Search the Community

Showing results for tags 'landeron'.

-

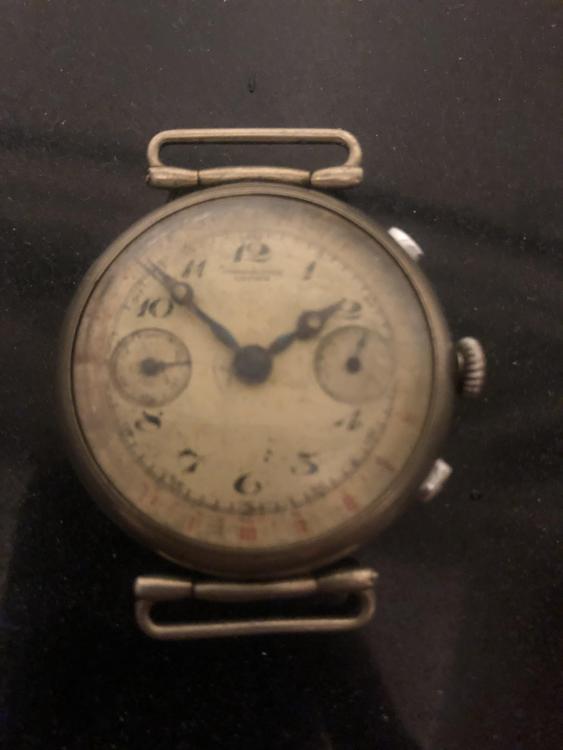

Sourced this watch, want to know your thoughts about it. Like the looks of early Landeron Hahn 15 1/2 dials. Looks like this is Landeron Hahn 2 (judging by 45 minutes register)? I am new to watches, so any insight/thoughts/help are welcome. Here are some questions I already have: 1) What do you think about restoring this one? 2) How hard would be to source the bezel for it? Where to look for it? Looks like case is quite large - 40mm in diameter. I assume sourcing mineral crystal later shouldn't be a problem? 3) How to fix that broken fixed lug? Or it's better to transform to non-fixed lugs? 4) Movement looks complete to me, seller says balance swings nicely (i hope so), hopefully just needs cleaning/oiling. Or you can already spot something off? 5) Missing seconds hand shouldn't be an issue? Probably regular Landeron should fit with 0,25 or 0,27 hole size? 6) What to do with hands (assuming seconds hand will be new, unless I will source by some miracle something with matching condition). Looks like someone restored similar watch: https://www.watchpatrol.net/listing/611413/

-

Beginner horologist here. I attempted to overhaul my first chronograph. I followed the manual from cousins to the tee from what I can tell, and everything is working great EXCEPT the chronograph will only start, and when I hit the bottom button to pause, it automatically resets to zero instead of pausing before a second click to reset. What would cause this? I've been scratching my head since it essentially works perfectly otherwise. Any help would be great appreciated!

-

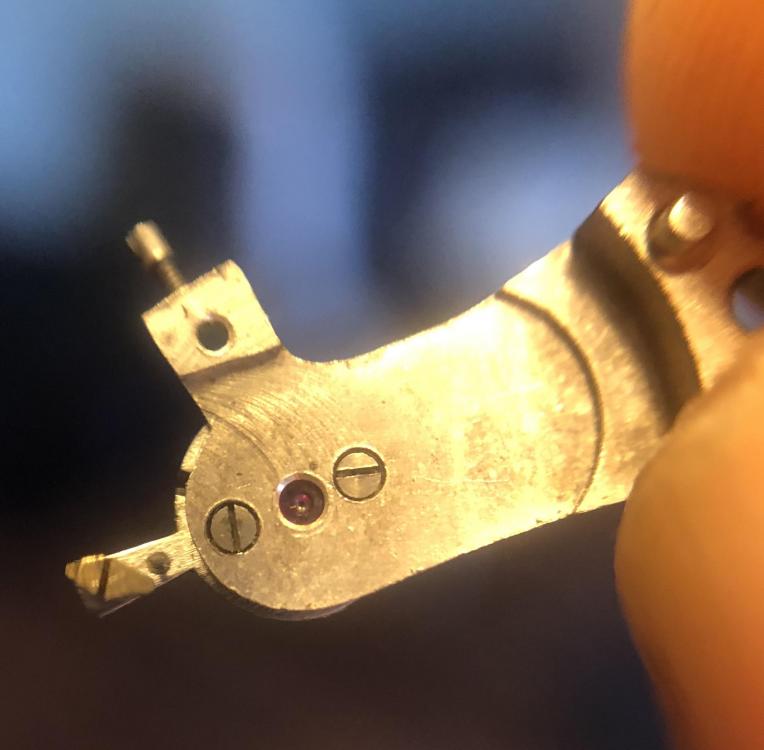

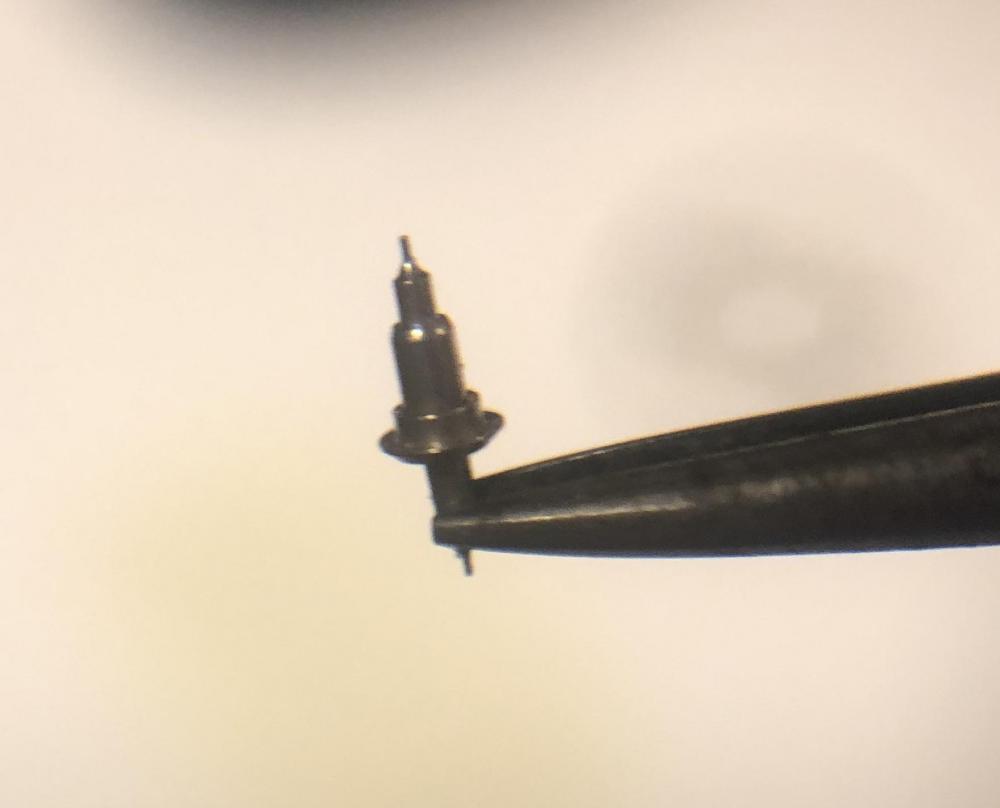

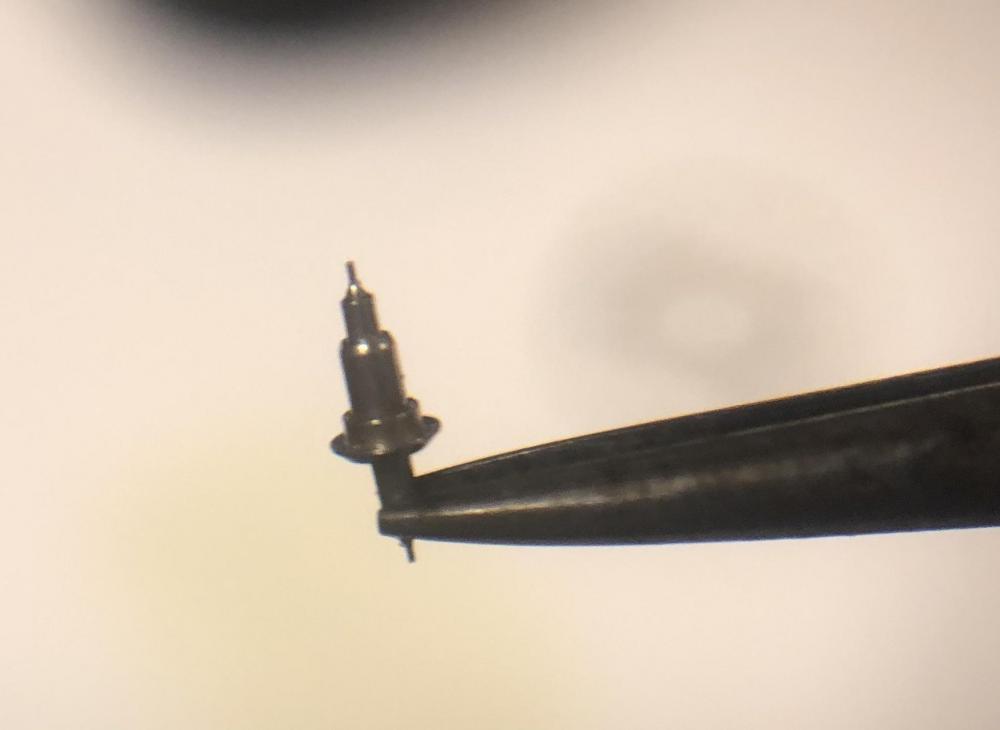

Hi all, hope your having a good day! I have finally got back to restoring a Landeron movement, a personal project I started a while back. I believe it is an early cal. 48 although it may be a 47? The balance was one of the many issues with the watch. With a broken pivot on the staff and the balance spring beyond fixing, without buying professional tools finding a complete balance would be the easiest way for me to fix the issue. I am at a complete loss as to what balance I need; I know its a non-incabloc, possibly made by either Barbell or Renata but I'm not sure what I should be looking for, or where to find one. There are many variants and I'm not sure if any of the calibers of Landeron house the same balance that I might be able to utilise? I've attached a picture of the movement before I disassembled if it's to any use? Any help is very much appreciated! Many thanks

- 4 replies

-

- 1

-

-

- landeron

- landeron 47

-

(and 2 more)

Tagged with:

-

Sourced on ebay some relatively inexpensive Landeron 3 watch. Looks like 30ties, all original. 40mm diameter without crown. Watch was sold for parts or repairs. This is all info what I got from seller: Watch looks very dirty (I will not wonder if that dirt is still from war)... Balance completely disassembled, but all parts present (in the same box as watch, at least hairspring was in container). One of the pusher levers is broken (but broken piece is there). Other pusher was not properly installed (fixed that already). Foil disc from under dial is also there inside the box. Dial was not tightened enough, so small register seconds hand was hanging around under scratched glass. Mainspring was fully wounded. I don't know what to think about that... I mean, I am a beginner, but at least I wouldn't left wounded mainspring, and probably disassembled balance parts I wouldn't just throw in a box with the watch. When I look at the balance staff, it doesn't look so bad to me (see the pics and comment please, I might be wrong), so I wonder, why it's disassembled. Could it be, that watch stopped working because of dirt/old oil, and someone unexperienced decided that balance needs to be disassembled? Any ideas where to start? I was thinking about bringing it to watchmaker to check/assemble the balance, and see if it swings more or less fine, and after that start with cleaning/oiling. P.S. Does anyone has spare pusher levers for this movement? Or could some laser welding work to fix broken one, or that will not be strong enough? And any suggestions about hands - should I restore them (blue layer is coming off at some parts) or keep them "patinated" as they are?

-

Hello! Do you oil the shouldered “safety” screws that hold in place the coupling clutch 8080, the sliding gear 8100 or the hammer 8219? If so, do you also put a very tiny drop of hp 1300 under them? you can find the entire doc here: http://watchguy.co.uk/wp-content/uploads/2012/12/Le-Landeron-48.pdf Thank you! Bogdan

-

Since I was working on the Landeron 48 with wrong dial, from which I used the case and a Landeron 151 and correct dial to make a new watch, I saw this Landeron 248 sitting in the drawer at my desk and devided to finally tackle the issue it had: a slipping mainspring. I documented the disassembly of the movement vith 3 videos, the first of which is here below: Hope you enjoy

-

Some of you already know that I bought myself as a birthday present, and to celebrate the birth of my first daughter, a Landeron 248 based Chronograph to restore / fix, and that I thought that it was a redial. Here the thread about it: Apparently it is not only the case ot a simple redial (albeit with a wrong dial which was adapted) but what I would define as "watchmaker's botchery", since the dial itself was fixed to the case with 2 screws (and from the front side...):

- 23 replies

-

- 1

-

-

- aftermarket dial

- repair

-

(and 4 more)

Tagged with:

-

Since June 8th will be my B-Day, and if all goes well I will also become father for the first time (well, that will probably NOT happen on the same day, but I can still wish, can't I?) I decided to pull the trigger on a watch I liked on eBay. The only issue is that I did so, while surfing the site with my mobile phone, so the pictures were rather small... Are you starting to get the picture of the issue, here? Fact is, that after analyzing the seller pics on my PC, I started noticing "strange" things... I will leave the pics talk for themselves... The movement looks ok, as does the case, the permanent seconds hand and minute counter are detached from their pinions, but that was declared in the auction, so no issue. The issue is that the dial markings appear not to match. Check the tachymeter marking for "60" which logically should be directly over and properly aligned with the 12 hour marking. Is it the picture angle that plays tricks on my eyes, or is it a bit shifted to the right?? I have not received the watch yet, so a personal inspection is yet to be made. Could eventually this be a reason to give the watch back? No mentio on a redial on the auction text... What do you experts think?

- 18 replies

-

- redial

- chronograph

-

(and 3 more)

Tagged with:

-

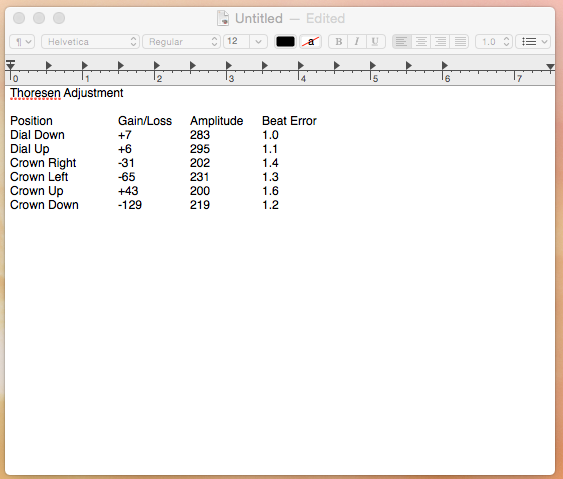

Today I wrapped up work on a Thoresen Recipro-Register Chronograph. Sounds like an exciting piece doesn't it? The Thoresen Recipro-Register is a Landeron 48 calibre chronograph. The one I'm servicing here was sold in about 1953. The watches were acquired back in the day via mail order for a bargain price of $29.95 USD. This is another "everyman" chronograph much like the Chronograph Suisse of the same period. I picked this one up from the Goodwill for a fair price as as it kept poor time and had a broken Speidel bracelet. This is quite a small watch compared to the chronographs of today. Diameter, including crown, is 37mm and the space between the lugs is only 16mm- that's quite a narrow strap. It's a men's watch but today would be quite at home on a woman's wrist as well. I knew it was running fast before I even put it on the timegrapher but I was pleased with the amplitude. The normal dirt and grime had accumulated around the caseback but the inside was immaculate! Only a tiny bit of rust staining at the top where water had entered at the pusher. The movement is marked Orator Watch Co. as is the caseback. Under the microscope a bit more dirt is visible but the screws look like they may have only been turned once in their lifetime. It's here that I get a lump in my throat. I almost feel bad putting my amateur hands on this one! I start breaking the watch down. The hands and dial come off first. The dial is in wonderful condition as well. The lime is radium based so extra care is taken. Dial side of the movement is utilitarian but clean. After snapping some reference pictures of the front and back I'm called to dinner. The movement goes under the glass for the next day... And the camera batteries go dead! No pics of the breakdown I'm afraid! There wasn't much to discover though. The movement looked quite good and there were no obvious issues noted. Probably just a cleaning and lubrication will do the thing. I put the movement though the L & R and start reassembly. Despite the nice amplitude registered before, the mainspring looks spent. Luckily I have a replacement at the ready. The gear train goes together simply enough. There's some rust staining on this plate as well. I tried rubbing it out with pegwood but let it be when elbow grease wasn't enough. The pallet fork (installed above) is a bit different from those I have seen before- clear rubies. It's not really a big deal but something different. Clear cap jewels are something I loath. They are very easy to lose. Luckily this watch only has clear jewels on the pallet fork! (Please note that the picture below was taken before cleaning the pallet fork!) Dial side is assembled next. The keyless works is properly greased and reassembled. So far things are looking good but there is one jewel setting that is bothering me. I take a better look at it under the microscope. If it looks funny that's because it's chipped. The chip is on the oil reservoir side. The pivot hole is still properly rounded however. I have a Seitz tool for replacing the jewel but no replacement jewel readily available. Seeing as I own this one and just want to get it off my desk, I continue with assembly while making a note to the fix the jewel later. On the timing machine I discover that there appears to be no impact. With the basic works back together i start on the chronograph. I've taken to returning the screws to the plate after disassembly so that they are readily available for reassembly. This has saved me a lot of time hunting for screws. Despite this, I still managed to mix up two pair of screws! The movement is reassembled and re-cased- how did I forget to take a picture of the reassembled chronograph movement? It took quite a bit of effort to get the chronograph to work flawlessly; there are three eccentrics that needed adjustment to get the gears to mesh just right. The flyback lever was also an issue until I realized I had mixed up a screw and needed to swap it with another longer shouldered screw. Lastly the sweep second hand had a tendency to reset a few degrees to either side of 12 o'clock when operating the flyback button. I fixed this by removing the hand and giving the tube a light tap with a stake to tighten up the post. Now tightened it always returns true. A new crystal completed the effort. What a darling! Now for the bad news, and hopefully the community can help me out here. Despite my best efforts I could not eradicate the beat error. I figured anything 1.0ms or less would be acceptable considering the age of the watch and in one position I can get that but the rest of the positions are not great. The cracked jewel is the lower pallet jewel- I'm sure that could have an impact on the timing of the watch and that will be the first thing I fix. Otherwise I'll be checking the balance pivot and the shake of each gear in the wheel train. If there are any other ideas I'm open to hearing them too. I wish I had caught this a little earlier but didn't check the watch in several positions before service or even after assembling the base movement. I can attest that the pivots and gears are in good order though. All in all, it is keeping good time sitting on my desk and I have to admit I'm smitten by it's appearance!

-

So today I received the set of spare Landeron movements I had bought last week. I received some spares, and 4 incomplete movements, various models, and a dial. Movements are completely dirty, will definitively need a good clean on my Elma, and the dial has also some patina, which actually I like. Here the pics: A very fast clean (by no means to make it working perfectly) and I put some parts together with the best looking movement, to have a working watch. I do not have proper cases for the chronographs as of yet, but I am still looking. Here my 3 chronos: The Walker and the Bovet are Landeron based, while the Gigandet is a Valjoux 7733 Sorry for the low quality pics, my mobile phone is just too bad...

- 34 replies

-

- 2

-

-

- chronograph

- landeron

-

(and 1 more)

Tagged with: