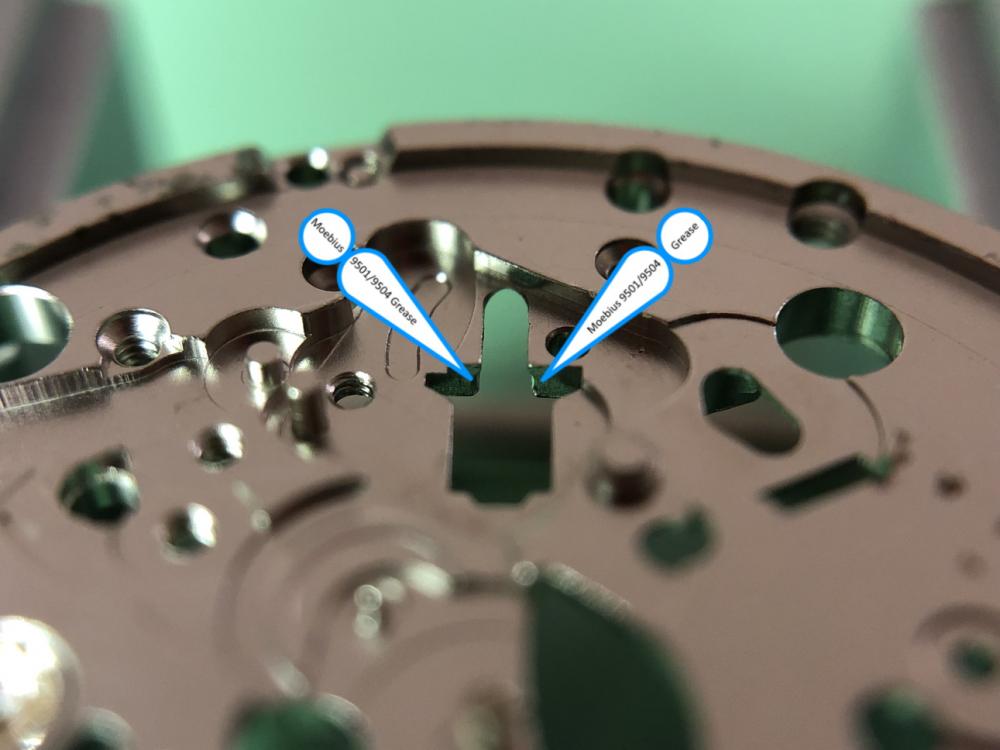

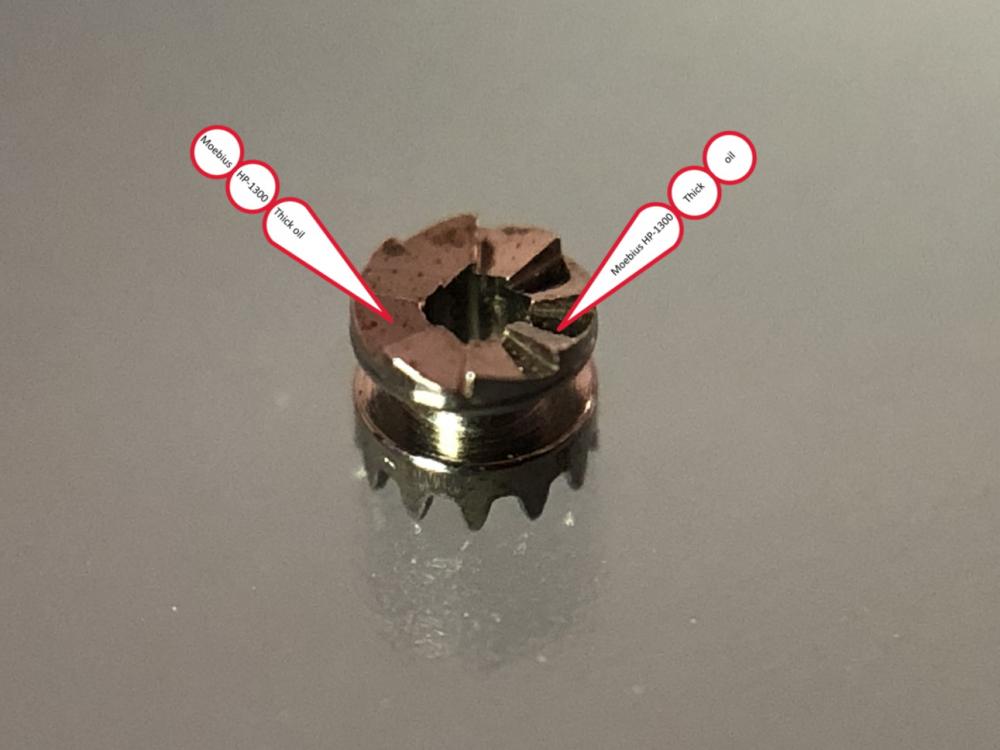

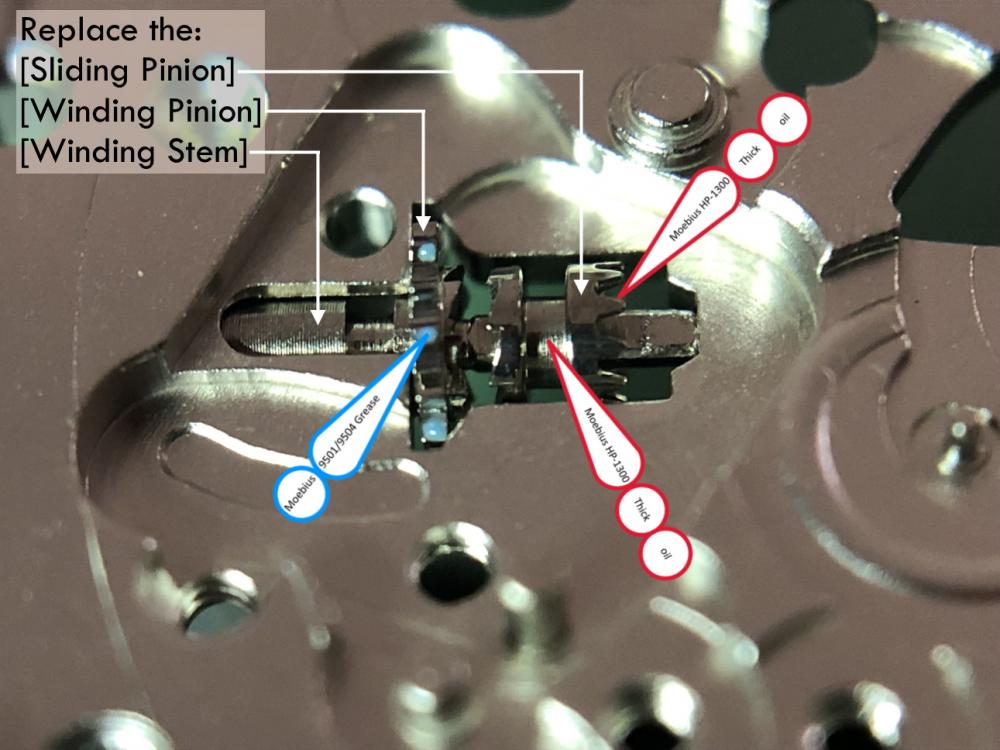

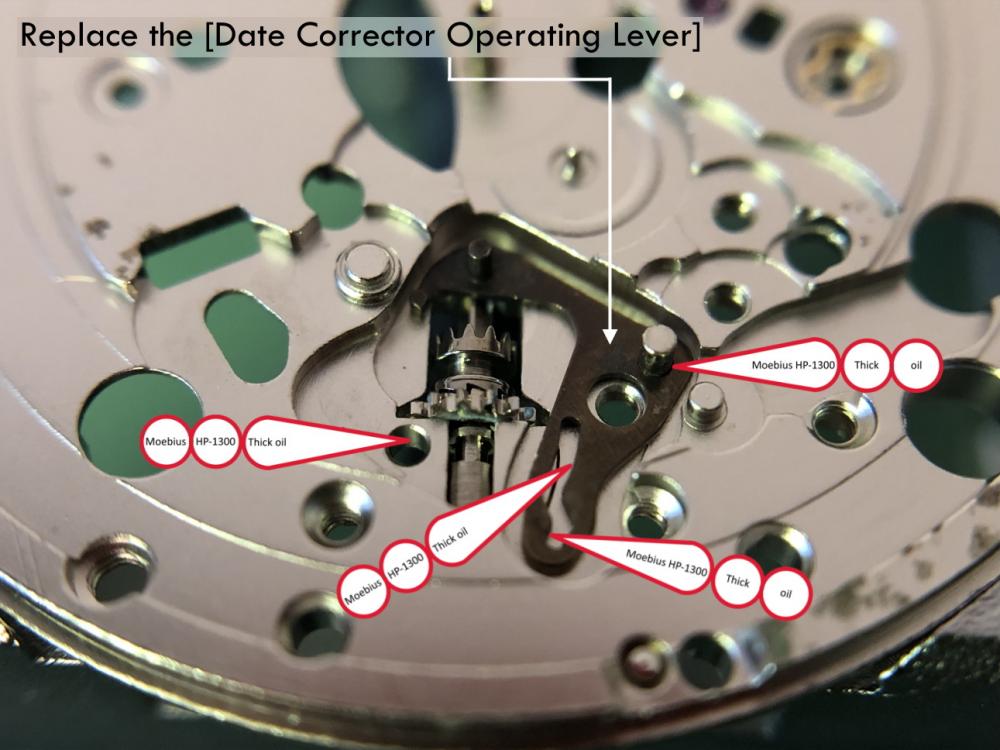

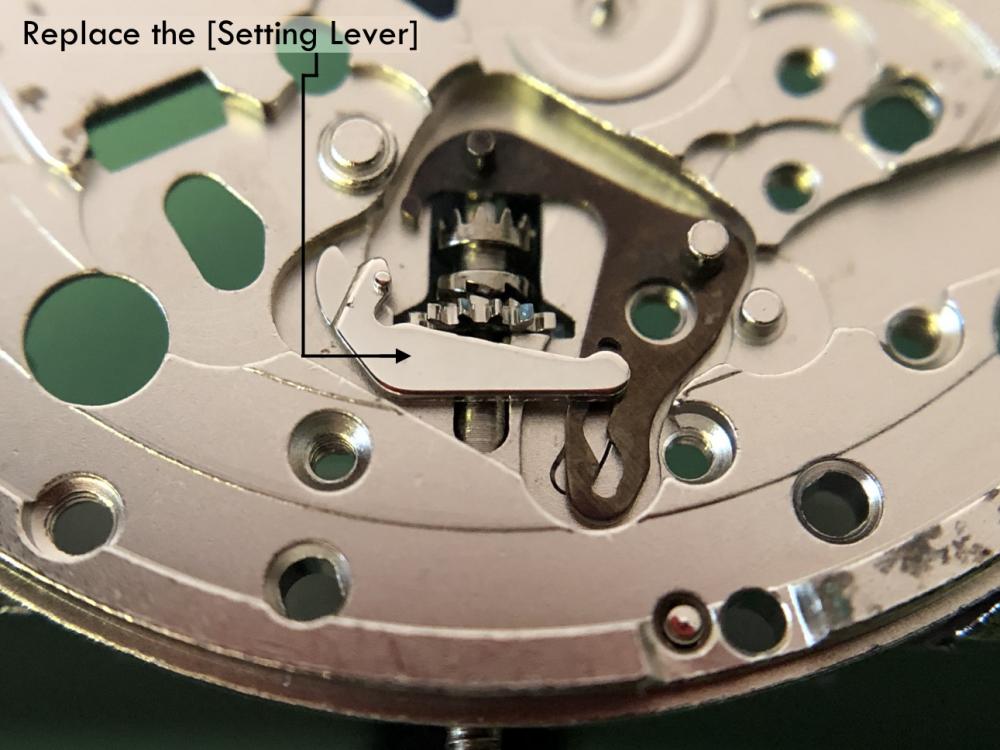

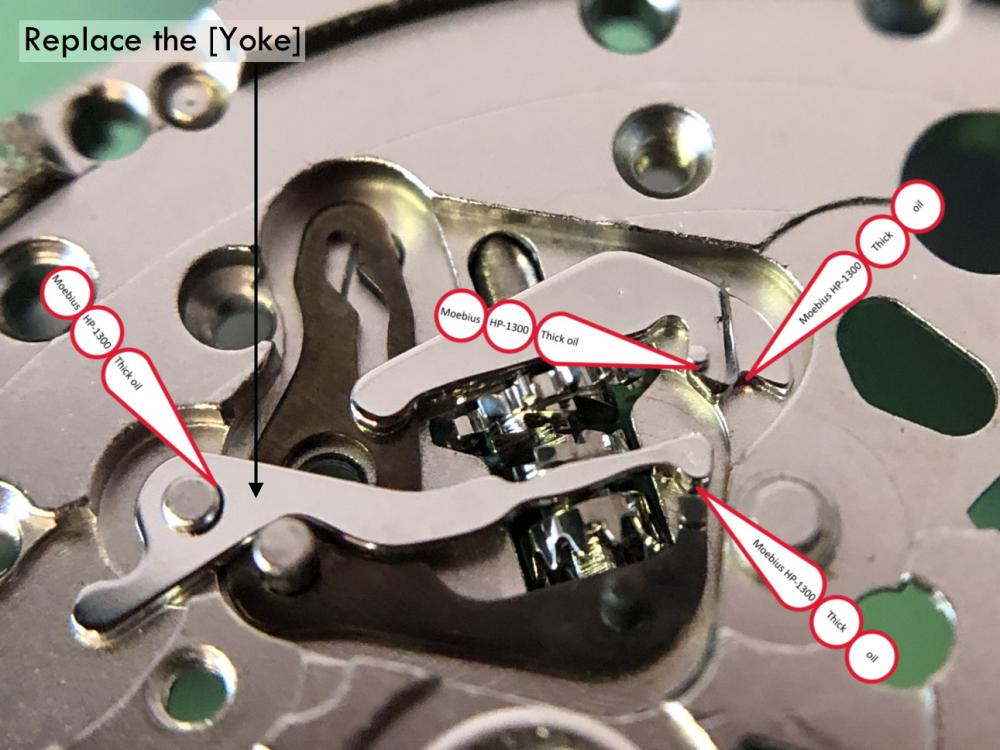

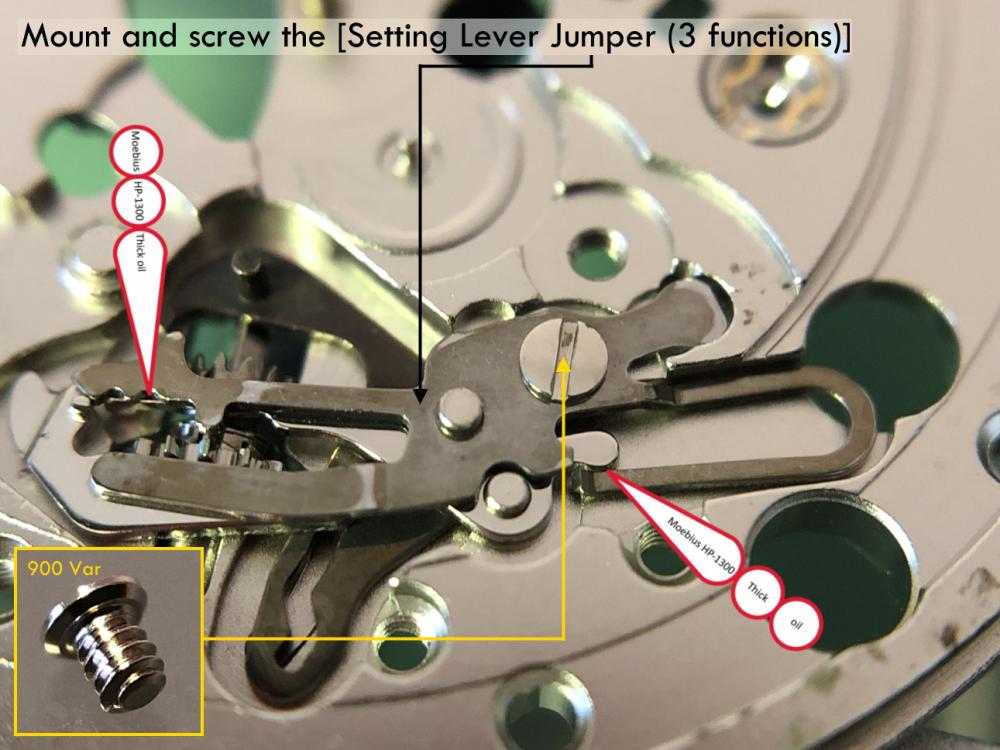

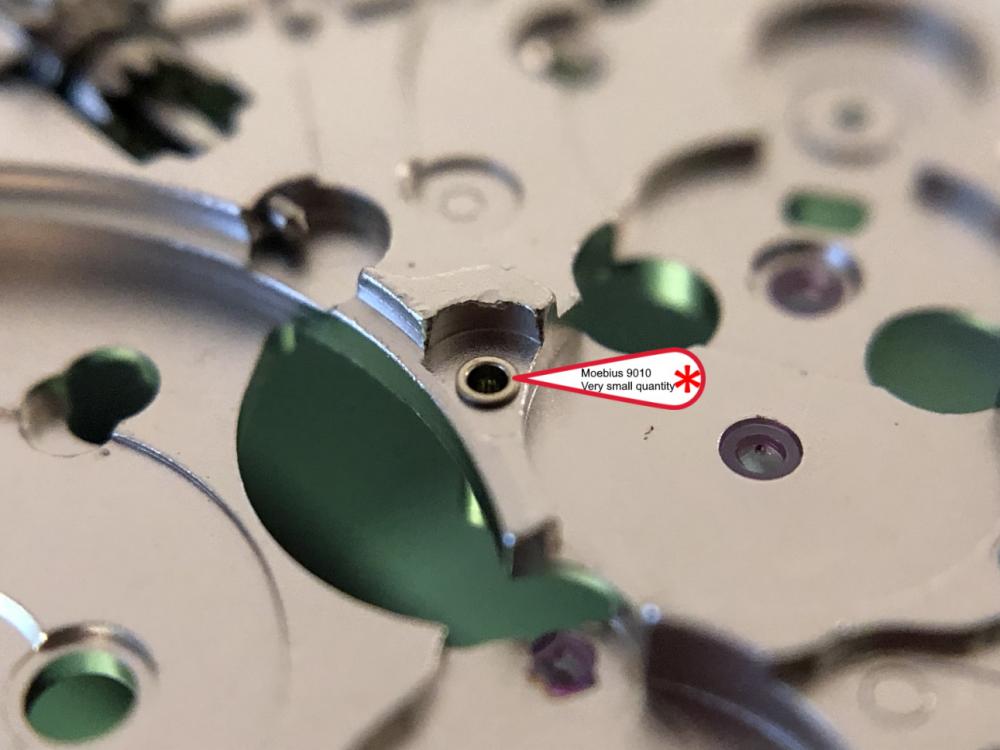

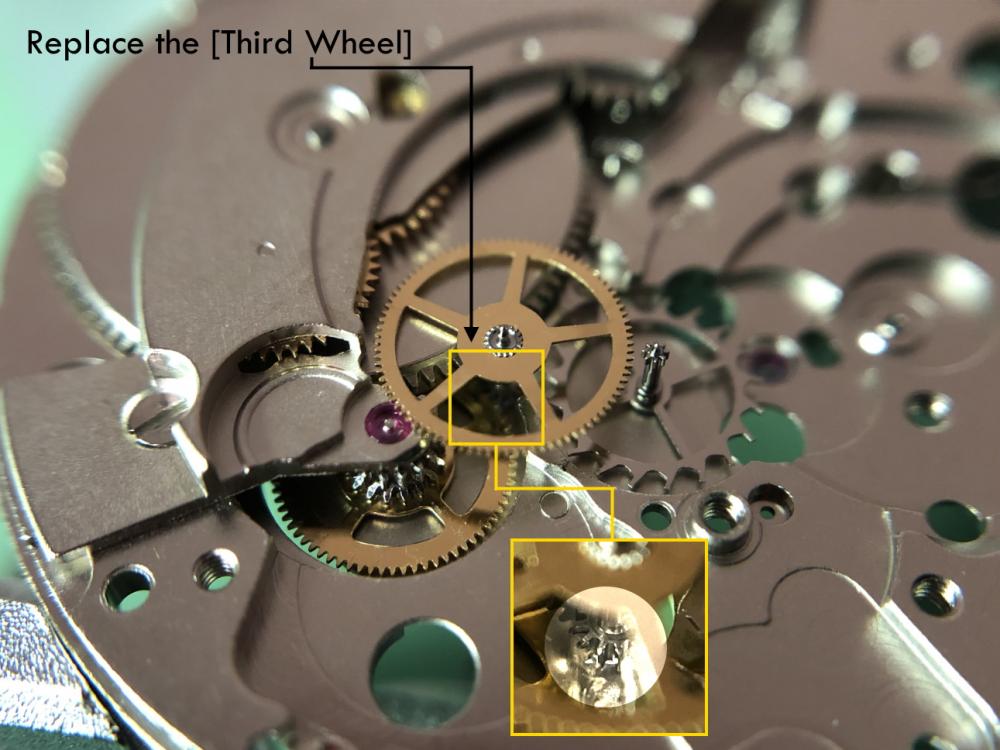

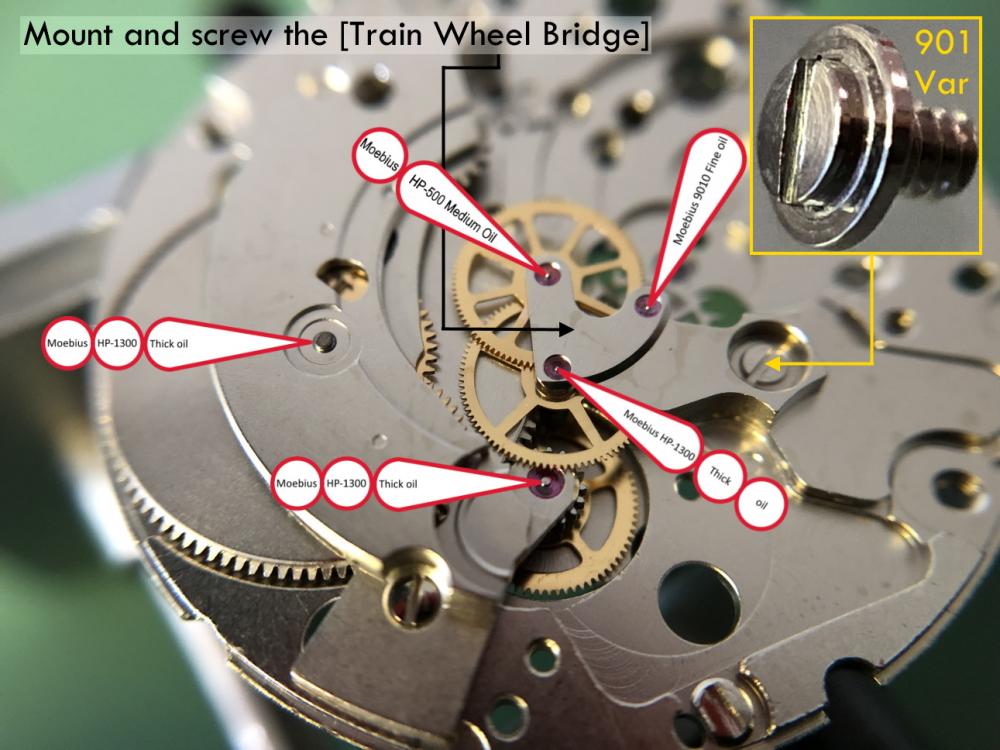

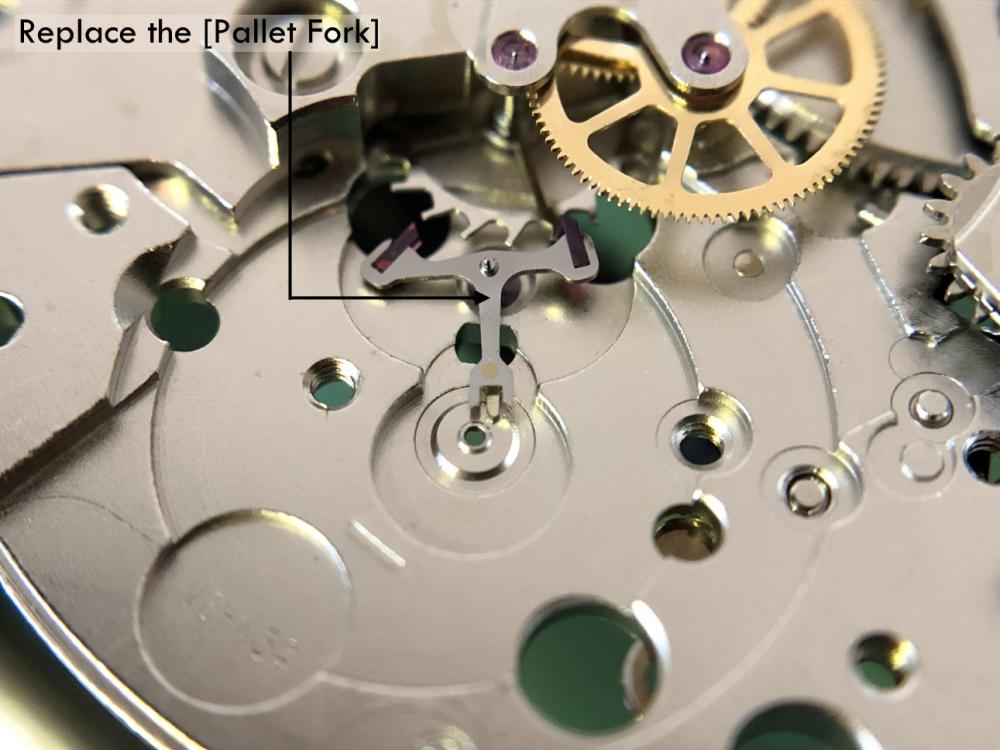

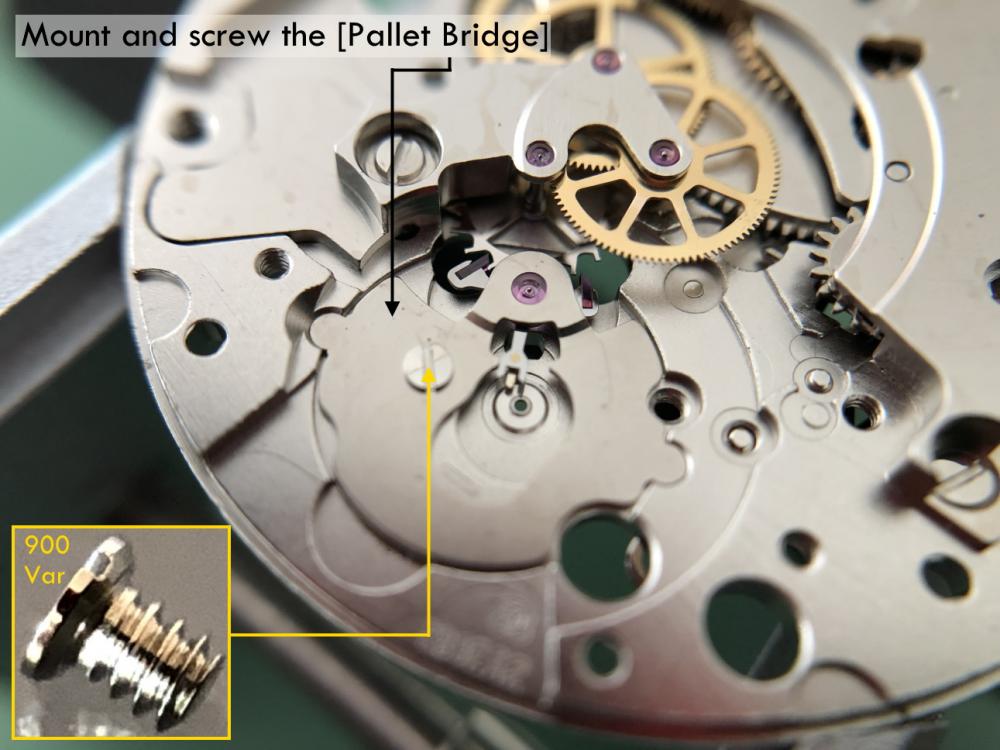

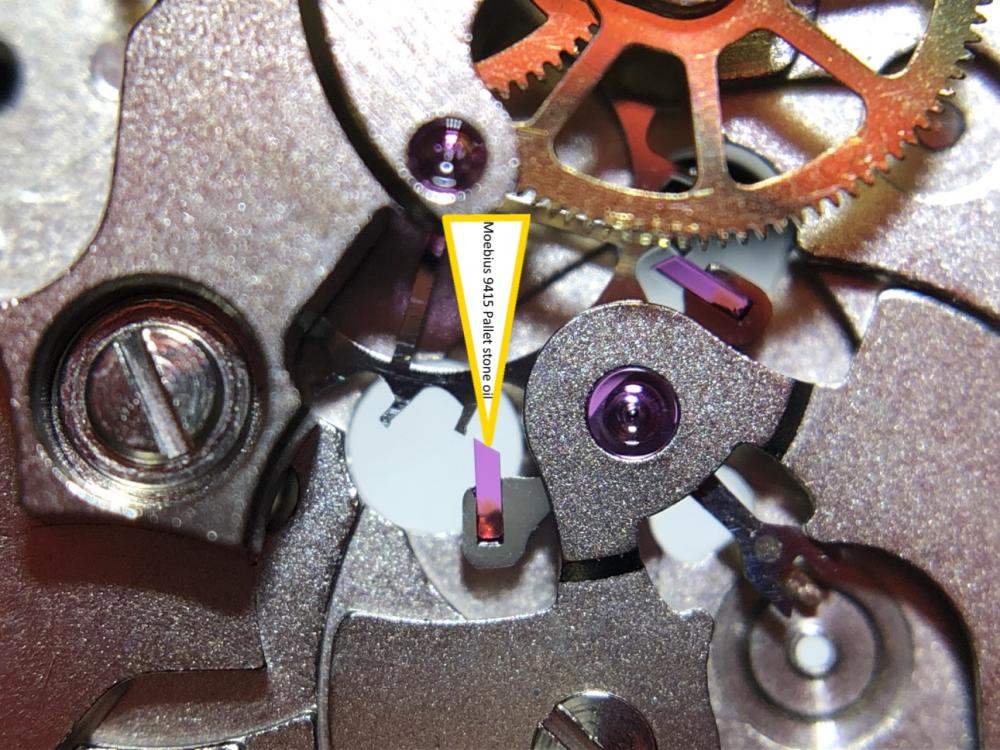

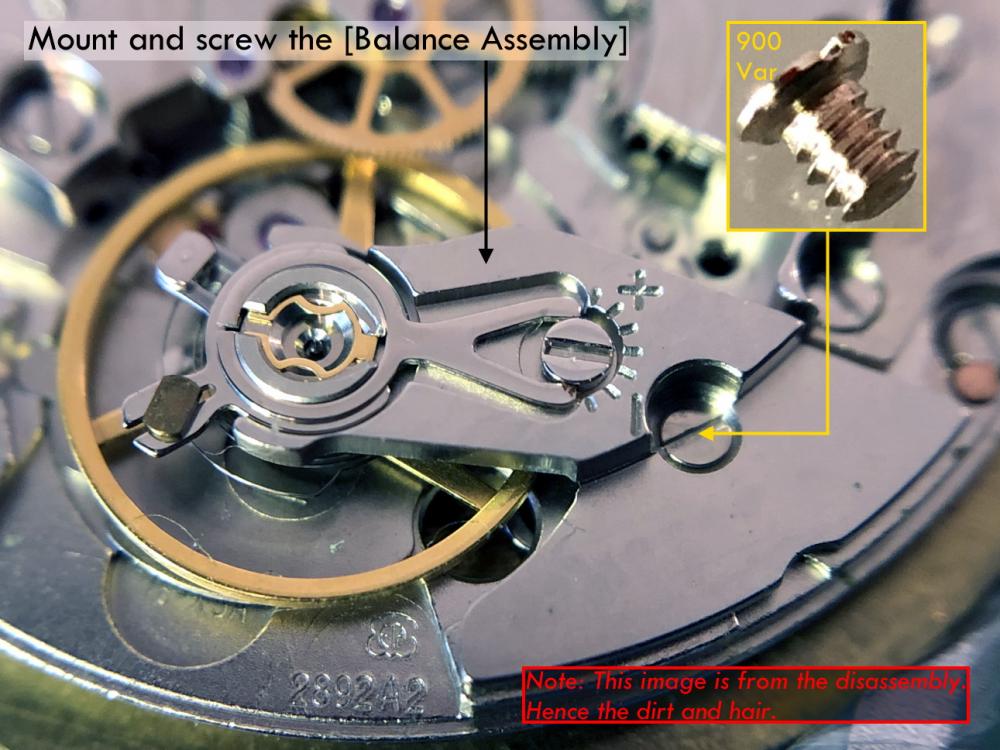

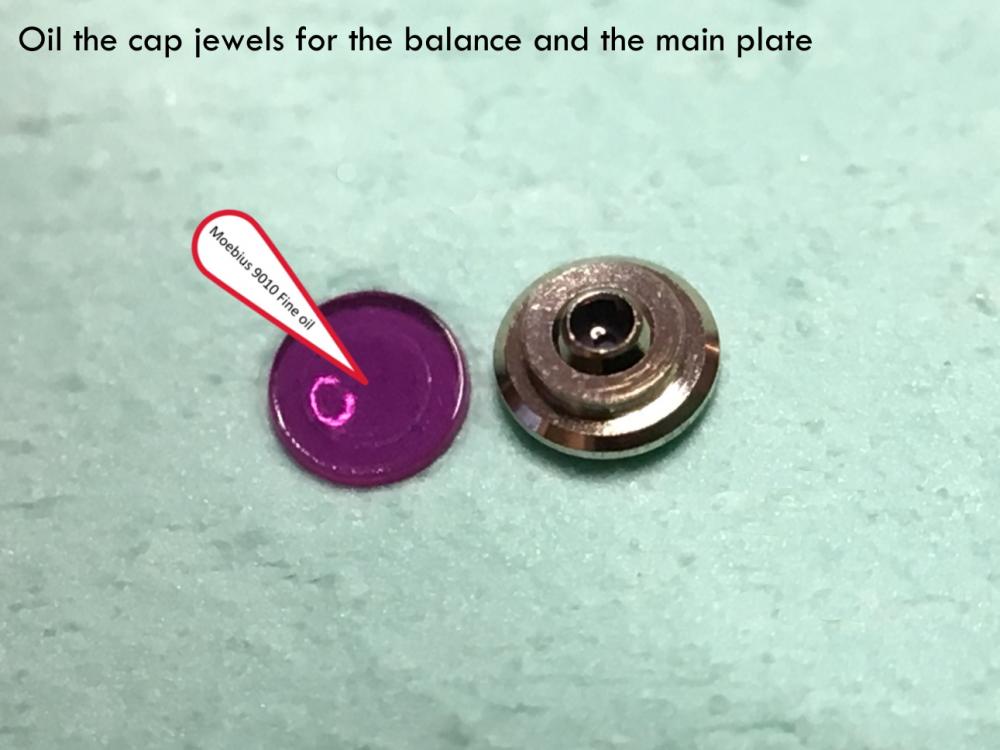

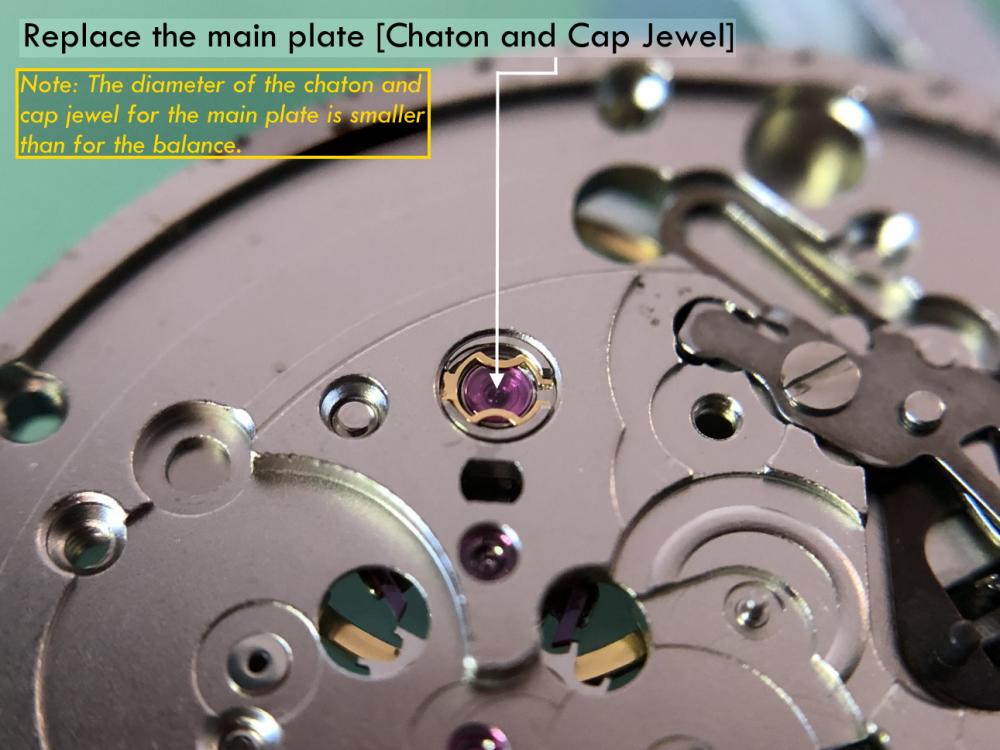

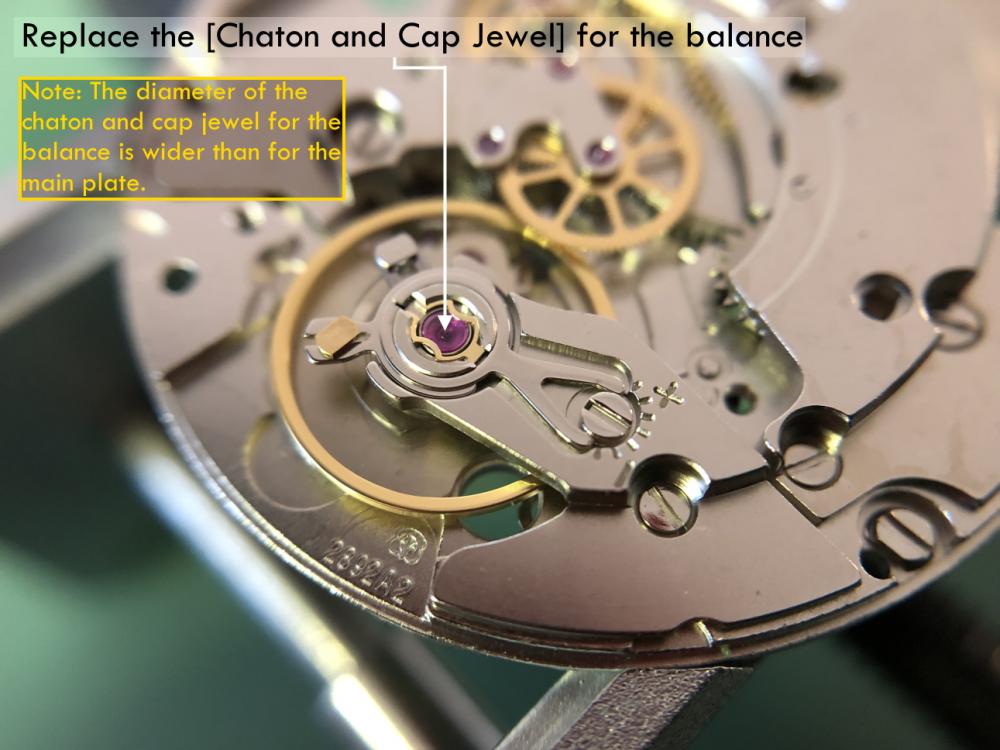

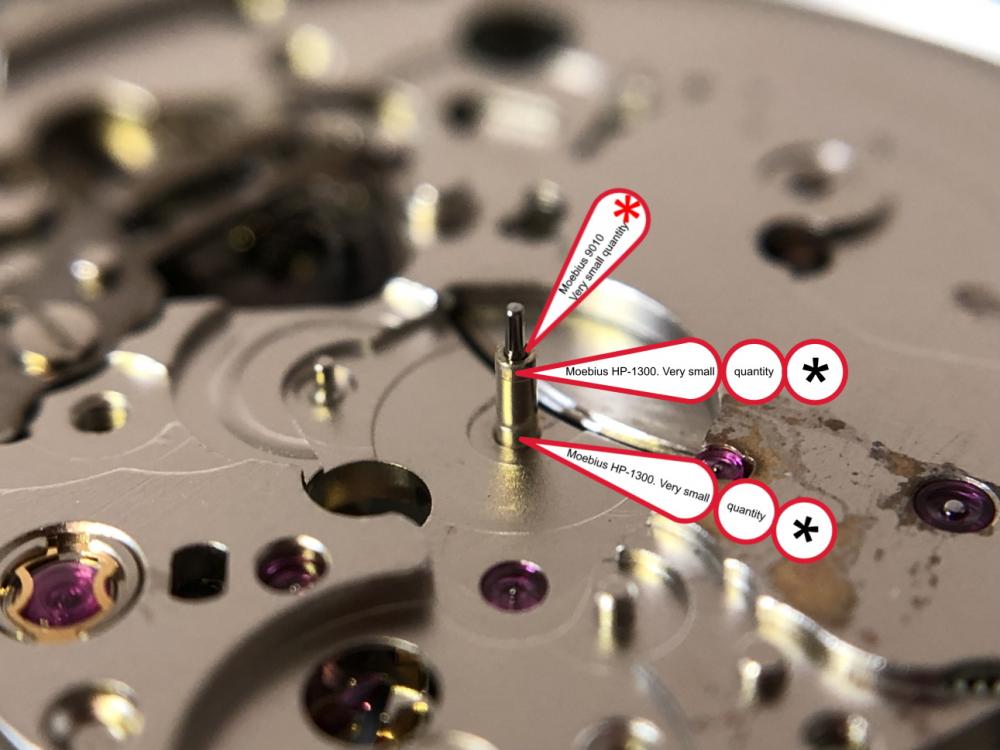

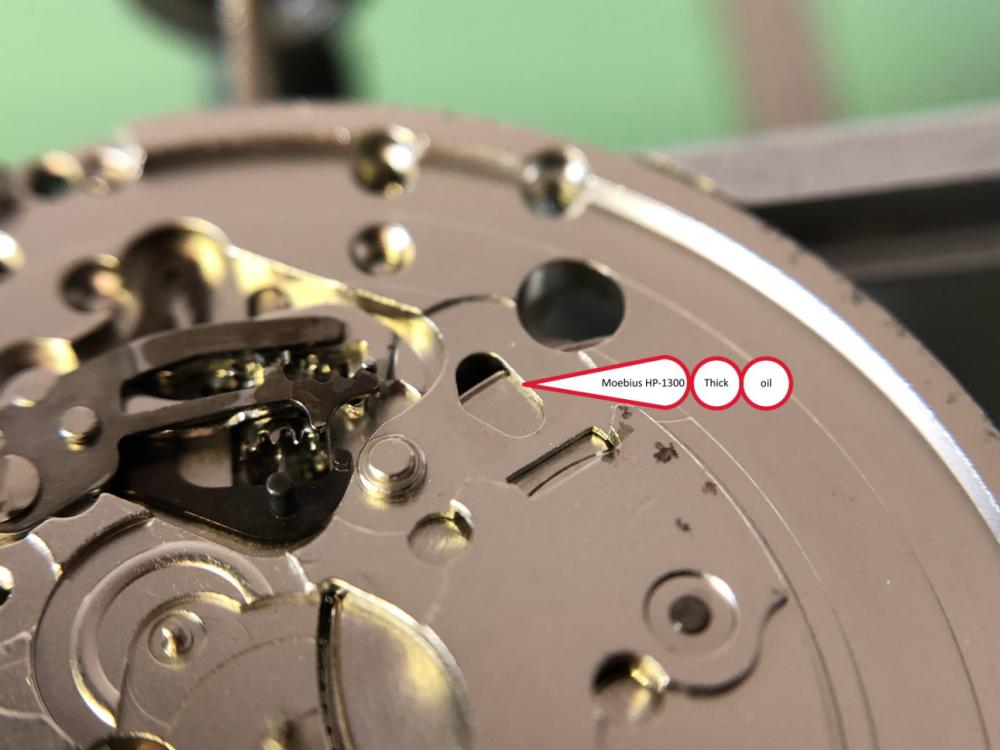

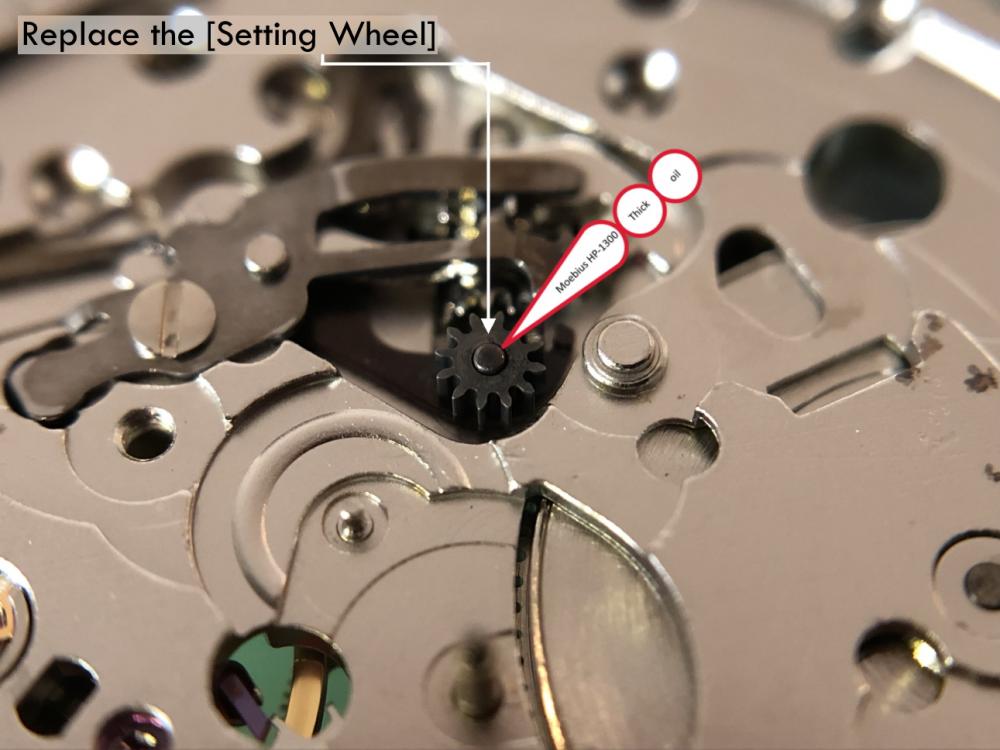

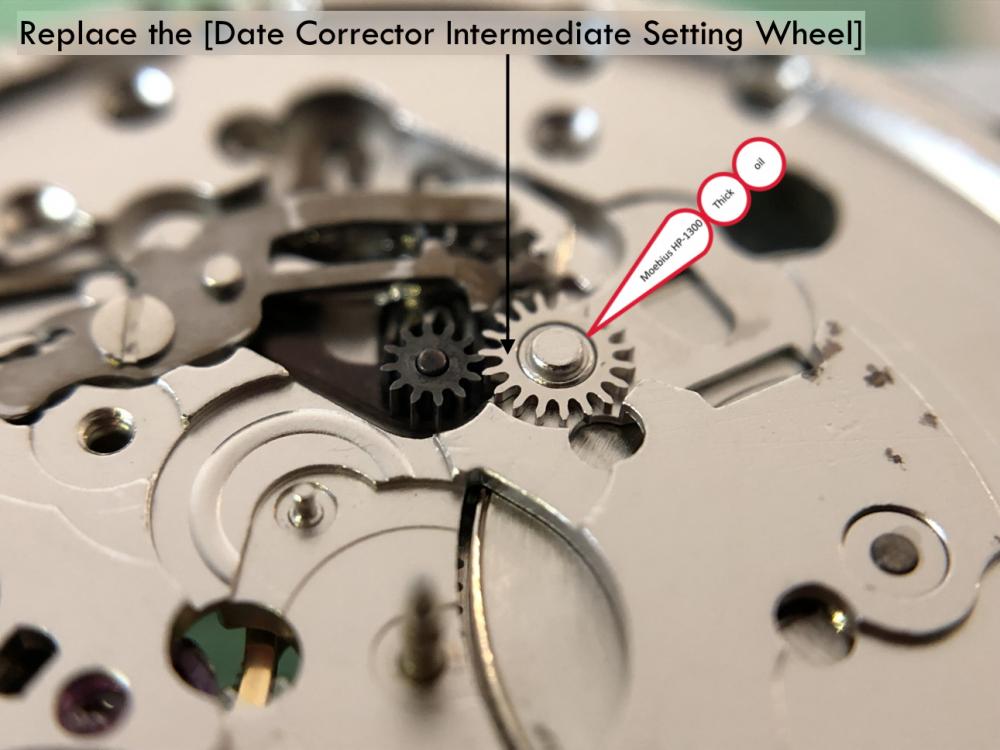

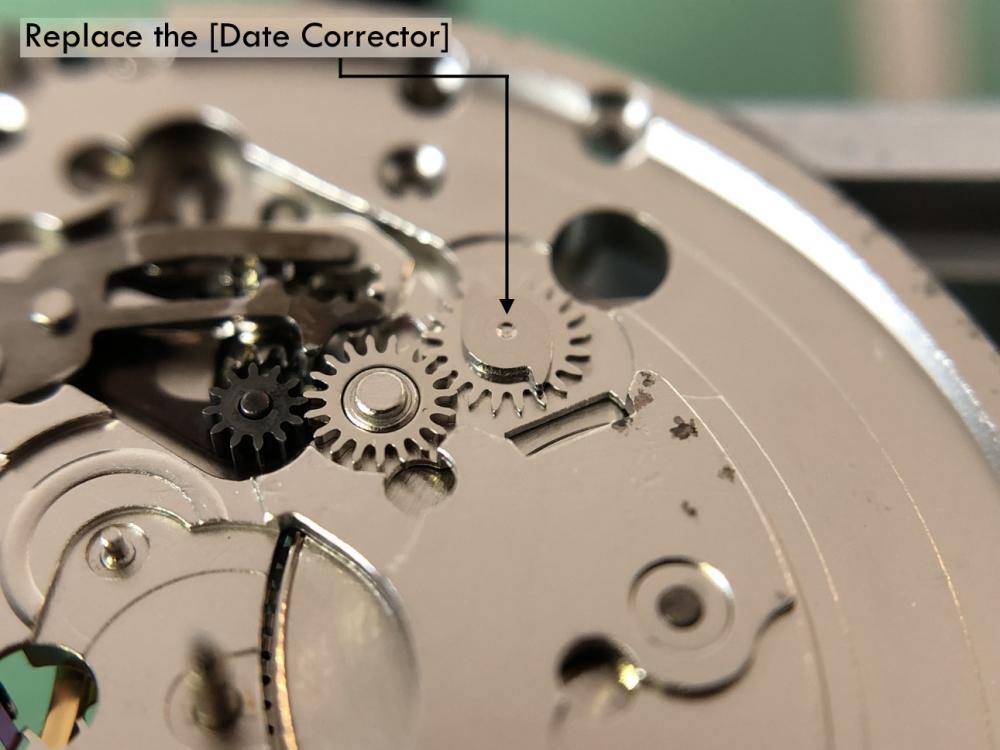

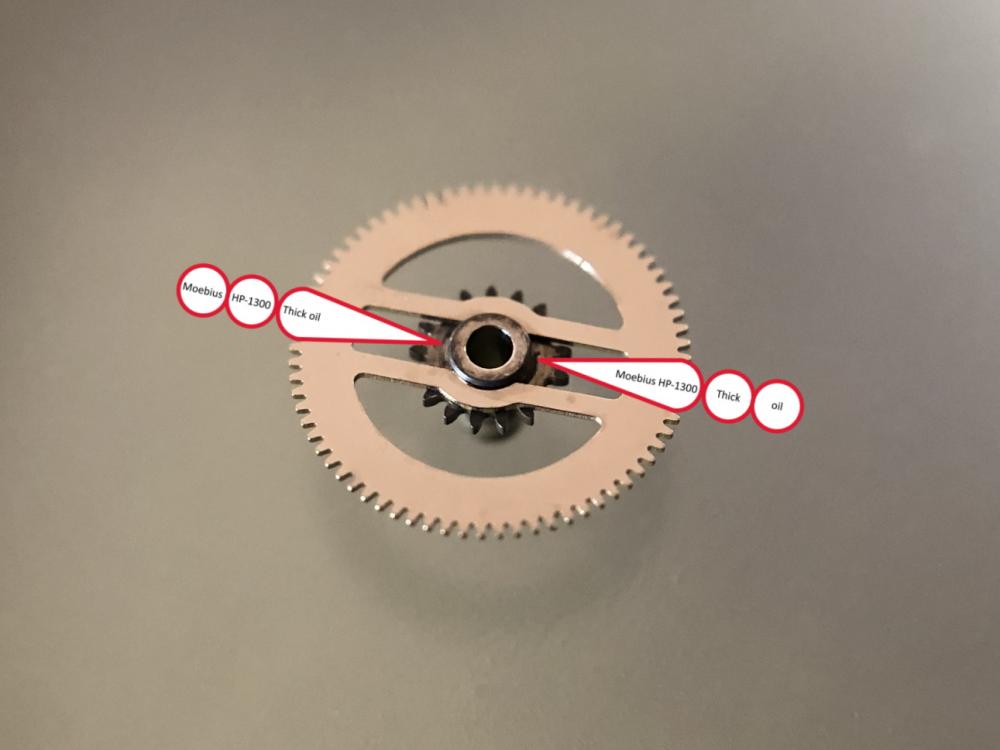

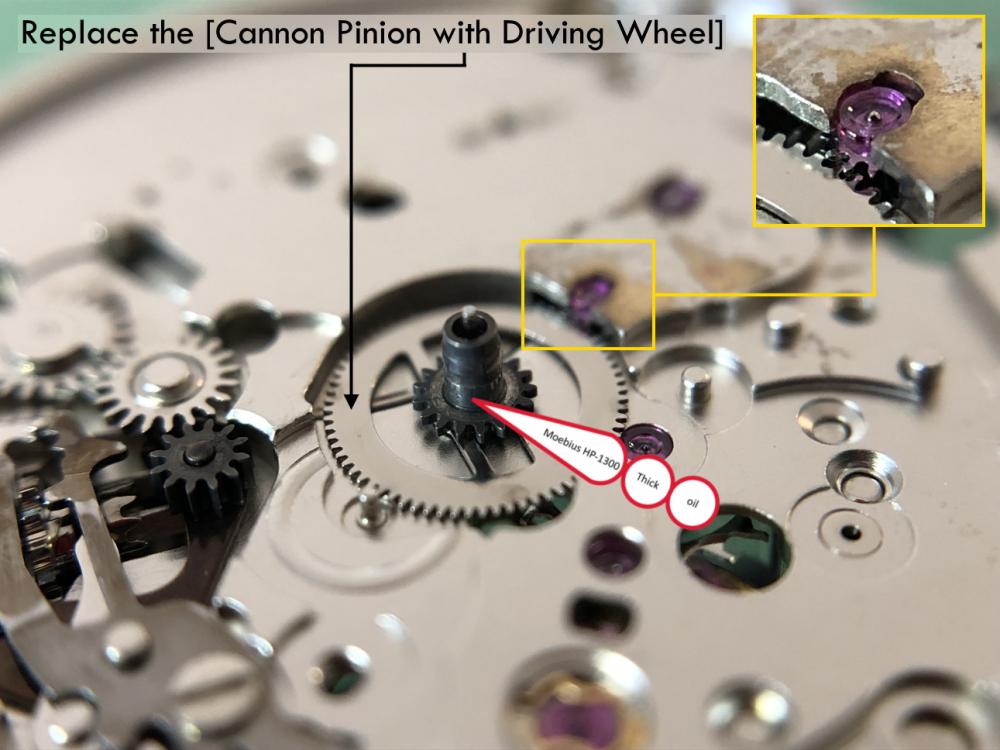

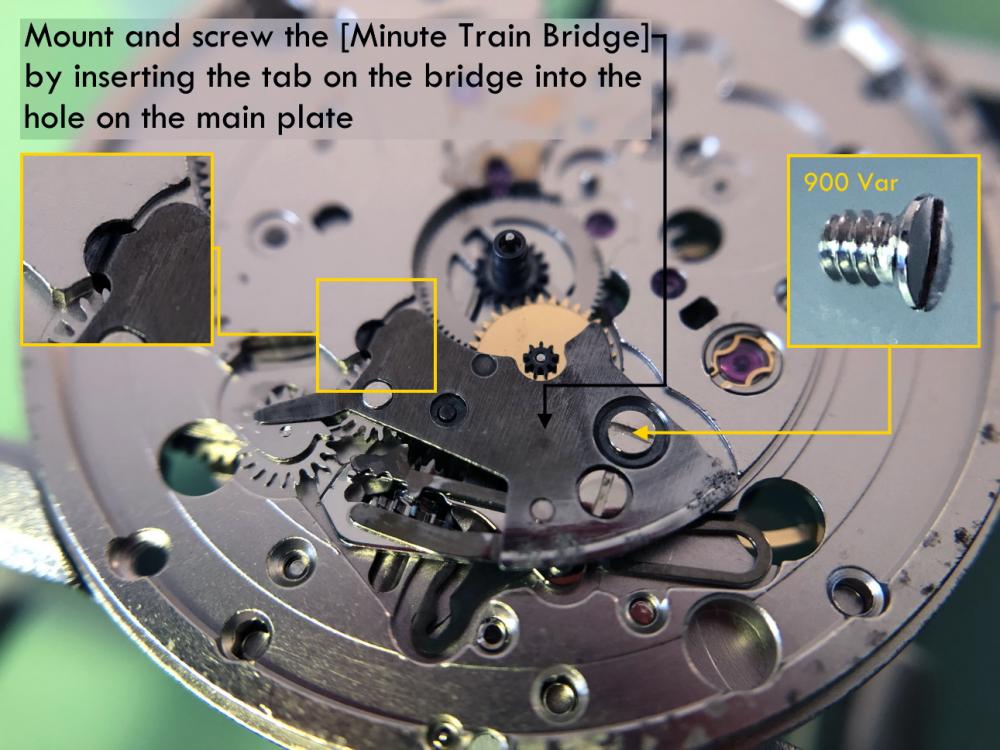

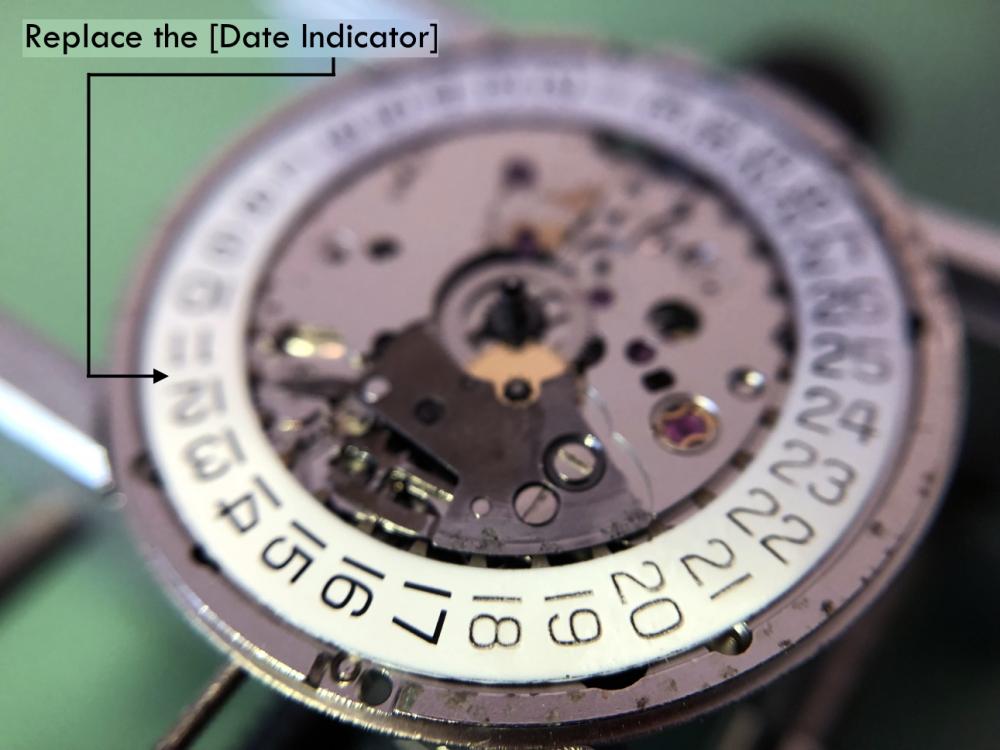

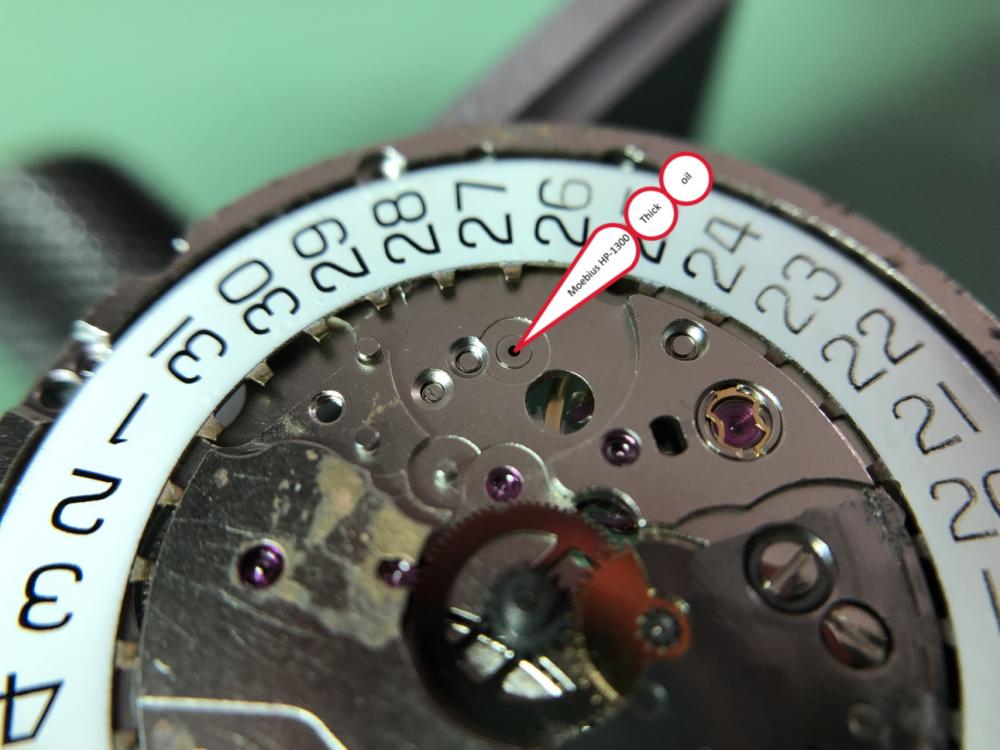

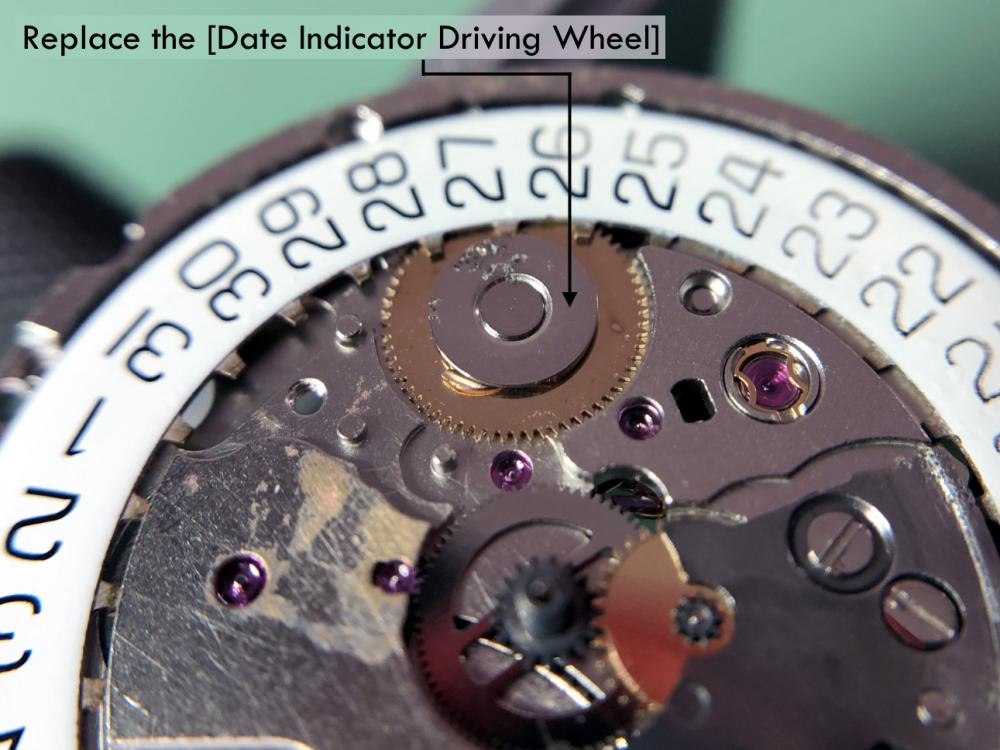

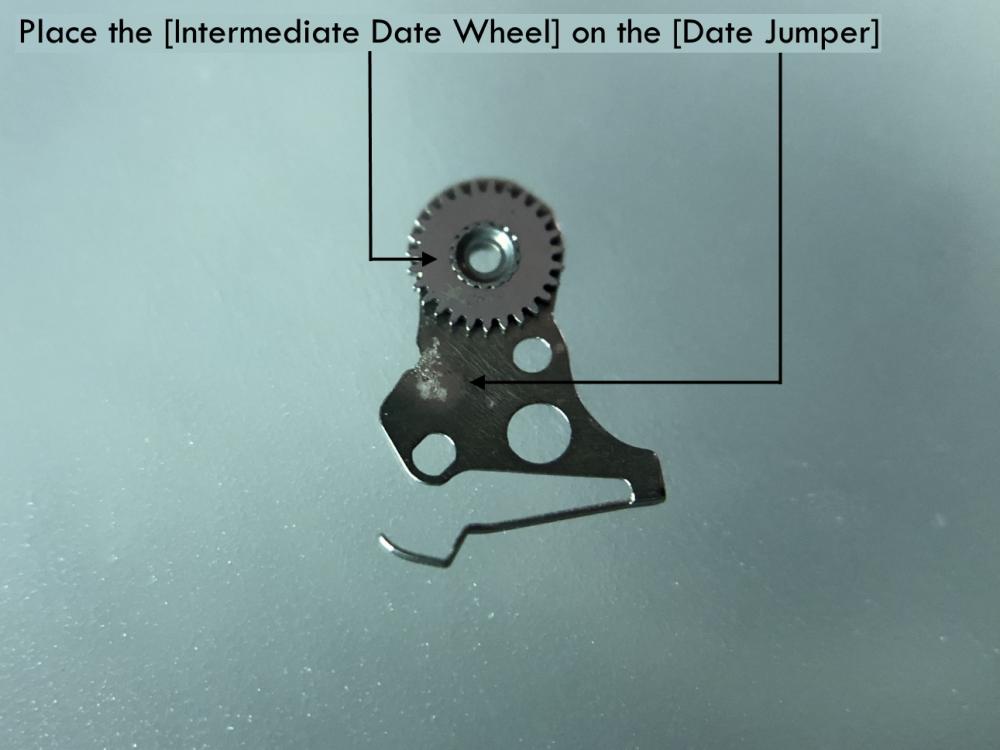

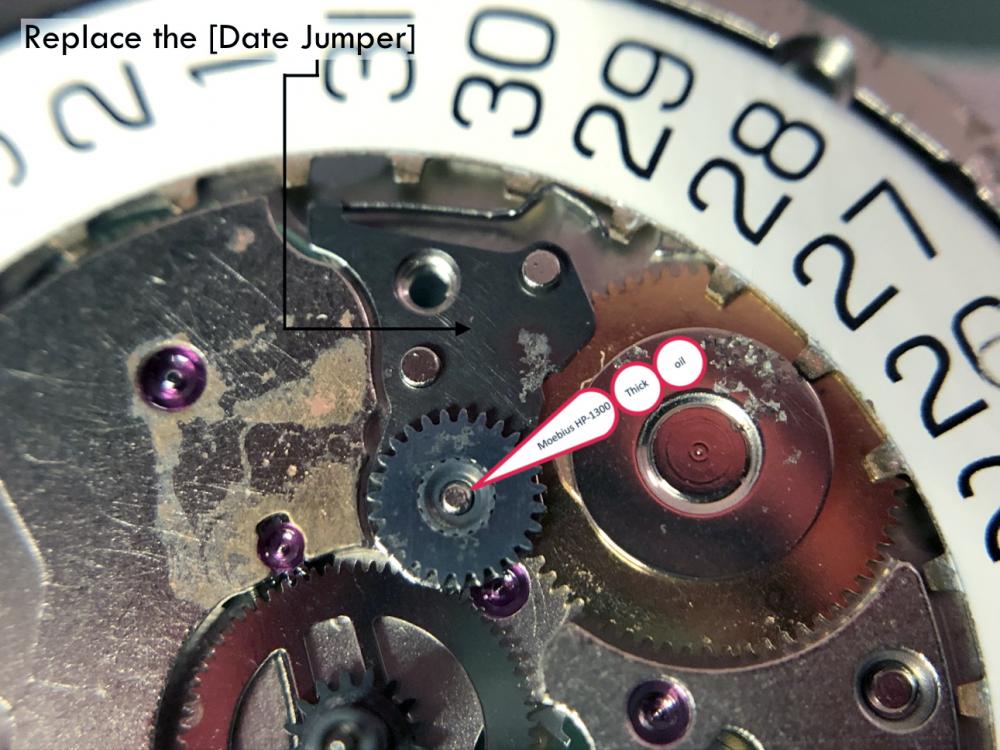

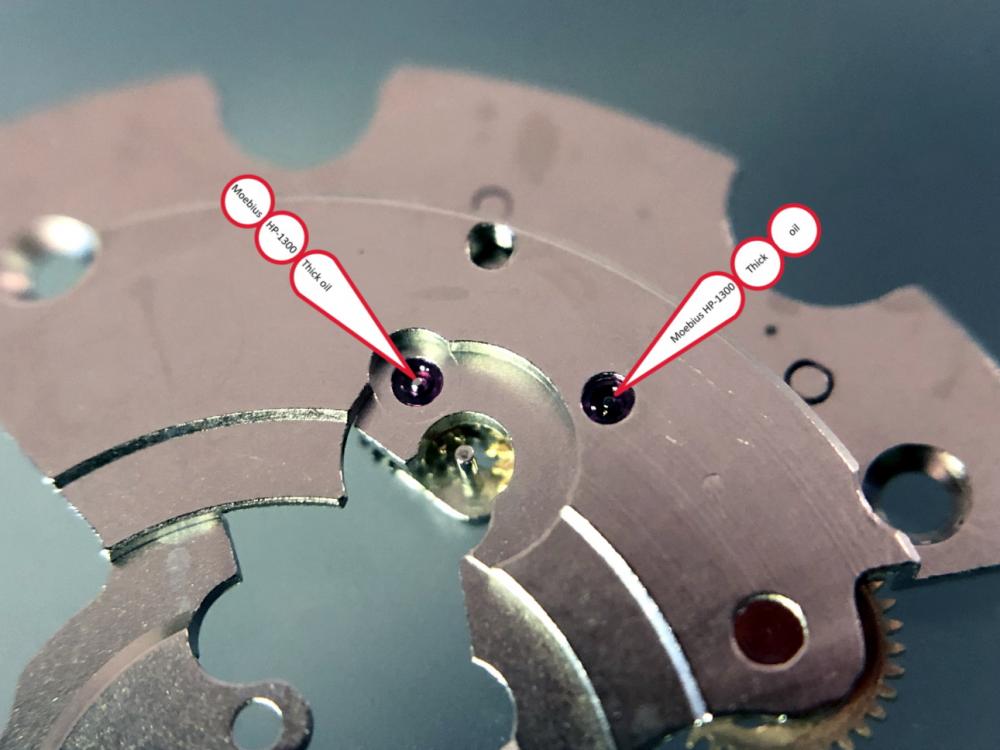

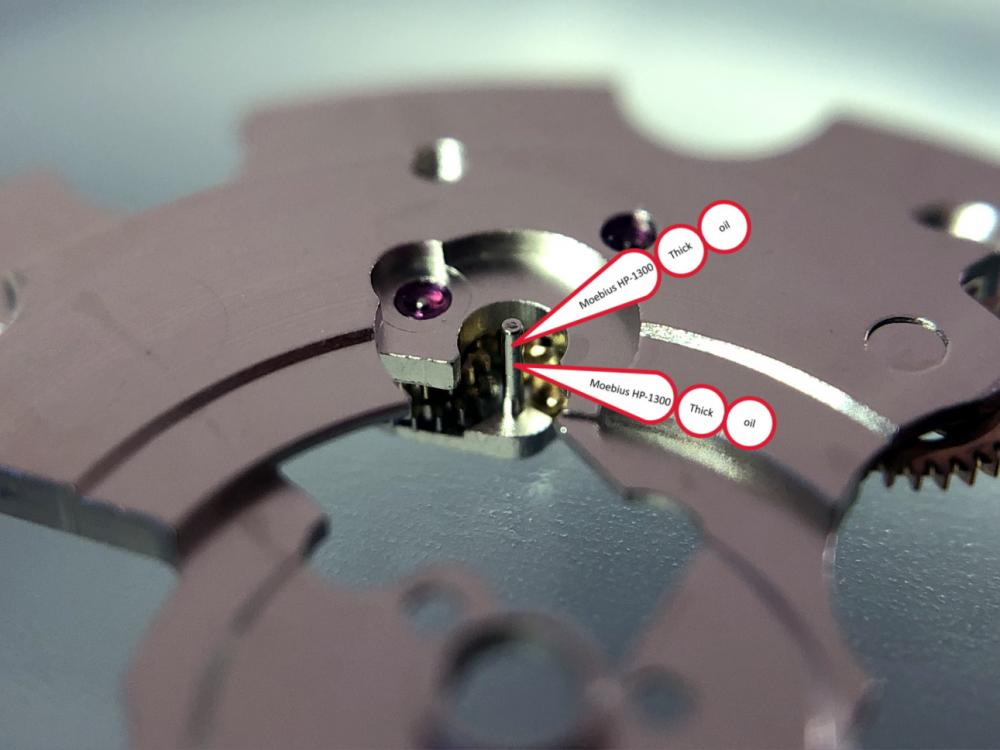

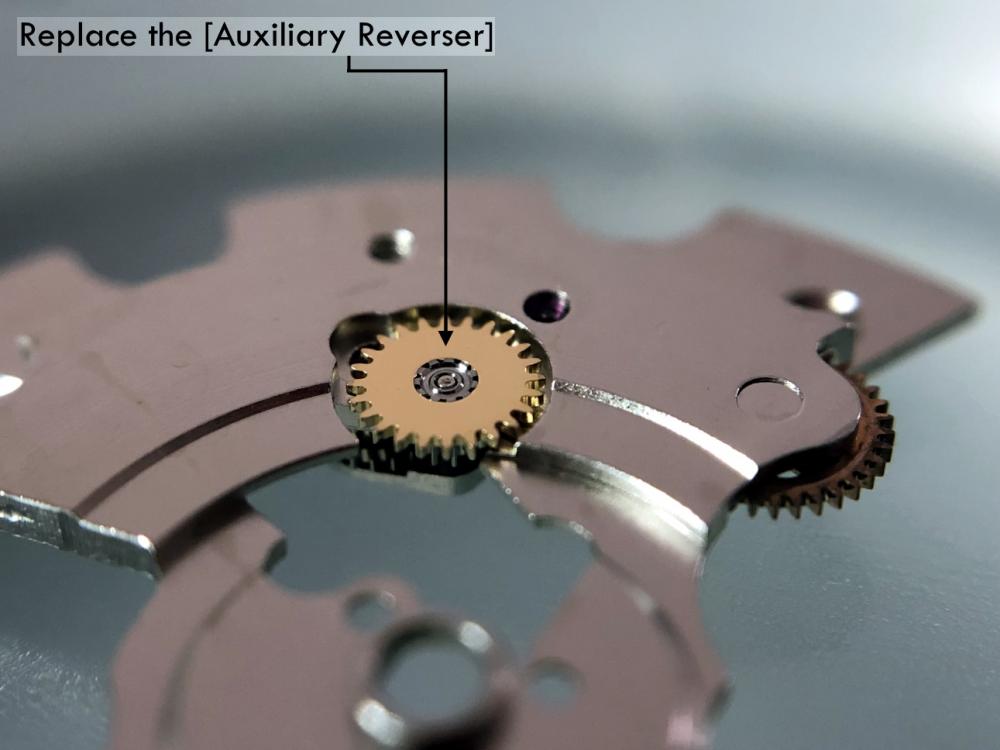

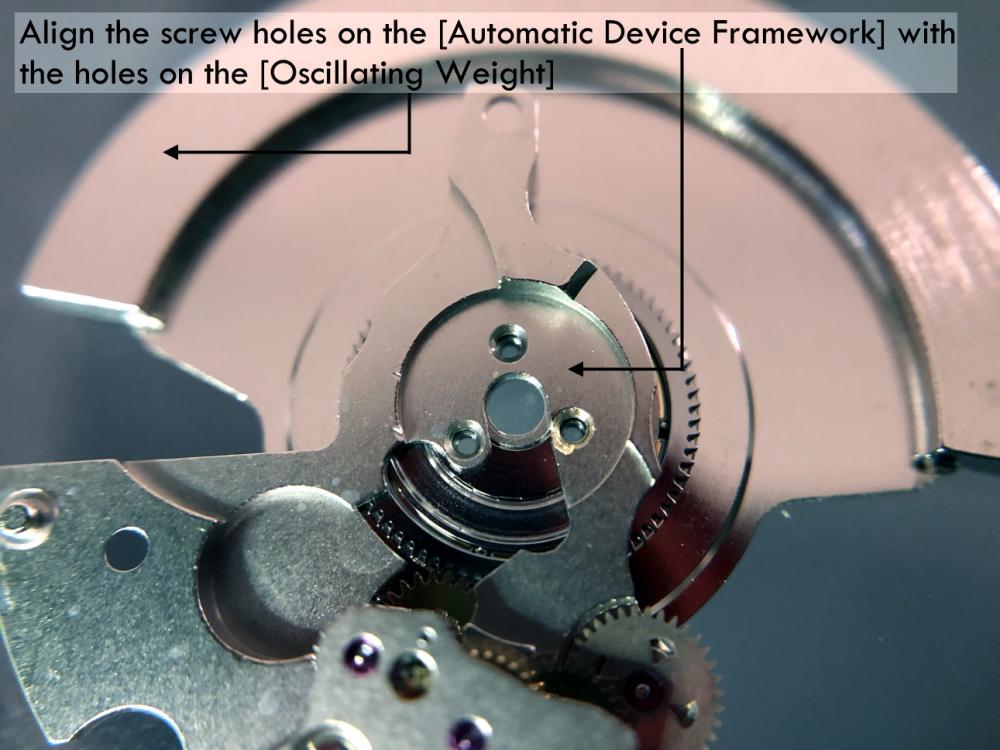

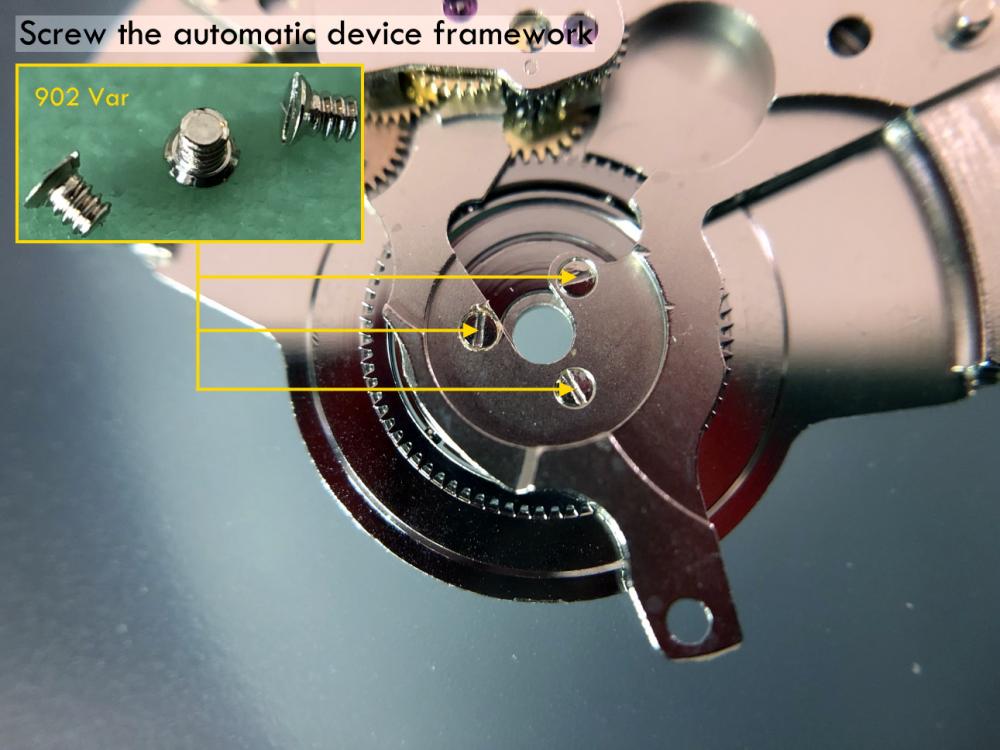

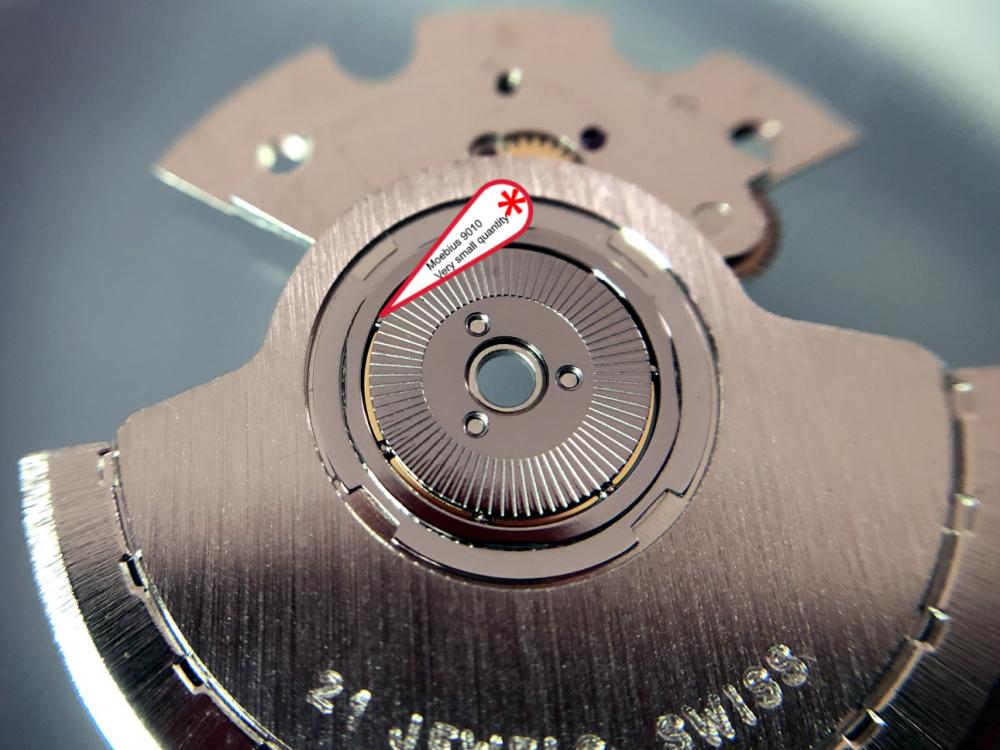

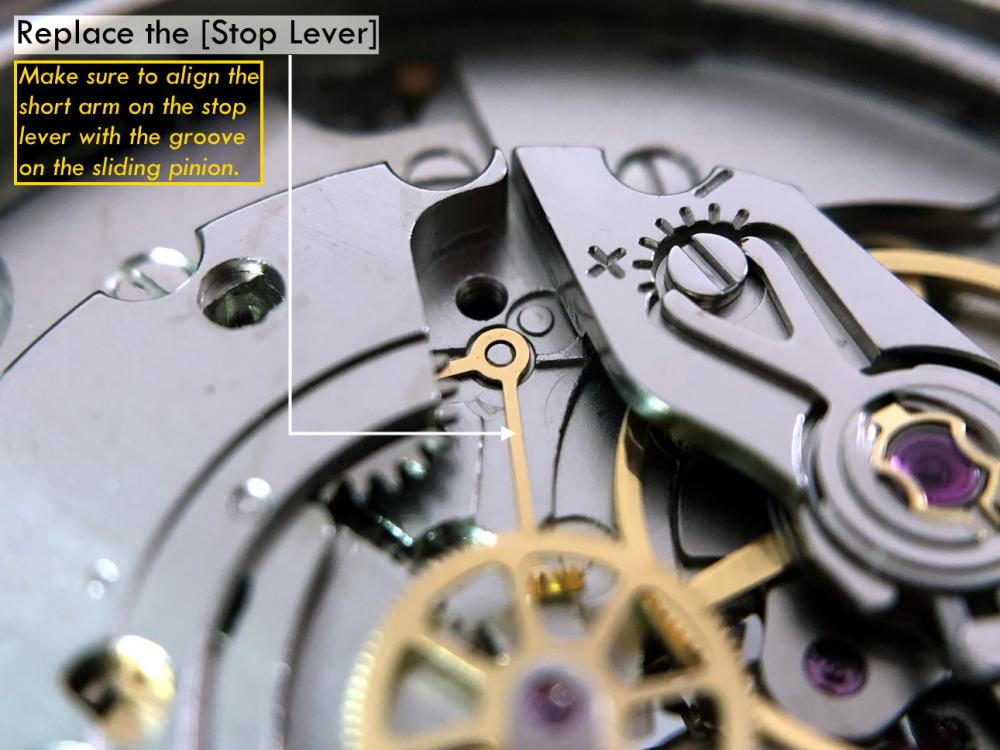

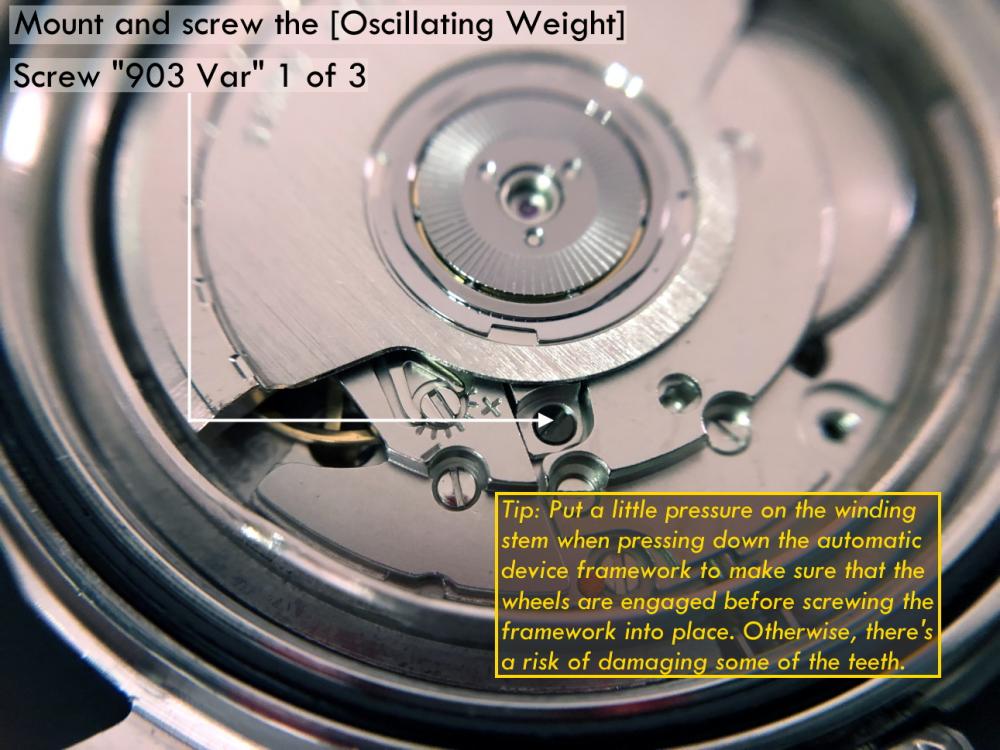

It is my impression that ETA's calibre 2892-A2 is usually found in more expensive watches and in luxury watches where oftentimes the movement has been modified. Mechanically, I don't think the 2892-A2 is superior to ETA’s classic 2824-2. Both movements have the same diameter (11 ½´´´ Ø 25.60 mm), the same frequency (28’800 A/h), and the same date complication. The decisive difference is the thickness where the 2892-A2 is one-millimetre thinner (3.6mm). That, combined with being a reliable and well-functioning movement, has made it popular for additional complications and alterations such as moon phase, power reserve display, co-axial escapement, chronograph modules from Dubois Depraz, and so on. The Swiss Sellita Calibre SW300-1 is, as far as I understand, an excellent clone of the 2892-A2. There is also a Chinese clone, the Seagull Calibre ST1812 (reviewed by @Markin the video “Chinese eta 2892-A2 Clone - Service and Review - Seagull ST1812”), and possibly others. Mark has made a playlist of videos that excellently demonstrate how to service the ETA 2892-A2 movement. The playlist is named: "Omega 2500 Co-Axial Stripdown and Service (ETA 2892-A2)" I recommend Mark’s playlist for several reasons. Among other things, he shows how to mount the barrel bridge safely and how to hold the minute train bridge with your tweezers to easily get it into place on the main plate (which I found a bit fiddly). In addition, he shows and compares the parts that are all too easy to mix up. One thing that is not shown in Mark's service video is that the Incabloc setting (chaton and cap jewel) for the balance and the main plate have different diameters. The main plate Incabloc setting diameter is smaller than that of the balance. The reason this is not shown in the video is probably that Mark removes, cleans, and lubricates the Incabloc settings one at a time after he reassembles the balance, so he wouldn’t notice. Anyway, don't mix up the two sets! Something that I appreciate about Mark's videos in general and that sets him apart from basically all other watch repairers on YouTube is that he doesn't continuously babble in his videos but mainly talks to make clarifications. I enjoy those segments of silence where I can just focus on the work being done. When I started my service, I decided to follow Mark's disassembly which worked perfectly. But for the assembly, I made up my mind to follow ETA's technical documentation to the letter. It turned out to be a mistake. In ETA's documentation, the assembly of the movement begins with the keyless works, then the train of wheels and then the barrel bridge. The crucial problem with this arrangement is that it is physically impossible to mount the barrel bridge if the train of wheels is already mounted. It is also very fiddly and difficult to baste the end of the winding stem into the winding pinion hole because the hole for the winding stem in the main plate is both open and tapered and therefore does not hold the winding stem. Mark takes a considerably more hands-on approach. He begins the assembly with the barrel bridge. He then mounts the keyless works whose constituent parts (the winding stem, the winding pinion, and the sliding pinion) are supported by the underside of the barrel bridge, making it considerably easier to get the keyless works in place. After I revised my strategy, this service walkthrough now follows Mark’s approach. It surprises me, but it seems like no watchmaker has proofread ETA's technical documentation. Alternatively, ETA follows an established practice and expects those using the documentation to understand that the assembly order in the document is not significant. I am also somewhat sceptical of ETA's recommendations regarding lubrication. Where we traditionally use grease, for example in the keyless works, ETA chooses mainly oil (HP-1300). I guess that ETA treats all parts of the movement with epilame (Fixodrop) and that oil may then be a better alternative. For better or for worse, my service walkthrough follows ETA's lubrication recommendations. As usual, I would like to remind those of you with no previous experience in watch servicing that this service walkthrough should not be seen as a tutorial on how to service a watch movement. A lot of tools, consumables, training and know-how are required to succeed. Fortunately, there are several excellent resources and watchmaking schools online. When looking through the pictures you’ll see that a few screws and plates are either marred or have pits and grooves in them. None of this is my doing but is either the result of rust (that I removed) or the doings of a less scrupulous repairer than myself. Finally, someone may ask, “Why to bother to do a service walkthrough with pictures when there is such an excellent video?" The main answer to the question is that I find it interesting and fun, and I see it as a complement to Mark's service video. Using this walkthrough, you can quickly scroll through the pictures to read what the different parts are called and where and in what order they should go, what the screws to be used look like, and to read ETA's lubrication recommendations. So, I hope you’ll find this ETA 2892-A2 service walkthrough useful, now or in the future. *** ETA Calibre 2892-A2 Disassembly *** ' *** ETA Calibre 2892-A2 Assembly ***

- 20 replies

-

- 16

-

-

-

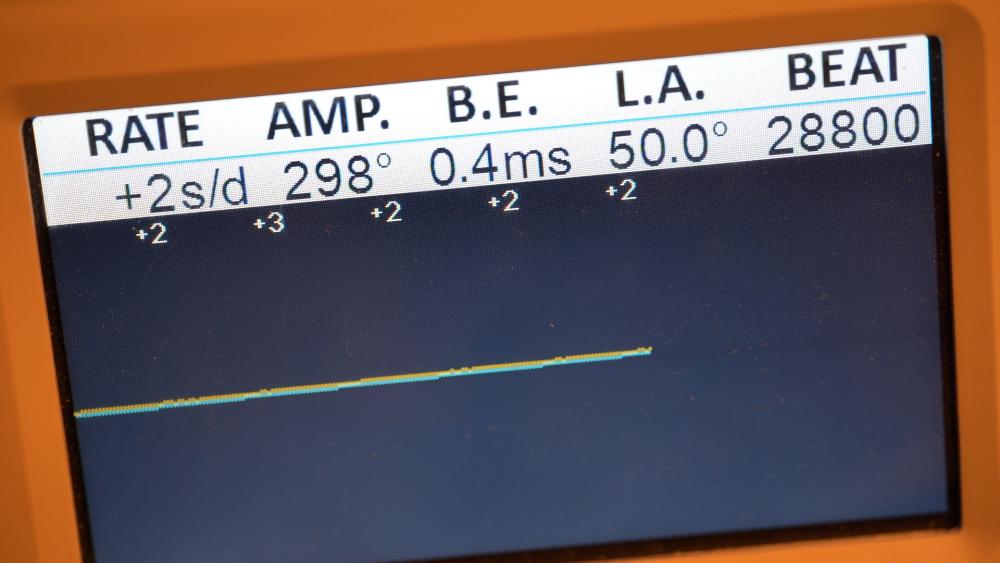

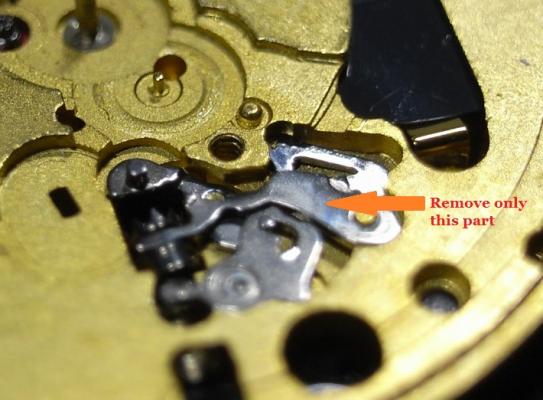

Hello Watchbangers! Welcome back to my usual watch repair report! It feels like an eternity since I’ve also had a bunch of other side projects and the upload schedule has changed but its good being able to present another solid watch! Now todays watch was, as always, bought over the local German eBay. It caught my eye because it was a swatch watch, but not any crappy swatch! It was a swatch with a mechanical movement! Till then I always thought that swatch only produced those small junky mechanical watches but low and behold! A swatch with a solid movement! And for the solid price of 50 Euros, with included box, papers (definitely super important ) and shipping I just had to snag it. Now before we jump into the whole process, here is a link to the full 4k commented video version on YouTube for the lazy readers out there: Now let’s go! After receiving the watch, this was the starting state of the watch: As you can see the outer appearance was still very good! The acrylic case has some scratches that would be easy to polish out and through the back, a clean looking movement was to be seen. The only thing which stood out was that the watch did not run after being wound. The seconds hand ticked a bit but stopped after a quarter of a minute. I was not sure what the issue was there, but I assumed that a good old service would do the trick! Disassembly: We start by prying off the see through case back. We unlock the watch spacer ring and movement in a counterclockwise direction from the case and lift them both out. We remove the hands. As you can see their condition is pretty good and the lume is pristine! After that we can just lift the minimalistic “chapter” dial from the watch face as well! Now we can carefully unlick the movement spacer ring and separate the two. Careful not to use too much force and snap the poor piece of plastic in half. After we have achieved in isolating the movement, we can strap it into our trusty holder. Unscrew the nicely blued rotor screw and lift of the smoothly signed rotor. I must say that the font reminds me of Comic Sans haha. Then unscrew the two screws for the automatic module. Flip it over to disassemble the whole automatic gear train. Once that is done, we can come back to the pretty movement body. A closer look reveals the stamped ETA 2842 marking. The numbers next to the caliber are probably the quality grade I assume. Unscrew the balance bridge and lift out the whole balance wheel carefully. I was super surprised at how tight the balance wheel and spring was sticking the bridge when lifting out. Usually, the wheel just droops into infinity xD The movement was already empty on mechanical power so I took out the pallet fork system here. Don’t forget the unwind the watch when doing this! Moving on we can take out the winding wheel above the mainspring and the click spring for the winding. You can see that these is a good amount of lubrication residue under the click wheel! Probably some Molycote DX I would say. Then we can unscrew the barrel bridge and take that away. Disassembling the train wheel bridge, we can see the whole power transmission journey laid out in front of us. I take out the whole gear train including the complete mainspring barrel to finish taking apart the whole back side of the movement. We can now flip the movement around. On the front side we can take of the minute wheel and hour wheel which is the canon pinion and the transmission wheel to the setting system. Now we can take away the small transmission wheel which engages and disengages when the setting system is used. Moving on to unscrewing and removing the smooth golden system cover. I was super careful here not to slip and scratch the cover since everything would be seen when looking down at the dial-less watch. Lastly, we can just simply take away the three parts of the setting system. Oh and the two part-clutch fell out while turning the movement so keep an eye on those too! With this last step, the disassembly of this Swatch ETA 2842 has been completed. Cleaning Process So this cleaning process has also been done the manual way. However! I did buy a cleaning machine now which I’m setting up and testing slowly. It should be in use in a few more weeks and then I can introduce it to you all! And clean my watches with it of course. Now the usual way of cleaning the watch parts is using lighter fluid and isopropanol alcohol for the rinse. And that’s exactly what I did! Now usually I also obviously service the mainspring and lubricate the balance jewels but this time I used the practical development of globalization and bought myself replacements for the complete barrel and balance of AliExpress to save some time and build into the Watch. Lubrication Here is a list of the used lubrication for the watch and their used areas. Moebius 9010 – Oil for jewel bearings with high rotation parts Moebius HP 1300 – Oil for slower moving parts and bearing. Molycote DX – Grease for high friction points on lever, wheels and contact points. Moebius 9415 – Grease for pallet jewels and escapement Crystal Polishing As mentioned at the beginning, the see through plastic case and case back had a number of tiny scratches from the years of use so I just polished them out with a rotary tool and some Polywatch. You can see a video of the method on my channel I think, but here was the result: Reassembly For the reassembly, we can just reverse the disassembly steps which I wrote down. I must however share a super smooth picture of the reassembled aftermarket balance. It just looks so good! Timegrapher Test And after everything was recased again I slapped the watch on to the timegrapher to see how well my work was done. Here are the the results without regulation: Looks like the aftermarket balance and mainspring barrel really do work out nicely! I did however regulate the watch a little to this: Just lowered the rate and beat error a little and bumped the amplitude up a few degrees aswell Final Results: I am very happy with the final results! The service went super smooth and I am glad that i tried out aftermarket parts for the first time. Now we just have to see how long these will actually last. Otherwise it was exciting working on my first swiss calibre! They definetly have a different style of design and function. A sort of different personality of a watch I would say Anyways I hope you all enjoyed going through the walkthrough and hope that this will help anyone looking for some sort of guide! If there are questions or comments, please comment! And critism is also always welcome! Till next time !

- 3 replies

-

- 4

-

-

-

- watch repair

- swatch

-

(and 2 more)

Tagged with:

-

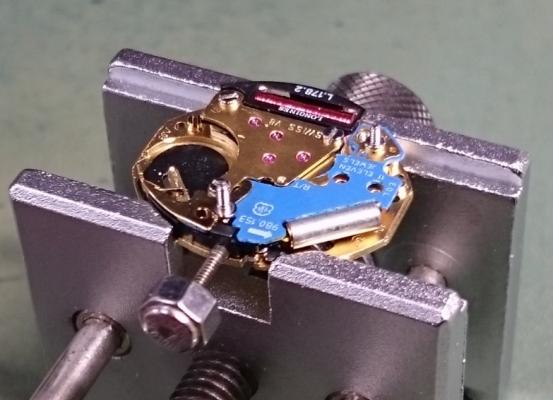

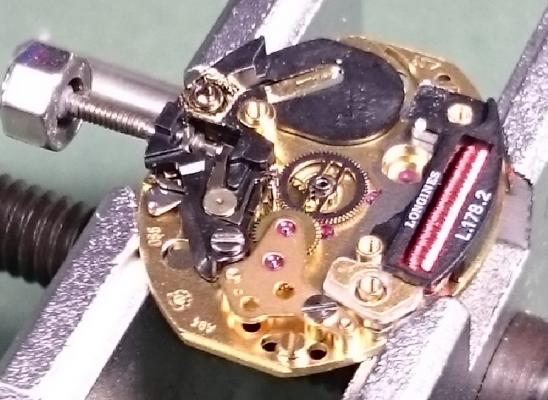

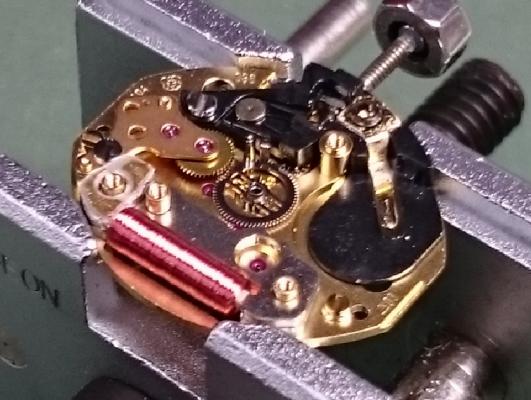

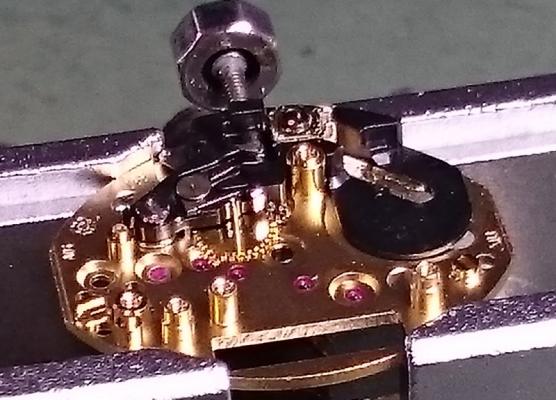

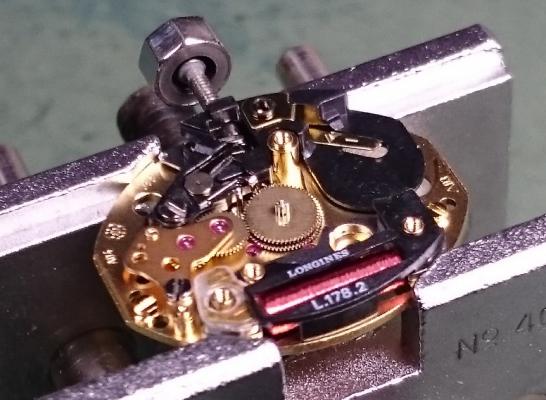

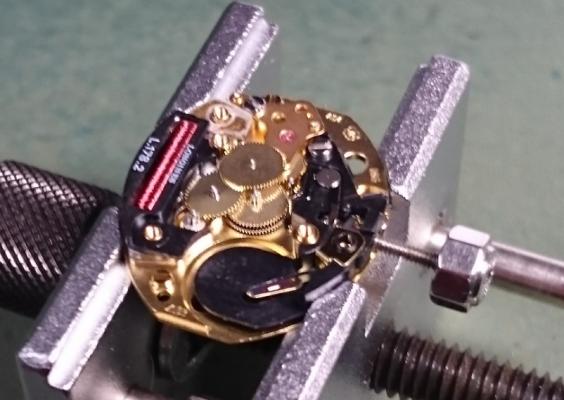

ETA 955 Service Walkthrough "The Workhorse of Highend Quartz" The ETA 955 and 956 Quartz Movements are the most commonly found movement in high-end quartz watches with three hands and a date feature. You will find them in Omega, Tag, and many other brands on the market. For this walkthrough I will be using an 955.412 Movement as my example; but the 956 is so similar to the 955, that this walkthrough will suffice for both. Please note that the numbers after the decimal place only relates to the factory in which the movement was made, so yours could read 955.112, or another factory number ... regardless, the parts are identical and interchangeable. As with all movements, quartz or mechanical, they have a service interval that should be adhered to for longevity of the movement. With quartz movements when the lubrication becomes dried out, or the movement becomes dirty, they will draw more and more current from the battery in order to maintain accurate time keeping. The ETA 955/6, when in optimum condition should draw around 800nA ~ 1.5uA, if the movement is drawing more power than this, a service is required. If a service is not performed, the battery life with decrease markedly, and can go as far as drawing more power from the battery than it was designed for, and damage the battery and cause it to leak and corrode your valuable time piece. Service Manual for the 955/6 Movement CT_956412_FDE_493024_06.pdf.PDF Disassembly Remove the two Date Wheel Keepers. I always start with the one holding the Date Jumper Spring in place. Sometimes the Date Jumper Spring can ping out of place, so be careful when removing the keeper plate above it. Here is a reference photo in case it moves before you see how it's properly seated. Next remove the Keepers and Date Wheel. Then remove the Date Jumper Spring, Motion and Calendar Work. This will leave only the Keyless Work; remove the Yoke and the Sliding Pinion only. We need to flip the movement over, and disassemble the IC Board before we can remove the rest of the Keyless Work. With the movement flipped over, remove the 3 screws holding the Coil Protector. Note for re-assembly the Gold Screw in the centre. Now that the Coil Protector is removed, GREAT care must be taken not to damage the exposed fine windings of the Coil. Then to remove the IC Board, simply remove the 2 remaining screws that hold it. Do this slowly and carefully, as you do not want to slip off the screw and damage this delicate circuit. The same level of care needs to be taken when removing the IC Board from the Main Plate. Take your time and carefully lift it off and store it immediately out of harms way. Next remove the black Insulator Block, and Battery Insulator. This will expose the Setting Lever Spring Clip, which will enable you to remove the rest of the Keyless Work. To remove the Setting Lever Spring Clip, place both points of your tweezers on the locations where I've placed the stars and gently push down on the spring. Then with a piece of Pegwood, push the spring in the direction of the arrow until it moves to the larger opening slot. This will now allow the Setting Lever to be removed, along with the rest of the Keyless Work. Next remove the Stop Lever and Switch, and remove the one screw holding the Train Bridge in place. Then carefully remove the Gear Train and the Rotor. The movement is now completely stripped and ready for inspection and cleaning. There are some parts that you do not place in the parts cleaner, they are as follows: Date Ring Rotor IC Board The rest should be demagnetized prior to cleaning to avoid any metal particles in your cleaning solution from sticking to your parts. When cleaning I also including the Insulator Block, and Battery Insulator in the basket, normal watch cleaning solutions do not harm these items and it is essential they are completely clean to provide the best insulation possible. The Rotor should be cleaned by use of Rodico. As you can see from the picture below, it's surprising the dirt and old oil this will remove ... and it is sufficient cleaning for the Rotor. I hope this has been a help to you, and I will post the assembly procedure later today, if time permits.

- 23 replies

-

- 12

-

-

vostok 2409 Vostok 2409 Service Walkthrough

VWatchie posted a topic in Your Walkthroughs and Techniques

Vostok 2409 Service Walkthrough Disassembly Pictures (Please sort by name in ascending order) Vostok 2409 Service Walkthrough Assembly Pictures (Please sort by name in ascending order) Being able to service the ETA calibre 2824-2 was a long-term goal and a dream when I started servicing and repairing watches some years ago. However, my first “calibre love” was the Vostok 2409; a reliable Soviet/Russian 17 jewels manual workhorse without any complications which has been around since 1970. It is still in production and found in Vostok’s Komandirskie series of watches, by some called the AK-47s of the watch world, together with its bigger brother the Vostok Amphibian dive watch. Modern-day Vostok Amphibians use the automatic Vostok 2415 (w/o date complication) and 2416 (with date complication) calibres, but the Amphibian that I’m servicing in this walkthrough, an Albatross Radio Room, popular among collectors, is from the 1980s and in those days the manual 2409, as well as its predecessor 2209, was commonly used in the Amphibians as well as the Komandirskies. While I was servicing this watch, I noticed that the crystal didn’t fit perfectly in the watch case. Being a serious dive watch originally designed for the Soviet navy this was, of course, unacceptable, so I replaced the crystal and video recorded the event in my “Bergeon No 5500 Crystal Press Review”. For me, the 2409 was a great movement to get started with as it probably is the most affordable movement on the planet, and spare parts are readily available and cost next to nothing. A lost or damaged part never spells financial disaster. Also, eBay offers an abundance of used Vostok watches in decent condition housing this movement for as little as $20 and sometimes less. A brand new Vostok 2409 (www.meranom.com) can be had for as little as $27. Be aware that, almost without exception, the eBay listings always state that these Vostok watches have been serviced, but in my experience they never are. Well, maybe dipped in a can of naphtha, left to dry and then injected with a bit of oil here and there. I’ve seen horrible examples! A somewhat tricky bit about the 2409 is to remove and replace the anti-shock springs. For this, I use a self-made tool made from peg wood. It’s shown in one of the assembly pictures together with a description of how I made it. A very similar tool is demonstrated in this video. Later, as I was working myself through Mark Lovick’s watchrepairlessons.com courses, I trained with the Unitas 6498 pocket watch movement which is the selected movement for the courses. In all honesty, from a learning point, the Unitas 6498 would have been an easier movement to get started with (especially the anti-shock springs), but the tinkering with the Vostok 2409 was a low-cost and fun way to get started and made me better prepared for the courses which answered a bunch of questions and was amazingly instructive. Eventually, I plan to publish a “Vostok 2414 Service Walkthrough”. The 2414 is identical to the 2409 but adds a very uncomplicated date complication. So, if you want a whole lot of fun for next to nothing when it comes to money, there is no other movement I would recommend before the Vostok 24XX movements, and the 2409 is a great starting point if you have a desire to begin tinkering with watches. Be warned though; tinkering may take over a substantial chunk of your life!- 33 replies

-

- 9

-

-

-

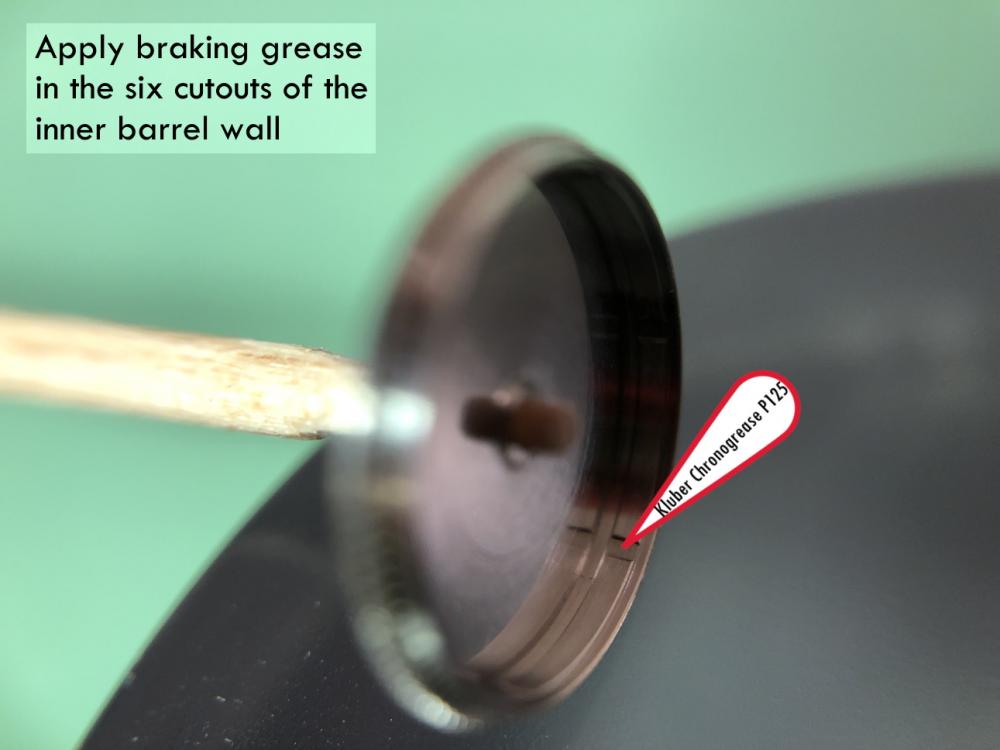

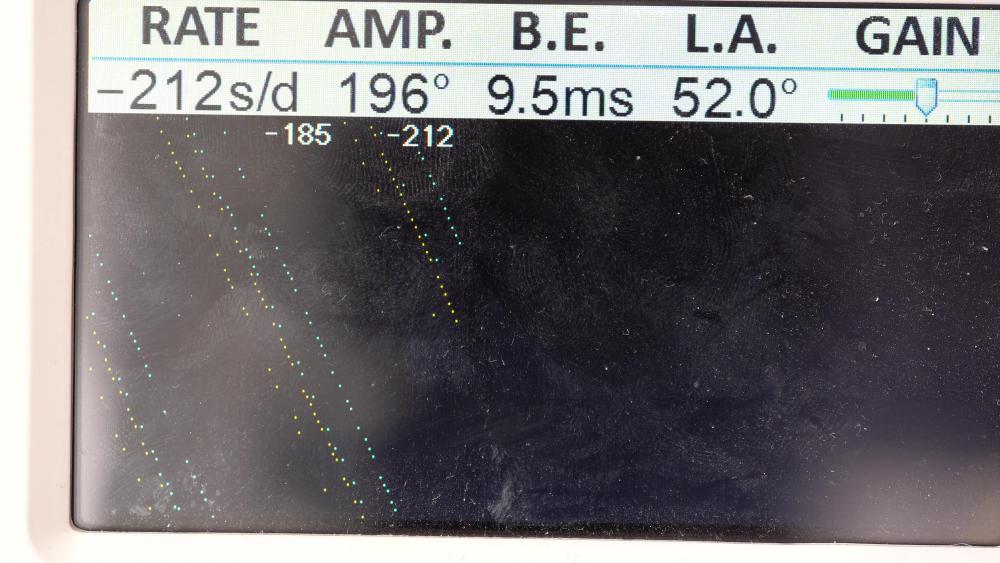

Hi Watch bangers! I did actually make it a personal goal of mine to present a watch every week but real-life caught up and ive been busy helping people move around haha. Bit nevertheless I am a week late but have another beautifull watch and project report for you guys! This watch was one of a few which I presented my Mother for her birthday to let her decide which one I should fix for her. She chose this vintage Seiko 4206A which I got from Ebay and so I sat down and got to work. Now I bought this watch online because I was really surprised at the remaining quality of the original dials and how there where still so many of them. After purchasing one and reading up a bit online it turned out that this movement line was particularly prone to behave irrationally or to repair so I kind of messe dup but nevertheless, I faced my challenge! The watch on arrival: Disassembly 1. Remove the watch case by unscrewing the back and removing the stem 2. Remove the Watch hands 3. Release the Dial feet from the back with the small levelr at the 10 and the 4 Position I think and remove the dial. As you can see it is in pretty good condition and has a very pretty sunbust effect. There is a slight stain though around the “ Automatic” text which left me kind of clueless since it is a metal surface and I wouldn’t really know what would stain it in such a way. I decided to leave it be to minimize the risk of further damage. Heres a close up picture: 4. Remove the Day clip and the Day wheel underneath it. This revealed a very interesting sping-like swan neck system for the day-wheel quick set system. Never seen that before! 5. Then remove the Day wheel spring and the 24 Hour day turning wheel. 6. Now you can unscrew and remove the main setting cover plate and the attached date wheel. 7. Take away the ( im not sure what this part really is called) but it is part of the quick set system which hooks into the second clutch wheel. 8. Now remove the Date Spring and lever, the bottom day wheel and the hour wheel to remove some more from the front side. 9. Remove the one translation wheel and the setting system sub cover which also separated the two clutches. 10. And finally take out the clitches and the yoke, setting system to completely disassembly the front side. Now you can turn the movement so we can work further on the back side. 11. Remove the Rotor 12. Take off the Automatic module 13. Remove the Winding wheel Y ratchet. I did try to remove the winding wheel in the first run but for some reason the screw did not watch to budge so I left it in for the picture. Off camera however I eventually did make. 14. Remove the elegant arching balance wheel. I was really surprised to see this in this kind of movement since I thought that this kind of design was only present in really high end watches. Interestingly enough the 4206 B however has the classical one winged balance. 15. Remove the Pallet fork system ( sorry for the blurry focus) 16. Take off the main bridge and and the small spring attached to one of the screws. 17. Pick out the Barrel, its ratchet and the 4th and 5th wheel. Interestingly enough the gears wheels have as many holes in them as the number which is kind of cool! 18. Now focus on the little winding module on the bottom right. Remove the translation wheel, the spring and the small bridge to take it out completely. 19. Almost done! Take of the final bridge which holds down the 6th wheel and the escapement. 20. And finally remove the 6th wheel and the escapement wheel. With that, we have completed the disassembly of the Seiko 4206A. Cleaning For cleaning im still sticking to the good old hand cleaning method. So this means that I let the individual parts marinade in lighter fuel for a while before giving them a scrub and rinsing them of in Isopropanal alcohol. I was thinking about dipping my toes into the ultrasonic cleaning branch but im unsure what fluids to buy and what parts I cannot drop into the cleaner so I think ill stay with what works at the moment. Additionally im broke haha. Mainspring service Now as always I did not have a spare Mainspring at hand so I removed the spring by hand and checked it out: As you can see it is / was absolutely disgusting haha so I gave It a good rub down in lighter fluid and isopropanol and the paper used for that was absolutely nasty in the end, see for yourself: However, I did clean it nicely I think and lubricated the spring with Moebius 8200 and the barrel wit Moebius 8217 before winding the spring back in carefully. After closing the barrel I did a mainspring wind test with the winding wheel and it had tension on it so it seems like I did a decent enough job. Lubrication Moebius 9010 – All jewels aside from the pallet fork jewel pivots Moebius HP 1300 – For parts which turn a bit slower. Between the arbour and the watches wheel, the barrel pivot in the main bridge or the metal pivots for translation wheels for example. But that’s just my personal tase Moebius 8200 – Used to lubricate the mainspring Moebius 8217 – Braking grease for automatic barrel wall Moebius 9415 – For the tip of the pallet fork jewels. Molycote DX Paste – Any strong friction contact points. So the setting and winding system basically Reassembly For the reassembly of course you just follow the above given steps and pictures from the disassembly backwards. Ive been thinking about making reassembly pictures as well, it would make the report way more comprehensive and would show more difficult nifty parts for example shock and balance jewel lubrication. However it would be way more annoying to take the pictures and it would cost me a lot more time. What do you all think? Timegrapher Test Okey, so once I’ve cleaned everything it was time to put my work to the test and I strapped the watch into the timegrapher. And this is the catastrophic result: This was the start of the snowstorm like reading which followed. It couldn’t really pick anything up and I was just devastated. Because I did not have any replacement balance on hand, I was desperate and opted to measuring the Rate my eye and stop watch. As you can think, this did not end up well so I ordered a lot of a few spare movement to butcher them for the balance. After placing in the 4th replacement balance however, I managed to get a decent reading. The Amplitide could be better, but this is the way I left it in the end haha. Final Results: After the timegrapher drama I closed the back up and attached a basic rubber strap for testing purposes. And from here on its basically B-Roll pictures! Here is a comparison of the movements size to my pinkie finger! And here the final satisfying shot: So yeah all in all a stressful but also fun little project which I could conclude by gifting the watch to my mother. I was very surprised to see the winged balance as well as challenged by working on a movement of this size but in the end I managed! I hope you all enjoyed reading this and that the guide may help other hobbysts or even professionals ( haha who am I kidding) in the future. Any comments, questions or criticism is of course welcome! If you guys would like the full commentated 4K Macro video of the whole process, ive uploaded it to my Youtube channel here and it would bring me great joy if you would watch it! And so as always watch bangers... Stay safe and healthy and till next time!

- 3 replies

-

- 2

-

-

- watch repair

- walkthrough

-

(and 2 more)

Tagged with:

-

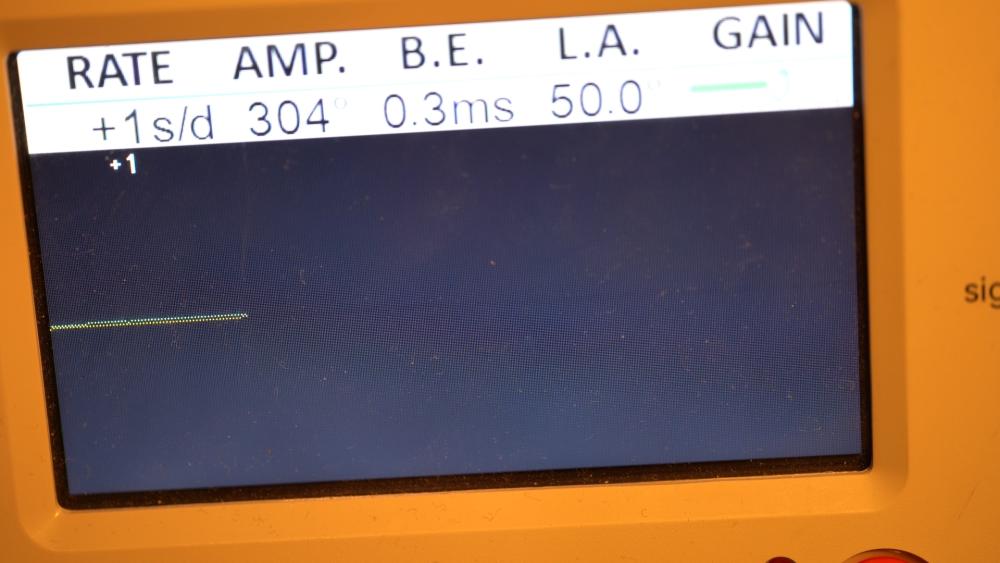

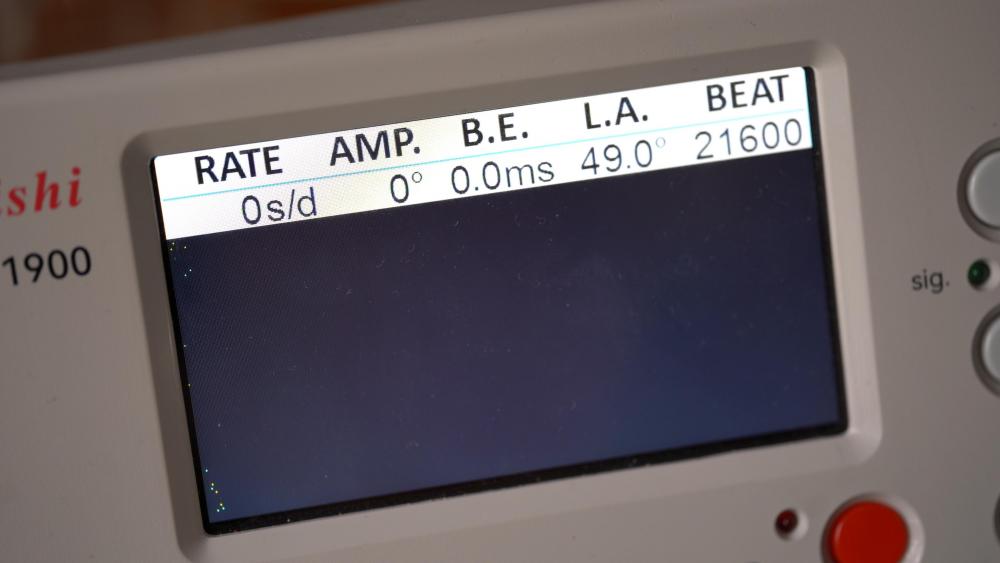

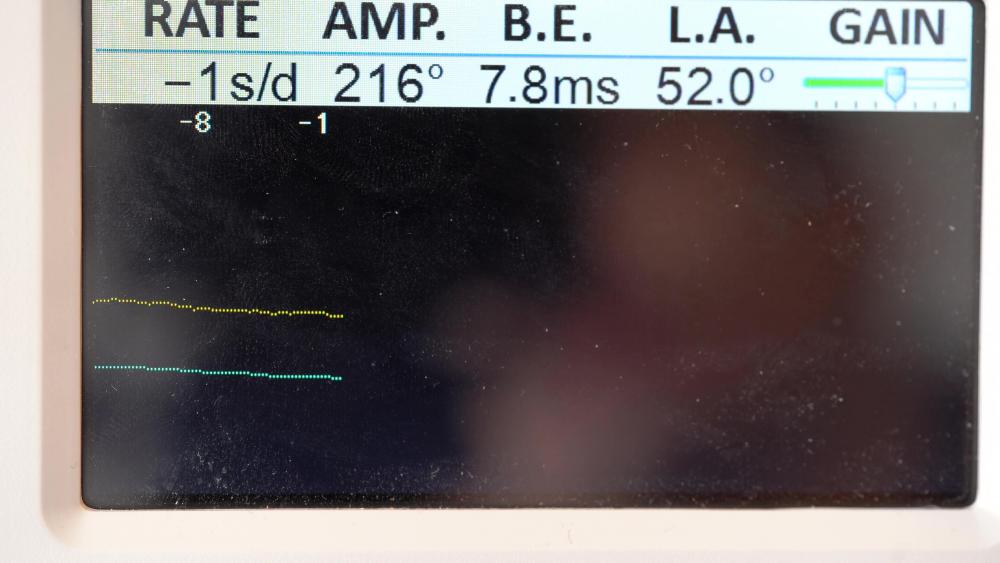

Hi everyone! This time I'm back again with a little something which turned out to be something of a hybrid project. I had repaired and planned a video on a Junghans watch with the 93 movement caliber to give to my younger brother ( which young adult doesn't need a nice looking watch) and had it all set out, planned and executed. The only downside was that the dial was slightly discolored on the right side due to bad cleaning on my part. Here you can see what I mean by that: But I happened to be at a local fleamarket on the day when I wanted to finalize the video and surprisingly found the exact same model! Even though the crystal was pretty scratched up, I was confident that the dial was in a good condition so I bought it for 10 Euros. And yeah, it looks like I hit the jackpot: So.. I got lucky and changed the dials in the end. But enough rambling around and here is the actual process of working on the watch movement: 1. Removing the movement from the case. This movement was from the “trilastic” model line of junghans and it got its name from the tri-legged support beams which held the movement inside the case. Just pop those up and remove the movement. Fun fact: While checking the inside of the caseback for marking I found one from 1981, thats so coooool! : 2. Remove the hands and and then the dial by unscrewing the dial feet clamps ( Forgot to take Pictures sorryyy) 3. Strap the movement into the holder and unwind the watch if needed. Then I removed the broken watch stem. 4. Remove the blued ratchet and the click spring 5. Remove the hour wheel, minute wheel, canon pinion and the very interesting looking yoke and its spring. 6. Then remove the clutch and flip the movement. The leftover lever will be released from the backside later on. 7. Remove the balance wheel and the pallet fork system. 8. Then remove the two screws holding down the mainplate and lift that. You can go ahead and unscrew the screw in between as well since that will release the left over lever on the front side. Do the same for the mainspring cover. 9. Remove the gear train and the mainspring And that's about it with the disassembly! Now moving on to the whole cleaning, lubrication and servicing part! Mainspring service: This Mainspring was something new to me since it had a very interesting arbor! Instead of the traditional small arbor inside the barrel, it extended outwards and acted as a lid and a wheel at the same time. While this is definitely cool, it also brings some negatives such as faster exposure to dirt and etc with it im sure. It looked fine so I just recleaned, lubricated and reinserted the whole thing: Lubrication: Here is a list of lubrications I used Moebius 9010 - All jewels Moebius 8200 - Mainspring and barrel lubrication Moebius HP 1300 slower moving parts such as canon pinion Moebius 9415 - Pallet Fork hooking jewels Molykote DX - Gearless works and high contact/friction zones (Front side only really) Oh and of course don't forget to clean and lubricate the balance shock jewels! Reassembly: Just reverse the disassembly steps or watch (no pun intended) the video for a step by step walkthrough. Timegrapher Test: Before Regulation After Regulation: Now i'm very happy that the rate is so much better. The amplitude can definitely be better however I would blame the old mainspring for that. The one thing that puzzles me really is the Bear Error. I've tried virtually every combination on the balance but the beat error does not improve. Maybe something is wrong with the hairspring? Final Result: After attaching the more aesthetic dial and recasing the watch and adding the straps, these are the final result pics: I must say I'm very happy with the whole process! Of course there were some up and down moments like when I destroyed the balance ( don't even ask) and had to get a replacement and such things but it all worked out in the end did it not? I was not sure how the beat error and the lower amplitude were going to show themselves while wearing the watch so I did a test wear for a week and the time only deviated by a second or two so I'm relieved! Now I apologize for the lack of pictures for a smooth documentation, I forgot and yeah, the rest is history. However, I have uploaded another fully commentated video so If you want explanations, more information or just a smoother experience go check it out: https://youtu.be/ZDXKiNnrmMk Any criticism, questions, comments and tips are always welcome and i'm happy to talk to you all! Hope you enjoyed it and until next time! Stay Healthy!

- 4 replies

-

- 6

-

-

- restoration

- walkthrough

-

(and 1 more)

Tagged with:

-

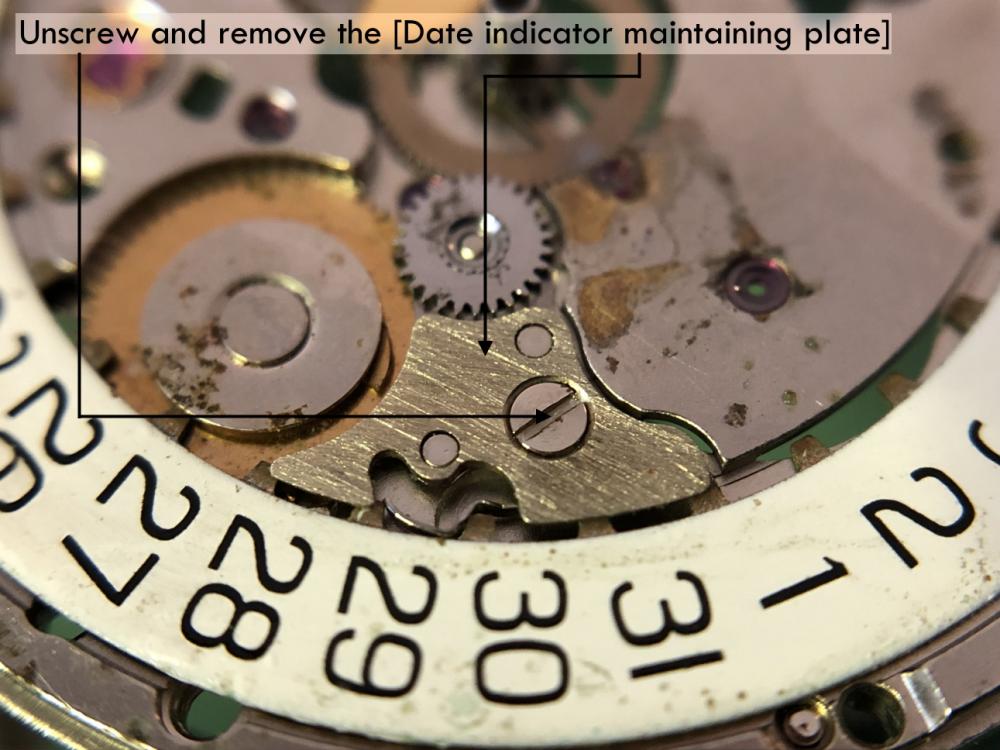

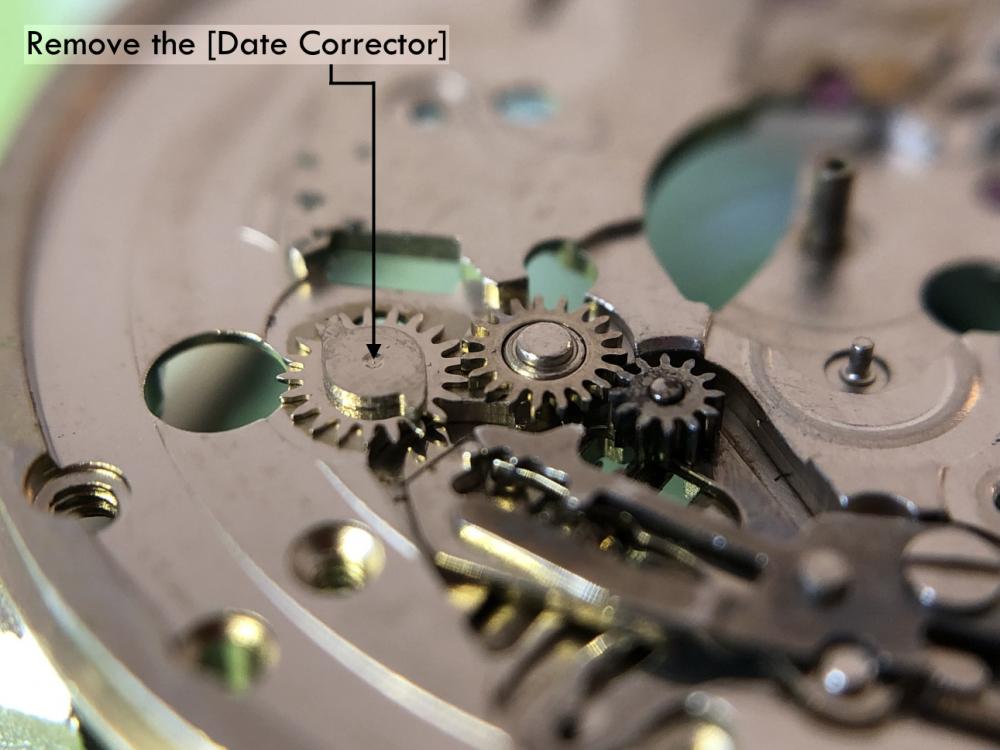

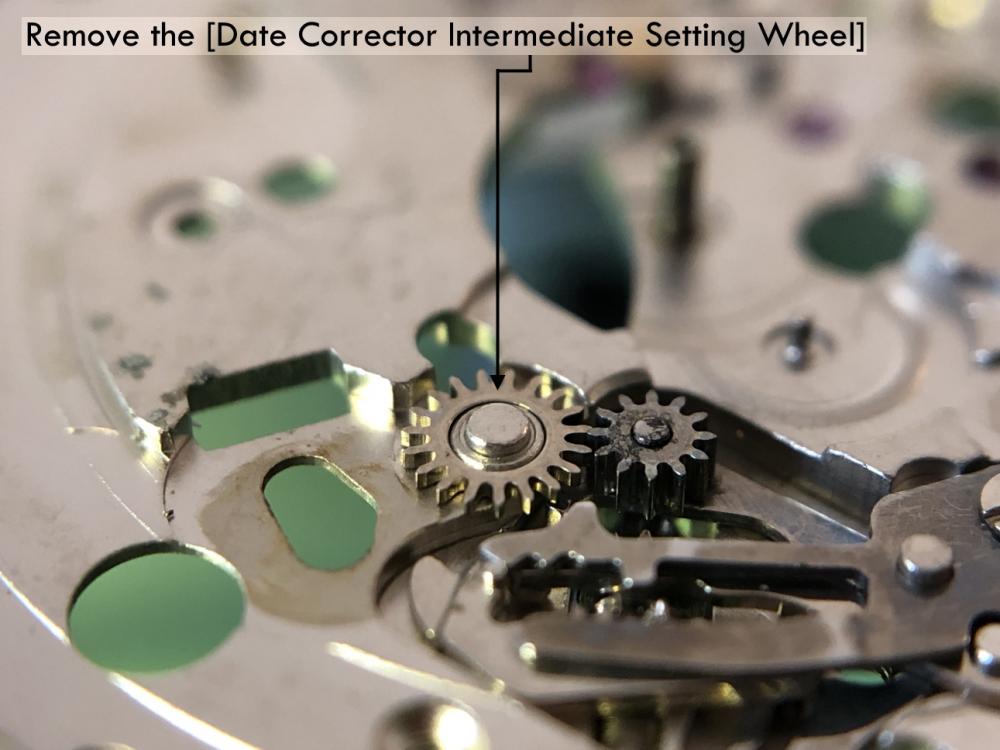

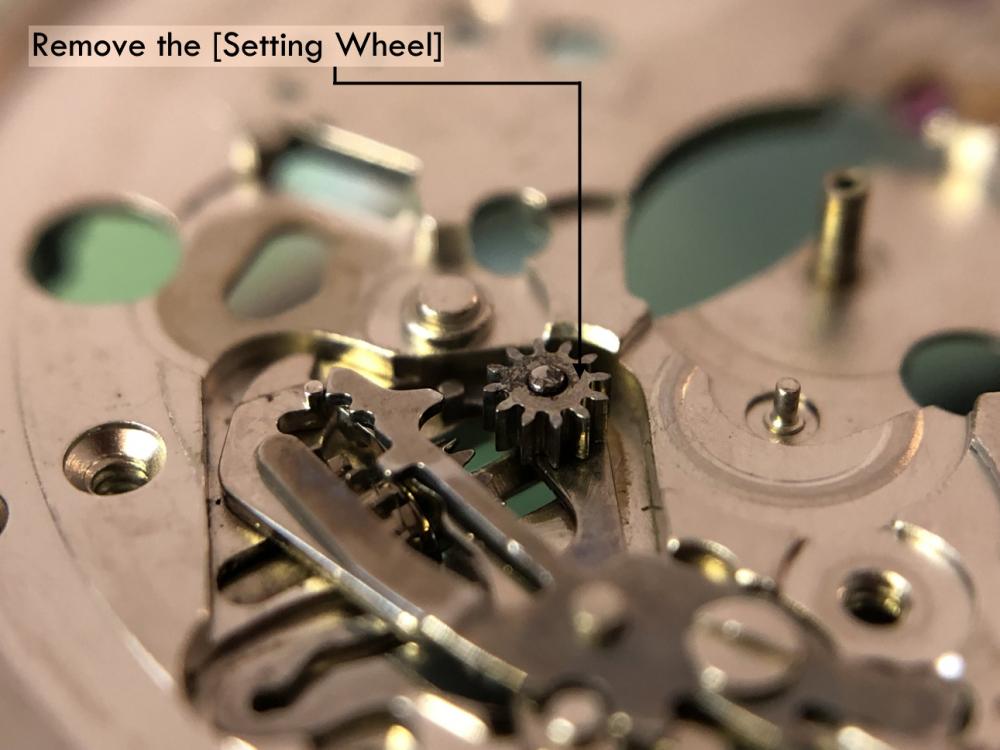

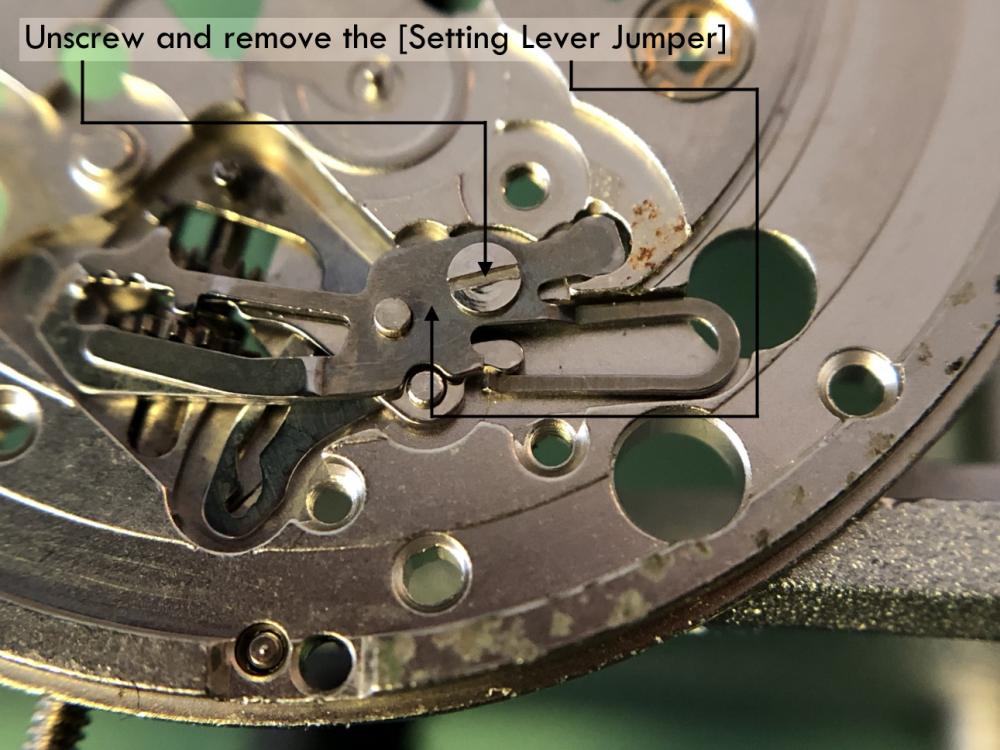

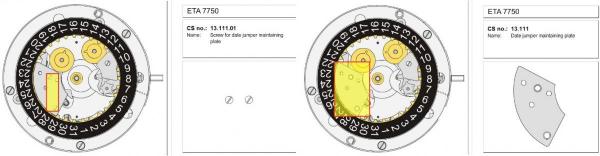

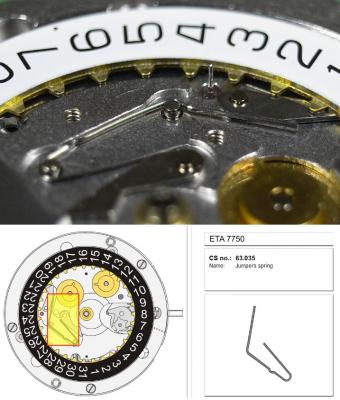

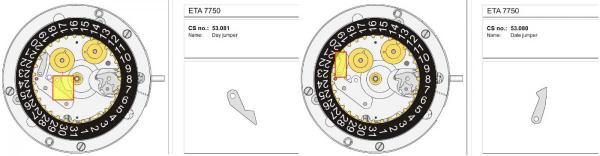

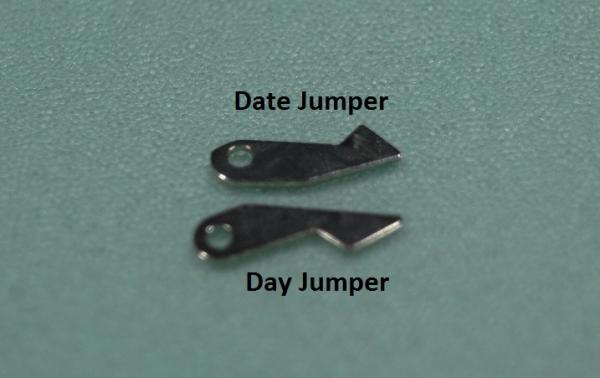

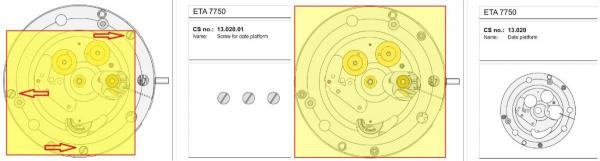

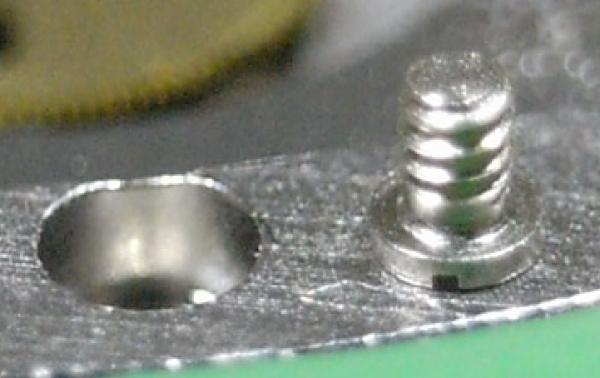

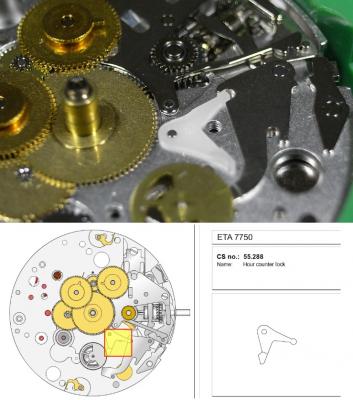

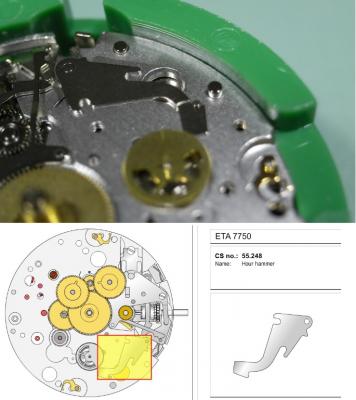

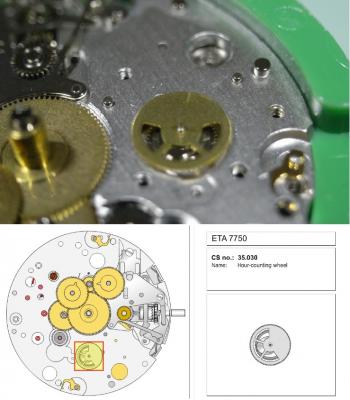

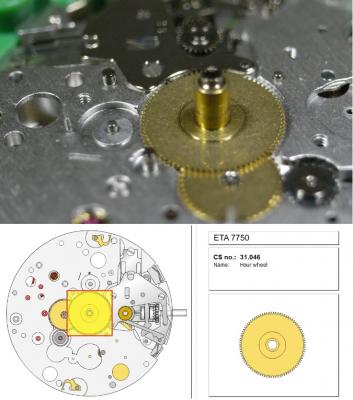

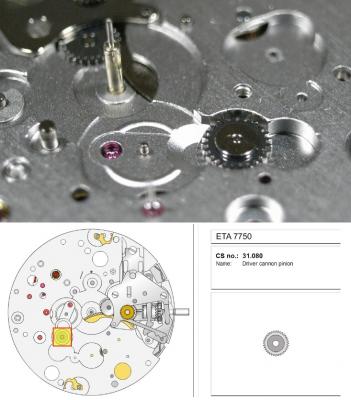

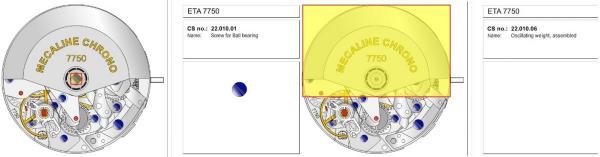

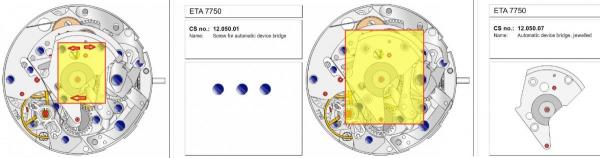

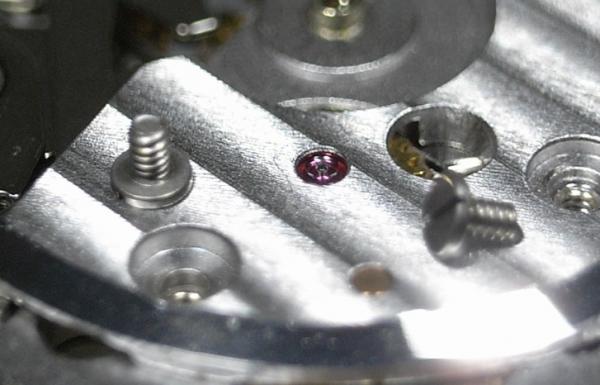

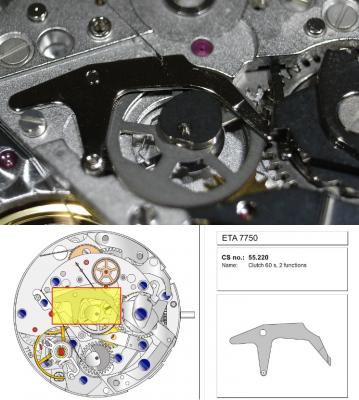

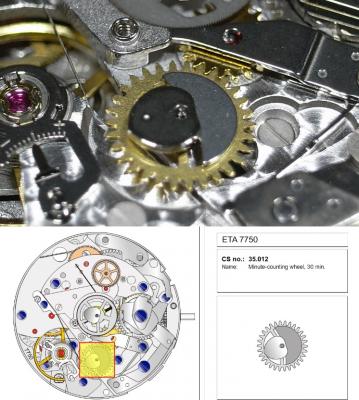

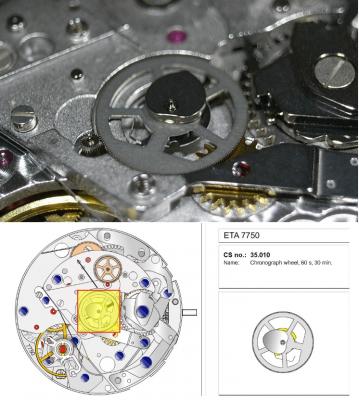

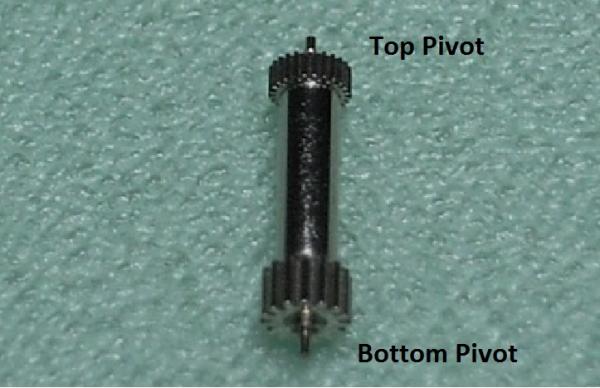

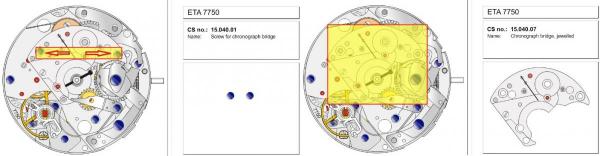

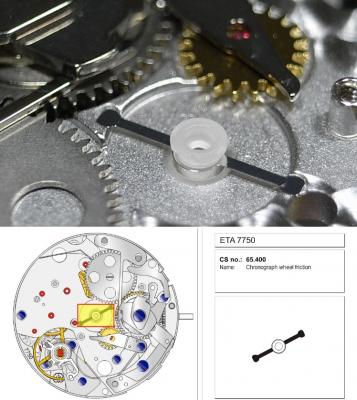

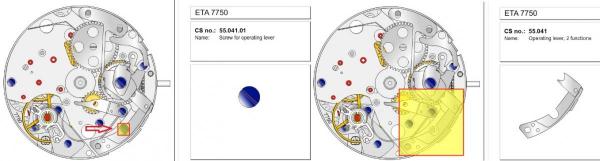

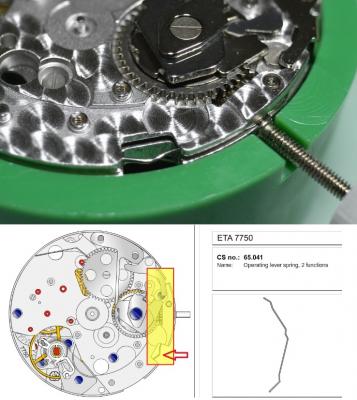

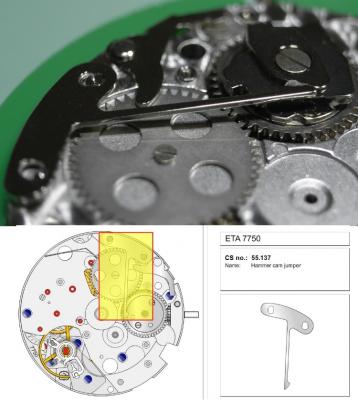

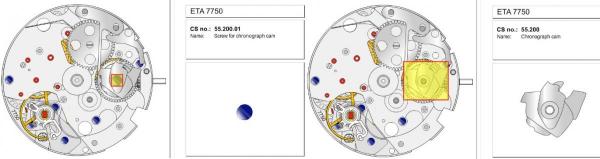

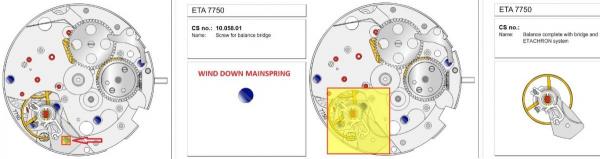

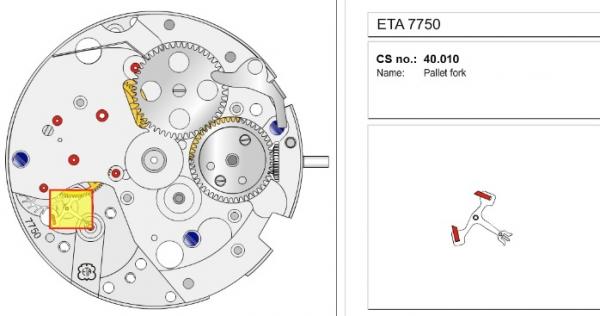

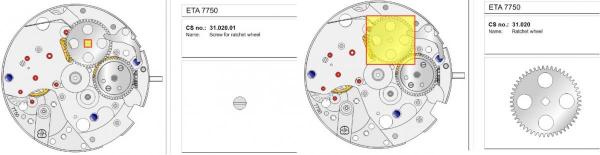

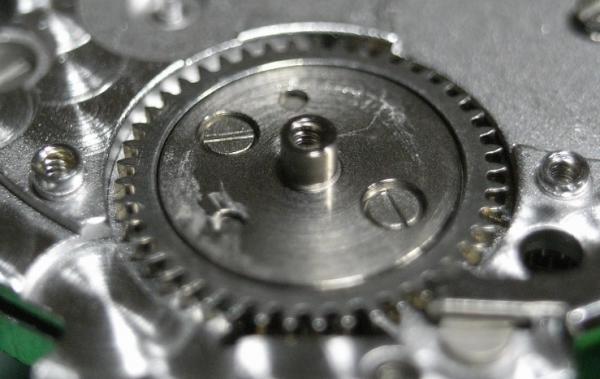

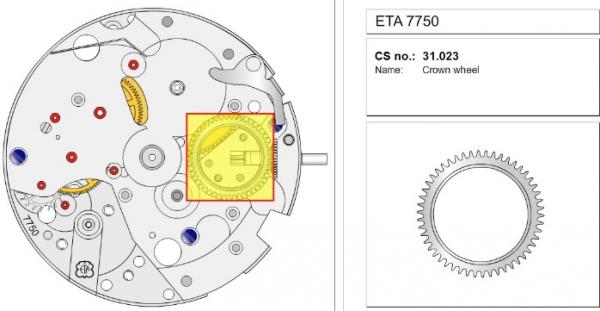

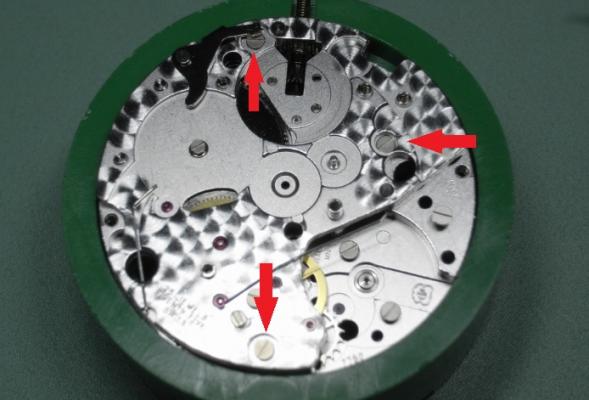

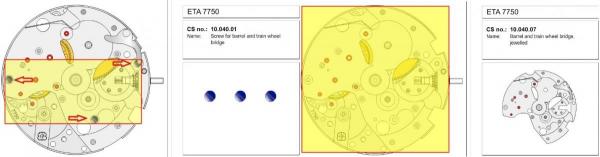

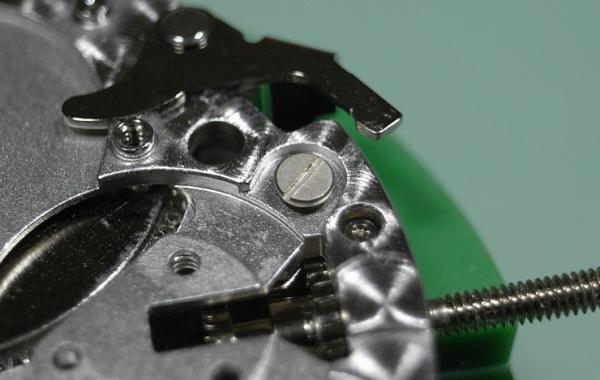

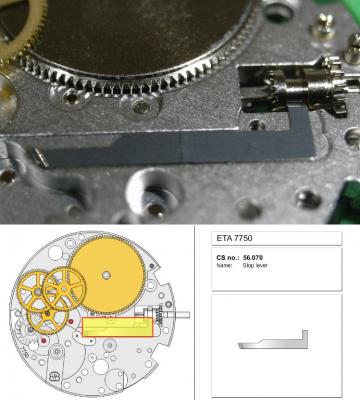

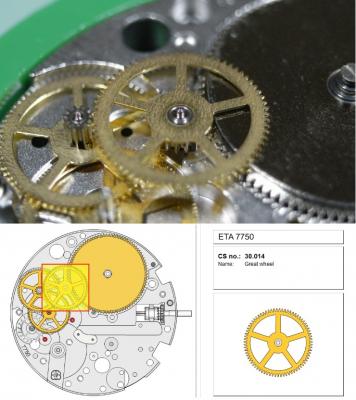

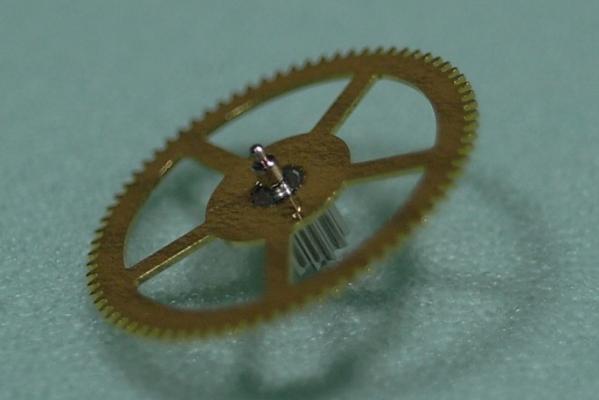

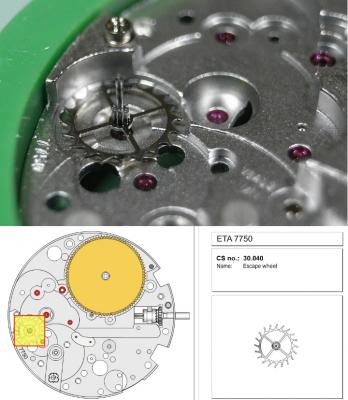

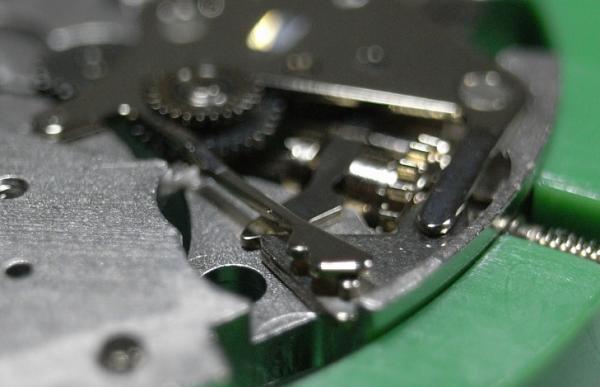

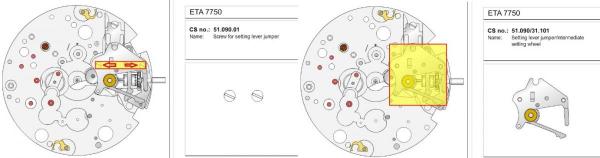

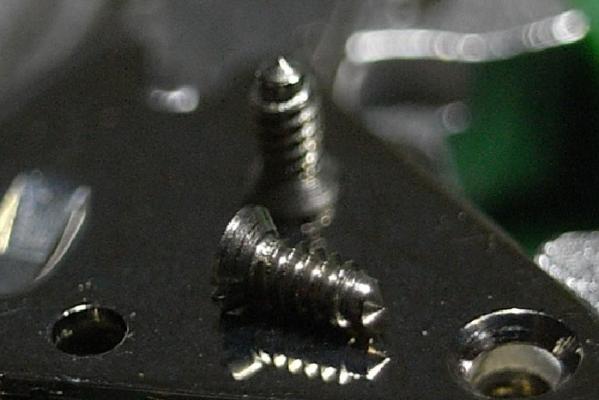

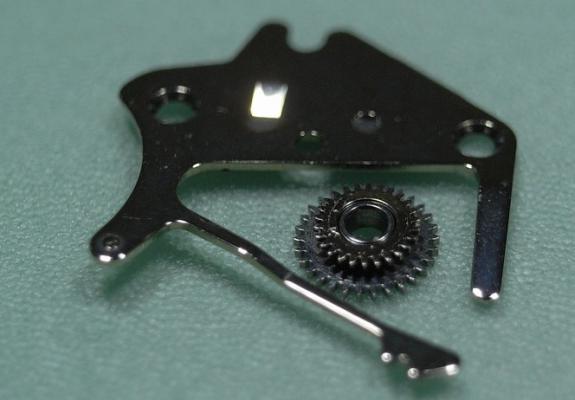

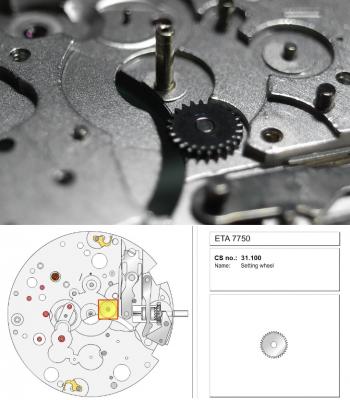

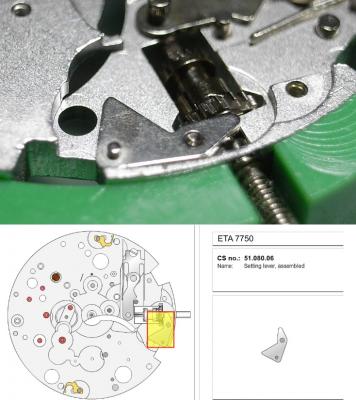

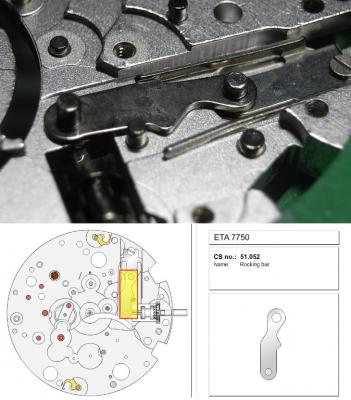

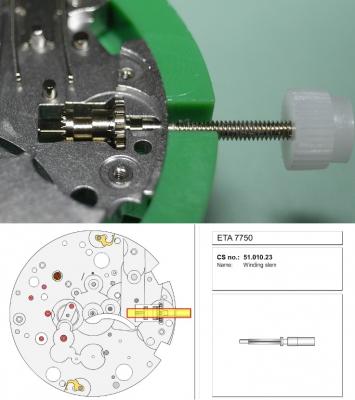

ETA 7750 Service Walkthrough The 7750 was first available in 1974, having been one of the first movements to be designed with the aid of a computer. It's hard to believe that the 7750 is still the industry standard movement for chronographs considering it's history. It was developed over 40 years ago by Valjoux, who was then a legendary movement maker that was part of the giant ASUAG conglomerate. But by the end of 1975 production was stopped due to the onslaught of the Quartz Era, and the 7750, along with many other mechanical calibers, was abandoned. Industry demand for this movement was so low that the stock produced in that 1 year manufacturing lasted until 1982! Such was the devastation of cheap Japanese produced quartz watches to Swiss manufactures. History may have forgotten the 7750 except for the local management at Zenith who ignored the orders by Valjoux to destroy the dies and equipment used to manufacture the 7750, instead hiding the equipment away from corporate eyes. You can find many more fascinating facts about this caliber online, and it's well worth the read. ................................................... This walkthrough will be very detailed, and I hope this will give people the courage to tackle this movement. I've serviced quite a few calibers, and this is one of the most beautiful, with a very logical layout. ETA7750 Tech.PDF If you have built your skills with basic movements, and become proficient in servicing them, I would highly recommend this movement to be your first chronograph to tackle. Lets begin. DEMAGNETIZE THE MOVEMENT BEFORE DISASSEMBLY. Remove the Day Indicator and store it in a safe place where it won't be damaged. Unscrew (0.8 Driver) the Jumper Maintaining Plate and remove it. Do the same for the Date Indicator Maintaining Plate Carefully remove the Jumpers Spring, holding it with a piece of pegwood so it doesn't ping away. Next remove the jumpers for the day and date. The jumpers differ from one another, so here is a reference photo so you can see the difference. Remove the Date Indicator and place it in a safe place where it won't be damaged. The last piece to remove on the Date Platform is the Double Corrector Now unscrew (1.4 Driver) the Date Platform and gentle pry it from the movement. Be careful when removing this plate, as there is a fine spring pressed into the plate that can be easily damaged. Here is a reference photo of the screws that hold the Date Platform. Remove the Hour Hammer Spring, once again using the pegwood to hold the spring while removing the tension. Here is a reference photo of the correct orientation of the spring. Remove the Hour Counter Lock. Remove the Hour Hammer Operating Lever. Next is the Hour Hammer, be careful when removing this item so as not to damage the Hour-Counting Wheel. Now remove the Hour-Counting Wheel. Remove the Date Indicator Driving Wheel Remove the Day Star Driving Wheel Then remove the Intermediate Calendar Driving Wheel Remove the Hour Wheel Then the Minute Wheel Remove the Cannon Pinion, which does not require a puller. The last component to be removed on this side of the Main Plate is the Driver Cannon Pinion. To lift the Driver Cannon Pinion I used what Mark used, a set of hand lifter from Horotec (MSA05.007); but you can also use a Presto Tool (30636-1) which will also work well. The dial side of the movement is now complete disassembled. Flip the movement over and unscrew (1.5 Driver) the Oscillating Weight. To remove the Hammer Spring lift it up gently over the automatic work and move it inwards. This will move the tail of the spring in a clockwise motion to the opening in the slots, which will free the spring. Slide out the Clutch Spring. Here is a reference photo of this spring, and it's orientation. Remove the screws (1.4 Driver) for the Automatic Device Bridge, and gently pry it loose. Here is a reference photo of these screws for the bridge. Once the Automatic Bridge has been removed, the two wheels for the automatic work are able to be removed. Below is a reference photo of how the sit inside the bridge. We now begin to disassemble the chronograph section of this movement. Begin with removing the Hammer, 2 Functions. Next remove the Clutch 60s, 2 Functions. Then remove the Minute-counting Wheel, 30min. Remove the Chronograph Wheel 60s, 30min. Gently lift out the Oscillating Pinion, 60s. Here is a reference photo of the orientation of this pinion. Unscrew (1.4 Driver) the Chronograph Bridge and gently pry it off the Train Wheel Bridge. Remove the Ratchet Driving Wheel. Remove the Chronograph Wheel Fiction. Unscrew (1.4 Driver) the Operating Lever, 2 Functions. Unscrew (1.4 Driver) the Lock, 2 Functions. Next remove the Minute-counter Driving Wheel, 30min. Slide out the Operating Lever Spring, 2 Functions. This spring can be fitting in both directions; but only 1 way is correct. Here is a reference photo of it's correct orientation. Remove the Switch. Here I digress from the order the SwissLab document illustrates the order of removal. They show to remove the Chronograph Cam before removing the Hammer Cam Jumper. This in my opinion is not the best way, as all the force from the jumper is pressing on the cam whilst your trying to remove it, and could lead to damage. Instead I move the Chronograph Cam until it reaches the notch as shown in the photo below. Then lift the Hammer Cam Jumper up to the top of the Chronograph Cam, which will release it's tension. Then, just as you removed the previous hammer, rotate the jumper to the opening in the slots, which will free the spring. Now you can unscrew (1.4 Driver) and remove the Chronograph Cam safely without tension on it. RELEASE THE MAINSPRING TENSION Once the tension has been released, unscrew (1.4 Driver) and remove the Balance Cock. Then unscrew (1.4 Driver) the Pallet Bridge and remove the bridge and Pallets. Unscrew (1.2 Driver) and remove the Ratchet Wheel. Then remove the Crown Wheel. Unscrew (1.4 Driver) the Train Wheel Bridge and gently pry it off the Main Plate. Note that one of the screws is under the Operating Lever. This needs to be moved out of the way to access this screw. The last level of this movement contains the train. Here is a reference photo of the wheel locations. Remove the Stop Lever. Remove the Great Wheel. Here is a reference photo of the underneath of this wheel. Remove the Third Wheel. Here is a reference photo of the underneath of this wheel. Remove the Second Wheel. Here is a reference photo of the underneath of this wheel. Note this has the long lower pivot. Remove the Escape Wheel. Here is a reference photo of the underneath of this wheel. Then remove the Barrel. This completes the removal of the train. Flip the movement over so we can complete the disassembly by removing the keyless work. Firstly, release the tension from the Setting Lever Jumper. Then unscrew (1.2 Driver) and remove the Setting Lever Jumper. These are unique screws with pointed ends, and below is a reference photo of them. This will also remove the Intermediate Setting Wheel. Next remove the Setting Wheel Then remove the Yoke. Remove the Setting Lever. Remove the Rocking Bar. Now pull out the Stem. Once the Stem is removed the Winding and Sliding Pinion should fall out of the movement onto your work mat. Disassembly of the 7750 is now complete If you've come this far, congratulation on completing the disassembly. Make sure you pegwood all the jewels and reinstall the Balance back onto the movement for cleaning. Assembly of the movement will be posted as soon as I complete the write-up.

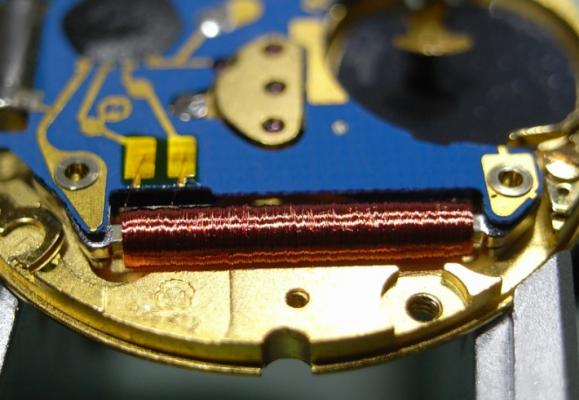

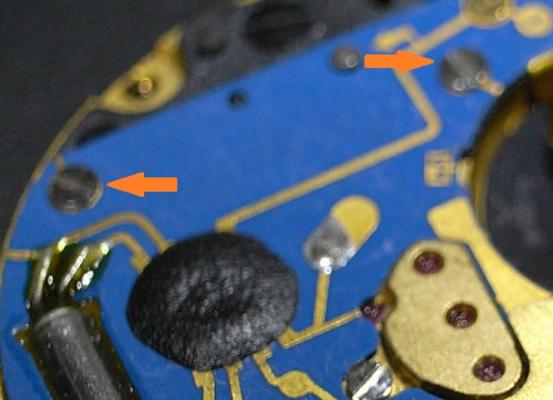

-

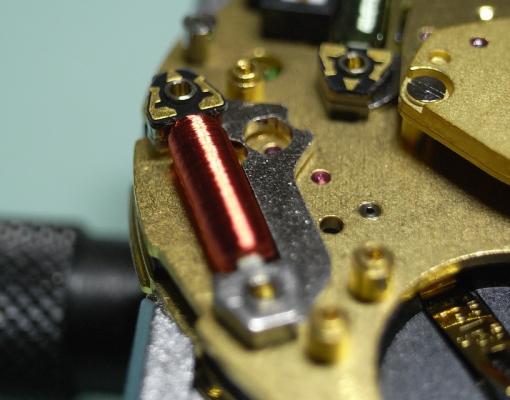

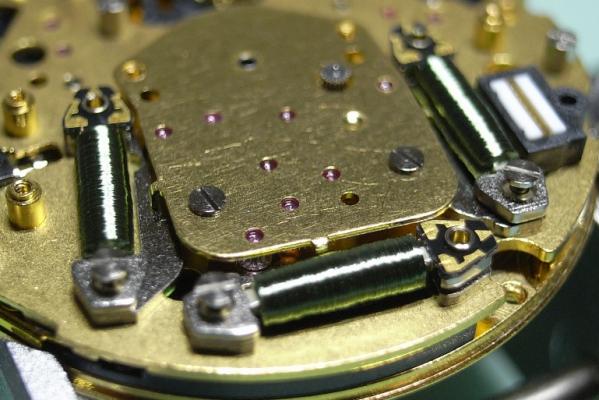

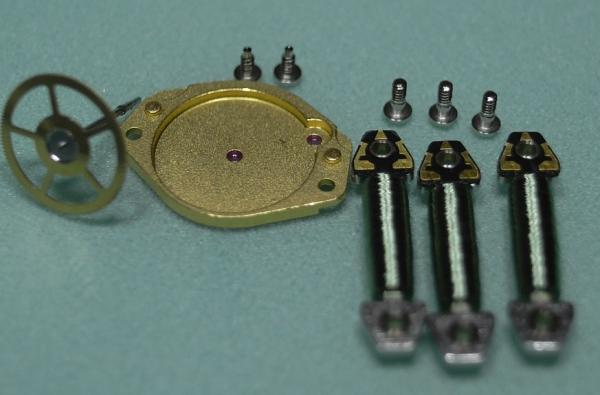

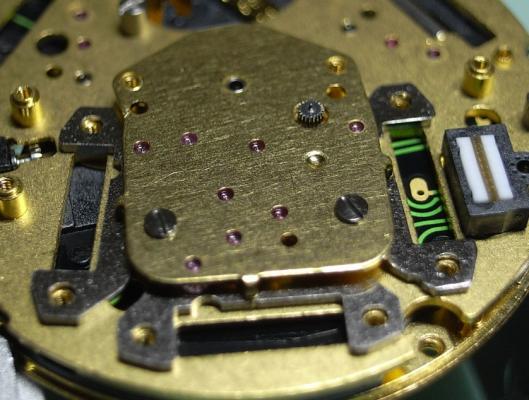

ETA 251.626 Service Walkthrough The 251.626 is often found in mid to high-end quartz chronographs on the market today. ETA 251.262.pdf It is a fairly complex quartz movement that has 5 motors, 2 with Red Coils, and 3 with Green Coils. To begin the service we start by removing the 3 Indicator Maintaining Small Plates, and Date Indicator. A 1.4mm screwdriver is all the is needed for every screw on the movement. Here's a reference photo of the 3 screws for the Indicator Maintaining Small Plates. There are no more components to remove from the dial side of the movement. Once the movement is turned over, remove the 2 screws that hold the Magnetic Screen. Once the Magnetic Screen is removed all the coils are very exposed, so work around these coils with great care. Here's a reference photo of the 2 screws for the Magnetic Screen. Next unscrew the 6 screws holding the Additional Printed Circuit and gently lift it off the movement. Store the Additional Printed Circuit away separately and safe from the rest of the parts. Here's a reference photo of the 6 screws for the Additional Printed Circuit. Next we tackle the 2 trains with the red coils. Right Side - Minute Counter Left Side - Hour Counter The right and left trains contain different size wheels and should be kept separate for ease of assembly. We shall start with the right side. Remove the Minute Counter Bridge Next remove the Gear Train and the Rotor. Next remove the Coil and Stator. Store the Coil away separately and safe from the rest of the parts. Here's a reference photo of the components and their corosponding screws. Note the 4 spokes on the Minute Counting Wheel. Remove the Hour Counter Bridge. Remove the Gear Train and the Rotor. Remove the Coil and Stator. Store the Coil away separately and safe from the rest of the parts. Here's a reference photo of the components. Note the 3 spokes on the Hour Counting Wheel. Store these 2 trains in separate sections in your parts tray, and when cleaning store them in sparate parts containers. Next remove the Chronograph Bridge Now remove the Chronograph Wheel Unscrew the Green Coils and remove them. Store the Coils away separately and safe from the rest of the parts. Here's a reference photo of the components and their corresponding screws. Remove the Train Wheel Bridge. Remove the Wheels of the Train. This is quite a complex train of wheels. So to assist you I've cleaned up the rather cluttered schematic supplied by ETA and colour coded each wheel and it's location on the Main Plate. Here's a reference photo of the top of the wheels, also colour coded to assist you. And also the underneath of the wheels, also colour coded to assist you. Remove the Rotors and Stators. Unscrew the 3 screws that hold the Upper Plate and remove it. Here's a reference photo of the Upper Plate, Connector, and the corosponding screws. This now exposes the Electronic Module. Remove the Stop Lever/Switch Remove the Cannon Pinion with Driver. Then remove the Electronic Module. Pull out the Stem and Sliding Pinion. Now store the Electronic Module away separately and safe from the rest of the parts. Remove the Minute Wheel, the Hour Wheel, and Contact Intermediate Wheel. Before we can remove the Date Indicator Driving Wheel, we need to pull back the Date Jumper. Gently lift the tab (Yellow Arrow) until it's at plate level and pull it backwards. This will pull the arm of the Date Jumper back and allow you to remove the wheel. Here's a reference photo of the wheels. Lastly we need to remove the keyless work. Unscrew the Setting Lever Spring and then remove the Setting Lever, Yoke, Driving Wheel, Internediate Setting Wheel No.1, and the Setting Wheel Here's a reference photo of the Keyless Work. The movement is now completely disassembled. I hope you've enjoyed this disassembly walkthrough and found it's given you the information and confidence to tackle this tricky but rewarding quartz movement. I will post the assembly procedures tomorrow, Lord willing :)

-

ETA F05-111 Service Walkthrough "The Workhorse Of Midrange Quartz" Moving on from the ETA 955.412 service, another common quartz movement, this time found in mid-range quartz watches, is the F05 111. It doesn't have the build quality of the 955/6 model; but it's still a very robust movement, and able to be serviced. In saying that, this movement is rarely serviced by a professional watchmaker due to the low cost of a replacement movement. Personally, I think it's sad we live in such a throw-away society, and are slowly loosing the skills and confidence to performance maintenance at home. So if you've got the tools and confidence to service this movement at home, do it, and save yourself $$$. Service Manual for the F05 111 Movement ETAF05.111.pdf We will first start with the Motion Work and Calendar Work. Remove the three screws holding the Cover Plate. You will see that this also has the Date Jumper Spring incorporated into it. Next remove the Hour Wheel, and the Date Indicator Driving Wheel. Note too that there is no quick date change on this movement. Remove the Minute Train Bridge, Minute Wheel, Canon Pinion and the Sliding Pinion And that's it for this basic movement on the dial side. Flip the movement over and we'll begin on the drive side Remove the three screws marked below and lift out the Electronic Module Cover. Next remove the two remaining screws that hold the Gear Train Bridge. As you can see with plastic wheels, this is not up to the same quality and finish as the 955/6 movement. Remove the Second Wheel, Intermediate Wheel, and the Rotor I would not recommend removing the Third Wheel at this time as the IC Board circuits are directly above it, and there is no point risking damage to it. To remove the IC Board, gentle lever up the where the location pin goes through the board just at the end of the Quartz Crystal housing. This pin is often firmly pegged to the board and must be lifted up first. This will loosen the board away from the Main Plate. Then gentle lift out the IC Board by sticking a piece of Rodico to the mark position below and lifting out. This will avoid any damage to the circuit or Coil. Now that the IC Board has been removed, access for removal of the Third Wheel is risk free. You can also remove the Insulating Block at this time. This is also the time to remove the Battery Insulator, but this being just a spare movement I own, it's been used elsewhere ... sorry :unsure: The Keyless Work is now exposed, and is a very basic setup, being held only with 1 shouldered screw. The movement is now completely stripped and ready for cleaning. All the parts can go in for cleaning EXCEPT the following Date Ring Rotor IC Board PLEASE NOTE: Due to most of the wheels being plastic, be careful when you come to the heating/drying stage if you are using an Elma/Pearl Parts Cleaner. Make sure the basket is high up in the drying cylinder and ONLY RUN FOR 11 MINUTES MAXIUM ... too much heat isn't good for those little plastic wheels. I hope this has been fun and edifying to read. I'll post the assembly procedures latter tonight after dinner ... my tummy is talking to me :)

-

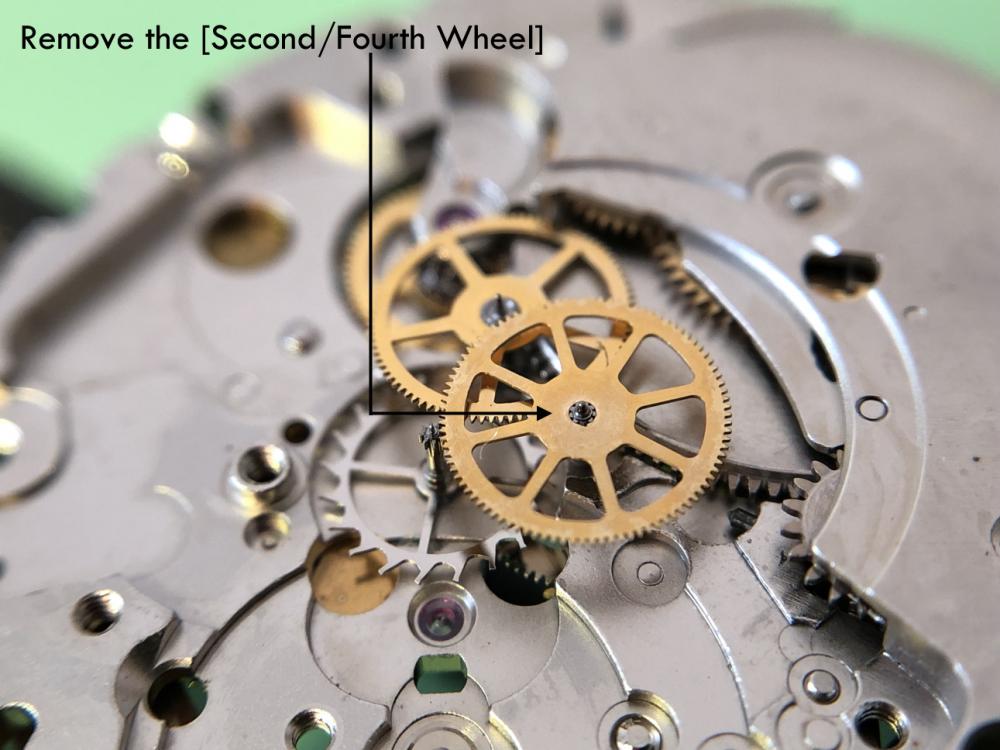

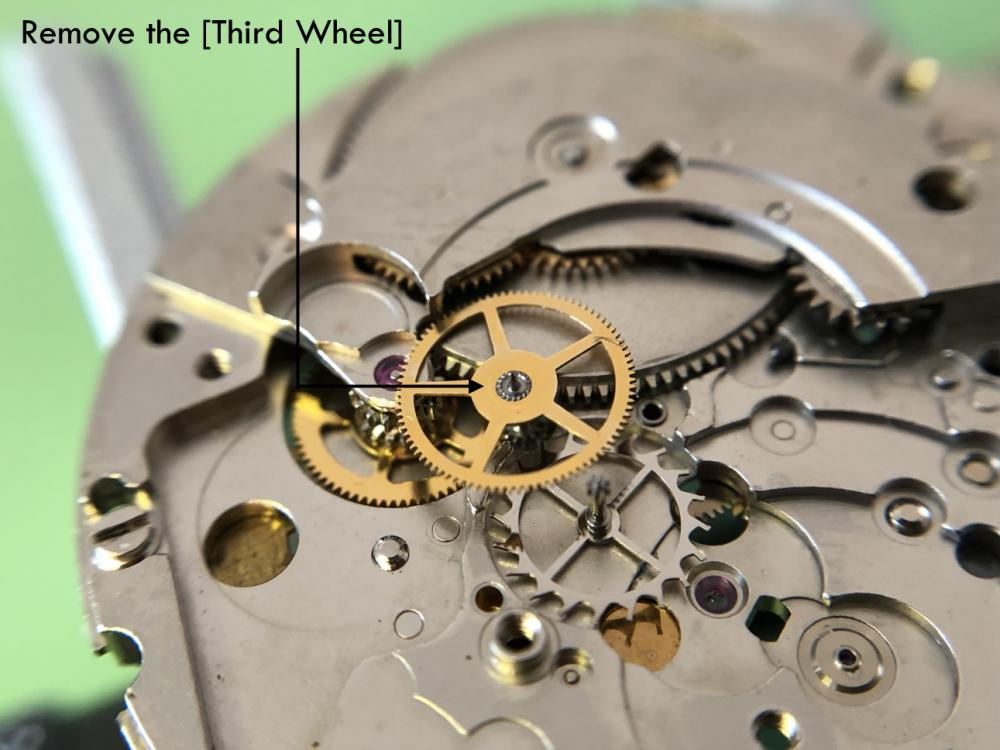

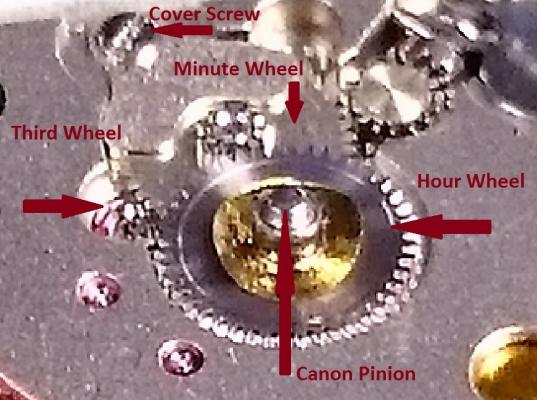

Good day, guys! This is my little way of giving back to this wonderful community. We usually receive for repair a watch handed down by a father to his son. In this case, its a watch given by the son to his father - a Seiko 5 from the early 1990s. The watch has seen better days, with its hardilex crystal beaten and the watch not moving at all regardless of the amount of shaking you give it. The hands are corroded and the dial mounted on the movement using contact cement. I'll skip the disassembly and show you how the Seiko 7009 movement works. The Seiko 7009 technical guide is easy to find on the net though. First to be mounted is the center wheel that drives the cannon pinion. After which I install the escape wheel and the center wheel bridge. The third wheel and fourth wheel is installed next. Note that the fourth wheel drives the second hand directly. Then the click comes next. Prior to installing the unified barrel and train-wheel bridge, you have to install the pawl lever and first reduction wheel assembly. The assembly is held in place by the first reduction wheel holder. Take note of the orientation of the pawl lever. I find it difficult to install the barrel and train wheel bridge while ensuring that the click spring doesn't get in the way. <end of part 1>

- 15 replies

-

- walkthrough

- watch repair

-

(and 1 more)

Tagged with:

-

ETA Calibre 2772 Service Walkthrough Pictures – Disassembly (Please sort the pictures by name in ascending order) ETA Calibre 2772 Service Walkthrough Pictures – Assembly (Please sort the pictures by name in ascending order) For the disassembly sequence to make sense it is important that the pictures are sorted by name in ascending order. Generally, the sequence of pictures first shows the part to be removed in its position on the movement and the following picture shows the removed part along with any screws that held it in place. For the assembly sequence to make sense it is important that the pictures are sorted by name in ascending order. Generally, the sequence of pictures first shows the part to be assembled along with any screws holding it in place. If needed, the following picture shows the section of the movement where that part is to be assembled along with my lubrication suggestion, and the picture after that shows the part when assembled to the movement. Note that this is not a maintenance servicing tutorial. To be able to service a watch movement some basic tools are required as well as some basic skills. It’s not difficult but it requires a bit of practice and perseverance. I’ve used a lot of sources on the internet to learn about servicing and repairing but watchrepairlessons have so far not only been the best source but also the most affordable source I’ve come across. I am a patron of watchrepairlessons but I’m in no way affiliated with it. Prior to servicing this calibre 2772, I’ve serviced an ETA calibre 2472 and two ETA calibre 2824-2s and the kinship between these movement is obvious. The 2472 is from the mid-60s, the 2772 is from the mid-70s, and the 2824-2 is from the early 80s. They all have the same type of distinguishing train. The keyless works of the 2472 and the 2772 is of the more traditional type whereas the keyless works of the 2824-2 quite a bit more sophisticated. However, the calendar works of the older 2472 is by far the more complex with its instant flip over of the date. It has been very interesting to study the similarities and differences between these three related automatic ETA movements.

-

Ronda 715 Service Walkthrough I thought I'd post a walkthrough on a simple quartz movement for people who are just starting out in watch repairing. The Ronda 715 is an excellent movement to begin with, as it's simple in design; but has all the components needed to practice your skills on. Even better is that it only cost around $10 to buy this movement brand new online. So if you break it or loose a part, you learn from the experience, and just buy another one :) Perfect!! The Ronda 715 is found in many of the "Fashion" brand watches, like Guess, JAG, Loyal, etc... As this is a walkthrough for novices there will be arrows to every part as we disassemble this movement. I also recommend you download the Tech Spec PDF and get familiar with how to read them. Here's the link to down the PDF 559_Ronda702,703,705,708,712,713,715.pdf Remember to have fun!! :lol: If you start to get frustrated, just have a break and come back to it later. Patience and perseverance will get you there, and once the skills are mastered it's very rewarding. Ok, lets begin Firstly, you identify this particular caliber of movement by the number stamped into the plastic surround. As you can see this one is stamped "715" The tools you will need for this service are as follows: Bergeon 4040 Movement Holder An Eye Loupe, or some type of optics 3x or better Pegwood 0.8mm Screwdriver 1.2mm Screwdriver Tweezers Hand Lifters A Hand Setting Tool A Parts Tray with cover And a piece of Rodico Since I am using a movement purchased from CusionsUK, I unfortunately don't have Hands or a Dial to remove. If you are servicing a movement presently in a watch, I suggest you watch one of Mark's video's to see how you remove Hands and the Dial. Mark's Videos are a fantastic resource to show you proper technics, and I highly recommend viewing them. They can be found here: https://www.youtube.com/user/jewldood/videos Once the Hands and Dial are removed, we then need to remove the battery, if one is installed, before we begin disassembly. On this movement it is done by gently pulling the Keeper Arm back away from the battery. Be careful when doing this so that you don't slip and damage the Coil. Then turn the movement over and remove the 4 screws, using a 0.8mm Screwdriver, that hold down the Date Indicator Guard, and remove it. Here is a reference photo of the Date Indicator Guard and screws. Next, hold down the Jumper Spring with Pegwood to stop it pinging away, and remove it with your tweezers. Then remove the Date Jumper and Date Indictor Ring. Next remove the Indictor Driving Wheel Then the Date Indicator Plate Followed by the Hour Wheel. Next remove the Setting Wheel Remove the Minute Wheel Remove the Secondary Yoke This completes all the components on the dial side of this movement. Turn the movement over in the holder. Unscrew the 3 screws, using a 1.2mm Screwdriver, that holds the Module Cover Plate, and remove it. NOTE: One of the screw is unique and larger than the others, remember it's location. Here is a reference photo of the Module Cover Plate and the 3 screws. Next remove the single screw that holds the Circuit and the Coil. Then remove the Circuit VERY carefully and store it somewhere very safe. Here is a reference photo of the Circuit and screw. Next remove the Coil by lifting it with the end with no circuit tracks on it, as shown below. Now unscrew the 2 screws, using a 1.2mm Screwdriver, that holds the Train Bridge and lift it off gently. Here is a reference photo of the Train Bridge and screws. Next remove the wheels of the train carefully, then the Rotor and Stator. From left to right there names are: Third Wheel, Second Wheel, and Intermediate Wheel. And here are the Rotor and Stator. Unscrew the single screw, using a 1.2mm Screwdriver, that holds the Centre Bridge and remove it. The Cannon Pinion should be on the centre post of the bridge and come away with it. NOTE: This screw is also unique with a thicker head, remember it's location. Here is a reference photo of the Centre Bridge, Cannon Pinion and screw. Next remove the screw, using a 1.2mm Screwdriver, that holds the Plastic Setting Lever Cover, and remove it. Here is a reference photo of the Setting Lever Cover and screw. Then lift out the Setting Lever and Primary Yoke. Lastly, pull out the Stem and the Sliding Pinion should fall to your work mat. You have now completely disassembled the movement ... WELL DONE!! :) The black plastic outer ring can not be removed, it is riveted to the Main Plate All the parts can be put in the cleaning machine or Ultrasonic ... EXPECT THE FOLLOWING PARTS! Battery Circuit Coil Rotor I hope this was a fun movement to begin your journey into watch repairing, and that it builds your confidence to advance further. Assembly will be posted soon...stay tuned!

-

First part of the disassembly, fixing and reassembly of my new Seiko 7T32-7C20 Flightmaster Chronograph that recently bought as defect. The damage was caused by trying to manually setting the date at around 11:30PM, when the watch usually starts to change the date automatically. Enjoy the first part of the video.

-

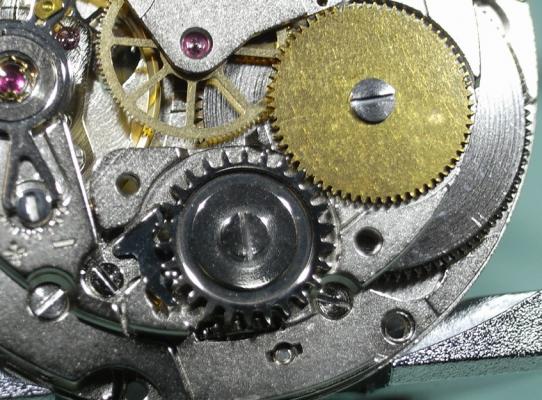

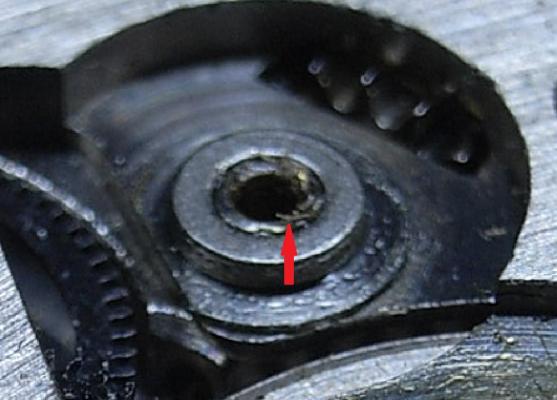

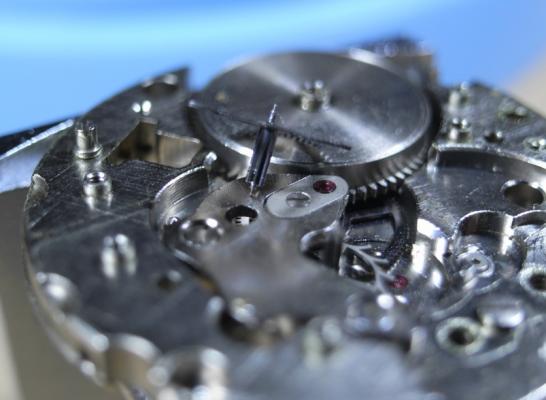

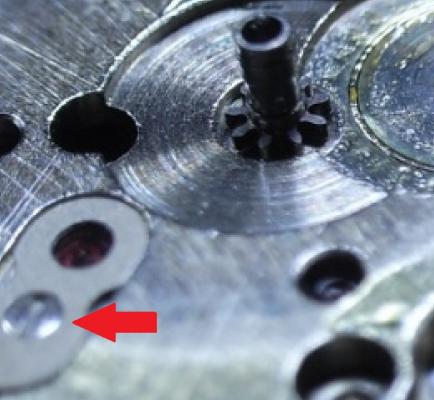

Miyota Automatic Service - "Three Screws to Rule Them All" Now for something completely different, a Japanese Automatic from Miyota. This is a budget driver's watch from a fashion brand called Scorpion, and I had no idea what I'd find when I removed the caseback :huh: Whatever! I just wanna work on watch movements, increase my knowledge, and the repertoire of movements I've had experience with. It's also a blessing to post these to help people with reference photos and walkthrough of various movements. When put on the timegrapher, it was quickly obvious that this movement was not running well at all. Extremely low amplitude, high beat error, and a graph that looks like the pepper in your mash potatoes :P Well, it happened to be a Miyota Automatic Movement ... I have no idea of the caliber, as there are no stampings on any of the plate ... beside the brand name. Once removed from the case, I pulled the Hands... ...and then the Dial. After that, I flipped it over and removed the oscillating weight to get a better look at the movement itself. Notice anything scary about this already?? There are only 3 screws holding the complete movement together!! :o Ack!! Visions of the Seiko 5J22A Kinetic "Auto Relay" , with it's 9 pivot gear train plate flashed before my eyes!! This was NOT going to be fun putting back together :P But I do so love a challenge. As per usual, I removed the tension from the Mainspring, and removed the Balance and Fork. Note: The red arrow is pointing to a very thin spring which you pull back to disengage the Click. Here's a closer reference photo of it after I'd pulled the plate off So as the title says ... Three Screws to Rule Them All .... Bam! The whole movement has to be located into ONE plate, that's only held by three screws ... this is not Rolex quality gentlemen ^_^ After tipping the movement up-side-down and telling the complete movement fall onto the desk (just kidding), you are left with only the Centre Wheel. Once the Centre Wheel Bridge was removed, the fault with the movement running so badly came to light ... RUST on the lower piviot! Rust also on the Pinion Over to the Calendar and Keyless Work ... looking way over complicated for a simple Date Wheel, as all the springs are there for a day complications as well; minus just the Day Wheel :( ... Gotta love cheap movements. Reference photos of the Keyless Work. One last thing to note with this movement. The setting lever is riveted into the Main Plate, so it's not able to be removed. Well this little gem is in the Watch Cleaner, and I've got a few weekend chores to do, so I'll put it back together tonight and post the results later. Hope you enjoyed this write-up, and got a few giggles out of it as well :)

-

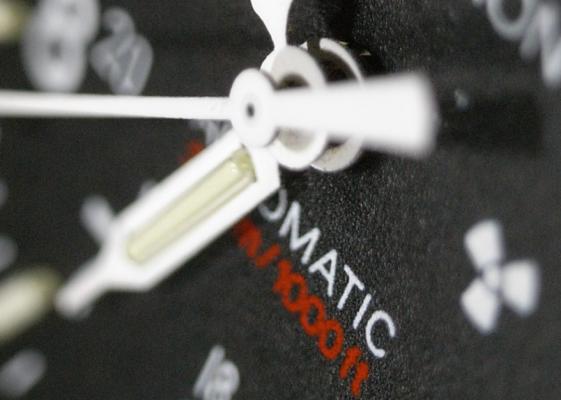

ETA2824 Service - The Radioactive Watch! Yes this watch is Radioactive ... so to speak :P It contains H3 Tritium Tubes to illuminate the dial at night. This watch belongs to my brother, and he has owned it for many years. I have to say that Marathon Watches are great "bang for buck", as this watch has served him well over those years, and he rarely takes it off his wrist. Unfortunately, on one of the rare occasions that he did (to wash his hands after work) he dropped it on the ground, and it stopped dead ... right at his quitting time 3:30pm. He was very angry with himself, and asked if I could found out what damage had been done by the drop, and repair it ... of course I was happy to help my bro :) While he was with me, I pulled the Caseback off and could instantly see the problem. The Hairspring was jammed up and the Balance was seized. I told him there also could be broken pivots, and I'd have to dig further to assess the total damage; but not to panic, as all parts for this movement are readily available (at the moment) ... so he left the watch with me. So I removed the movement from the case, pulled the Hands, and the Dial off to inspect the Calendar Works ... everything looked good. Next I removed the Oscillating Weight, and checked that the bearing hadn't been damaged by the impact ... it was fine too. Next I pulled the Automatic Work off the movement, so I could gain access to the main body of the watch. Here's a reference photo of the Automatic Work for ya Next I undid the screw of the Balance Cock and began to gently lift it ... and hey presto, and Hairspring dropped back into place, and the movement started tickin away ... these are a solid movement indeed! I carefully watched the movement ticking away, noting to see that the Pallet was working properly, and that the Train Gears ran smoothly ... all seemed fine, and the problem with this movement was resolved. I could have just stopped there, but this movement hadn't seen a service in over 8 years, and was already out of the case and 1/4 stripped, so I deiced to burn the midnight oil and do a complete service on the watch. And yes, that is a real radiation dosimeter, as I wanted to be sure nothing from those glass vials had leaked into the movement I was handling ... I'm glad to say it was clean B) Continuing with the strip down. All mainspring tension was removed from the unit. Notice with this movement too, that the click is on the Crown Wheel; instead of the Ratchet Wheel. Balance and Pallet was removed Crown Wheel, Ratchet Wheel and Barrel Bridge was removed. This is a reference photo of the Click Spring sitting on the Barrel Bridge. Under the Barrel Bridge there is a small Balance Hack to be removed as well. Next I flipped the movement and removed the Calendar Work. Then the Keyless Work Back the to other side and Train Gear was removed. Here is a reference of the Gear Train. Lastly the Automatic Work was stripped. Back from a bath, and all parts clean and ready for inspection and assembly. All pivots where intact and unburred, no damaged teeth or pallet stones, and no wrapped gears ... GOOD NEWS!! Ready to be put back together! :woohoo-jumping-smiley-emoticon: Nice clean and shiny Gear Train, Train Bridge and Barrel back in place and oiled Back on with the Barrel Bridge, Ratchet Wheel, Crown Wheel and Click Keyless Work clean, oiled and working smooooooth Automatic Work back together as well The rest of the re-assembly wasn't photographed ... sorry guys, it was VERY late, or should I say EARLY, in the wee hours of the morning, and I just got carried away with the build :huh: But it all went smoothly and as per the reference photos early. After the Dial was attached, the hands where next. Let me tell ya, these are NOT easy to fit correctly! With those glass tubes of H3, there is NO room for error fitting them. You literally have a couple of thousands of an inch to play with ... here's the photos to scare ya :o. This type of watch will really test your hand setting abilities. Here's she is all back in the case with the Automatic Work and Oscillating Weight fitted, purring like a kitten! Job Complete!! And as you can see, it now is showing my quittin time of 4:11am OUCH!! :hot: Hope you enjoyed this post as much as I enjoyed working on this movement. It was really nice to finally work on a watch that hasn't been molested, with nice clean screwheads, and no rust to deal with.

-

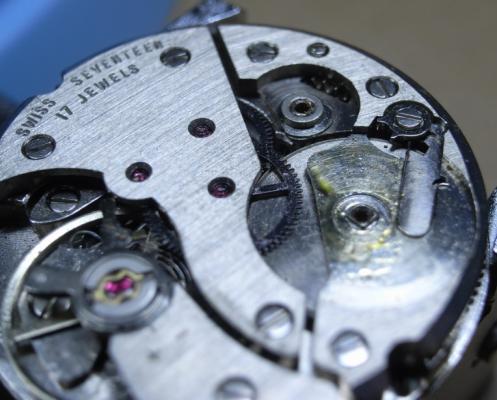

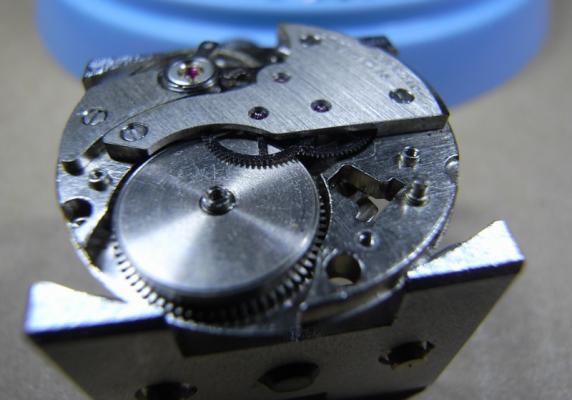

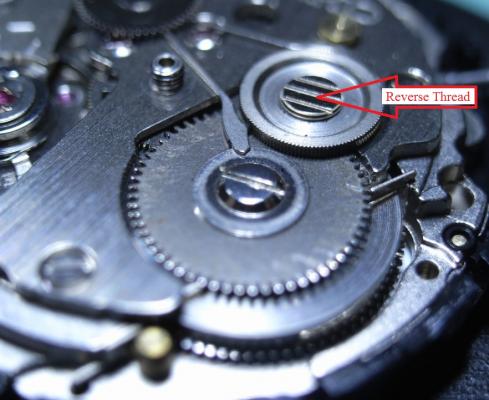

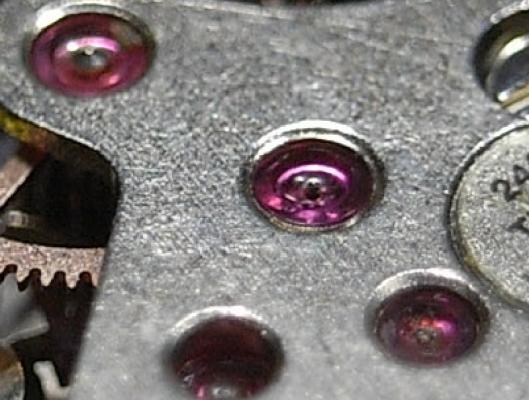

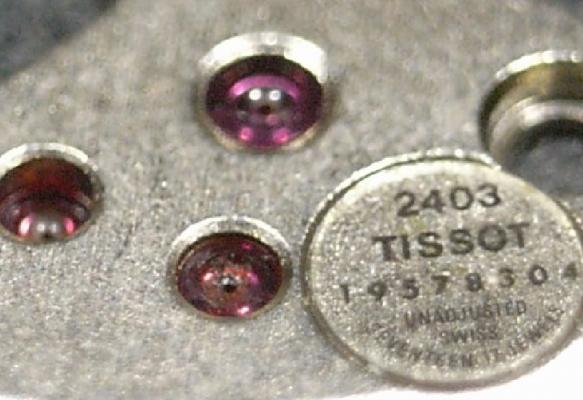

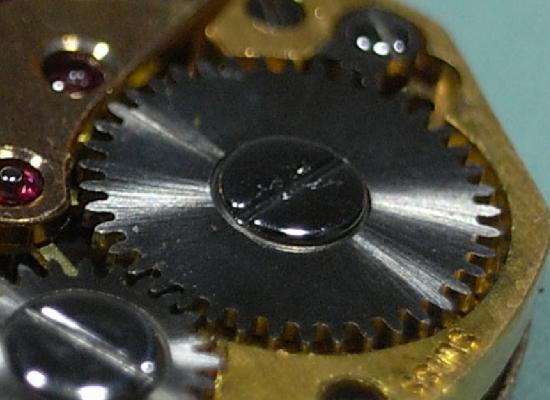

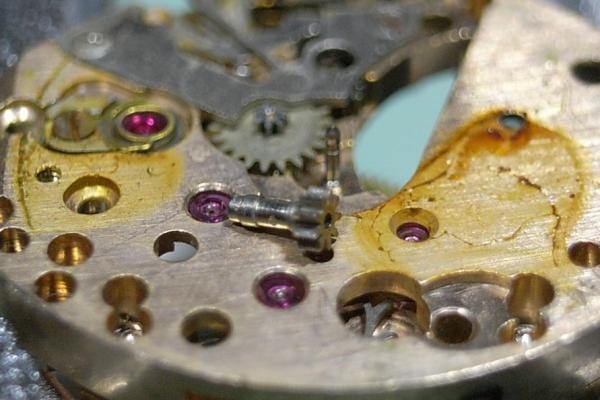

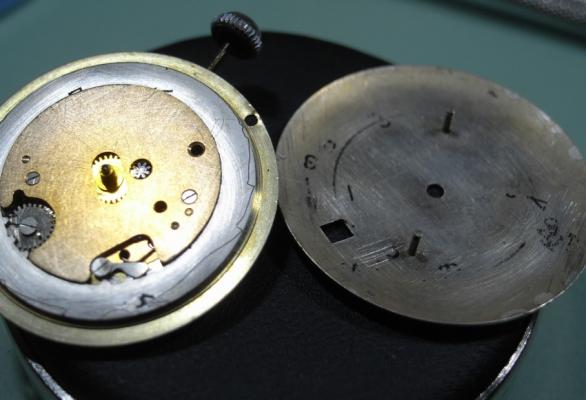

ST96 Restoration Walkthrough I got a new project to start on: restoration of my brother's watch he got for his 9th birthday. This is not an expensive watch in dollar terms; but the memories and history are priceless, and one I really want to restore to excellent condition. It stopped running decades ago, but he has still kept this watch for nearly 40 years, how many of us can say the same about their first watch?! My brother has placed a lot of trusted in me to restore this watch, and I want to repay that trust by restoring this watch to the best of my ability. Note his name (blocked out) and date it was given to him are engraved on the back plate. After opening the back I was pleasantly surprised to see it was a 17 Jewel movement ... so for it's day it was a proper watch; and not a cheap throw-away item you buy at a service station. This would have been purchased at a professional jewelers back in 1975. Unfortunately, the first issue was discovered. The locating ring is missing, and the only thing holding the movement in place is the stem ... not good. So the disassembly begins. Once removed from the case, the hands and dial were removed to get to the movement. Then the first of the motion work is to be removed. Remove the Hour Wheel Then the Minute Wheel pinion and it's Guard Plate. Next remove the intermediate pinion for the Minute Wheel. Also notice the over oiling of this movement, someone got very enthusiastic with their oiler! Again oil everywhere! Here's is the Minute Wheel glued to the Guard Plate with oil. Pull the Cannon Pinion and remove the Endstone. Release the spring tension from the Mainspring. Remove the Ratchet Wheel and Crown Wheel Look at the flood of oil over the bridge! Second issue with this movement. The thread for the Crown Wheel Screw is stripped. It looks like someone has been inside this watch, many years ago, to try and see why it stopped running, and unscrewed this anti-clockwise; not knowing that it's a reverse threaded screw, and stripped the thread :( Continuing with the dismantling ... remove the Click and Click Spring. Note the orientation of the spring. Remove the Barrel Bridge Remove the Balance, Pallet Fork Cock, and the Fork. Remove the Centre Wheel and Third Wheel. Remove the Escape Wheel and the Mainspring Barrel. Remove the Endstone from the Centre Wheel Bridge, and then remove the bridge itself. Remove the Centre Wheel Whatever lubricates were used on this movement it has crystalized into a nasty mess. I tried to capture it on this photo, but it didn't really comes out as I'd hoped .... but notice all the white specs. To finish off, remove the Keyless Work. Start with removing the Setting Lever Spring. Next unscrew the Setting Lever, remove tension from the Yoke Spring, and then remove the Yoke. Note: more evidence of over oiling it present here. Note the orientation of the Yoke Spring. Lastly, remove the Endstone from the Main Plate, and you are complete. After fully dismantling the movement, I opened up the Mainspring Barrel and found what the original issue must have been ... a broken Mainspring. This is the third issue that needs to be addressed to restore this movement. Probably broken by a young boy over winding his watch :) Note: The break in the spring, and how it doesn't attach to the Barrel Arbor any more. So with a missing Locating Ring, stripped Crown Wheel thread in the Barrel Bridge, and a broken Mainspring: I need some spares!! .... off to the Fleabay .... Being a movement in an obscure brand of boys watch, I wasn't exactly hopefully in finding spares readily available ... but praise the Lord Jesus Christ, they were there in abundance! It seems India has cornered the market on ST96 Movements :P They had it least 10 to choose from. I ended up choosing a "Rare" Tressa model in "Excellent" condition, that was a "MUST SEE" I placed an offer for AU$28 on this rare collectable (including shipping) and won it **chuckle** Regardless of the hype, it is guaranteed to work for 12months, and is the movement I require to secure the parts I need. Including that all important Locating Ring. With free shipping comes a long wait for delivery to Australia ... 12-22 days. So while I'm waiting for the watch parts to arrive, I'll clean up the case and bracelet. ... to be continued

-

ETA Caliber 2540 Complete Service Walkthrough Looking for more movements that would expand my training scope. I found this one on the Fleabay: an ETA 2540. It's a "New Old Stock (NOS)" replacement movement, therefore it's not cased, and came with no hands. As there are many ladies watches, especially vintage ones, that are very small, this was my next obvious choice of movement to work on. As you can see next to my thumb nail, it's quite a small and compact movement indeed. Disassembly First remove the Hour Wheel, and leave the tension spring in place. Remove the Minute Wheel, Canon Pinion with Drive Wheel, and the Winding Pinion. The Canon Pinion on this movement isn't the standard fiction fit, it is a "Circlip" type fitting with the Driving Wheel. Therefore no pinion puller is required on this movement. Below is a reference photo. The motion work is now removed, so it's time to turn the movement over. With the Movement turned over, release all tension from the Mainspring. Remove the Balance. Remove the Pallet Cock and Fork. Remove the Crown Wheel and Ratchet. Remove the Click and Click Spring, then the Barrel Bridge. Here is a reference Photo of the Click Spring. Remove the Train Bridge. Remove the Second Wheel, Third Wheel, Intermediate Wheel, Escape Wheel and lastly the Barrel. Finally turn the movement back over, and complete the disassembly by removing the Keyless Work. Remove the Setting Lever Spring. Remove the Yoke Spring and then the Yoke. Then remove the flip the movement over and unscrew the Setting Lever Screw. Pull the Stem out and the Clutch Wheel and Winding Pinion will fall out. Here is a reference photo of the Yoke Spring. Disassembly is now complete.

-

I was asked to have a look at this family heirloom just handed to me from a friend of a friend as it was not working and they thought it may have some value. The quality of the movement did not inspire, to say nothing of the identity of the watch !!! As I had never done a pin-lever before I decided to have a go and get it running again. On inspection I found it be in reasonable condition but very dry and the balance was very stiff and not working. Once the balance and lever were out all ran freely, so I reckoned a good clean and lube would solve the problem. For those interested I have done a walk-through for the assembly as the strip-down is just the reverse basically. After a good clean of all the parts in lighter fuel (I'm only a hobbyist) and a strip and relube of the mainspring, the assembly followed First the gear train, block for stem gears and intermediate wheel were assembled and lubed Next the barrel was installed (sorry for quality of pic) Then the train wheel bridge/plate was added and checked for free running from barrel to escape wheel, and lubed The keyless works are added and lubed, note the yoke also acts as a spring against the setting lever and action checked The winding wheels and the unusual click spring are added and lubed and action checked. I forgot to take pic of this next stage but the assembly can be seen in the dial fitting below. The pin-lever was added and checked for kick The pins and escape wheel where epilame treated and oiled with M941, and the fork was wiped with M941 on a wedged end of pegwood, this is because they are all metal to metal contacts. Even the balance table jewel is metal !! The balance was added, lubed and checked for function. There are no balance pivot jewels (in fact there are no jewels at all !!!) just holes in the main plate and balance cock. The holes lie under the round plate on the mainplate and the regulator on the balance cock. These were removed/lifted to lube with M9010, the cock plate being a bit tricky/delicate. The canon pinion was added and lubed. This is not a friction fit but is driven by the intermediate wheel. The minute wheel and dial washer are added and lubed The dial has split posts which are just spread open (what technology !!) so this was fitted very carefully so as to avoid damaging the balance or lever which are very close by as shown in pics Stuck in on my timegrapher which showed a very noisy trace (not surprisingly) but managed to get it reasonably regulated despite iffy beat error and rates in some positions. I aimed at a reasonable rate when worn and it actually keeps fairly good time within 1 minute a day on average. The hands are fitted, and the movement put into the case-back and case-top/bracelet are refitted. AND NOW I CAN REVEAL THE IDENTITY OF THIS HIGH END WATCH Yes its a really awful 1970's fake !!!! So no family fortune here then !!

-

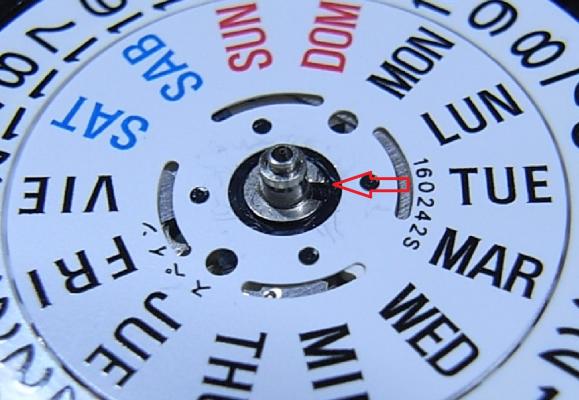

Seiko 7S26A Complete Service Background I have a good friend, a brother in Christ Jesus, who I've known for many years. He knows I've embarked on retraining myself for a new career in Watchmaking, and seen my first two restored watches. He told me that his old faithful Seiko 5, which he's worn everyday for 12 years, has recently had issues. Occasionally it will advance rapidly in time (up to an hour in a few seconds) and then just keep ticking away normally. I told him I'd be happy to take a look at it, and put it on my ACEtimer Timegrapher. The pattern on the screen looked like a B-52 drop in Nam (stupid me forgot to take a photo), and I told him that his watch definitely needed an inspection and service. So started my research on what the problem might be. After reading a "Practical Watchmaking", and the many forums that I've read, I was pretty sure it was the Pallet Fork ... either very dirty or damaged stones, or a broken/damaged fork pivot. So onward to the service... Disassembly One unusual aspect of this watch is the crown ... or lack there of, more to the point. I suppose since this is an automatic watch, they thought it didn't need to be wound. This watch also has a display back, so extra special care not to mark any of the plates, or damage screw heads! The first issue you'll face when working on a 7S26A Movement, is how to get the stem out! It isn't obvious at all, and there is a little trick. The crown needs to be pushed all the way in to expose the push plate (it is hidden in the other crown positions). I took this photo once the movement was out to best illustrate where to push. Remove the Hands, Dial and Oscillating Weight (2.0mm Screwdriver). Gently lever up one end of the circlip and carefully work your way around. You then should be able to raise the circlip up the length of the shaft without it pinging off. Remove the Day Wheel and the four screws holding the Date Dial Guard. (Use a 1.40mm Screwdriver, and this driver is good of all the screws from now on; bar one.) NOTE ORANGE ARROW: Seiko Special Tool needed for the 0.98mm Philipshead Screw (Part Number: S-921) I had to journey down to my nearest Seiko Distributor and grab one ... cost was AU$24.00 Here's a closer look at the troublesome screw. Remove Date Jumper, and note that the Date Drivewheel lips over the top of the plate. Remove all the motion work, and pull the Cannon Pinion Remove the tension from the Mainspring. Remove the Ratchet Wheel and the Second Reduction Wheel and Pinion. (remember the Reduction Wheel has a reverse thread) Unscrew the Balance Cock and remove the Balance. Also unscrew the Pellet Cock and remove the Pellet Fork. BINGO! Found the problem with my friends watch. The top pivot on the fork is broken. Easy fix with a replacement fork :) Remove the Barrel/Train Wheel Bridge Remove the Click, then the Barrel. Remove the Fourth Wheel, Third Wheel and Escapement. Unscrew the Centre Wheel Bridge and remove the Centre Wheel Now to the Keyless Work. Remove the Setting Lever Spring Remove the Yoke and the Setting Lever Pull the Stem out, and the Clutch and Intermediate Wheel will fall away. Lastly, pull the black plastic location ring off. ... and now it's bath time!!! I hope this has been of help to you guys. I'll post the Assembly steps in this thread tomorrow morning.

- 94 replies

-

- 12

-

-