Search the Community

Showing results for 'accutron' in topics.

-

Hello, I am working on an Accutron Astronaut and after putting it back together, (cased up) I notice it hums, (doesn’t hack) and the minute and hour hands don’t move... everything was looking good during the overhaul. Paul and index line up how they should, the tuning fork vibrates the coils are good. Can anyone with more experience on these help me out? Please and thanks.

-

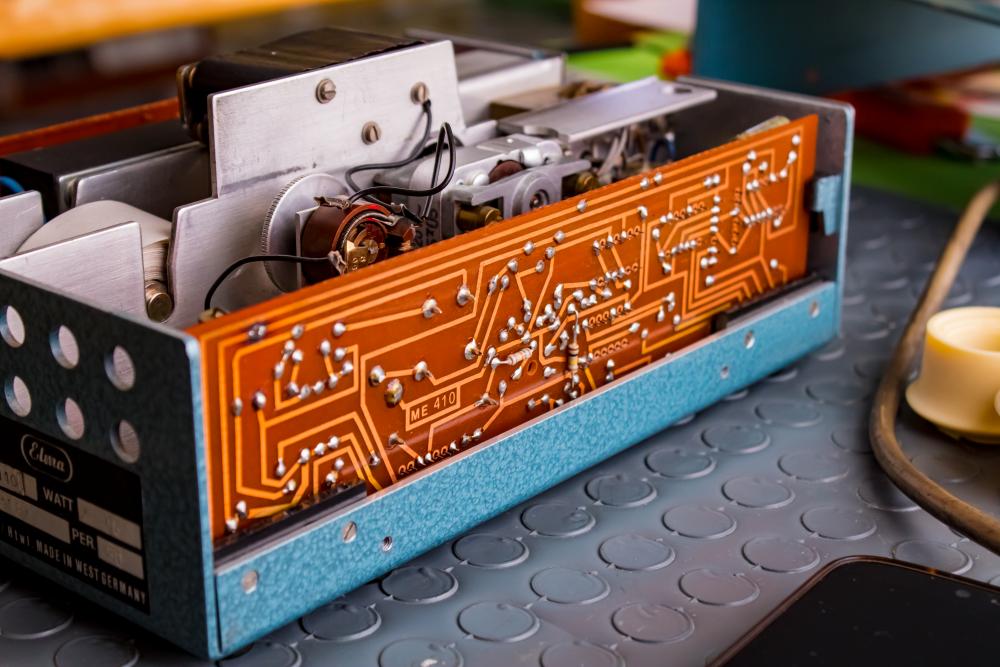

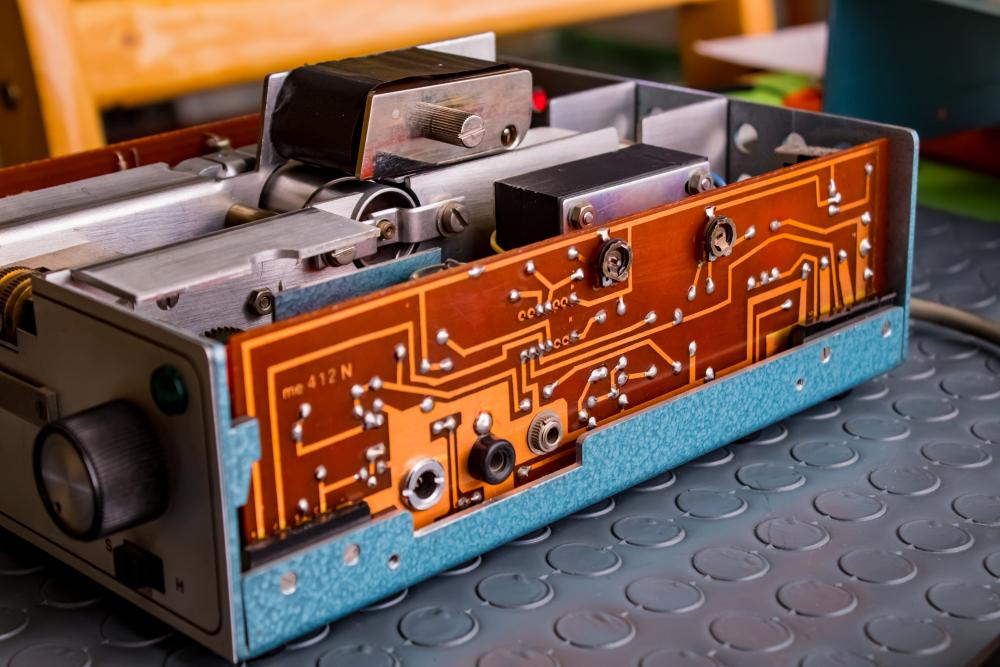

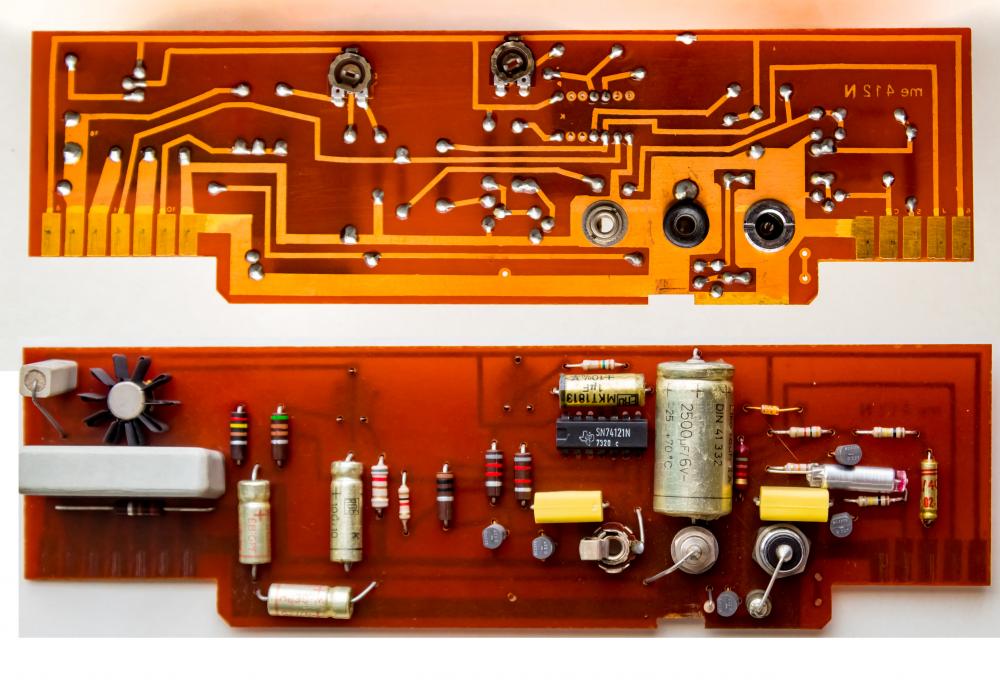

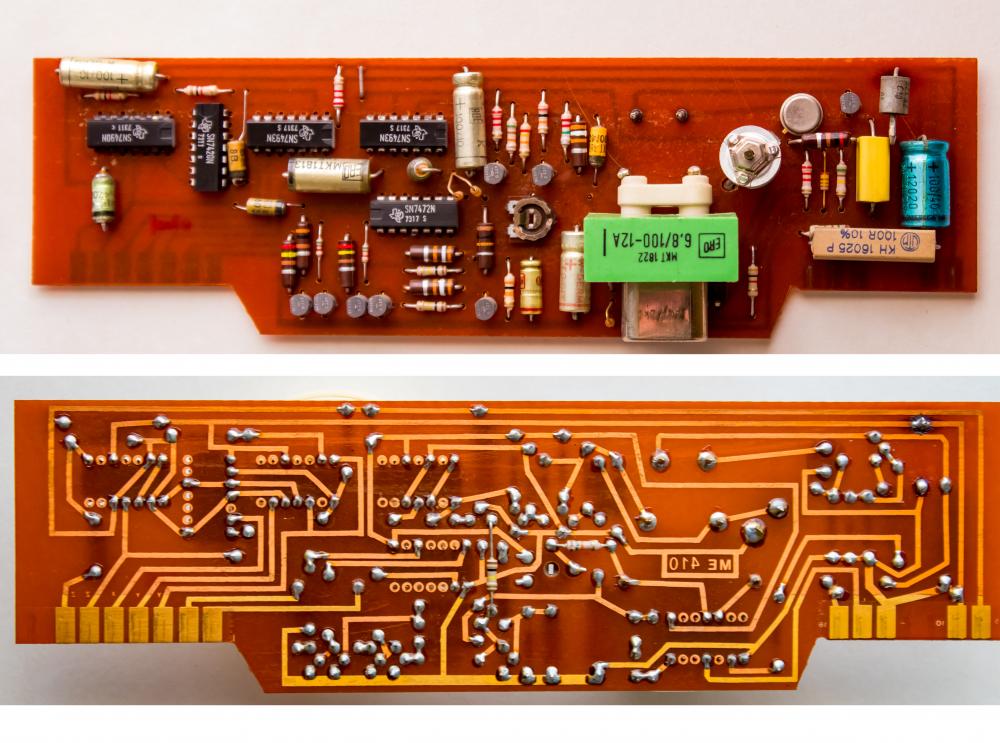

Good afternoon everyone. I have a great project, however my skills and knowledge on the subject are limited. Let's say that I inherited from a relative of mine, my father's brother, a watchmaker, this beautiful machine from about 1974. Although it is very well cared for, it does not work. I have inspected and I think the problem is with a zener diode (BZY92C10). Or a pair of transistors that activate the solenoid that hits the cylinder with the helical track that prints the succession of points. PCB1. The side tracks is rotate to match PCB 2 Is rotate o mirror to match The motor turns and the paper strip advances. But the characteristic sound of the impression tapping is not heard. In fact I was able with the help of a tip to check current of 12-24 volts, I could see that at the output to the printer / solenoid, a pulse corresponding to the beat of the clock is generated. But it seems that the current is not enough to drive the solenoid coil. The solenoid coil works if I activate it with a 9 volt battery. In other words, you can hear the “click”. If any of you wish to join me in this project, I would greatly appreciate his help. Thanks

-

@JohnR725Forget I ever mentioned anything about age. Is there really such a thing today as "Synta Visco Lube"? I was wondering what the Moebius equivalent would be for the two oils (OK, one grease, one oil) that the manual suggests. I have Moebius 9000 for quartz watches. Would that be a good substitute? I've been using 9010. BTW, have you seen the Horotec oiler I mentioned? I don't recall having seen them sold until very recently. It's possible that they've been around for years but I just missed them. The wire that they use is very thin indeed. Maybe even .06mm, if that's possible? I received the Accutron index/pawl post tool yesterday and I'll see how that works for getting the pawl finger sitting better. Maybe I'll get lucky and I didn't de-mag the fork by pulling it from the US while it was running. I hope I wouldn't have to be lottery-winning lucky for it to be possible. Cheers. @JohnR725Oh, and BTW, since you attended Accutron class, and are obviously quite knowledgeable about them, I'm wondering if you know an Accutron expert named "Samantha"? She used to post Accutron related posts on the NAWCC board but I haven't seen her for a couple of years now. She seemed to really know her way around them. I'm just curious to what happened to her? Cheers.

-

2x Barlow lens yes/no ?

HectorLooi replied to Endeavor's topic in Eyeglasses, Loupe's, Microscopes and other Optics

I think most of us use a 0.5 barlow lens, giving a magnification of 3.5 - 22.5 X. The 0.5 barlow lens halves the magnification but doubles the working distance. When I want higher magnification, I use a 20X eyepiece. This gives a magnification of 14 - 90 X, but at a more useful working distance. The only time I wished I had higher magnification is when working on Accutron watches. The teeth on an Accutron index wheel are so small, that even at 90X magnification, they are still hardly visible. But higher magnifications with optical microscopes become impractical because of the shorter working distance and shallow depth of field. I'm still trying to convince myself to get an industrial digital microscope with a magnification of 200X. -

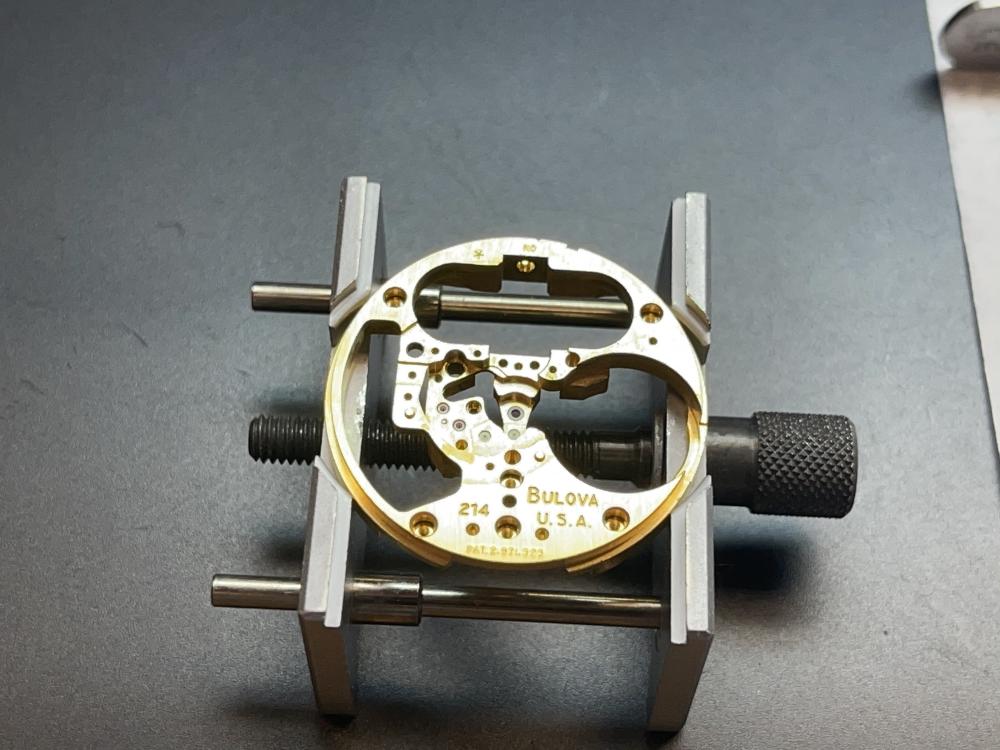

Ok. Working on a 214 tuning fork astronaut! I am getting dizzy trying to fix this one. I lack the experience on tuning fork watches. So my big question is what is affecting the gears from rotating on the dial side. After I install hands? The cannon piñion rotates well on its own, the minute wheel will rotate if added, then after I put the minute bridge on it will stop, but this isn’t happening with a different bridge(without hack) a lot shorter bridge just covers minute and setting wheels. So that’s how I have it on now, saw rotation of gears, got excited so I dialed up and installed hands, watch buzzes the second hands spins, but the hour and minute hands don’t move... so my quiestions are as follows. specific to astronaut model only 1. Does it matter if I use regular 214 minute bridge? 2. What causes the rotation of dial side to seize, when the stem hasn’t even been installed? If the hack is missing ( watch can’t be hacked) correct? if stem is out of the casing, it can’t be the stem! Right? I am sure I am overthinking. Your help is appreciated. TIA Ps. I did replace the centre second pinion jewel with new shatton.

-

After 21 Months

Neverenoughwatches replied to rossjackson01's topic in Your Current Projects and Achievements

I love your updates Ross, you're making good progress. Do you have any immediate plans to learn some repair techniques involving staking and jewelling tools ? Many years ago now but It was my first time for having bacon eggs and honey pancakes on the same plate, i remember thinking # what the hell is this all about # You can do it Nessie, organise that space , set up the scope, lay out the tools, crack your knuckles stretch out them pinkies and off you go. Is this the single eyepiece accutron scope ? -

I recently picked up a late 1970's Bulova Accutron Deep Sea 19810 "devil diver" with the Caliber 242 movement. It is a very impressive movement in terms of its modular design and I would love to see it running again. I have taken apart the movement, cleaned the mechanicals and put it back together with everything running smoothly when manually manipulated. I installed a fresh battery and the stepper motor will click twice in one direction, not enough to move the seconds hand, and then reverse direction for a couple of clicks. This goes back and forth a bit then stops. Just to be sure I removed the hacking lever and checked the mechanicals and cannot find any fault. So I am guessing this is a problem with the stepper motor. I would appreciate hearing if: a. Does anyone have any further ideas about what might be wrong/ what I might try b. Does anyone have a 242 movement or stepper motor that they would sell me for this project? I have searched the web for a motor and cannot find one in stock, but that is not much of a surprise. Thanks in advance.

-

EvergreenParts supplier...interesting

HectorLooi replied to LittleWatchShop's topic in Chat About Watches & The Industry Here

Hmmm.... I wonder if they can machine Accutron index wheels? -

I came across a replacement motor from Cas-Ker recently but it's a little pricey to just buy and try. https://www.jewelerssupplies.com/accutron-242-step-motor-20-510-900.005.11.html I wrote about my adventures with a Bulova 242 last year. I just bought an untested 242 movement off eBay and am praying hard that it works. You might find it useful. Apparently, this twitching problem is quite common with the 242 stepper motor. I haven't really looked into the cause.

-

It's not that difficult. But you'll need a microscope, Accutron test meter, ultrasonic cleaner and Accutron adjustment tools. Since your father was repairing Accutrons, he would probably have had all the tools. The most difficult part in repairing any tuning fork is getting replacement coils and index wheels. IMO most non-working Accutrons would need replacing a coil or index wheel or both. The design of tuning fork watches is such that if the index wheel stops moving and the fork continues to hum, the pawl/index jewels would probaly damage the index wheel. I have tried to repair some by increasing the tension on the pawl/index fingers to compensate for tooth wear of the index wheel, but that results in higher current consumption and shorter battery life. So until someone finds a way to manufacture new index wheels or finds a stash of NOS index wheels, I'll probably turn down Accutron repair jobs. But just for the experience, I would encourage you to try it yourself. It's like trying durian for the first time. That's what we say in South East Asia.

-

Well I finally did it. Dug out the old Hamilton with its demised 500 movement and modified it--just a bit! but not with a 667 Hamilton to make 'Pacermatic' oh no, much more fun with a tuning-fork movement, still 'electric' and still a revolutionary movement, with that graceful seconds hand flow motion. Go Quartz?--You Must be joking! The original 500 movement had broken trip/contact wires, and try as I did, cant find any anywhere. Looks like they went unobtainium sometime last century! I recently got hold of a mens Accutron, I had thought was a 2180, but turned out to be the smaller 2301 so-called, ladies movement in the mens case with a substantial brass spacer-ring. This movement is just a fraction bigger than a British penny, runs at 480Hz with 240 tooth Index-wheel but unlike the other ladies Accutron this caliber has a seconds hand. I dismantled both watches. The coil was dead in the Accutron, so I sourced another complete working watch for £20--Bargain! I serviced the first movement then borrowed the coil from the worker fitted it, where it ran under a glass in its holder for a couple of weeks. I used the now coil-less worker movement as a template for my experiments. I examined the Hamilton movement ring. This part has two projections that serve to retain the battery overhanging the side of the 500 movement, so these would need to be removed. A small grinder took care of that. I now had a more or less round hole in the Hamilton spacer-ring, into which I hoped to fit the Accutron brass spacer. The Accutron spacer was just a little too big, so I reduced its external diameter a little until it fitted the Hamilton ring. I lined up the stem slots and roughly held in position with rodico. fitted the template movement in the middle then came the dial. Here I had a problem. The feet were exactly in line with the outer diameter of the Accutron movement and the inner diameter of Accutron spacer-ring--Bugger, they had to go, which is a shame as I had wanted to retain them, hoped to drill the spacer-ring to accept them, it was not to be! So,--Off they came and the dial feet stumps ground down flush. Again with Rodico (love that stuff!) held the dial to the combo spacer-ring then offered it all into the front case half. Snapped the back on and checked for position of stem hole in movement to case--Amazingly, it was a straight clear shot right into the movement, so I tried the Accutron stem, all good! Out it all came again, so cleaned everything and securely soldered both the spacer-rings together, making one solid part. I then fitted the running movement to the spacer combo after flux and excess solder removed, and reattached the dial with a small amount of double-sided tape, that strong very thin stuff. Only issue now was the hands. The original Hamilton ones are all too big for the Accutron movement, so until I find a solution, I took the original straight gold hands from the mens donor Accutron and cut them to size, fitted them and reassembled back to the case. If you didnt know what a Hamilton Ventura or Pacer is supposed to look like, I guess you wouldnt tell, Its not too bad. The stem proved a Lot easier than I first thought. I shortened the mens case stem and again surprisingly, the Hamilton crown fitted perfectly. Its running now and will take some pics when I strip it all out again to clean the case and crystal, but its nice to wear this frankenstein love-child of two arch rival American watch makers.... --It even has kept time more or less to the second too! Anyone any ideas how I can source or modify hands to fit the Accutron movement so to re gain its correct appearance?

-

Yes they figured out things easier with time for instance the ESA 9162 Phasing is interesting. They give you a little test plug you put it in and you just the fingers to be in the proper place for the plug you remove the plug you put the watch together and if you're lucky it might just run otherwise you barely tweak the phasing screw. Plus the electronic part is separate from mechanical part Oh thinking about phasing I've attached a couple of things. The article on basically where the factory way back when was servicing the watch to run at a much higher voltage so silver cells for the most part shouldn't be a problem. Even the specifications sheet shows that the high-voltage phasing voltages much higher than it says in the service manual itself. 1996-08-web horological times Accutron silver cells phasing.pdf Accutron_Specifications.pdf

-

For unknown reasons the 219 service manual is incredibly hard to find. But I was sure that I had a PDF in the computer doing a search revealed A two-part PDF and the quality sucked. So I was thinking what would be the chance that I could figure out where my physical copy is and find it without searching the entire section. Fortunately I guessed correctly. That's now been scanned and attached as a PDF and much more readable condition than the previous thing I downloaded. I think it will answer the questions you have testing the various components etc. Accutron 219 ServiceManual.PDF

-

Looks like it's to adjust if you have drift in the seconds hand. From the Accutron 242 service manual found over at Watchguy:

-

If it hasn't run "in years" there's a good chance it just needs an overhaul, no parts. My mom got an accutron (for my birth), 1973, changed batteries every 12-18 months, then I serviced it in 1998, 25 years later (I was in watchmaking school). It was impeccable, sorry to say, but I've also serviced Rolexes for friends where I'm assured it hasn't seen a bench in decades. Yes, if lube goes wrong after 5 years you can get wear. But 10 years, good watch, epilame your stuff, yeah . Accutron, you can go double service interval easy and then, it grinds itself to death. If you google "accutron service" you'll get the like 1 or 2 last dudes who do this as a passion. If they even manage to get a tiny bit of oil where needed your watch will outlive you!

-

The index wheels all seem to have a strangely large amount of runout. As long as the teeth are intact they just seem to work though. When phasing, I do as in the quote above, but I don't want to see any hesitation- smooth running only. That's a shame they skip the actual phasing part in the vid! Henry was actually a guest instructor when I was in school to teach us Accutron work- interesting guy and he really did know his stuff. You could check with AWCI, the American Watchmakers and Clockmakers Institute, who made the video; if you are a member you can check out books and videos from their library.

-

So first of all: yes, I'm a dummy. Yes, I learned my lesson. While cleaning my Accutron I pegged out the jewel holes as usual, but realized too late there were burnished-in cap jewels on the other side and managed to get bits of pegwood trapped between the hole and cap jewels. I was able to clean one out through the hole jewel with a sharpened oiler, but the other is not budging. I've been soaking the bridge over night in hexane, but it's no better this morning. I'm worried about chipping the edges of the jewel hole if I keep it up. Any other suggestions on what might soften/dissolve pegwood?

-

Accutron train bridges are very easy to assemble because the jewel holes have something like a funnel to guide the pivots in. Just put the the bottom pivots into the bottom holes, gently drop the top plate on and tap the holder. The plate will just drop in. It's really satisfying. I suspect it's because your bottom holes have pegwood in them that you can't get the plate on.

-

Accutron 700 meter

JohnR725 replied to ManSkirtBrew's topic in Watch Timing & Testing Equipment / Timegraphers

There used to be somebody out there that didn't do this but I think he got overloaded and work and doesn't do it anymore. Then when you're making a machine for winding coils about a machine to make index wheel's. Then I figured out where I put the information on phasing for silver cells. I'm attaching a PDF on that. 1996-08-web horological times Accutron silver cells phasing.pdf -

Accutron 700 meter

HectorLooi replied to ManSkirtBrew's topic in Watch Timing & Testing Equipment / Timegraphers

Is that a 218 movement? 218s are a good starting point to learn Accutron repair. They are infinitely simpler than 214s. The uA are an indication of the amount of current drawn. It should be within the current range for the movement. An abnormally high current could indicate a faulty circuit, a dirty gear train or a high amount of pressure of the pawl/index fingers on the index wheel. A high current draw will result in short battery life. The adjustments to the index finger that we are talking about here are incredibly small. My 218 just died on me after two years. I found that it's due to an open cell coil. Looks like it's time to build a jig to do coil rewinding as working coils are getting really hard to find. -

Hi all.. I recently purchased the above watch with 221 movement for my daughter. Everything works, but as expected it runs fast. Does anyone know of anyone in the UK that can sort this out? It's a lovely, clean example that should be worn (if it can tell the time) Thanks in advance

.thumb.jpg.4c8af3ef6b0ebd38fcf9dd76f0dc2292.jpg)