Search the Community

Showing results for tags 'movement holder'.

-

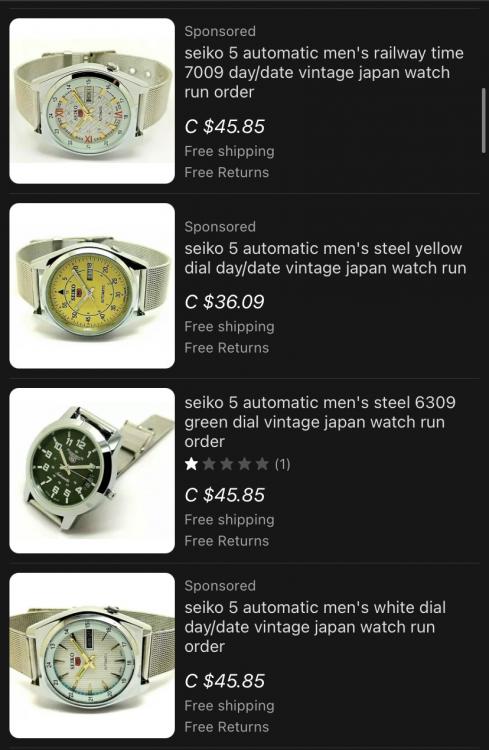

I recently purchased what I call a “Franken-watch” Seiko from a seller on eBay from India. As I’m sure many of you know by now there are hundreds of listings (see screenshot below) for cheap Seiko watches with weird dials, most likely repainted. They aren’t fully “fake” as most of them come with genuine Seiko movements. My Retro Watches has a good video where he looks at a watch he bought from a dealer similar to this if you’re curious, see link below. https://youtu.be/G_m4b3OBEMI Anyways I thought one of these cheap weird watches would be a fun one to play around with as my first project, and I paid $20CAD for mine which I thought to be good especially if the movement inside was genuine Seiko. First problem I noticed was the bracelet (which was cheap and terrible) was held in by shoulder-less spring bars which would be fine if the lugs had holes but they do not so I had to saw the bracelet off so I could put another one on (see wreckage below). There’s more but I won’t bore you too much.. MY MAIN PROBLEM: The watch came with a Seiko 6349A (23J) movement which is a variation of the Seiko 6309 (17J) movement. The movement was held into the case only by the crown (see pictures below) and didn’t have a movement ring. As I understand this is bad because the movement isn’t securely held in the case by anything. I’ve tried to find one on eBay but I’ve had no luck, and I can’t find anywhere that has the ring size so I can’t try and find an aftermarket one. Does anyone know where I can get one of these movement holder rings? Is it even possible to get one off of CousinsUK or Esslinger or somewhere? Do any of you have one I could buy? I am very stuck and any help is greatly appreciated!

-

Well its been a while since i shared a post and i thought id share a mini project with you splendid folks as i know you all like looking at new and shiny things Ive spent several months working away almost non stop on various repairs and services, so when i finally had a chance to clear my table i figured id get stuck into a small project idea i had. When i set out with a specific idea/design in mind i usually write down every dimension and draw up diagrams and spec sheets etc, but i figured for this project id just play it by ear, or eye in this case. I was working on a pocket watch movement when it occurred to me how boring ( although reasonably functional ) my movement holder was, and i thought to my self why not make my own. With some metal stock lying under one of my cabinets i got to work and just lost myself in my machines........... Top corner is my trusty albeit ragged holder, with parts machined by eye underneath..apologies for lack of focus After a clean up and light polish ( lets not go too crazy it is a tool after all ) i got round to assembling the holder and setting the bar shims and threads with some Loctite > As you can see i didn't go too crazy with the finishing of every piece as it is going to be put to work but i think its an improvement over the standard el cheapo i use for large movements. As i used thicker parts overall , the holder is much more rigid Im sure i will likely be making some more in the near future but im going to design them next time rather than play it by eye I do like Bergeon Holders but nothing quite beats something you made for yourself . Next project is a new tweezer/forcep stand for my trusty Dumonts ( For those interested in boring details > M4 Threaded centre stainless steel > 12mm Free Machining Brass Knurled knob & retainer screw > 6mm Brass shims > 4mm Brass sliders with M4 threads 3mm long >2 x Aluminum flat bars machined in mill and hand finished angle ZZZzzzZZzz )

- 16 replies

-

- 6

-

-

- tools

- movement holder

-

(and 2 more)

Tagged with:

-

As you know, I am working on a couple of movements, a Landeron 248 and a Valjoux 7733. I use a normal brass movement holder that I bought for real cheap on the bay a couple of years ago, but apart from being a bit unstable (china made...), it has worked me well for the simple watch servicing I have made for hobby. I acquired a cleaning machine the other day, and while I was at it, I was looking for other tools to buy (I had some spare dough I could throw at it... ). I found this auction for a 3d-printed movement holder for a Valjoux 7734 movement, and was intrigued both by the price (a professional one can cost upwards of 100€ here in Germany) and the quality of it. 3D printing is just amazing, and provided you have the right printer and correct design (with correct dimensional measures) it can do wonders... I contacted the seller asking if he could make one "to order" for my 7733 and my L248, and he replied "Yes of course, I've done it already..." WOW! I was in! I looked at the other items he was selling on the bay, and wrote him another email, asking a couple of other things, to which he complied, of course. I received the package from France today.... Ladies and Gentlemen, let me present you my new 7733 and L248 3d-printed holders, and stackable 2-stories parts box: The movement holders are incredibly precise, and themovements fit in perfectly: The holders are marked with the respective movement they were made for, so no problems figuring out which is which: And you can see in the picture above the stackable parts box does come with an acrylic cover... NICE! As you can see, I already put it to use: The seller makes them to recover the costs of the 3d-printer, and each holder costs about 10€ (if he already has the dimensional data - that is, if he made one in the past) plus 6,50€ shipping costs (to Europe, to England I do not know). If you need a holder he has not done yet, you can send him a wrecked movement or the precise dimensional data, and the first prototype will cost around 25-35€ to make. He has made quite a few models up to now, so probably he already has what you need. Manufacturing time is a couple of days only. If Mark agrees, I will post here the contact details of the seller, but you can easily find it on eBay, like I did. The guy speaks english, so no problem in communication either ;) And now... back to the working bench with my new holders!

- 17 replies

-

- 2

-

-

- 3d printer

- 3d printing

-

(and 3 more)

Tagged with: