Search the Community

Showing results for 'accutron' in topics.

-

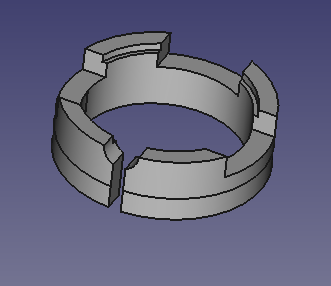

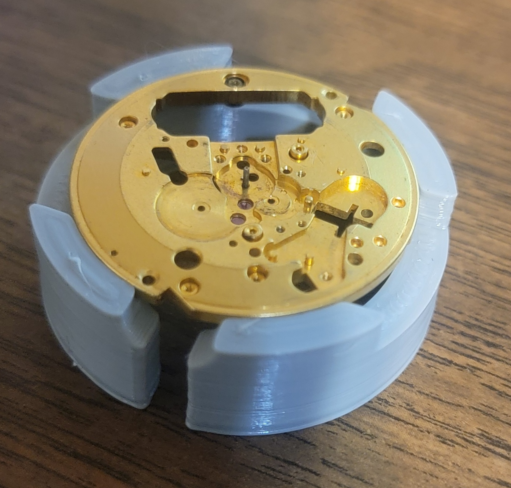

Nice work. In the last year, I have been servicing Accutron 218s. I have the official Accutron hoder that provides electrical contact to the movement. It is a pretty clever design. There is a cut in the ring of the holder (shaped like a "C"). When in relaxed state, the holder is slightly smaller than the watch movement. You spread the cut slightly and drop the movement in and release. Very clean. I have made 3D versions of this setup. Have not explored using it generally for other movements.

-

Accutron 218 transistors

rjenkinsgb replied to ManSkirtBrew's topic in Quartz and Tuning Fork Battery Operated Watches

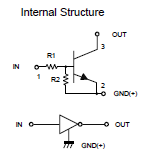

So-called "Digital transistors" are just transistors with appropriate resistors included in the package to allow them to be driven directly from digital logic ICs & microcontrollers etc. You definitely need a normal transistor for the Accutron. -

Accutron 218 transistors

JohnR725 replied to ManSkirtBrew's topic in Quartz and Tuning Fork Battery Operated Watches

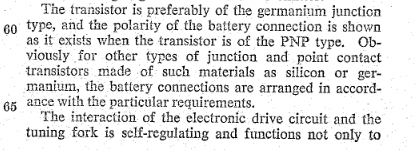

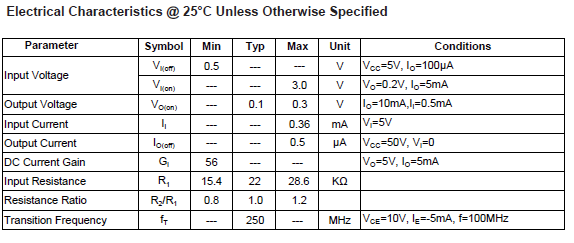

what? We live in the digital world everything is digital today except I believe this is a linear circuit seems like it should need something that's not digital. then I suspect pure digital transistors designed for high-speed switching might not actually be happy to biased it into to a linear mode. I wondered about this because for instance the 214 came out in the early 60s and I don't know how plentiful silicon transistors were? Then yes the 218 is later but the circuitry is basically very similar. out of curiosity as doing a quick patent search the see if it tell us what the transistors they used our and right this instant know they have not been to have schematics though. Then unlike general concept patents Bulova was very nice and made exact patents for a variety of their watches because it wanted the mechanical + aspect patented .then I did remember something about the transistor so I searched for a transistor number and Bulova this came up first all snipped out an image. Now you have at least one transistor that was used in tuning fork watches. So this will give you an idea of specifications. Then yes I really like where the meaning of Accutron comes from you can see it in the title down below. Which works out nice for them now that they have all kinds of electric watches including one powered by static electricity and it does not go against the name which everyone thinks means tuning fork watch. Yes you really should check out the nifty static electricity watch it's really quite amusing. https://www.hodinkee.com/articles/five-star-general-omar-bradley-special-bulova-accutron hadn't quite closed out my patent search basically the patents for the 214 we have this. then before I closed out my Google patent search added in NPN and it only came up three entries of attaching one of them as it says silicon. US3421309 Bulova NPN silicon.pdf -

Having had success replacing the resistor and capacitor in a few 218 and 219 circuits, I've gone down the rabbit hole trying to find a modern replacement transistor. I've searched everywhere I know to look for specs on the original transistors and come up empty. My last digital design class was too many decades ago, so I was hoping one of y'all out there is a EEE (Electronics Engineer or Expert) and can offer some advice. For example, let's say I'm considering an NPN digital transistor. When I look up the part, it's available with a built in 47k, 22k, or 10k ohm input resistance. How does one decide? I assume that's what the starred *R resistor in the schematic below is for. And then how do we make the decision between a digital and bipolar transistor?

-

Hi there Somewhat of a novice collector tending to lean towards Hamilton vintage watches. Although I do have an Omega Polaris and an Accutron. Trying to play with battery replacement on my own having purchased a kit recently. My first challenge is how to get the back off of my Omega Polaris!

-

I have an issue with this as well. The bi-directional friction bezel on my 1970 Accutron Deep Sea 666 was turning a bit firmly. I needed to clean the case anyway so removed the bezel. The spring was left surrounding the upper portion of the case, but I don't see how it does much good there. There's a groove around the inside of the bezel that seems designed to hold the spring, but the spring is too small in diameter to fit into it. When I try bending the spring into a larger diameter it just springs back to its original size. It seems too thin, and so possibly fragile, for me to bend it excessively. Does anyone know how this is supposed to go?

-

Which Watch Have You Got Coming In The Mail ? Show Us !!!

Zandr replied to SCOTTY's topic in Your Watch Collection

On the way, the tiniest Accutron, and my first 404 club-eligible project (since I've learned about it, anyway). "Untested", so expectations are low. -

Before I lose my mind, I could use some help with another o-ring issue. According to the case #, I have the correct o-ring (Bulova G852 for case #3423), which sits in a groove in the case. The crystal is supposed to press fit into it. The problem I'm having is the crystal drags the o-ring out of the groove when I press it in, no matter what I do. I have generously lubricated the o-ring. It does seem like the o-ring is a slightly loose fit in the groove, so maybe I need to go a size up from the factory one?

-

After servicing about six with minimal issues, I have run across a couple that stump me. I think I mentioned one before that seemed electrically sound but did not hum. I have another. All components check to the extent that I have measured them (cannot measure transistor Beta). When measured on the test set, I get a little over 25uA. This is about right if the unit is not oscillating. 1.5V and a 2.2M bias resistor with a beta of 50 would get in the ball park of 20uA. A little more beta and you are north of 25uA. This further confirms that the circuitry is functioning. The cap measures about right. I do not believe its value is too critical anyway. It mostly serves as dc blocking and not establishing resonance. I tried another tuning fork and...no luck. I am going to drive this one to the end so that I can understand root cause.

-

I doubt ESD would be able to destroy a coil. The problem of open Accutron coils has always baffled me. Even if 1.55V were to be applied directly to the coil, it shouldn't be able to fuse the wire. And if anyone noticed, it's always the cell side coil that fails. So is it a design fault that's causing that coil to burn? Maybe as the components age, the waveform changes and creates more back EMF? Maybe @LittleWatchShop could investigate the cause of the failure and solve the mystery.

-

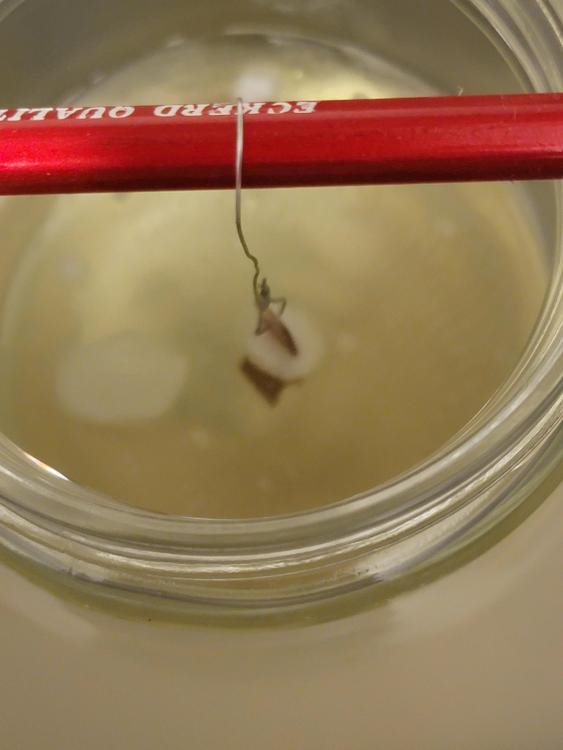

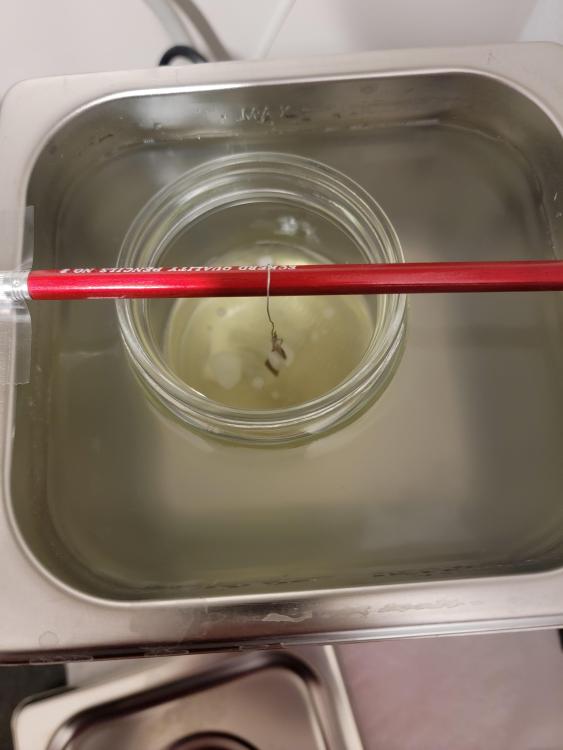

According to the patent at least, the Accutron wire is 0.6 mil which is about 15 microns. I will try to find some info about the quartz coil wire. I pulled a quartz coil and measured it with my JKA and got between 15 and 18 microns. The JKA resolves 10um tic marks, so I am interpolating to get this number. Thus, the quartz coil and Accutron coils have comparable wire diameters. I never worried about measuring quartz coils, so I will no longer worry about measuring Accutron coils. A further experiment might be to measure the fusing current for a quartz coil. A test for another day!!

-

It's been a long time and I rarely work on quartz stuff, but had one for a friend I suspected a coil was bad, grabbed my trusty Radio Shack (Micronta) digital meter I bought as a teenager, thinking it should have a low enough output. From memory, you want less than 2v to be safe with quartz coils. I recall we had meters in school with a resistor across the leads to drop the voltage. Turns out the Micronta puts out 4v, which is common. Didn't have a resistor on hand, so didn't test (ended up not being the coil- but at least I didn't kill it!). I don't know the difference in the coil wire diameter between common quartz and Accutron; my gut says the Accutron is a bit heavier, so probably doesn't mind the extra voltage?

-

LOL Yes my first VOM was a Triplett Model 630, 1970. However, I am not a luddite...my best meter is a Fluke 87V. I made the measurements with Cen Tech P35017. This morning, I measured the current output of the CT with my Fluke. When measuring resistance with the CT, I get 484uA. When in diode mode, I get about 800uA. I know you have lots of Accutron experiene...I take it you have never knowingly popped one of those coils via measuring?? ---non sequitur--- the going train on these things continue to amaze me. I was initially deathly afraid of it because of the index wheel. No more. About 20% of the time, the wheels just jump in place as soon as you drop the plate down. The rest yield quickly with a few nudges with my modified oiler. I only wish Bulova used similar engineering on their cases. Yes

-

Background: Somebody sent me an "Accutron" that was a gift many years ago. Somewhere along the way, the Accutron died and somebody replaced it with an NH35. It, of course was too thick, so they removed the auto wind oscillating weight. Ouch!!! Since the dial feet did not match, they cut them off the Accutron dial and used sticky tabs to attach the dial to the NH35. What a frigging abomination!!!! Anyway, this "somebody" sent me two accutron movements in hopes that I could return the watch to its former glory. OMG, these were hacked up as well. But!!! I was able to make one functioning movement. Cleaned, oiled, and soon to be adjusted. The BIG issue now is the dial. I am pretty sure I cannot solder feet on the dial. I did give it a try. No bueno. Here is my idea. Drill holes through the dial where the dial feet belong. Then insert and glue posts (feet). I checked the visibility of the dial through the crystal and the drill holes would not be visible. Thoughts??

-

OK, I am on my fifth or sixth 218 service with great success. Once you establish a methodology, these are relatively easy. I am servicing a 218 D now and it will not hum I have verified the following -drive coils -phasing coil -resistors -capacitor -EB junction, CB junction (have not verified beta) Kind of at a loss. All connections seem to be fine. Wondering if the watch was accidentally demagnetized??? Using a compass, I verified that the tuning fork does have some magnetic attraction. Scratching my head.

-

For the time when these were introduced, the technology was truly leading edge. The 218 movement seems solid...not difficult to service. But...and this is a BIG but, Accutron (really Bulova) fails at the non-tech stuff. While I like the two-piece back, the case quality is generally poor. The dials seem fine enough, but the hands are low quality compared to a nice swiss watch. I have one case where the crown interface appears to have been milled incorrectly. Not sure...still investigating.

-

I suppose if you like the other PDF may be of like this one. it's not a complete PDF it only has 214 and 218 stuff. Bulova had parts kits a box with a large card that when in the lid and all the envelopes corresponding to the parts and I think they would add empty envelopes. So if you were servicing these at one time it would be smart to have these although I'm pretty sure they were expensive. So somebody kindly scanned them into a nice PDF I had scanned a couple of the cards but this is much nicer it's all in one place. So then were missing all the other watches but typically the majority of the tuning fork of Bulova would be 214 and 218 and the others while popular not as much and I don't think every single other one had a parts kit that was probably at 230 kit and a 221 kit don't think there was a 219 kit may be. Bulova Accutron Parts.pdf

-

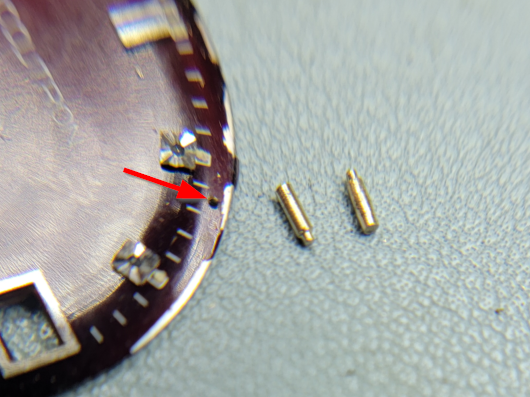

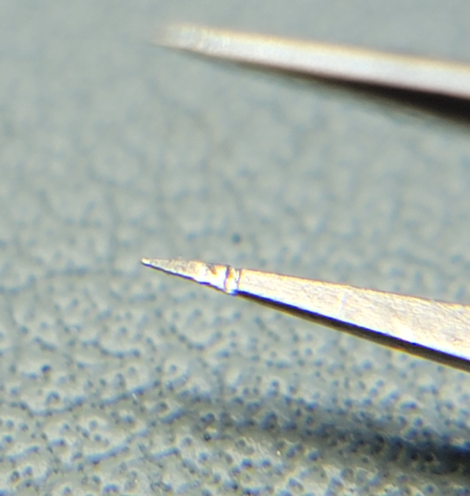

When I clean the index wheel I put it in the Accutron index wheel holder. What have found is that while holding the arbor, the wheel flops around because the tweezer will not hold it in a fixed orientation. Well, I fixed that!!! I modified a set of 3C tweezers by adding a notch so that the index wheel arbor is held orthogonal to the length of the tweezer and will not wobble. The notch is on both legs of the tweezer but only one is shown.