Search the Community

Showing results for tags 'Mainspring'.

-

More than one time I saw requests for mainspring sizes. There are rules, how to calculate the optimum mainspring for a given barrel. I packed them into a tiny windows app: just enter the barrel diameter and the optimum spring will appear. App attached for download (unpack the zip file). Frank Mainspring.zip

-

Just about to service my old Omega Seamaster Automatic in a 165.003 case (15ct rolled gold with s/st back) with Cal 552 movement but need some help before I go further. Serviced (very badly) about 15 years ago (but not used much since except for last 2 years or so) and I remember sending it back as movement was loose in the case!! Just opened it up to find gouge marks in it which appear to have been caused by screw or something jamming under rotor and only 1 dial screw fitted ( I have a new one ready)!!! However it still runs well but is obviously ready for a service. What I would like to know is;- 1. Was there a dial washer fitted to this cal/case combination (none currently present) ? 2. I do not have any Kluber P125 grease for the mainspring barrel as per Omega current spec (expensive to buy for just one watch!) but do have Moebius 8217 grease. Can I use this instead? Any help/advice appreciated.

- 16 replies

-

I'm really interested in finding out what main characteristics in a mechanical watch decide how much power reserve one can achieve. Can an existing watch be retro-fitted to enhance power reserve and is it recommended? I'm thinking does it impact on the other components in a watch?

- 9 replies

-

- mainspring

- power reserve

-

(and 1 more)

Tagged with:

-

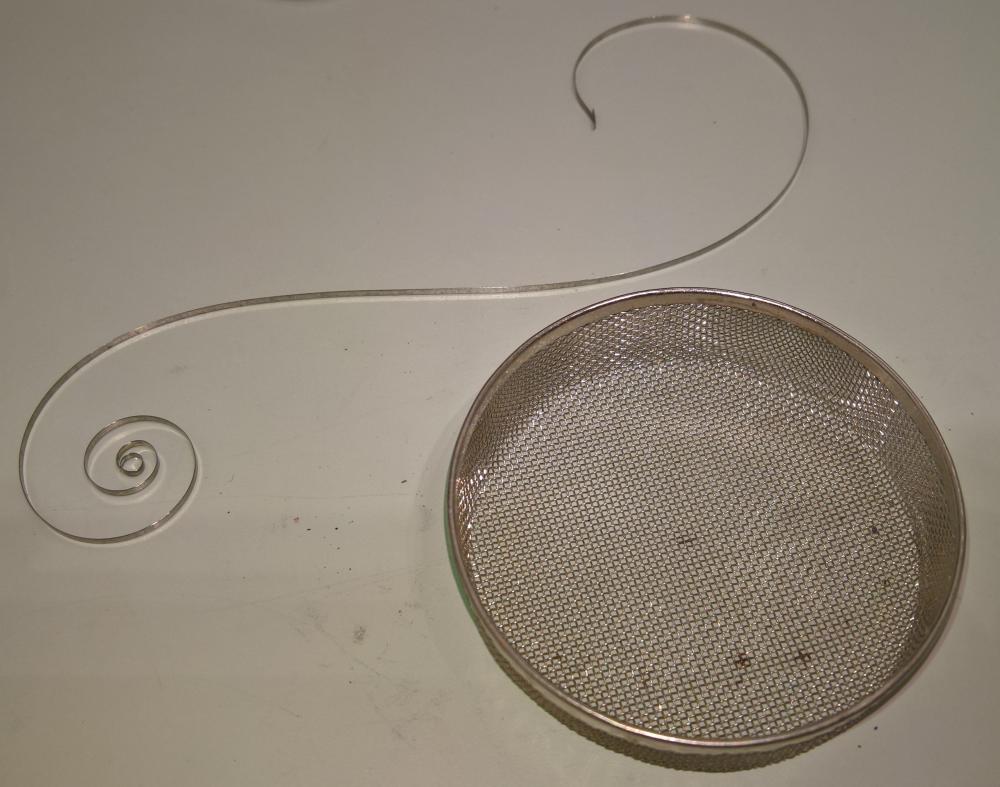

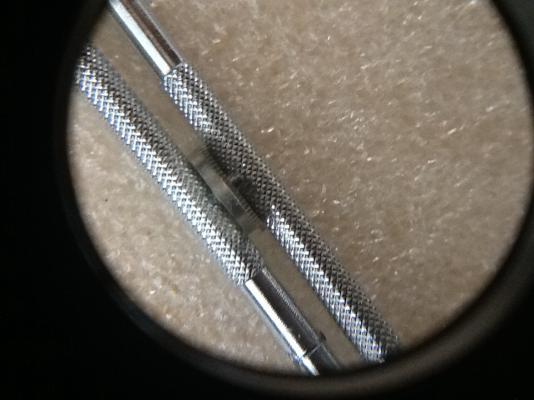

Hi gurus, I have picked apart my first actual watch (although a cheap one I bought for this purpose), and am preparing to clean and oil it. For the mainspring, I am however not comfortable with how I'm supposed to clean it and could use some help! I have an L&R style cleaner that rotates through three jars, and below is the picture of the bottom basket and the mainspring. My question is: do I simply coil the mainspring into the basket or do I need to clean it "old style" with a piece of paper and oil? I believe Mark said in a video that he puts the spring in the bottom basket of his machine? -- Thanks, Stian

- 5 replies

-

- cleaning

- mainspring

-

(and 1 more)

Tagged with:

-

I need help finding a certain mainspring for an old pocket watch I have. The dimensions are: Length=520mm, Height=2.4mm, Strength=0.22mm, Inner barrel diameter= 15.5mm. It uses a normal bridal hook

-

Hello, This is a 690 x 2 x 0,20 mainspring I found broken in a Rosskopf pocket watch with holes in both ends. I've tried with cousins but they say they don't have it. If you have tips for me how to do this ... most welcome

-

I'm trying to find the correct mainspring for a watch I have. Here is the caliber it has: http://boley.de/en/caliber/watch-movements/as/480 . I've been looking and I cant find the right kind with the information provided. Any help and references will be greatly appreciated.

-

Hello! I measured the old spring in the Slava stopwatch that I opened here: The numbers are: 480-520mm/2.74mm/0.39mm, give or take a couple of microns I couldn't find this combination on Cousins. Does anyone know where I could find one? The ends are like this: Thank you, Bogdan

-

Never been inside a barrel before but decided now was the time... I got it out without injury as well! Now, if it's ok, it just needs cleaning and greasing, but since this is my first, thought I would just ask if it looks ok to re-use? The hook looks fine and it is in one piece. What else should I be looking for that would suggest it should be replaced rather than re-used?

-

I recently had a 1962 vintage Longines cal 280 men's mechanical watch serviced. The mainspring was "tired" and the watchmaker ordered a replacement from his supplier. Upon receiving it, he noticed the end did not match the one he removed. He nonetheless installed it and advised me that the watch would require winding more often due to the spring slipping if it was tightened too much. The watch runs fine other than the more frequent winding required. I would like to locate an original mainspring if possible. I found on the ranfft website that the cal 280 movement has a mainspring with the dims 1.10 x 12 x 0.13. I assume 1.10 is the spring height and 0.13 the spring thickness, but am not sure if 12 is the spring length in inches or the barrel diameter in mm (the spring does appear to be about 12 inches long, though). On another website I found a diagram showing various spring ends, with one of the figures showing a "Longines T end." It was the only figure that had the word Longines associated with it. My question is: how would one go about locating the correct replacement mainspring for the Longines cal 280 movement? See attached photos which suggests the spring removed does not have a T end, but a thickened bridle (I think that is the correct term, anyway). Thanks from a watch amateur.

- 16 replies

-

- MainspringLongines

- end type

-

(and 3 more)

Tagged with:

-

Everything is going well on my ETA rebuild, but I got the new mainspring in and this is what it looks like. My Seikos all have a really snug twisting shove required to engage the arbor, then an audible 'click' when the arbor lug engages the mainspring slot. Any suggestions on adjusting the grip - if I do nothing, the watch won't wind....

- 19 replies

-

- Mainspring

- arbor

-

(and 1 more)

Tagged with:

-

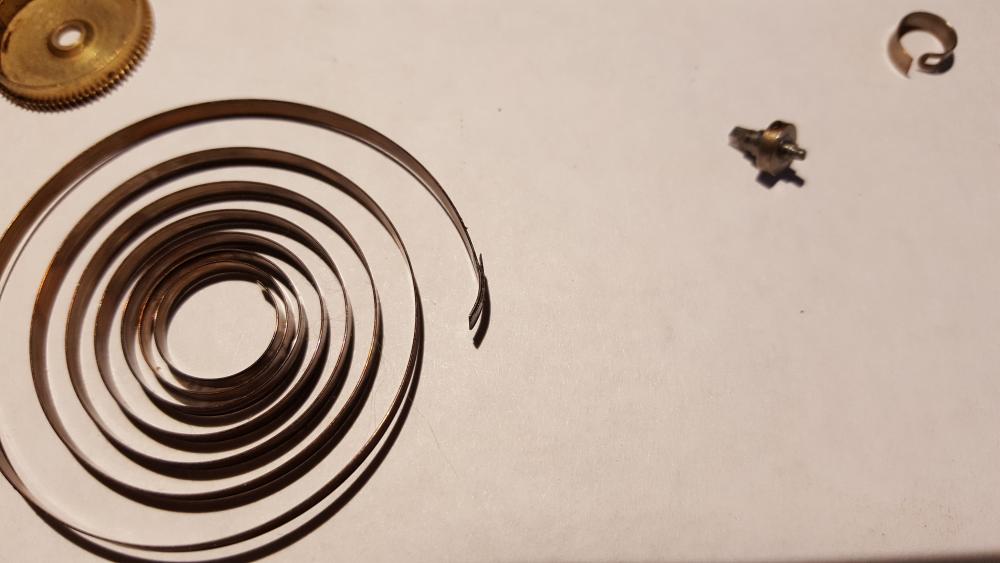

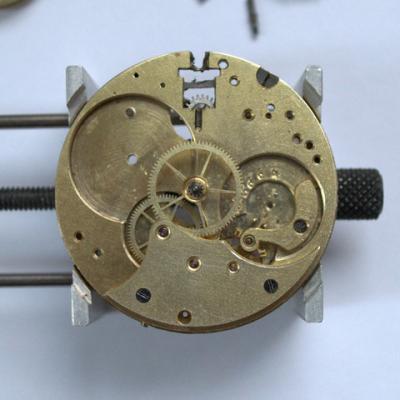

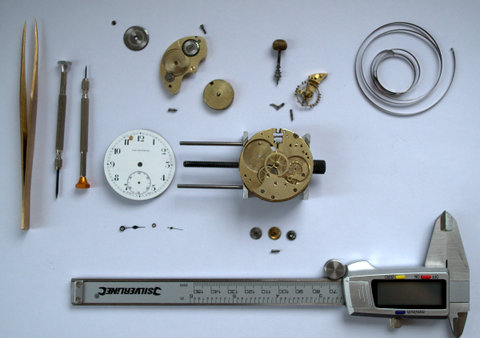

Dear readers, This is my first post. I hope we will get know one another and with your co-operation we will trade the pleasure of learning for the satisfaction of sharing one's knowledge. To illustrate my story I have added some pictures below. You can see some basic tools, a partly disassembled antique 19 lignes (42.8 diameter) lever movement and the removed parts. I had never disassembled a movement before and this one seemed like the perfect candidate to experiment, but now that I have learnt to assemble/disassemble this movement, I want to fix it. After all, we are talking of a fully jewelled movement from a century ago. On close inspection several issues are revealed: broken mainspring, broken balance staff... ...and missing roller jewel. I have not been able to identify the maker, but the dial and the case (935 silver) confirm it is Swiss. The balance cock bears a factory symbol consisting of a five-pointed star connected to three lightning bolts that come out the star each in a different direction. I am aware that getting spare parts is going to be hard work, but I want to learn to solve these issues. I have measured the broken mainspring with a Vernier caliper but I cannot find a replacement in Cousinuk.com. Perhaps someone could check for me in the Générale Ressorts catalogue? These are its specifications: Height: 2.2 mm. Thickness: 0.22 mm. Length: 24 inch (61 cm). Barrel: 16.5 mm. End hole type. Any advice, guidance, comments, support, contributions, collaboration will be greatly appreciated. I will be watching this space!

- 11 replies

-

- WatchmakingRepairs

- Beginners

- (and 6 more)

-

i would greatly appreciate some advice. I have taken a Hamilton wristwatch apart for cleaning. It is a caliber 986A. It is completely apart except for removing the mainspring from the barrel. Here are my questions: should I remove the mainspring from the barrel, or just place it in cleaner and ultrasound the mainspring and barrel together? If it is necessary to remove the mainspring, how do I get it out of the barrel? What should it be lubed with? In the attached pictures, is the "rub" on the barrel an indicator that it does not fit correctly? In the picture of the mainspring barrel on its side, is that a crack in the barrel , or perhaps just a scratch? Thank you in advance for all comments, suggestions, or criticisms. Bill

- 2 replies

-

- mainspring

- mainspring lube

-

(and 1 more)

Tagged with:

-

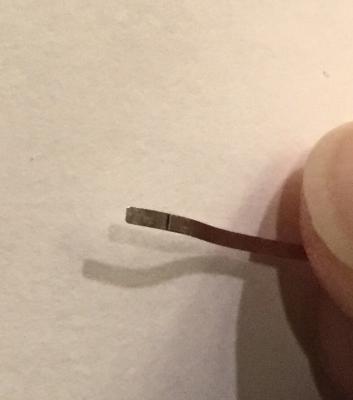

Attached is a picture of a mainspring from a watch I'm working on. I took the mainspring out of the barrel to clean and lubricate it but when I was about to put in back in, I noticed it was broken at the arbor end. did I do it, I ask myself? Well, id took the picture before I removed it from the barrel and it looks like it was already broken, but I need a more expert eye to confirm it. I'd appreciate your diagnosis. Thanks!

- 1 reply

-

- mainspring

- arbor end

-

(and 2 more)

Tagged with:

-

I have an A. Schild watch movement with a broken mainspring. Searching around I found that the Marathon No. 745 is the right replacement. The numbers are as follows: 7 x 11 10 1/3 which I assume mean: Dennison width: 7 Dennison strength: 11 Dennison length: 10 1/3 However what I'm calling the Dennison strength could actually be the Dennison length, not sure. There are two other numbers on the Marathon 745: 1.6 x 10 which I take to mean: Metric Width: 1.6 mm Metric Strength: 10 1) Is my interpretation right? 2) Would a spring with the following be a proper replacement? Dennison width: 7 Dennison strength: 11 Length in inches: 10.5

- 1 reply

-

- mainspring

- Dennison Width

-

(and 2 more)

Tagged with:

-

- 11 replies

-

- 2

-

-

- mainspring

- sizing

-

(and 2 more)

Tagged with:

-

Hi, As a 'newbie' a little introduction seems polite: flushed with the success of fitting a new ETA 955.412 to a Rotary and curious about the workings I took apart the old movement and re-assembled it. Well, most of it, I had the salutary lesson of watching a small calendar part ping off never to be seen again but no matter - it was for experience. From that straight into mechanical watches and I have bought a couple of cheap 'trench' watches off ebay to get some experience on. By 'cheap' I mean around £10 so I can afford to make mistakes though I'd rather hear them tick again. I have stripped the first - a very basic no name movement with no jewels and a cylinder escapement, all seems OK other than there is no sign of the mainspring so my question is; given just the barrel can a reasonable guess be made about the required mainspring? The internal diameter of the barrel is 12.1 mm, its depth is 2.22 mm and the external diameter of the arbor is 4.0 mm Any answers, suggestions or questions gratefully received :)

-

I've decided to replace the mainspring in my current project watch and I'm a little confused about the measurements. On the Ranfft movement archive, the mainspring dimensions are given as 1.15 x 10.0 x 0.11 x 320mm. From what I've read, I'm guessing that 1.15 is the width, .11 is the metric strength?, 10 is the Dennison strength? And 320mm is the length. Does this sound accurate? I'm hoping to order from a local supplier who lists mainspring length in inches. If 320mm is the metric length, then I should buy a new spring with a length of 12.5984 inches or less? The closest they carry is listed as: Metric Width: 1.15 mm, Metric Strength: 0.11 mm, Length in Inches: 10.5 Dennison Width: 2 1/2, Dennison Strength: 10 Would this be a suitable replacement? The next size up is longer than the original: Metric Width: 1.15 mm, Metric Strength: 0.11 mm, Length in Inches: 13.5 Dennison Width: 2 1/2, Dennison Strength: 10 Any help would be appreciated. Don