Search the Community

Showing results for tags 'chronograph'.

-

Greetings, I am looking forward to being part of the WRT forum community and diving in with one of my favorite pieces I've found so far: About two weeks ago I picked up what I believe to be a 1940s era Valjoux 22 chronograph branded by CYMA as a Ref. 400L movement. I am struggling to find any info on the particular movement and was hoping that someone here might know a little bit about the Ref. 400L. Or, what the differences are between the 400L and the 22. Quick searches on eBay and Google leave me wondering what I really do have here. The only thing I have done with it so far was change the hands and add the chrono second hand (which was missing when I bought it) with something more era-correct and not as in-your-face as the bold hands that were on there when I initially received it. Unfortunately, Its not 100%... Now, I'm no watch maker by any means, but the movement looks quite dirty to my eye, and maybe even a bit pitted/rusty. And the balance assembly seems weak; visually ticks slower than I would have expected. The balance spring is not perfectly all in the same plane, it slouches downward a bit. And the chrono second hand resets beyond the zero position. Yet, the watch keeps decent time, haven't regulated it, but if I had to guess its somewhere around +10-15 s/d. So, at this point, I'm just looking for info on the movement. Does anyone have experience working on such movements? And then further down the line, I hope to either find someone to service it, or if I find enough info and feel confident enough, I may attempt seeing what I can do with the reset function personally. What are your thoughts? Any info is welcome. ~Cheers, Zach

-

Since June 8th will be my B-Day, and if all goes well I will also become father for the first time (well, that will probably NOT happen on the same day, but I can still wish, can't I?) I decided to pull the trigger on a watch I liked on eBay. The only issue is that I did so, while surfing the site with my mobile phone, so the pictures were rather small... Are you starting to get the picture of the issue, here? Fact is, that after analyzing the seller pics on my PC, I started noticing "strange" things... I will leave the pics talk for themselves... The movement looks ok, as does the case, the permanent seconds hand and minute counter are detached from their pinions, but that was declared in the auction, so no issue. The issue is that the dial markings appear not to match. Check the tachymeter marking for "60" which logically should be directly over and properly aligned with the 12 hour marking. Is it the picture angle that plays tricks on my eyes, or is it a bit shifted to the right?? I have not received the watch yet, so a personal inspection is yet to be made. Could eventually this be a reason to give the watch back? No mentio on a redial on the auction text... What do you experts think?

- 18 replies

-

- redial

- chronograph

-

(and 3 more)

Tagged with:

-

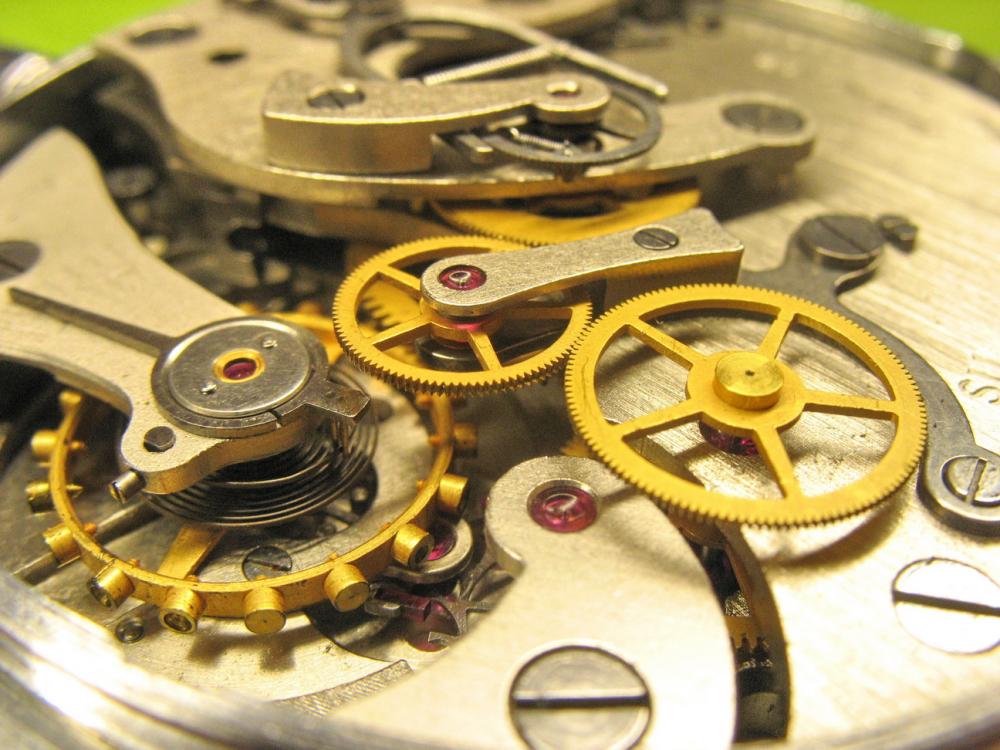

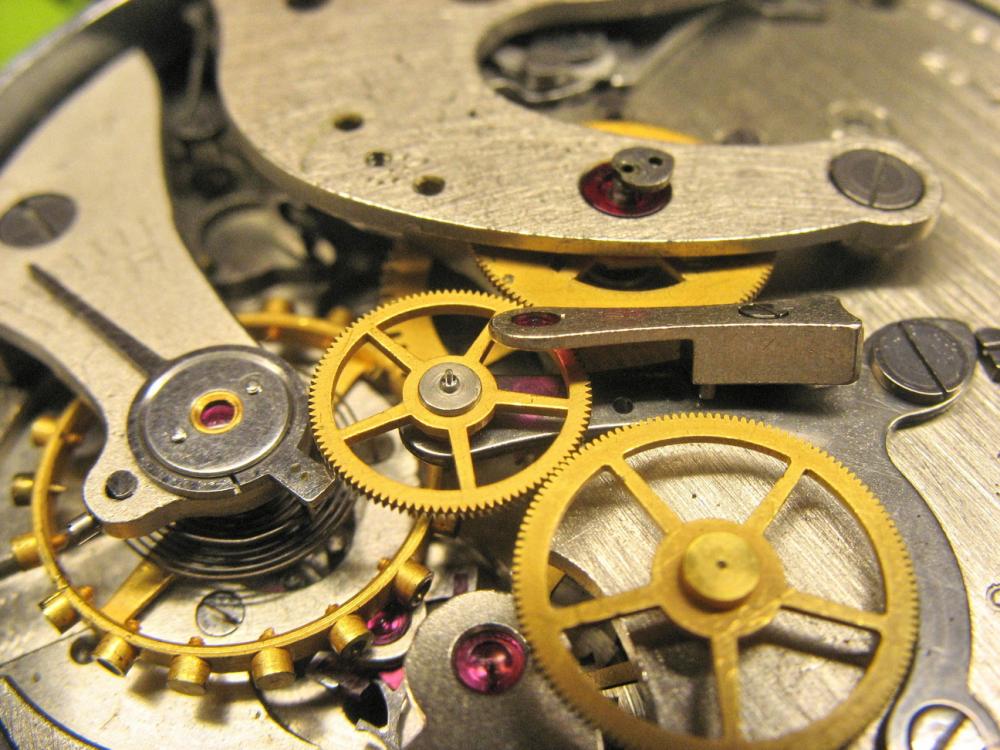

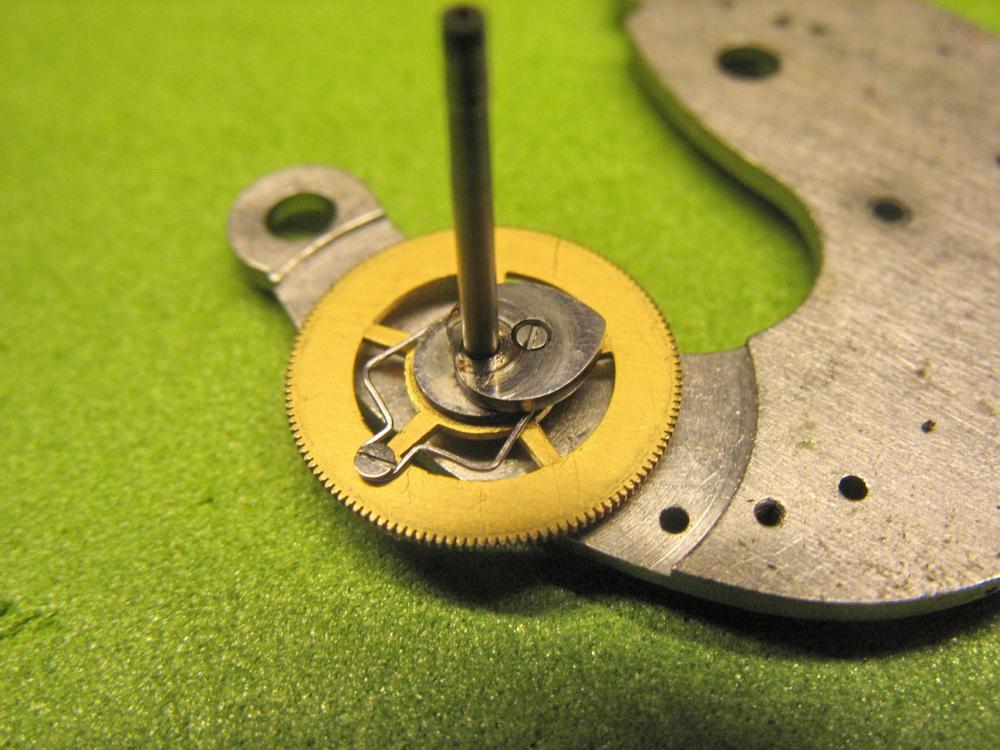

I am in the process of servicing the Landeron 48 movement that came with the complete watch with wrong dial applied, as many of you can recall from my other thread. After a brief check I noticed something was wrong with the balace wheel, so after inspection of the part, I discovered that the upper pivot was broken. I had another balance wheel with bent hairspring, so I decided to replace the balance wheel using the original hairpring. After a bit of tinckering, I managed to do just so, but a new problem arised, which will be shown in the linked videos here below. The first video shows how the new balance wheel turns freely after a bit of adjustment in the movement: The second video shows the problem I faced after replacing the hairspring onto the balance wheel and reassembling everything back together. Basically, the amplitude is extremely low, but I cannot figure out still what can be the problem. The second video above shows the issue better than a thousand words... I need the help of the experts, here: what can the issue be? I followed all Mark's videos on putting the watch in beat, checking the pivots, pallet stones, everything. I have never seen such behaviour before. What can it be?

- 8 replies

-

- landeron 48

- chronograph

-

(and 1 more)

Tagged with:

-

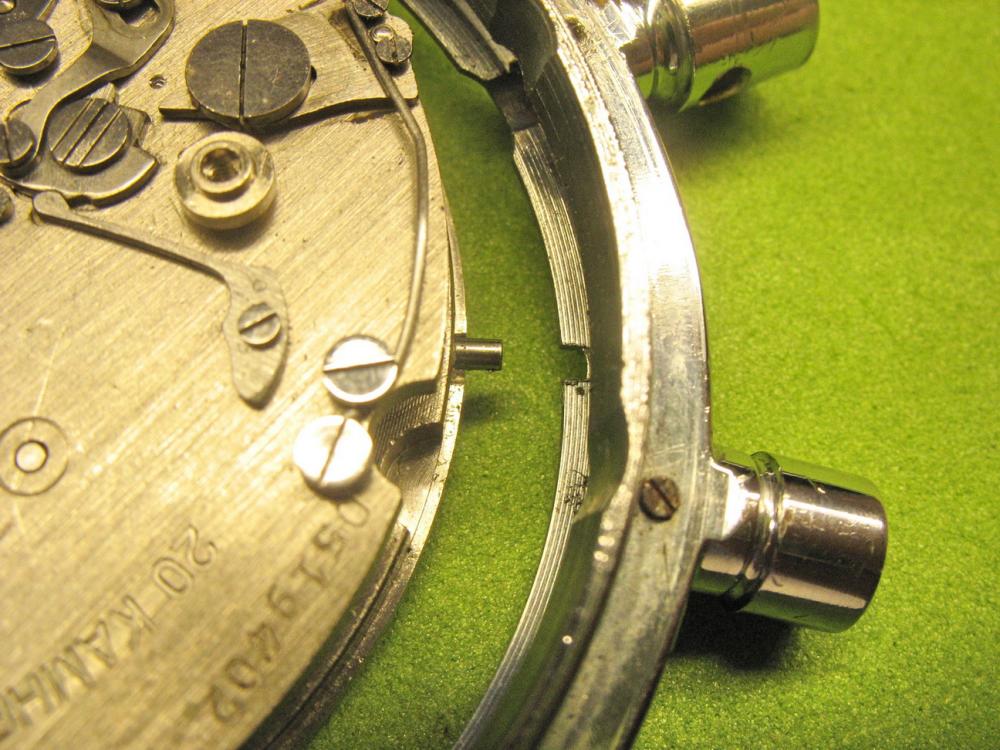

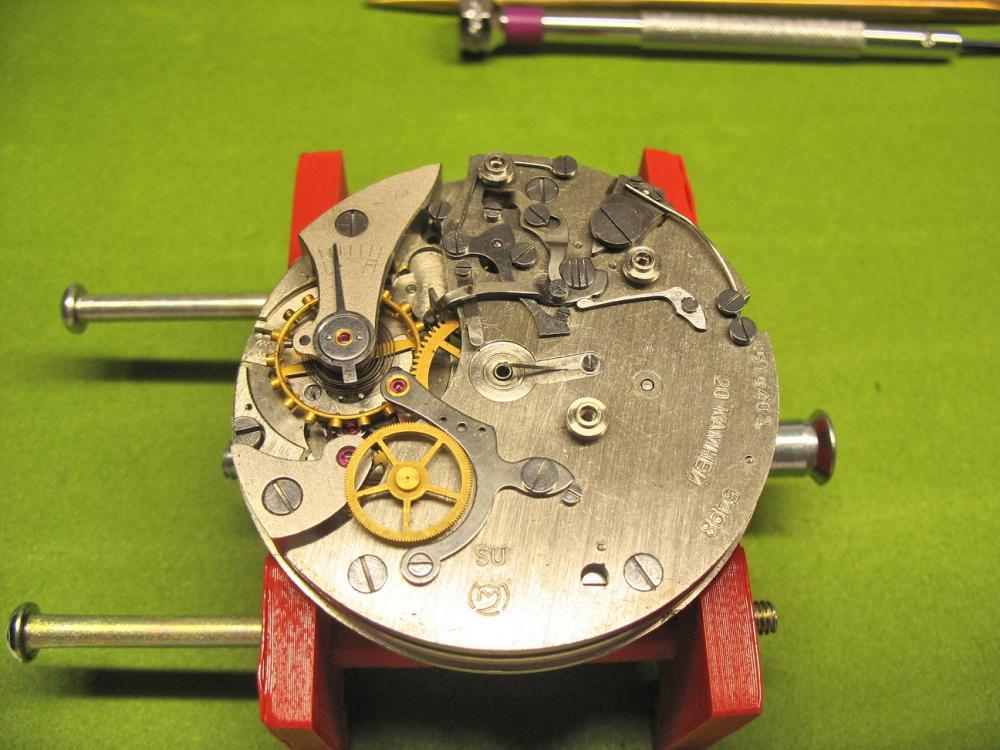

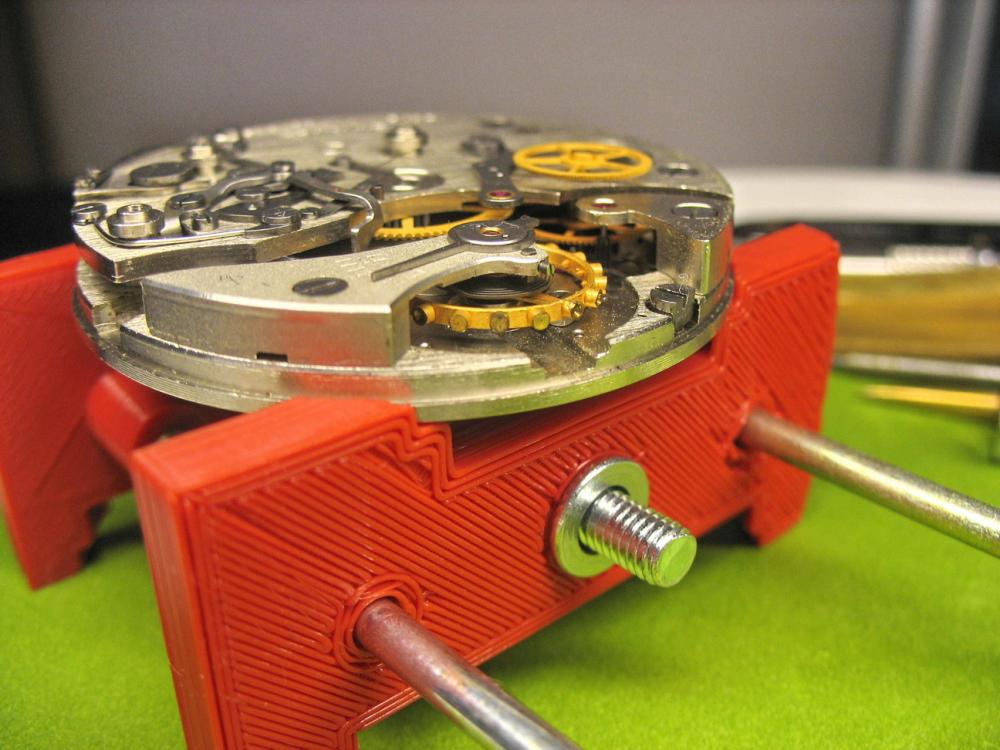

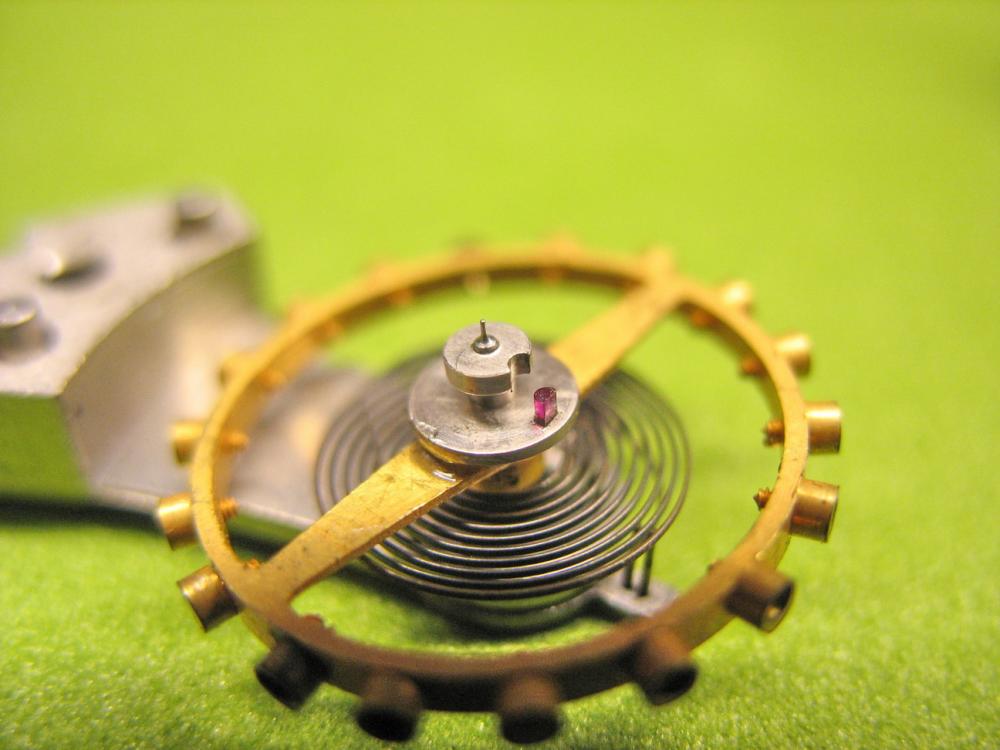

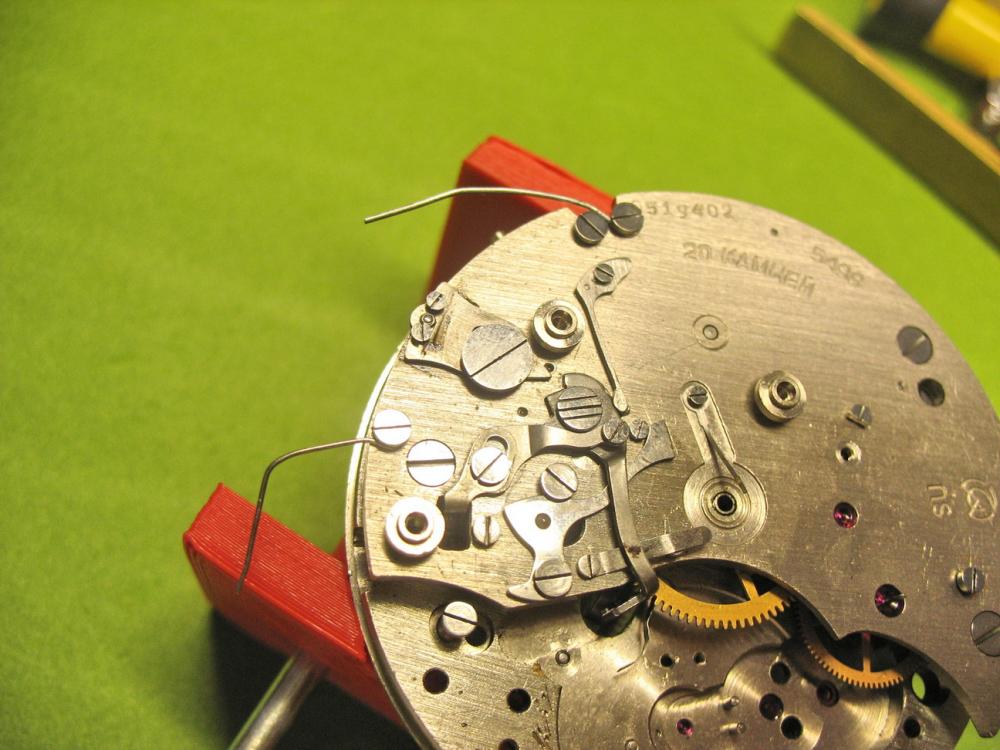

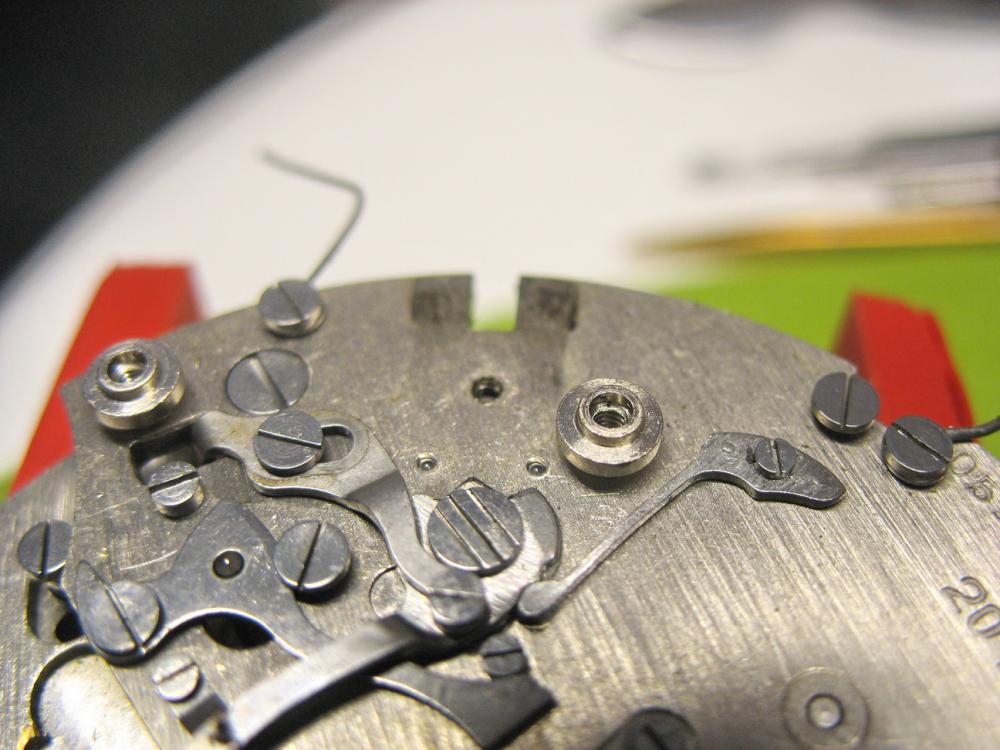

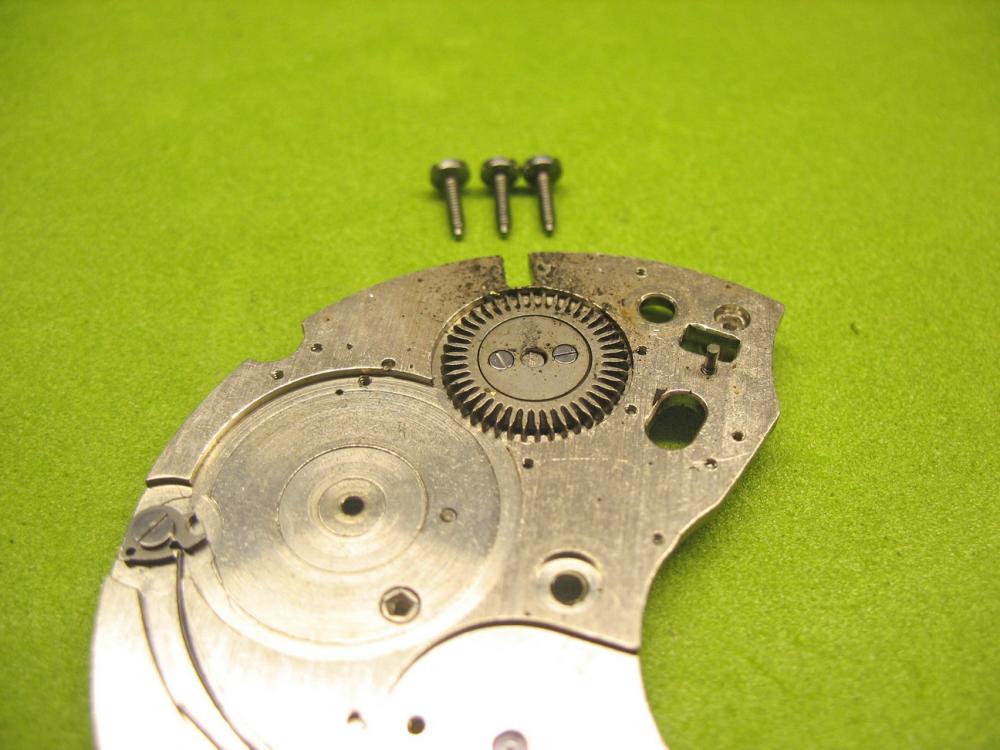

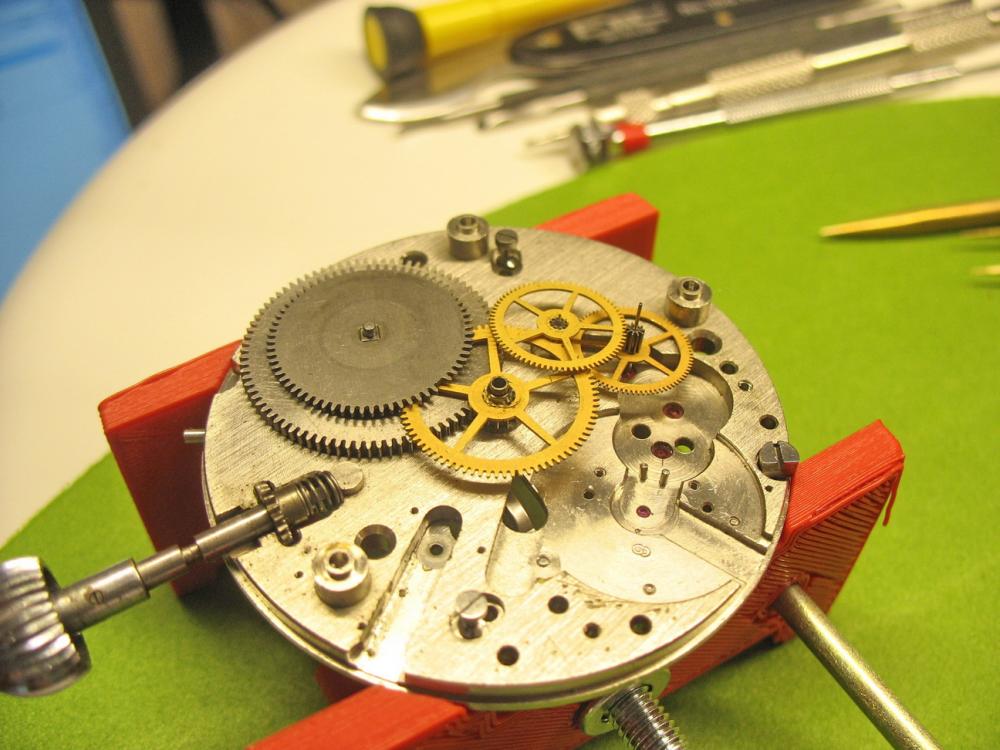

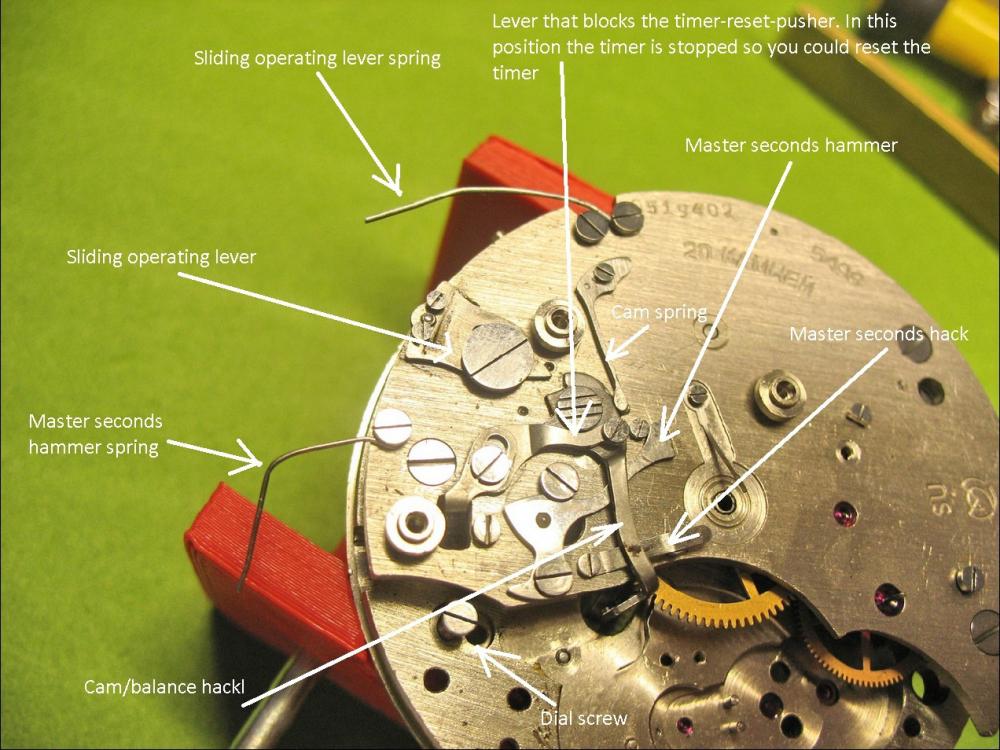

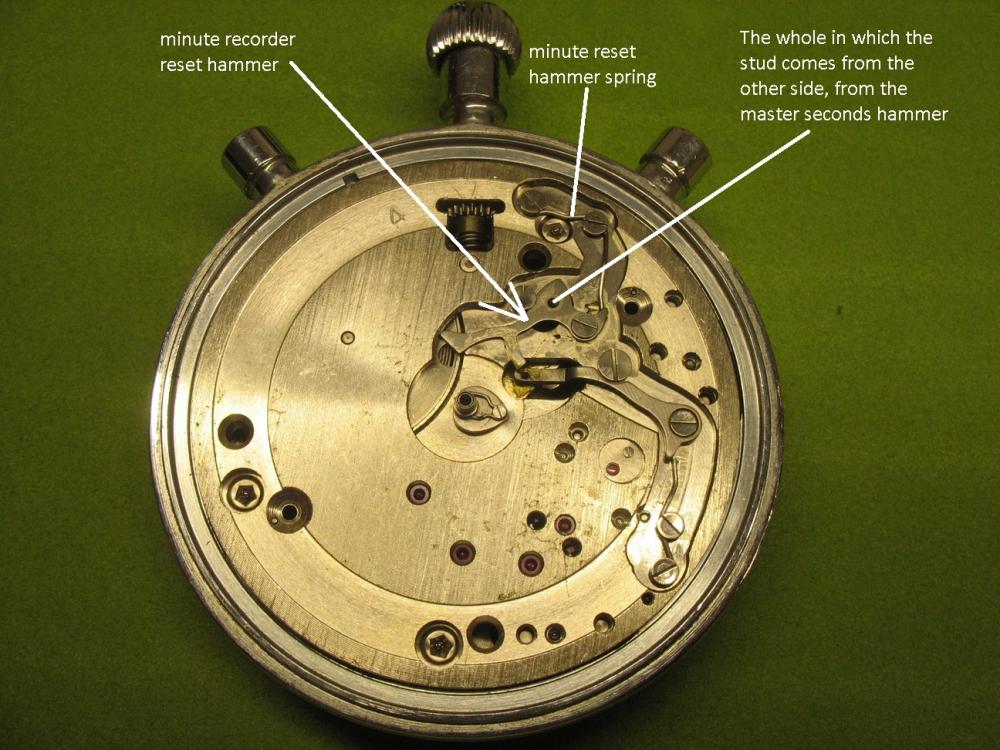

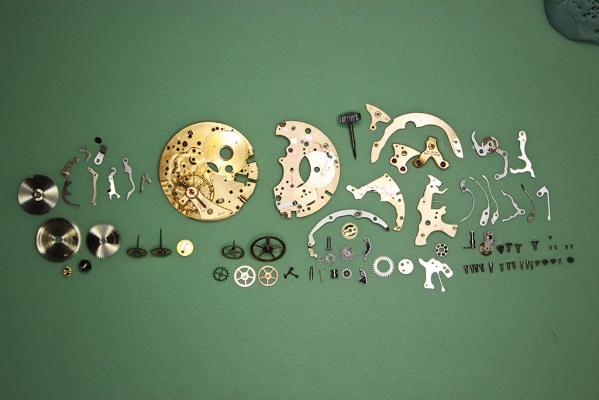

Hello all! I am doing this because I couldn't find any detailed information on this caliber, except some general photos. So I sort of explored it. Yes, I was an explorer, so please forgive the clumsiness! This is going to be more of a parts list presentation then a proper tutorial. I don't know what the parts are named, but I will try to explain what most of them do, from my understanding. Also this is the first time I opened a chronograph-like mechanism. It is a 24 ligne (55mm!!) russian rattrapante timer Slava 5498. Everything in it is huge comapared to any decent watch. It has 36000bph though so it is able to measure one tenth of a second, like a propper timer. It also has a Breguet hairspring on that huge balance wheel. I will call the two seconds as follows: the master seconds (or the second (2nd) seconds wheel, because it's at the bottom) which runs continously if you start the timer and the slave seconds (or the first seconds wheel, because it is at the top) which stops when you press the left pusher and hurries back after the master seconds when you push it again. Beneath both of these seconds hands lies the minute wheel which records 30 minutes. The middle pusher winds the timer. It also starts and stops the timer. When you press it, it both hacks the balance wheel and also hacks the master seconds wheel - it sort of needs two brakes to stop the beast . The left pusher stops the slave seconds wheel and, if pushed again, it allows it to quickly follow the master seconds wheel. The right pusher works only when the timer is stopped (via the big knob in the middle) and it resets all the hands to 0, except for the slave seconds wheel which, if stopped (from the left pusher), it stays in place. A couple of reference photos of the movement: The following two levers stop and release the slave seconds hand. They are acted by that column wheel (it certainly looks like one, but it has fewer functions then in a column chronograph). Next comes the spring that hold the column wheel in discreet positions, and the one that acts upon the lever that increments the column wheel: Next comes left pusher lever together with its piece that increments the column wheel: Next is the column wheel: I now take out the dial. For the picture purpose I leave two screwdrivers inside the movement to indicate the dial feet screws. I didn't take a photo when I pulled out the hands using a presto tool. Next I take out the slave seconds wheel and its cock. It sure is a long seconds hand axle. Beneath it you can see the lever with its spring which helps it follow the cardioid (heart piece) on the master seconds wheel axle. That lever has a rectangular jewel at it's end to minimise the friction - if you look closely you can see it is damaged. Also the cock jewel isn't hallowed but it is a sort of cap jewel that doesn't even touch the axle. Next I take out the intermediary chrono wheel: Next I take out the master seconds bridge - it is held by three screws. I do not disassemble the whole thing because I don't know how at this moment. To take out the Master seconds together with its bridge you need to stop the chronometer so the balance hack could get out of the way - so you could have access to the Master seconds hack screw to release it a bit so you could take the master seconds hack out of the way (long sentence!): Next I wanted to release the tension from the mainspring but I didn't know how to. So I cheated! I took the movement out of the case and looked at it from its side (I will show you how to get the movement out too). So there is a cutting on the side of the movement in which you can see a click appear when you wind the watch. You must hold that click with a 0.8mm screw and release the mainspring tension in a controlled manner - at least this is what I did: Now I show you how to get the movement out . It I expected two case screws but I was wrong. Russians used a simpler way: one screw combined with one stud. You can see the one screw that has its head cut in half near the balance - you unscrew it and release the movement. Now you can see the stud, diametrically opposed: I forgot to tell you that I 3D-printed a movement holder for this 24 ligne movement: Now you can better see the click: Now I take the balance out. That is one big balance wheel! And the pallets together with their bridge: Next I take out the intermediary chrono wheel holder (the equivalent of the coupling clutch). Carefull! It is hold only in one screw the one from its right. The bottom one is an excentric. I learned it the hard way - it was a 50/50 chance and I didn't win Next I take out the driding wheel. You can see in the photo that the escape wheel and its cock are missing - I didn't take a photo of those. Next I start on the main timer mechanism. I appreciate that all the springs are secured with a screw. It helps quite a bit! So you can see that it is a cam chrono after all, though the cam is also the balance hack. The column wheel is only for the slave seconds wheel operation. The Master seconds reset hammer has a stud between it and the minute reset hammer on the bottom side - you cand see it right about in the middle of it - I will show it to you later. I take out the sliding operating lever: Then the cam and the reset-blocking lever: Next goes the seconds hand reset hammer and the stud to the other side: I also take out the springs for the sliding operating lever and the master seconds reset hammer - carefully - the screws are not the same! I take out the train bridge. Check out the dirt! If you look closely, the ratchet wheel has two broken teeth - I didn't notice it before - the timer didn't present any problems during winding... russian stuff! Barrel and mainspring: I take out the crown wheel: And the click and its spring. You can see between them a ratchet wheel tooth I didn't tell you but in the mean time, on the bottom side, I had taken out the minute heart. It angages the minute wheel via a spring and it permits the recording of minutes and the reset of the minute recorder. It resembles a canon pinion with a different design and purpose. The bottom side: I take the hammer and lever out: Finally, the parts list: I will let you know how it goes when I will put it back together. Thank you, Bogdan

- 14 replies

-

- 4

-

-

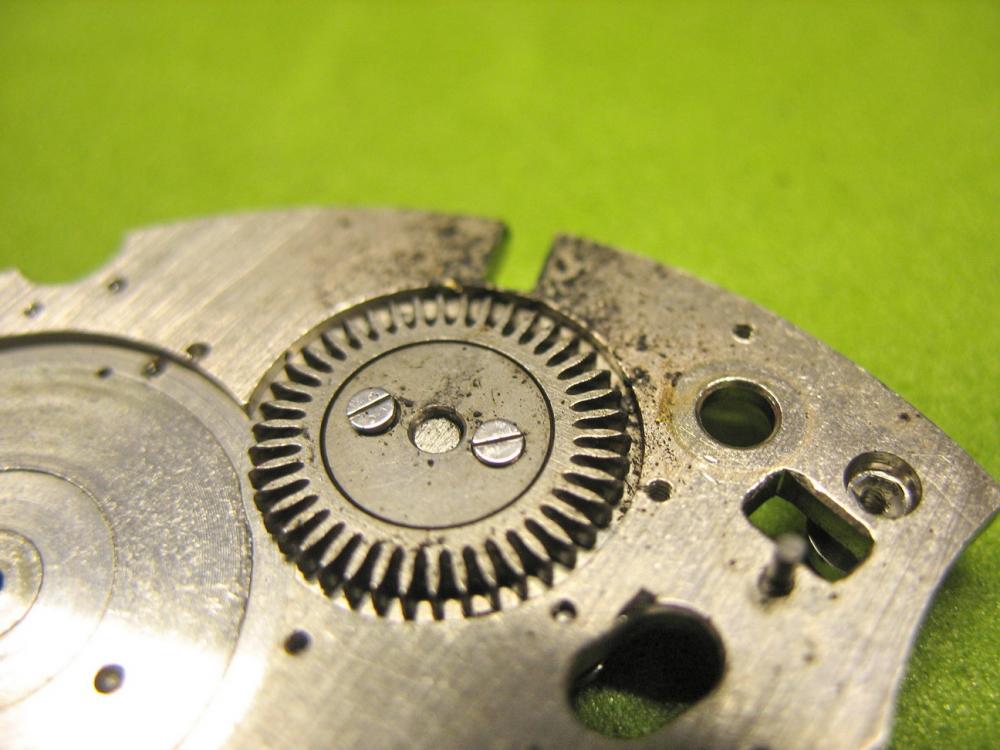

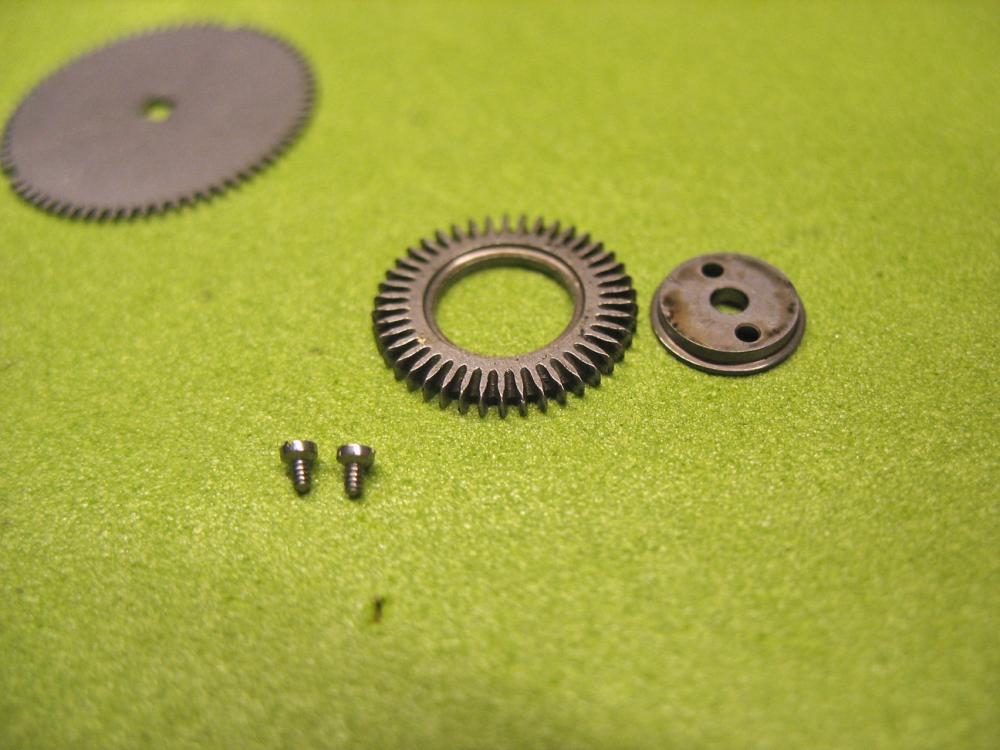

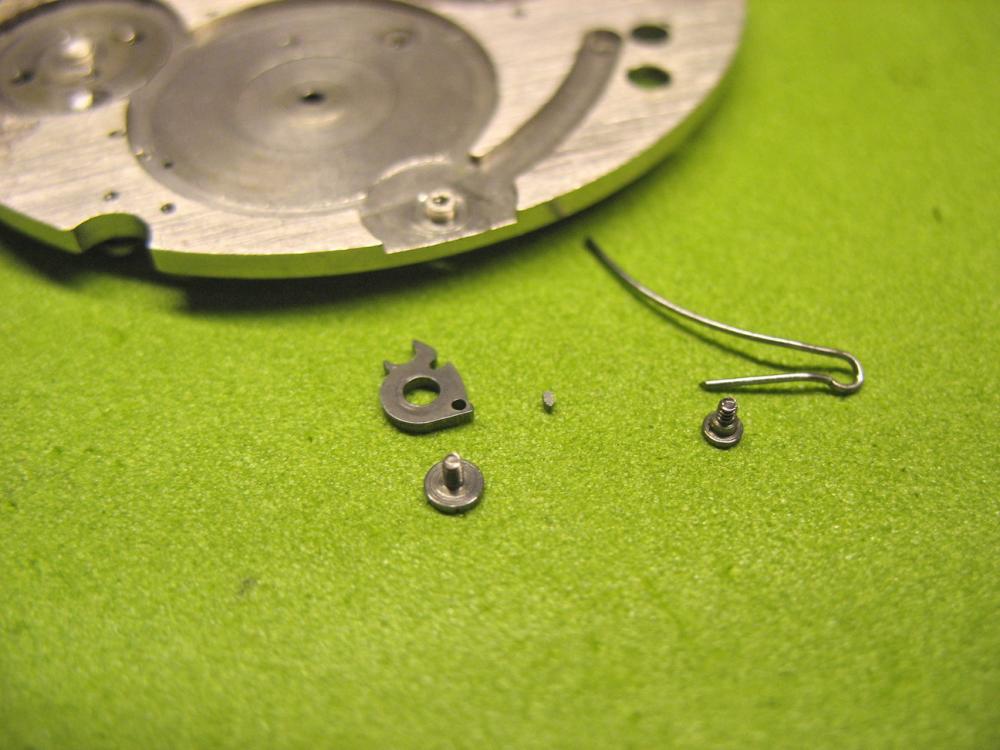

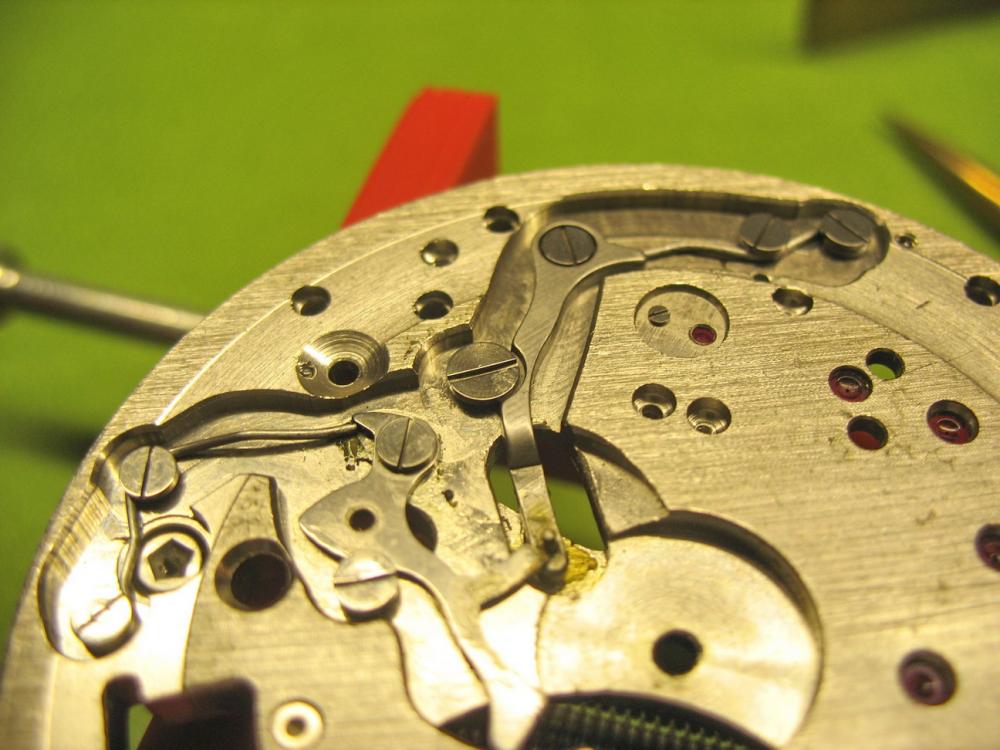

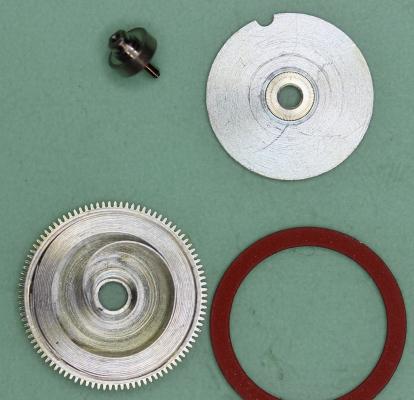

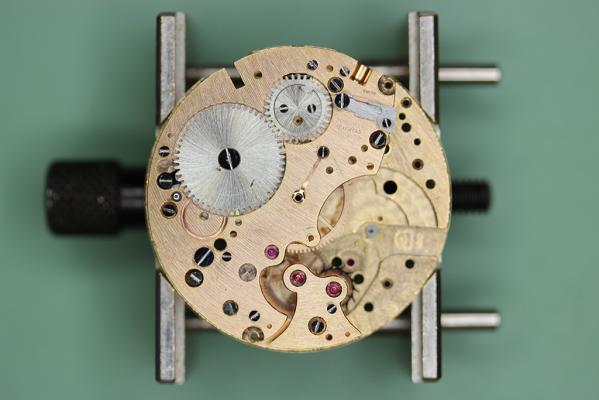

I'm a true novice and this is my first actual repair job but from the attached images you may get the impression that my real struggles are with camera in hand! Any input how how to get the best pictures (and lighting) when working with such a small subject matter are appreciated! I've been an enthusiast for complicated watches for sometime and this past Christmas my wife gifted me a vintage Breitling Navitimer- a replacement for the one we sold to help finance our wedding some eight years back. Having done without for eight years I'm dead set on treating this timepiece right and so embarked on a quest to learn all I could about maintaining vintage mechanical watches. This has as fueled an new found passion in me and I've now accumulated a few swiss watches from the 40's and 50's to work on. My first purchase was an Omega Speedmaster 321 which was delivered in an Altoids tin... in many pieces; but that's a different story. My second purchase is the above referenced Pierce Navigator Chronograph. Manufactured in the late forties or early fifties, the Pierce Navigator was the everyman's chronograph and was priced more reasonably that most Swiss chronographs on the market. The movement within (Pierce Calibre 134) is a little strange though, it utilizes a vertical clutch mechanism and the clutch plate is made of soft rubber. The dial layout is a little different as well with the running seconds at six o'clock and the minute counter at the 12 o'clock position. Here you can see the watch the shape it was delivered to me. It was sold as not working but did begin ticking as I handled it. As you can see the crystal and the start/stop pusher are missing. Since the little guy was trying to give it a go, I placed the movement on the timegrapher to see what its vitals were. Time to crack it open! Inside- dirt, dirt, and more dirt! The chrono works don't look too bad. Dial side is a bit worse. Here I've already removed the minute wheel and cannon pinion. The keyless works under the microscope. Lots of dirt here. This watch has no form of waterproofing. Even the pushers lack gaskets and as a result lots of grime is able to enter the case. Luckily for me there was very little rust. Disassembling the gear train. More dirt is apparent here. The mainspring was shot (no picture I'm afraid) but sourcing a replacement was not difficult. I cleaned the movement in my L & R cleaner then reassembled. With the watch keeping time I moved on to the chrono works. Pierce cases are plated brass as are the crowns and pushers. They don't hold up well over time unfortunately. The movement appears to be plated, perhaps in nickel or chrome and is polished to a mirror finish as are the various steel levers and springs. Here I got a little ahead of myself as the base movement worked well but had a sizable (3.6 ms) beat error. I first tried adjusting the collet to correct the error. And this worked- to an extent. Now I had no beat error but the watch ran phenomenally fast... then slow... The timegrapher showed a beautiful Sin curve on the display. Turns out the coils of the hairspring had exited the single plane and were now high on one side and low on the other. I removed the hairspring and carefully reworked the coils under a microscope until they sat nice and flat. Then I watched Mark's video on hairspring adjustment to make sure it was reassembled with minimal beat error. Here' I line up the hairspring with the regulator before pressing it to the balance wheel. My staking kit is vintage but works well enough. This was my first time taking it out. No need for a hammer here though. Now this may sound easy, but I had to remove the hairspring three times before finally getting it just right. I'm quite pleased with the results though. Here you can see how it performs with the chronograph engaged. The choro still slips slightly and a new rubber clutch may be needed but thus far I'm impressed with what has been accomplished. Lastly I'll need to source a second pusher and a crystal. I'll be sure and post pics of the finished job though.

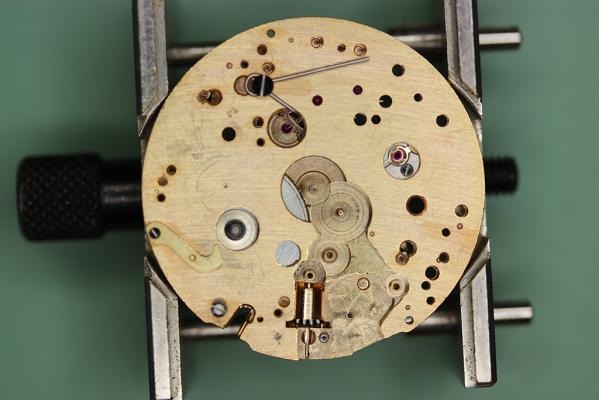

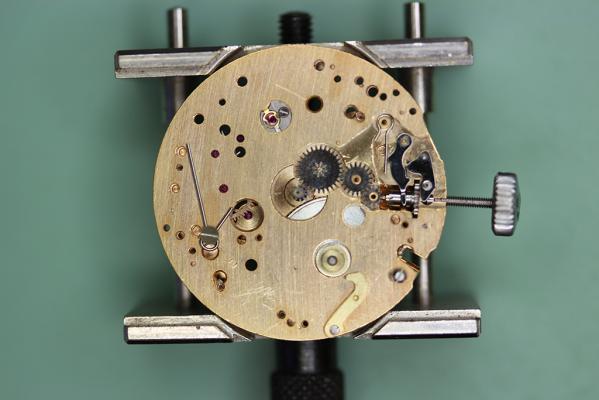

-

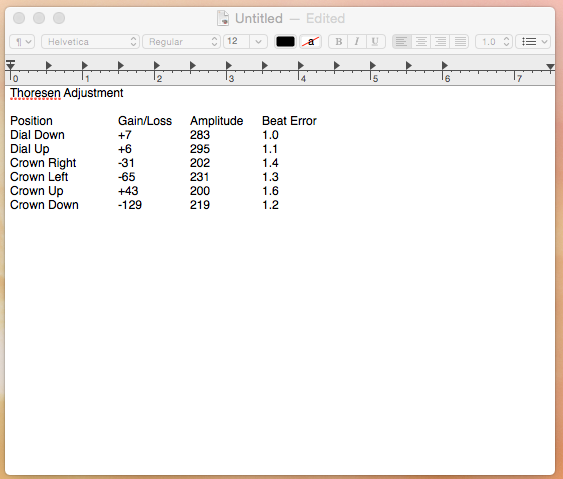

Today I wrapped up work on a Thoresen Recipro-Register Chronograph. Sounds like an exciting piece doesn't it? The Thoresen Recipro-Register is a Landeron 48 calibre chronograph. The one I'm servicing here was sold in about 1953. The watches were acquired back in the day via mail order for a bargain price of $29.95 USD. This is another "everyman" chronograph much like the Chronograph Suisse of the same period. I picked this one up from the Goodwill for a fair price as as it kept poor time and had a broken Speidel bracelet. This is quite a small watch compared to the chronographs of today. Diameter, including crown, is 37mm and the space between the lugs is only 16mm- that's quite a narrow strap. It's a men's watch but today would be quite at home on a woman's wrist as well. I knew it was running fast before I even put it on the timegrapher but I was pleased with the amplitude. The normal dirt and grime had accumulated around the caseback but the inside was immaculate! Only a tiny bit of rust staining at the top where water had entered at the pusher. The movement is marked Orator Watch Co. as is the caseback. Under the microscope a bit more dirt is visible but the screws look like they may have only been turned once in their lifetime. It's here that I get a lump in my throat. I almost feel bad putting my amateur hands on this one! I start breaking the watch down. The hands and dial come off first. The dial is in wonderful condition as well. The lime is radium based so extra care is taken. Dial side of the movement is utilitarian but clean. After snapping some reference pictures of the front and back I'm called to dinner. The movement goes under the glass for the next day... And the camera batteries go dead! No pics of the breakdown I'm afraid! There wasn't much to discover though. The movement looked quite good and there were no obvious issues noted. Probably just a cleaning and lubrication will do the thing. I put the movement though the L & R and start reassembly. Despite the nice amplitude registered before, the mainspring looks spent. Luckily I have a replacement at the ready. The gear train goes together simply enough. There's some rust staining on this plate as well. I tried rubbing it out with pegwood but let it be when elbow grease wasn't enough. The pallet fork (installed above) is a bit different from those I have seen before- clear rubies. It's not really a big deal but something different. Clear cap jewels are something I loath. They are very easy to lose. Luckily this watch only has clear jewels on the pallet fork! (Please note that the picture below was taken before cleaning the pallet fork!) Dial side is assembled next. The keyless works is properly greased and reassembled. So far things are looking good but there is one jewel setting that is bothering me. I take a better look at it under the microscope. If it looks funny that's because it's chipped. The chip is on the oil reservoir side. The pivot hole is still properly rounded however. I have a Seitz tool for replacing the jewel but no replacement jewel readily available. Seeing as I own this one and just want to get it off my desk, I continue with assembly while making a note to the fix the jewel later. On the timing machine I discover that there appears to be no impact. With the basic works back together i start on the chronograph. I've taken to returning the screws to the plate after disassembly so that they are readily available for reassembly. This has saved me a lot of time hunting for screws. Despite this, I still managed to mix up two pair of screws! The movement is reassembled and re-cased- how did I forget to take a picture of the reassembled chronograph movement? It took quite a bit of effort to get the chronograph to work flawlessly; there are three eccentrics that needed adjustment to get the gears to mesh just right. The flyback lever was also an issue until I realized I had mixed up a screw and needed to swap it with another longer shouldered screw. Lastly the sweep second hand had a tendency to reset a few degrees to either side of 12 o'clock when operating the flyback button. I fixed this by removing the hand and giving the tube a light tap with a stake to tighten up the post. Now tightened it always returns true. A new crystal completed the effort. What a darling! Now for the bad news, and hopefully the community can help me out here. Despite my best efforts I could not eradicate the beat error. I figured anything 1.0ms or less would be acceptable considering the age of the watch and in one position I can get that but the rest of the positions are not great. The cracked jewel is the lower pallet jewel- I'm sure that could have an impact on the timing of the watch and that will be the first thing I fix. Otherwise I'll be checking the balance pivot and the shake of each gear in the wheel train. If there are any other ideas I'm open to hearing them too. I wish I had caught this a little earlier but didn't check the watch in several positions before service or even after assembling the base movement. I can attest that the pivots and gears are in good order though. All in all, it is keeping good time sitting on my desk and I have to admit I'm smitten by it's appearance!

-

So today I received the set of spare Landeron movements I had bought last week. I received some spares, and 4 incomplete movements, various models, and a dial. Movements are completely dirty, will definitively need a good clean on my Elma, and the dial has also some patina, which actually I like. Here the pics: A very fast clean (by no means to make it working perfectly) and I put some parts together with the best looking movement, to have a working watch. I do not have proper cases for the chronographs as of yet, but I am still looking. Here my 3 chronos: The Walker and the Bovet are Landeron based, while the Gigandet is a Valjoux 7733 Sorry for the low quality pics, my mobile phone is just too bad...

- 34 replies

-

- 2

-

-

- chronograph

- landeron

-

(and 1 more)

Tagged with:

-

I am collecting, repairing and mostly interested in Seiko 7Txx and 7Axx series of watches, when it comes to quartz movements, but for the 7Txx I limit my search to the 32 and 36 series, I made a small exception, though, when I saw this 7T42-7A2A: The watch was sold as non-working, but I thought I could repair it no problem. after all, I got some spare parts for the 7T32 movement in my spare box, so I gave it a go. Actually, I found out later when it arrived that is was a NOS! And it was not working because it had no battery :D So I installed a new fresh battery, but nothing moved...I stripped it down, cleaned it, oiled it, reinstalled the battery and... voila! it lives! The chronograph minute counter doubles up as a countdown second/minute counter, when the second crown is pulled out to the first position, just as you'd do to engage the alarm in all Seikos 7Txx series watches. Pressing the top left pusher you set the amount of time, in minutes, to be counted, and pressing the top right pusher starts the countdown. I like this watch particularly, since it has basically all the functions one would expect from a modern chronograph: stopwatch and countdown, alarm and dual time. It is a complete time piece. Furthermore, the fact that it is a NOS just makes it perfect for collection.

-

I purchased this off eBay and it came all the way from Oz. So it's completely jammed up. A little rust found so far but the wheels are jammed solid. Hopefully no bent teeth. It's a Landeron149 and i'm looking forward to getting this baby working.

- 28 replies

-

- 1

-

-

- avia

- chronograph

-

(and 2 more)

Tagged with: